How to Test Block Heater: The Ultimate Diagnostic Guide (Multimeter, Ohm’s Law & Safety)

In the realm of automotive engineering and maintenance, the engine block heater is often relegated to the status of a simple accessory. However, for vehicles operating in sub-freezing climates, it is a fundamental component of the thermal management system, critical for preserving engine longevity, ensuring reliability, and minimizing emissions. When ambient temperatures descend below -15°C (5°F), the internal combustion engine faces an environment hostile to its operation.

The physical properties of lubricants, the chemical reactivity of lead-acid batteries, and the dimensional tolerances of metallurgic components all shift drastically, creating a scenario where a “cold start” becomes a significant stress event.

Research indicates that a single cold start at -5°C (23°F) can induce cylinder wear equivalent to driving approximately 99 kilometers (62 miles). This wear is attributed to the delay in oil pressure build-up, the contraction of piston-to-wall clearances, and the condensation of acidic combustion byproducts on cold cylinder walls. Furthermore, the initial phase of combustion in a cold engine requires a rich fuel mixture, leading to “wet stacking” in diesels and cylinder wash-down in gasoline engines, both of which dilute the oil film and accelerate wear.

The block heater mitigates these risks by maintaining the thermal equilibrium of the engine block and coolant. By keeping the engine core at a temperature significantly above ambient (typically 20°C to 40°C rise), it ensures that oil viscosity remains within a pumpable range, battery load is reduced, and fuel vaporization is optimized. Consequently, verifying the operational integrity of this component is not merely a matter of convenience but a requisite maintenance protocol for fleet operators and private owners alike.

This comprehensive report serves as the definitive reference for testing, diagnosing, and maintaining engine block heaters. It synthesizes electrical theory, specific vehicle data (with a focus on Ford platforms), and practical diagnostic procedures to empower technicians and owners to identify failures—from open circuits to resistive shorts—before they result in catastrophic no-start conditions or fire hazards.

Block Heater Diagnostics

Don’t Get Stranded at -30°F. Trust Data, Not Luck.

The Silent Failure

Block heaters are simple resistive devices, but they fail silently. Often, the only warning sign is a truck that refuses to start on the coldest morning of the year.

1. Power Cord

2. Heating Element

3. Connections

Where Do They Break?

Estimated failure distribution based on repair data.

The Gold Standard: Resistance Testing

The only accurate way to test a heater is measuring resistance (Ohms/Ω) with a multimeter. Different vehicles require different wattages, which dictates the healthy resistance range. Lower resistance means higher power.

The Formula

R = V² / P

Resistance = Voltage² divided by Power.

The Multimeter Decision Tree

Follow this logic path to diagnose your system safely.

START: Set Meter to Ohms (Ω)

Unplug heater. Touch probes to flat prongs.

Reading: OL / ∞

(Open Loop)

Diagnosis: Broken Circuit

Cord is cut OR Element is burnt out.

Reading: 9 – 40 Ω

(Target Range)

Diagnosis: Healthy

Heater is functioning correctly.

Reading: 0.0 – 0.2 Ω

(Zero Resistance)

Diagnosis: Short Circuit

Immediate breaker trip hazard.

CRITICAL: The Ground Test

Even if the heater works, it might be dangerous. Always test for a “Short to Ground”.

Required Result

OL (Open Loop)

Usage Efficiency

You don’t need it plugged in all night.

Use a timer to save electricity.

Thermodynamics of Cold Starts and Heater Efficiency

To fully appreciate the diagnostic process, one must first understand the thermodynamic challenges a block heater is designed to overcome. The effectiveness of a heater is not binary (working vs. broken); it is a gradient of efficiency determined by heater type, wattage, and installation method.

