Ford Transmission Identification Chart: The Definitive VIN, Tag, and Casting Decoder Guide

Accurate transmission identification is paramount for anyone maintaining, repairing, or upgrading a Ford vehicle, whether modern or classic. The Ford Motor Company’s transmission catalog is extensive, spanning nearly a century of technological evolution, from simple planetary gear systems in the Model T to the modern 10-speed electronically controlled automatics. A systematic identification methodology is essential to ensure the correct parts are ordered, the right fluids are used, and compatibility during powertrain swaps is guaranteed.

The identification process relies on triangulating information from three primary sources: the Vehicle Identification Number (VIN) for modern vehicles, physical production tags and labels for specific factory data, and engineering or casting numbers for component dating and interchangeability confirmation.

The initial verification step, often overlooked by those immediately heading under the hood, involves consulting factory documentation. The most specific and reliable information about a vehicle’s original configuration, including the precise transmission code, can be found on the window sticker, a comprehensive Build Sheet, or an official Vehicle Identification (VIN) Decode Letter obtained directly from Ford. Obtaining these documents can frequently bypass the need for physical inspection, offering the definitive specification straight from the manufacturer.

FORD TRANSMISSION

IDENTIFICATION

Deciphering the codes, pan shapes, and performance specs of Ford’s legendary drivetrain history.

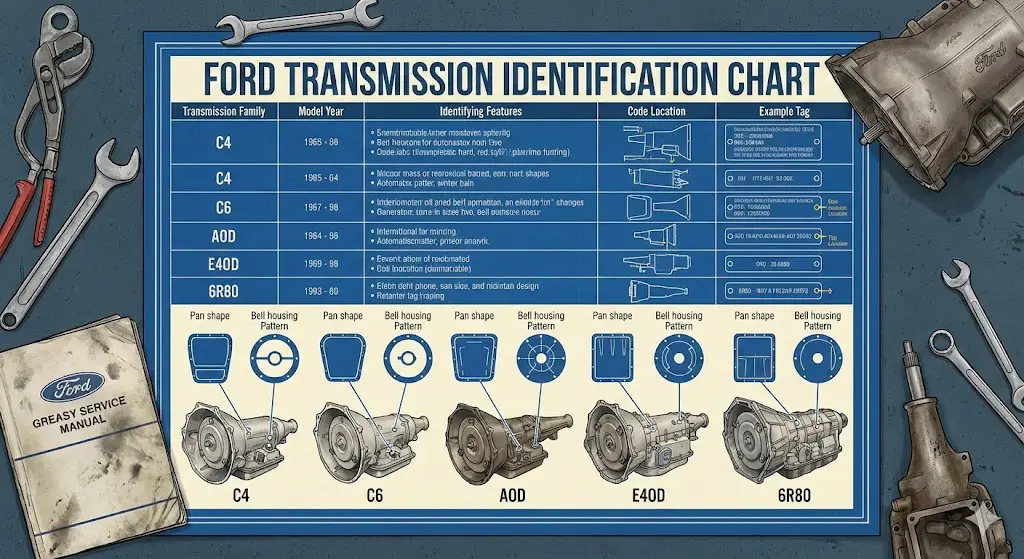

Identifying a Ford transmission can be a challenge due to decades of engineering changes, tag variations, and casing updates. Whether you are restoring a classic Mustang or upgrading an F-150, knowing exactly what gearbox you have is critical for parts ordering and performance tuning. This visual guide breaks down the key identifiers: Pan Bolt Counts, Tag Codes, and Gear Ratios.

The “Bolt Count” Method

The quickest way to narrow down your transmission type without crawling inside is to count the bolts on the transmission fluid pan. While shape matters, the bolt count is the primary filter. The chart highlights the unique bolt signatures of Ford’s most common units.

- C4 & C6: The classic muscle car duo.

- AOD Series: The first generation of overdrives.

- E4OD/4R100: Heavy-duty truck applications with massive pans.

QUICK TIP: The C6 pan has a distinct “Utah” shape, while the C4 is square.

Transmission Pan Bolt Counts

Ratio Evolution

As engines became more efficient, transmissions evolved from simple 3-speeds to complex 10-speed units. This chart compares the First Gear (Launch) vs. Overdrive (Economy) ratios.