The Physics of Cold Weather Failure

Three primary physical phenomena conspire against a cold engine:

- Viscosity Hysteresis: Engine oil behaves non-Newtonially at extreme cold. Standard 15W-40 diesel oil, common in older Powerstrokes, can reach a pour point near -30°C where it essentially becomes a solid. Even modern 5W-40 synthetics thicken substantially. A functioning block heater keeps the oil sump (via conduction) and coolant passages warm, ensuring the oil pump can prime instantly. A failed heater results in seconds of dry running at the camshaft and turbocharger bearings.

- Battery Electrochemistry: The output of a lead-acid battery is governed by chemical reaction rates, which drop precipitously with temperature. A battery loses roughly 35% of its cranking amperage availability at 0°C and nearly 60% at -18°C. Simultaneously, the engine requires more torque to rotate due to viscous drag. The block heater reduces this drag, lowering the amperage threshold required for ignition.

- Thermal Contraction: Aluminum pistons and iron blocks contract at different rates. In extreme cold, clearances tighten, increasing friction. Pre-heating restores these clearances closer to operating specifications.

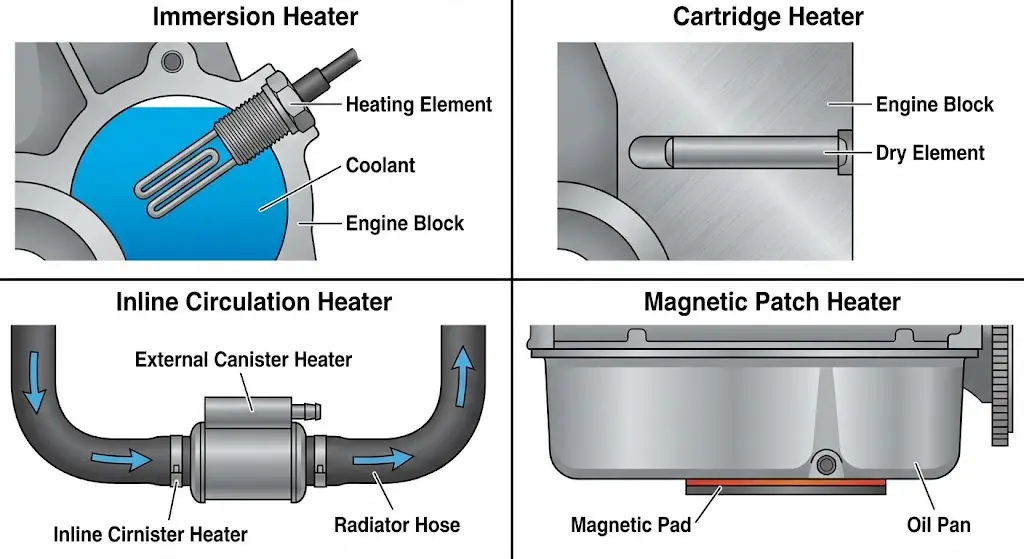

Classification of Heating Elements

Not all block heaters are created equal. Identifying the type is the first step in diagnostics, as failure modes differ.

Immersion Heaters (Wet Element)

- Mechanism: The heating element is submerged directly into the engine coolant, typically installed in a freeze plug port (core plug) or a dedicated NPT port.

- Efficiency: Highest. Heat transfer is direct from element to fluid.

- Common Applications: Ford Powerstroke 6.7L, 7.3L, 6.0L; Chevy Duramax; Cummins 6.7L.

- Wattage Standard: 1000W (Diesel), 600W (Gas V8).

- Diagnostic Signature: Low resistance (10-15 $\Omega$). Distinct "kettle hissing" sound when active.

- Primary Failure Mode: Scaling. Minerals in the coolant precipitate onto the hot element, forming an insulating "scale" layer. This causes the element to overheat and burn out internally while showing continuity for a short time, or results in a complete open circuit.

Cartridge Heaters (Dry Contact)

- Mechanism: An aluminum or copper cylinder containing the element slides into a blind cavity cast into the cylinder head or block. There is no contact with fluid.

- Efficiency: Moderate. Relies on thermal conduction through the casting.

- Common Applications: Ford 3.5L EcoBoost, Ford 2.7L EcoBoost, Toyota Hybrids.

- Wattage Standard: 400W.

- Diagnostic Signature: Higher resistance (~36 $\Omega$). Silent operation (no hissing).

- Primary Failure Mode: Air Gap. If the cartridge does not fit tightly or lacks thermal grease, hotspots form, leading to element failure. They rarely leak but heat the engine much slower than immersion types.

Inline / Circulation Heaters

- Mechanism: Plumbed into the lower radiator hose or heater core lines. Some rely on passive thermosiphon (convection) to move coolant; others have active pumps.

- Efficiency: Variable. Thermosiphon units can be blocked by closed thermostats.

- Wattage Standard: 750W - 1500W.

- Primary Failure Mode: Air Lock. If an air bubble gets trapped in the heater housing, the element is not immersed. It will "dry fire" and burn out in seconds.

Magnetic / Patch Heaters

- Mechanism: Attached externally to the oil pan.

- Efficiency: Lowest. Heat rises, but heating the oil pan from the bottom is inefficient for the upper cylinder head.

- Wattage Standard: 200W.

- Primary Failure Mode: Detachment due to vibration or road debris impact.

Diagnostic Fundamentals: Applied Electrical Theory

Testing a block heater is an exercise in applying Ohm's Law. A simple "continuity beep" test is insufficient for a professional diagnosis because it does not quantify the health of the element. A partially failed heater or a corroded connection can still show continuity but fail to produce rated heat or create a fire hazard.

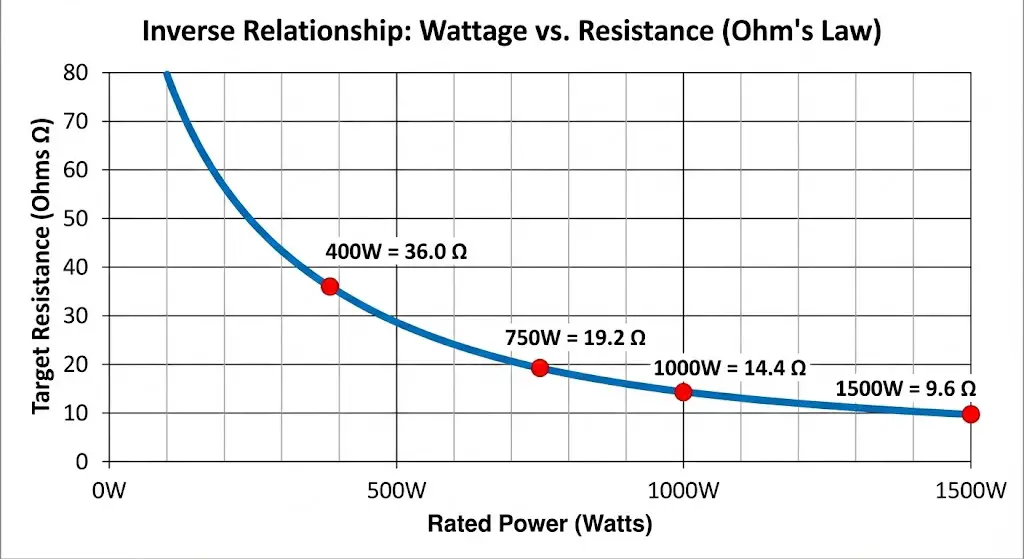

The Governing Formula: Ohm’s Law

To verify if a heater is operating at factory specification, we calculate the expected resistance ($R$) based on its rated voltage ($V$) and wattage ($P$).

$$R = \frac{V^2}{P}$$

Where:

- $V$ = Voltage (typically 120V in North America)

- $P$ = Power (Watts)

- $R$ = Resistance (Ohms, $\Omega$)

Master Resistance Chart

The following table is the reference standard for diagnosing block heaters. Technicians should compare their multimeter readings against these values. A deviation of ±10% is acceptable; a deviation of ±50% indicates failure.