Notice the massive jump in first-gear aggression in modern units (like the 10R80) compared to the classic C4, allowing for faster acceleration with smaller engines.

Decoding the ID Tag

Found on the passenger side or tail housing bolt, the ID tag is the “VIN” of your transmission. Here is how to read a typical 1980s-1990s Ford tag.

Transmission Model Code

The first three letters (e.g., PKA) designate the specific transmission model family (e.g., AOD, E4OD).

Service Level

Suffixes indicate internal revisions. A “BC1” might have different clutch packs than a “BC2”.

Build Date

Format: DD-M-Y. “12 D 4” = 12th of April, 1994 (Year depends on decade context).

Family Hierarchy

Understanding the broad categories helps in identification. Most Ford transmissions found in restoration projects fall into one of these three primary groups.

Hydraulic 3-Speeds (The Classics)

C4, C6, FMX. No electronics, vacuum modulated. Found in 60s-80s muscle cars and trucks.

4-Speed Overdrives (The Transition)

AOD, AODE, 4R70W, E4OD. Introduced specifically for fuel economy highway cruising.

Modern 6/10 Speeds (High Tech)

6R80, 10R80. Computer-controlled, clutch-to-clutch architecture, no bands.

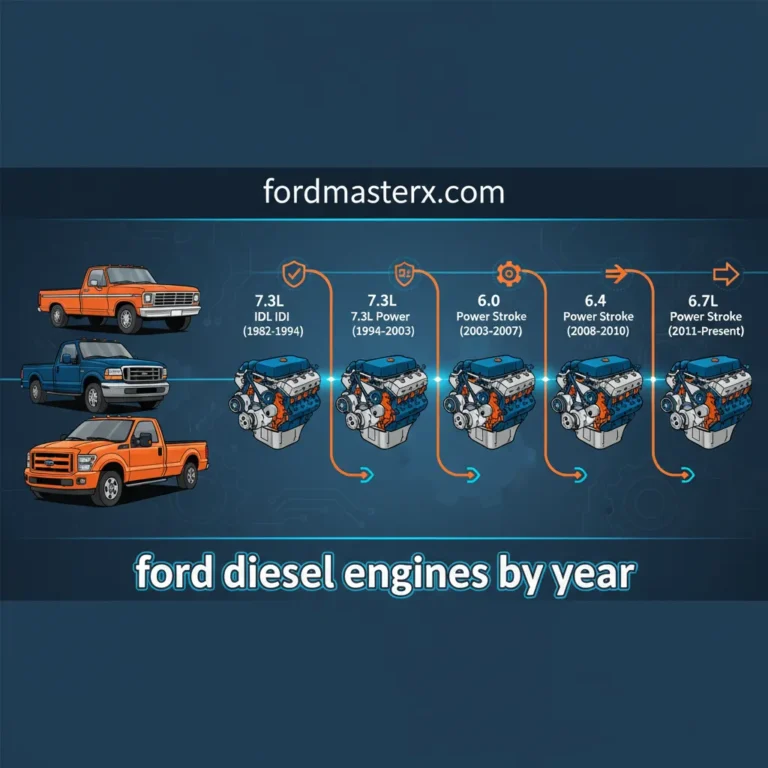

Production Timeline

1964: The C4 Arrives

Lightweight aluminum case 3-speed. The go-to for small block Mustangs and Falcons.

1966: The C6 Heavy Hitter

Built for big blocks. Cast into a single piece including the bellhousing. Virtually bulletproof.

1980: The AOD Era

Ford’s first domestic Automatic Overdrive. Mechanical lockup torque converter improved MPG significantly.

1989: E4OD / Electronic Control

Massive truck transmission based on C6 internals but with electronic overdrive and control.

2011: 6R80 & Beyond

Adopting the ZF 6-speed design. Wide gear ratio spread, compact size, handling high torque.

Modern Identification: Using the VIN and Digital Resources

Decoding Your Ford Transmission Using the Vehicle Identification Number (VIN)

For all vehicles produced since 1982, the 17-character VIN serves as the foundational data source for vehicle specifications. This alphanumeric code encodes vital information regarding the vehicle’s manufacturing details, including the Model Year (Position 10), the Assembly Plant (Position 11), and crucially for powertrain identification, the Engine Type.

The Critical Role (and Ambiguity) of VIN Position 8

Position 8 of the VIN is designated universally as the Engine Type Code. This character provides the primary clue for deducing the transmission type, as manufacturers typically pair specific engines with a narrow range of suitable gearboxes. For example, in a 2021 Ford F-150, the engine code '4' signifies the 2.7L EcoBoost V6, an engine that is exclusively paired with Ford’s advanced 10R80 10-speed automatic transmission.

However, reliance solely on the Engine Type Code can be problematic, particularly in high-volume or performance platforms where multiple gearbox options are offered for the same engine. This creates an "ambiguity trap." For instance, a 2020 Ford Mustang with a 5.0L V8 engine (coded 'H' in Position 8) could have been equipped at the factory with either the 10R80 automatic transmission or the Getrag MT82 six-speed manual transmission. In such cases, the VIN provides confirmation of the engine, but additional verification methods are required to resolve the manual versus automatic distinction and prevent critical errors in parts purchasing or repair preparation.

The identification process for modern platforms highlights a shift in necessary verification methods. The move toward advanced electronic control units (ECUs) and Powertrain Control Modules (PCMs), which manage high-speed transmissions like the 10R80, means the vital configuration data is less frequently stamped onto a physical tag and more often digitally stored. Consequently, definitive identification relies heavily on accessing this electronic fingerprint through digital decoders and official documentation rather than traditional mechanical inspection, unless the goal is to confirm the presence of a manual transmission.

Step-by-Step Verification via Official Decoders

When physical documents are unavailable or a quick verification is needed, several digital resources can be consulted. The National Highway Traffic Safety Administration (NHTSA) provides a publicly accessible VIN decoder that confirms fundamental vehicle data reported by the manufacturer, including the build plant. For professional applications, Ford Pro offers specialized VIN decoders designed for fleet vehicles, which often link the engine code (Position 8) to detailed transmission guides, aiding the identification process. Furthermore, contemporary tools like the FordPass app now integrate vehicle specification lookup, making VIN decoding increasingly accessible to the average consumer.

The primary data points extracted from the VIN can be organized as follows:

VIN Position Diagram

| Position | Content | Relevance for Transmission ID |

| 1–3 | World Manufacturer ID (WMI) | Confirms Ford (1FA, 1FT, etc.) |

| 4–7 | Vehicle Line, Series, Body Type | Narrows potential transmission pool. |

| 8 | Engine Type Code | Crucial input for transmission inference. |

| 10 | Model Year | Defines the era (e.g., pre-AOD, post-10R80). |

| 12–17 | Production Sequence Number | Less relevant for type, but important for historical documents. |

Classic and Physical Identification: Tags and Casting Numbers

For transmissions produced before the era of mandatory VIN use (pre-1982) and for those produced concurrently but lacking comprehensive VIN data integration, physical inspection is mandatory. The two key physical identifiers are the stamped metal production tag and the molded engineering/casting number.

Finding the Tag on Automatic vs. Manual Cases

The metal tag or label, which contains the most specific production-run information, is usually located on the transmission case itself. For automatic transmissions, the tag is typically secured to the driver's side of the case, while manual transmissions may have the label affixed to the top or side.

A quintessential example of this system is found in the classic 4-speed Toploader manual transmission (1964-1973). Toploaders feature a small metal tag at the front edge of the main case on the passenger side. This tag displays an HEH or RUG number (e.g., HEH-A, RUG-AU) that explicitly codes the year, vehicle, engine, ratio (wide or close), and output spline count. It is critical to note that the lower number stamped on this tag represents the transmission's serial number in the order it was tagged, entirely separate from the vehicle’s VIN.

Interpreting Ford Casting/Engineering Numbers

Casting or engineering numbers are alphanumeric codes stamped into or molded onto the transmission case during the manufacturing process. These numbers designate the year the part was originally designed and the vehicle for which it was initially engineered. Importantly, the presence of a casting number does not preclude the part from being used in subsequent years or on different vehicle lines.

A common identification error involves confusing the casting/engineering number with the service or part number used for ordering components. While both follow the same prefix decoding rules, they serve different inventory and identification purposes and are not interchangeable.