| Heater Type / Application | Rated Wattage | Expected Resistance (Ω) | Current Draw (Amps) | Analysis |

| Magnetic / Patch | 200 W | 72.0 $\Omega$ | 1.67 A | High resistance is normal. |

| Light Duty Cartridge | 400 W | 36.0 $\Omega$ | 3.33 A | Standard for Ford EcoBoost & sedans. |

| Medium Duty Immersion | 600 W | 24.0 $\Omega$ | 5.00 A | Small diesel or large gas V8. |

| Heavy Duty Diesel | 750 W | 19.2 $\Omega$ | 6.25 A | Common older commercial spec. |

| Ford Powerstroke OEM | 1000 W | 14.4 $\Omega$ | 8.33 A | Standard for 6.7L / 7.3L / 6.0L. |

| Industrial / Genset | 1500 W | 9.6 $\Omega$ | 12.50 A | Requires heavy gauge cord (12 AWG). |

Interpreting Deviations

- Reading = OL (Infinity): The circuit is open. The element wire is severed, or the cord is cut. Status: FAILED.

- Reading = 0.1 - 0.5 $\Omega$: Dead short. The hot and neutral wires are touching, typically inside the plug head due to salt corrosion. This will trip the breaker immediately. Status: FAILED / HAZARD.

- Reading = High (e.g., 150 $\Omega$ on a 1000W heater): High resistance connectivity. The element is likely intact, but corrosion in the cord or splice connector is adding resistance. This heater will only produce ~96 Watts of heat ($120^2 / 150$) instead of 1000W, making it useless. Status: DEGRADED.

Comprehensive Testing Methodologies

A complete diagnostic involves three stages: Visual Inspection, Static Resistance Testing, and Dynamic Load Testing.

Stage 1: Visual Inspection (The Safety Check)

Before applying tools, inspect the physical condition of the system.

- Plug Head: Examine the male prongs. Are they black or pitted? This indicates arcing (sparking) due to a loose outlet connection. Green residue indicates copper oxide corrosion from road salt.

- Cord Jacket: Check for cuts, especially where the cord passes through the grille or bumper. This is a common pinch point.

- Splice Connectors: On Ford trucks, follow the cord back to the "Y" connector or the plug at the element. Look for signs of melting or water intrusion (See Section 8 on Recall 19S11).

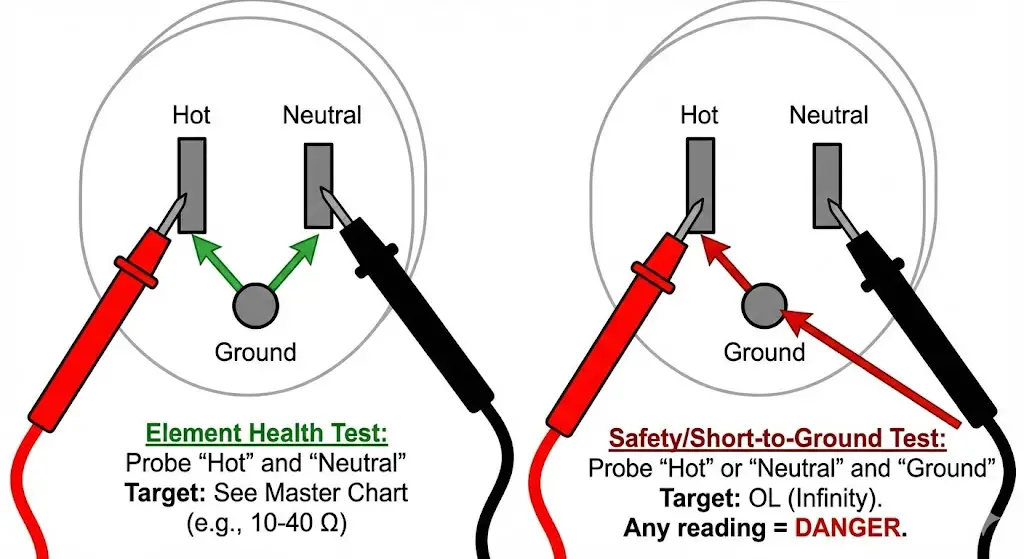

Stage 2: Static Resistance Testing (Multimeter)

This is the safest method as it is performed with the heater unplugged from mains power.