The structure of the engineering number is highly systematic, allowing for precise decoding of its origin:

Decoding Ford Casting/Engineering Number Prefixes

| Position | Code Description | Example (C9AE-9510-M) | Significance |

| 1st Letter (Decade) | B (1950s), C (1960s), D (1970s), E (1980s) | C (1960s) | Defines the design era. |

| 2nd Digit (Year) | 0–9 (Year within the Decade) | 9 (1969) | Defines the original design year. |

| 3rd Character (Vehicle Line) | A (Full Size Ford), Z (Mustang), T (Truck) | A (Full Size Ford) | Identifies the vehicle line the part was designed for. |

| 4th Character (Engineered Component) | E (Engine), T (Truck), (Transmission Assembly) | E (Engine) | Identifies the component family. |

| Suffix (Engineering Version) | Alphanumeric (A, B, M, etc.) | M (13th Version) | Revision level or iteration. |

The Ford Casting Date Code Decoder

In addition to the static casting number, components also typically feature a date code that provides the exact day, month, and year the part was cast. A typical date code, such as "6M08," is deciphered as follows:

- 6 = The year of the decade (e.g., 1976).

- M = The letter representing the month (M=December).

- 08 = The day of the month (8th).

For example, a date code of '5A13' decodes to January 13, 1975. The specific decade (e.g., whether the '6' refers to 1966, 1976, or 1986) is resolved by referencing the first letter of the accompanying casting number prefix (e.g., 'C' for 1960s, 'D' for 1970s).

Understanding the temporal relationship between the casting number and the date code is crucial for restorers. A part bearing a casting number designated 'C5AR' (a 1965 design) might display a date code indicating it was produced in 1967. This confirms the component was manufactured after the initial design date but without requiring a major engineering revision. This differentiation—between the original design date (casting number) and the actual production date (date code)—is vital when seeking historically accurate replacement parts.

For a deep dive into historical Ford engineering data, including detailed parts and service breakdowns, visit our resource on Decoding Ford Engine Casting Numbers.

The Ford Automatic Transmission Technical Chart

Comprehensive Guide to Ford Automatic Transmission Families and Specs

Ford’s automatic transmission history is characterized by a drive for greater durability and, later, greater efficiency through the integration of overdrive and electronic controls.

3-Speed Durability: C4 and C6 Fundamentals (1960s–1990s)

The C-series automatics defined the mid-century Ford drivetrain.

- Ford C4: Produced between 1964 and 1981, the C4 was a light-duty, compact unit designed primarily for small-block V8 engines. Its defining physical characteristic is a detachable bellhousing, simplifying engine swaps and repairs. The stock 1st gear ratio was 2.46:1.

- Ford C6 (SelectShift Cruise-O-Matic): Introduced in 1966, the C6 was the heavy-duty complement to the C4, built to handle the high torque of big-block V8s. The C6 is instantly identifiable by its one-piece bellhousing and main case design. Stock C6 units were rated for approximately 475 lb-ft of torque 10 and shared the C4's 2.46:1 1st gear ratio.

The C6’s mechanical robustness made it a legend. Although the official factory rating was 475 lb-ft, the fundamental mechanical strength of the design allows performance builders to safely push highly modified versions to 700 lb-ft or more. This disparity between the cautious factory torque rating and the unit’s proven potential capacity makes the C6 a preferred legacy platform for high-power street and racing applications that demand mechanical reliability without the complexities of modern electronic control.

The Overdrive Transition: AOD vs. 4R70W Evolution

The shift toward overdrive represented Ford’s response to demands for better fuel economy.

- Ford AOD (Automatic OverDrive): Launched in 1980, the AOD was Ford’s first four-speed automatic transmission, integrating a mechanical overdrive gear.13 Utilizing Ravigneaux geartrain components borrowed from the older FMX transmission, the AOD featured a 2.40:1 1st gear ratio. The AOD was strictly mechanically controlled, but its early iterations suffered from durability concerns, particularly within the overdrive clutch unit.