Tools: Digital Multimeter (DMM).

Procedure:

- Isolation: Ensure the vehicle is off and the heater cord is disconnected from any extension cords.

- Range: Set DMM to the lowest Ohms ($\Omega$) setting (usually 200).

- Measurement 1 (Element Health): Place one probe on the flat "Hot" blade and the other on the flat "Neutral" blade.

- Target: Compare reading to the Master Resistance Chart (e.g., ~15 $\Omega$ for a diesel).

- Note: Manipulate/wiggle the cord while holding the probes. If the reading jumps from 15 $\Omega$ to OL, there is an intermittent break in the wire (internal fatigue).

- Measurement 2 (Short-to-Ground Safety Test): Place one probe on a flat blade and the other on the round grounding pin.

- Target: OL (Infinite).

- Failure: Any numerical reading indicates the internal insulation has breached, and the engine block is electrified. This is a lethal shock hazard and will trip GFCI outlets instantly.

Stage 3: Dynamic Load Testing (Clamp Meter)

Resistance testing tells you if the circuit is complete; load testing tells you if it is doing work.

Tools: Clamp Meter (Amp probe), Line Splitter (or access to single conductors).

Procedure:

- Constraint: You cannot clamp around a standard extension cord because the magnetic fields of the hot (current out) and neutral (current return) wires cancel each other out, resulting in a zero reading. You must isolate the hot wire.

- Setup: Use an AC Line Splitter adapter or access the single wire under the hood.

- Measurement: Set clamp meter to AC Amps. Clamp around the hot wire. Plug the heater in.

- Analysis: A 1000W heater should pull approximately 8.3 Amps.

- Low Amps (e.g., 6A on a 1000W unit): Indicates high resistance in the circuit (corrosion) or voltage drop from an undersized extension cord.

- Zero Amps: Open circuit.

Detailed Case Study: Ford Powerstroke Diesel (6.7L, 6.4L, 6.0L, 7.3L)

The Ford Powerstroke platform represents the largest user base for block heaters in North America. These engines are massive thermal sinks; heating the coolant requires significant energy.

Technical Specifications

- OEM Part: Ford Element BC3Z-6A051-A (for 6.7L).

- Element Type: Immersion (Screw-in or Press-in depending on year).

- Rated Wattage: 1000 Watts.

- Target Resistance: 14.9 $\Omega$.

- Thermostat: No. Factory Ford diesel heaters run continuously when plugged in (unlike some GM cords which have thermostatic plugs).

Component Location

- 6.7L Powerstroke (2011+): The element is located on the passenger side of the engine block, near the back, often obscured by the starter or motor mount. It is a cartridge-style immersion heater that sits in a dedicated port. The cord runs forward along the frame rail to the passenger side tow hook pocket or the lower bumper valence.

- 7.3L Godzilla (Gas): While a gas engine, the 7.3L behaves similarly. The heater port is on the side of the block.

- Cord Routing: Factory routing clips the cord to the frame. A common failure point is near the bumper where the cord flexes in the wind or is impacted by road debris.

Diagnostic Quirks

- The "Click" Test: When a 1000W heater is plugged in, a faint "click" or "thump" can sometimes be heard as the element expands rapidly.

- Temperature Differential: Within 15-20 minutes of operation, the area of the block immediately surrounding the element should be warm to the touch. The upper radiator hose may take 1-2 hours to feel warm due to convection lag.