- Ford 4R70W: Beginning in 1993, the AOD evolved into the electronically controlled AODE, which was quickly refined into the 4R70W. The "W" in 4R70W signifies "Wide Ratio," indicating a crucial change in the gearset: the 1st gear ratio was dropped significantly to 2.84:1, and the torque capacity was elevated to approximately 700 lb-ft. This wider ratio configuration was intentionally implemented to compensate for the different power delivery and reduced low-end torque characteristics of the newly introduced 4.6L Modular V8 engine family, providing better standing-start acceleration than the previous AOD configuration.

Heavy Haulers: E4OD and 4R100 Specs

For heavy-duty truck applications, the C6 was superseded by electronic overdrive units. The E4OD (Electronic 4-Speed Overdrive) replaced the C6 in 1989. Its successor, the 4R100 (1999–2004), was a further electronic refinement built for extreme loads. It featured enhanced components and an output speed sensor. The 4R100 shares a 1st gear ratio of 2.71:1 and is robustly rated for up to approximately 1,000 lb-ft of input torque (factoring in the torque converter multiplication), making it a formidable choice for high-power diesel and heavy towing applications.

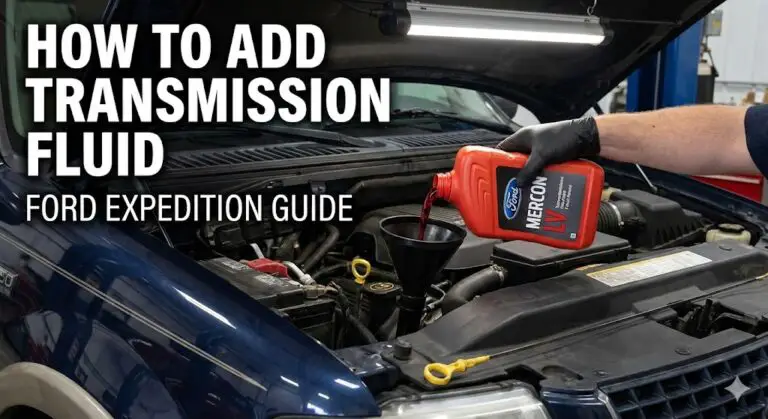

The 10-Speed Era: 10R80 Identification and Fluid Requirements

The latest generation of Ford automatics, developed in partnership with General Motors, is the 10R series. The 10R80 (2017–Current) is the dominant modern rear-wheel-drive (RWD) and all-wheel-drive (AWD) automatic transmission, found in high-volume models such as the F-150 (paired with 2.7L, 3.5L EcoBoost, and 5.0L V8s), the Mustang GT, Expedition, Ranger, and Bronco.

The 10R80 is electronically controlled via the PCM and features an aggressive 4.696:1 1st gear ratio, maximizing launch capability. A critical identification and maintenance requirement for the 10R80 is its exclusive use of Mercon ULV (Ultra-Low Viscosity) fluid.20

The evolution of these automatic transmissions demonstrates a key engineering principle: as the number of forward speeds increased (from 3-speed to 10-speed), the 1st gear ratio became significantly lower (2.46:1 in the C6 versus 4.696:1 in the 10R80). This design adaptation is necessary because modern, highly efficient engines often achieve peak torque higher in the RPM range. The extremely low first gear provides aggressive torque multiplication for powerful launches, while the 10 speeds ensure tight ratio spacing for fast shifts and the inclusion of multiple deep overdrive gears guarantees maximum efficiency during highway cruising.

Key Ford Automatic Transmission Specifications and Identification

| Transmission | Years | Speeds | 1st Gear Ratio (Stock) | Approx. Stock Torque Cap. (lb-ft) | Control Type | Key Feature/ID Note |

| Ford C4 | 1964–1981 | 3-spd Auto | 2.46:1 | ~350 | Hydraulic | Light-duty, compact, detachable bellhousing. |

| Ford C6 | 1966–1996 | 3-spd Auto | 2.46:1 | ~475 | Hydraulic | Heavy-duty, one-piece case/bellhousing. |

| Ford AOD | 1980–1993 | 4-spd Auto (OD) | 2.40:1 | ~300 | Mechanical/Hydraulic | First OD unit, utilizes FMX components. |

| Ford 4R70W | 1995–Current | 4-spd Auto (OD) | 2.84:1 | ~700 | Electronic | Wider ratios to support Modular engines. |

| Ford 4R100 | 1999–2004 | 4-spd Auto (OD) | 2.71:1 | ~1,000 (Input Max) | Electronic | Heavy-duty E4OD successor. |

| Ford 10R80 | 2017–Current | 10-spd Auto (OD) | 4.696:1 | ~664 | Electronic (PCM) | Advanced 10-speed, requires Mercon ULV fluid. |