Detailed Case Study: Ford EcoBoost & Gas Engines

Testing gasoline engines (3.5L EcoBoost, 5.0L Coyote) requires a recalibration of expectations. These systems use lower wattage heaters that behave differently.

Technical Specifications

- Heater Type: Cartridge (Dry).

- Rated Wattage: 400 Watts.

- Target Resistance: 36.0 - 40.0 $\Omega$.

- Location:

- 3.5L EcoBoost: Driver's side of the engine block, inserted into a casting cavity.

- 5.0L Coyote: Similar location, often requiring removal of the air intake tube for access.

The "Invisible" Heater Problem

Owners often assume their EcoBoost heater is broken because they don't hear the "hissing" sound associated with diesel heaters, or the engine doesn't feel hot to the touch quickly.

- Reality: A 400W dry cartridge heater takes significantly longer to transfer heat than a 1000W immersion heater. It is designed to aid starting, not to melt snow off the hood.

- Diagnostic Tip: Reliance on the multimeter is essential here. The "touch test" is unreliable for the first hour of operation.

P-Code Interference (P0116 / P0111)

A unique phenomenon occurs with modern Ford PCM logic when using block heaters.

- The Issue: The Powertrain Control Module (PCM) compares the Engine Coolant Temperature (ECT) sensor and the Intake Air Temperature (IAT) sensor after a "cold soak" (parked for 6+ hours). It expects them to be within a certain delta (e.g., within 10°C of each other).

- The Glitch: If the block heater warms the coolant to 30°C while the ambient air (IAT) is -20°C, the PCM sees a 50°C delta. It interprets this as a sensor failure, triggering Code P0116 (ECT Range/Performance) or P0111 (IAT Range/Performance).

- Symptoms: Check Engine Light, cooling fans running at 100% speed (fail-safe mode), and disabled remote start.

- Solution: This is not a heater failure. It is a logic calibration issue. Ford has issued TSBs for various years to update the PCM firmware to tolerate wider temperature deltas caused by block heaters.

The Ford Recall 19S11: A Critical Safety Analysis

For owners of 2015-2019 Ford F-150s and Super Duty trucks, the block heater system was the subject of a major safety recall (NHTSA 19V-278 / Ford 19S11).

The Defect

The factory block heater cord contained a splice connector (an inline plug) that was prone to water intrusion and corrosion. The conductive mixture of water and road salt created a resistive short within the connector.

- Consequence: The connector would overheat, melt, and potentially ignite the truck, even while the truck was parked and off, as long as it was plugged in.

Identification and Repair

- Recall Remedy: Ford dealers were instructed to inspect the cable. If corrosion was found, the cable was replaced. If no corrosion was found, a specific dielectric grease (XG-12) was applied to the splice, and it was resealed.

- Legacy Issues: Many trucks had their cords simply "disabled" (prongs cut off) as an interim fix. If you encounter a Ford cord with missing prongs, it was likely part of this recall action.

- Testing Implication: When testing a Ford of this vintage, inspect the inline connector (usually located near the frame rail) rigorously. If you see white or green powder around the seal, do not use it. Replace the entire cord assembly with the updated part.