Automatic Transmission 1st Gear Ratios

| Transmission | 1st Gear Ratio |

| C4 | 2.46 |

| AOD | 2.40 |

| 4R70W | 2.84 |

| 10R80 | 4.696 |

The Ford Manual Transmission Technical Chart

Essential Ford Manual Transmissions: Toploader, T-5, and Tremec Families

Ford's manual transmissions have focused on developing extreme mechanical durability in the classic era and optimizing for overdrive efficiency in the modern era.

Toploader Identification: Decoding RUG/HEH Tags and Ratios

The Ford Toploader (1964–1973) is a highly durable, cast-iron four-speed manual transmission, recognized by its characteristic top-loading access plate.21 Identification, beyond the external HEH/RUG tag codes, is often required internally to confirm the gear set when the external tag is missing.

Toploaders were produced in two main variations that significantly impact driving characteristics:

- Wide Ratio: Designed for street cruising or lower-powered vehicles, featuring a deep 1st gear ratio of 2.78:1.

- Close Ratio: Designed for high-performance applications where engine RPM must be maintained between shifts, utilizing a taller 1st gear ratio of 2.32:1.

The definitive verification of the ratio type can be achieved by counting the teeth on the 2nd gear cluster: Close Ratio units feature 28 teeth, while Wide Ratio units feature 31 teeth. The Toploader is notable for its non-overdrive configuration (4th gear is 1.00:1) and rugged nature, capable of handling well over 500 lb-ft of torque.

Borg-Warner T-5: The Lightweight Overdrive Standard

The Borg-Warner T-5 marked a major shift by introducing a critical 5th overdrive gear, significantly improving highway fuel economy and comfort. Used widely in the Fox Body Mustang 5.0L (1983–1995), the T-5 utilized a lightweight aluminum housing.

Identification factors include:

- Torque Capacity: The stronger World Class (WC) version, produced after approximately 1990, is rated for 300 lb-ft of input torque.

- Input Spline: Ford V8 applications typically use a 10-spline input shaft.

While the T-5's 300 lb-ft rating might deter enthusiasts running higher-powered engines, historical usage indicates that for typical street driving—where peak engine torque is not constantly sustained through the transmission—the T-5 proves surprisingly resilient. This makes it a popular and cost-effective upgrade for older, non-overdrive Ford muscle cars seeking a 5-speed solution.

Modern Tremec Performance and Getrag Units

As performance levels increased, Ford migrated toward dedicated high-strength manual suppliers.

- Tremec TR-3650: Replacing the T-5 in the Mustang GT platform (2001–2010), the TR-3650 increased the torque capacity to 360 lb-ft. A key physical identifier is its integrated bellhousing designed specifically for the 4.6L and 5.0L Modular engine families. It offers multiple 5th gear overdrive ratios, including 0.67:1 and 0.62:1.

- Getrag MT-82: This six-speed unit has been used extensively in the Mustang GT since 2011, providing two overdrive gears for efficiency.

- Tremec TR-9070: Reserved for extreme applications like the Shelby GT500, this 7-speed unit demonstrates Ford's continued pursuit of performance manuals with multiple ratios for optimized track and street use.

Key Ford Manual Transmission Specifications and Identification

| Transmission | Speeds | 1st Gear Ratio (Wide/High) | Max Stock Torque Cap. (lb-ft) | Input Spline Count (Ford V8) | Key Ford Application |

| Ford Toploader (Wide) | 4-spd Manual | 2.78:1 | 500+ (Non-OD) | 28 or 31 | Classic Mustang, Fairlane (1964-1973) |

| Borg-Warner T-5 (WC) | 5-spd Manual (OD) | 3.35–3.97:1 | ~300 | 10 | Fox Body Mustang 5.0L (1985-1995) |

| Tremec TR-3650 | 5-spd Manual (OD) | 3.38:1 | 360 | 10 (Stock) | Mustang GT (2001-2010) |

| Getrag MT-82 | 6-spd Manual (OD) | Varies (approx. 3.66) | ~380 | 23 (Implied) | Mustang GT (2011–present) |

Interchangeability and Bellhousing Bolt Patterns

Ford Engine-to-Transmission Compatibility: The Bellhousing Guide

Positive transmission identification must extend to confirming bellhousing bolt pattern compatibility. A transmission cannot be successfully mated to an engine unless the bolt patterns align, or a specialized adapter plate is employed. Ford has utilized several distinct bellhousing standards throughout its history.

The Classic Small Block and Big Block Patterns

In the classic era, Ford employed three primary RWD bellhousing patterns for V8 engines:

- Later Small Block V8 (SBF): This is the most common classic pattern, introduced after August 3, 1964, utilizing six bolts to secure the bellhousing to the block. It is standardized across the 289 (post-64), 302, and 351W/C engine families.

- FE (Ford-Edsel) Pattern: A distinct six-bolt pattern engineered for the high-torque FE engine family, including the 390, 427, and 428 V8s.

- Big Block 385 Series: A separate pattern used for the 429 and 460 V8 engines.

The highly versatile C6 automatic transmission was notable for its production with distinct, non-interchangeable cases to accommodate all four major engine families (SBF, FE, 385 series, and later, Diesel).

The Modular V8 Bellhousing Standard

The Modular engine family, introduced in the 1990s, established a new universal bolt pattern for all modern Ford RWD V8 and V10 platforms. This Modular Pattern is standard across the 4.6L, 5.0L Coyote, 6.2L Boss, 6.8L Triton, and the 7.3L Godzilla engines.

This consistency allows for direct interchangeability between modern gearboxes. Transmissions designed for the Modular pattern, such as the 6R80, 10R80, Tremec TR-3650, and aftermarket Tremec Magnums, are direct physical swaps when used behind any modern Ford V8.

However, the Modular pattern creates a significant barrier—often referred to as the "Modular Wall"—when attempting to utilize older, mechanically controlled transmissions. Mating a classic unit like the C4 or AOD to a modern Coyote engine requires a specialized adapter bellhousing. Furthermore, even if the older unit is physically adapted, modern electronically controlled automatic transmissions (like the 6R80 or 10R80) require sophisticated standalone transmission controllers to function correctly when not paired with their stock ECU/PCM.30 This forces builders to choose between the mechanical simplicity of legacy transmissions (requiring physical adapters) and the maximized performance of modern electronic transmissions (requiring electronic controllers).

Major Ford Bellhousing Bolt Patterns

| Bellhousing Pattern | Key Identification Note | Representative Engines | Compatible Transmissions (Examples) |

| Early Small Block V8 | 5 Bolts to Block (Pre-Aug 1964) 29 | 221, 260, Early 289 V8 | Early C4, Toploader |

| Later Small Block V8 (SBF) | 6 Bolts to Block (Most Common Classic Standard) | 289 (Post-64), 302, 351W/C | C4, AOD, T-5, TR-3650 |

| FE (Ford-Edsel) | Unique 6-bolt pattern | 352, 390, 427, 428 V8 | C6 (FE specific case), Toploader |

| Modular V8/Coyote | Modern Standard (Integrated design) | 4.6L, 5.0L Coyote, 7.3L Godzilla | 6R80, 10R80, Tremec Magnum, TR-3650 |

For detailed guidelines on mating classic transmissions to modern powerplants, consult our guide on Coyote Engine Transmission Swaps.

Diagnostics: Recognizing Ford Transmission Failure

Accurate transmission identification also involves recognizing symptoms that confirm a unit is operating incorrectly, which may lead to component failure diagnosis. Early detection of distress signals can prevent minor repairs from escalating into costly total transmission replacement.

Identifying Mechanical and Hydraulic Distress

- Slipping Gears: One of the most critical symptoms, gear slippage occurs when the engine RPM increases rapidly without a corresponding engagement or increase in road speed. This typically indicates worn clutch packs, friction materials, or failing bands in older hydraulic units. It signals a severe internal mechanical degradation or critical loss of fluid pressure.

- Delayed or Harsh Shifting: A hesitation before a gear engages or a noticeable, jarring jolt during gear changes. In electronic transmissions (like the 4R70W or 10R80), this often results from a defective solenoid, sensor malfunction, or corrupted control module data. In mechanically controlled transmissions (C4, C6), it suggests issues with the valve body or internal mechanical linkages.

Fluid Contamination and Overheating

Transmission fluid condition is the most reliable external diagnostic indicator.

- Fluid Leaks: The presence of red or brown fluid on the ground signals a fluid leak. Fluid loss reduces hydraulic pressure, leading directly to overheating and component failure due to lack of lubrication.

- Contaminated Fluid: The observation of metallic particles or debris, or detecting a distinct burnt smell, signifies advanced internal destruction. The presence of metal shavings means internal components—such as planetary gear sets or bearing surfaces—are actively shearing and eroding. This indicates the problem has progressed beyond simple seal or sensor failure and demands immediate inspection to avoid catastrophic loss of the unit.

If you are experiencing delayed or rough shifting in an electronically controlled Ford, dive deeper with our guide to Advanced Diagnostics for Rough Ford Shifting.

Conclusion and Quick Reference Summary

Effective Ford transmission identification demands a comprehensive, layered approach, moving systematically from general encoded vehicle data to specific physical markings. For contemporary vehicles, reliance on the VIN (especially Position 8 for engine data) and digital verification tools from sources like Ford support or NHTSA is the most effective initial strategy. However, the inherent ambiguity of the VIN necessitates follow-up verification, particularly in models offering both manual and automatic options.

For classic and vintage platforms, positive identification relies on the preservation and interpretation of physical data: the HEH/RUG tag number, the systematic decoding of the part’s engineering/casting number (which dictates original design date), and, in many cases, internal component measurements (such as the 2nd gear tooth count in Toploaders) to confirm ratio type.

Ford's transmission history is defined by the technical divergence from simple, mechanically robust three-speed units (C4/C6) toward increasingly complex, electronically controlled, multi-speed systems (4R70W, 10R80). This evolution has prioritized efficiency (via deep overdrive and wide gear ratios) but simultaneously shifted the diagnostic burden from purely mechanical inspection to advanced electronic troubleshooting and fluid specification adherence. Successful maintenance and modification rely on adhering precisely to the identification methods detailed above.

Frequently Asked Questions (FAQs)

What is the easiest way to identify a Ford transmission?

The easiest and most authoritative method for identifying a Ford transmission, especially on modern vehicles, is to consult the original factory documentation, such as the window sticker, a Build Sheet, or a VIN Decode Letter provided by Ford Customer Support. These documents provide the explicit transmission code directly.

Is VIN Position 8 enough to identify my transmission?

VIN Position 8, which indicates the Engine Type Code, is a vital first step, as it narrows the field of possibilities. However, it is often insufficient on its own. If the specified engine was available with both an automatic and a manual option (e.g., the 5.0L V8 in a Mustang), the engine code alone cannot distinguish between the two, requiring additional verification.

What is the difference between a Wide Ratio and a Close Ratio Toploader?

The difference lies in the first three gear ratios, which impact acceleration and RPM drop. Wide Ratio Toploaders feature a deeper 1st gear (2.78:1) suitable for heavy vehicles or low-RPM cruising. Close Ratio Toploaders use a taller 1st gear (2.32:1), optimizing for high-speed performance and minimal RPM drop between shifts. The primary internal identifier is the 2nd gear tooth count: 28 teeth for Close Ratio and 31 teeth for Wide Ratio.

Why did Ford replace the C6 with the E4OD/4R100?

The Ford C6 was a durable three-speed, non-overdrive unit. It was replaced by the E4OD (and subsequently the 4R100) primarily to incorporate an overdrive gear for improved fuel economy and highway efficiency. The E4OD/4R100 also introduced electronic control, allowing for enhanced shift quality and diagnostic capabilities necessary for modern heavy-duty applications.

What type of fluid does the 10R80 transmission use?

The 10R80 10-speed automatic transmission requires Mercon ULV (Ultra-Low Viscosity) fluid. Using any other type of fluid can negatively impact the performance, shift quality, and long-term durability of the advanced electronically controlled unit.