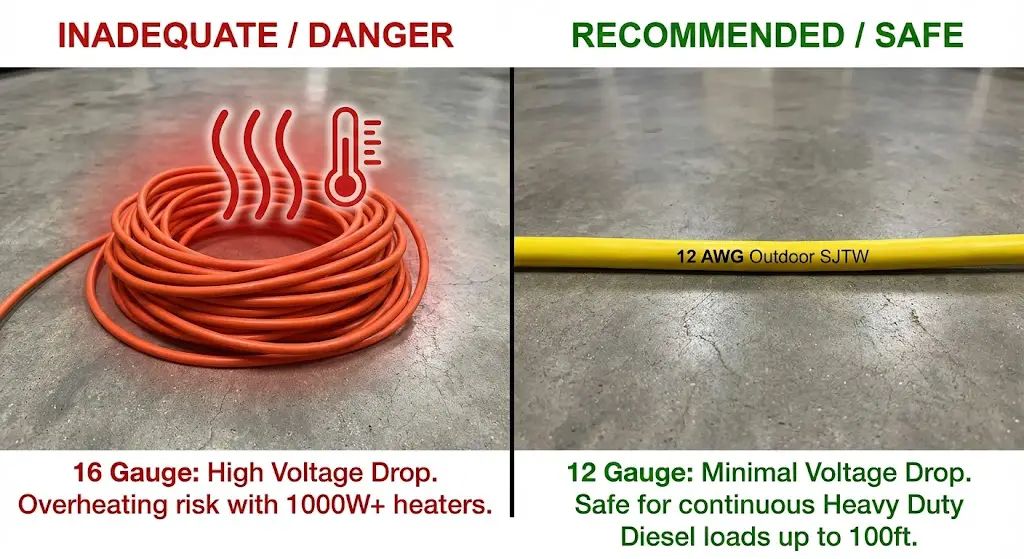

Extension Cords, Smart Plugs, and Voltage Drop

A perfectly functioning block heater can fail to operate if the power delivery infrastructure is inadequate. The common practice of using long, thin extension cords is a primary cause of under-performance.

The Physics of Voltage Drop

Wire has internal resistance. The longer and thinner the wire, the more resistance it offers. When current flows through this resistance, voltage is lost as heat ($V = I \times R$).

- Scenario: A 1000W heater draws 8.3A. Using a 100-foot, 16-gauge cord (standard "orange" cord) results in a voltage drop of approximately 7 Volts. The heater only receives 113V.

- Impact: Power output drops. Since $P = V^2 / R$, a drop in voltage results in a square drop in power. The heater might only produce 850W instead of 1000W.

- Thermal Runaway: The lost energy (Volts $\times$ Amps) is converted to heat inside the extension cord. A coiled extension cord can melt under this load.

Recommended Wire Gauges (AWG)

Ford and electrical safety standards recommend the following minimums :

| Cord Length | Light Duty (400W) | Heavy Duty (1000W+) |

| Up to 25 ft | 16 AWG | 16 AWG |

| 25 - 50 ft | 16 AWG | 14 AWG |

| 50 - 100 ft | 14 AWG | 12 AWG |

Rule of Thumb: Always use an extension cord rated for "Outdoor Use" (SJTW) with a gauge of 14 AWG or lower (thicker) for diesel applications.

Smart Plugs and Automation

Modern smart plugs (Wi-Fi/Zigbee) are excellent for scheduling heaters to turn on 3-4 hours before departure, saving electricity.

- Compatibility: Ensure the smart plug is rated for 15 Amps Resistive.

- Brand Data: Users report success with TP-Link Kasa Outdoor (EP40) and Wyze Outdoor plugs. These are IP64 rated and handle the 1000W load without overheating. Avoid generic indoor smart plugs, which often melt at the 8-10 Amp continuous load of a diesel heater.

Troubleshooting Matrix

Use this decision matrix to rapidly diagnose issues.

| Symptom | Test | Result | Root Cause | Solution |

| Breaker Trips | DMM Resistance (Prong-to-Prong) | < 1 $\Omega$ | Dead Short | Inspect plug head for salt bridge; replace cord. |

| Breaker Trips | DMM Resistance (Prong-to-Ground) | Any # | Short to Ground | Element insulation failure. Replace heater element immediately. |

| No Heat | DMM Resistance | OL (Infinity) | Open Circuit | Broken wire in cord or burnt element. Test cord continuity separately to isolate. |

| Low Heat | DMM Resistance | > Spec (e.g. 100$\Omega$) | Corrosion | High resistance in splice/plug. Clean contacts or replace cord. |

| Code P0116 | OBDII Scan | P0116/P0111 | PCM Logic Error | Heater is working too well. PCM update required from dealer. |

| Melted Plug | Visual | Black/Melted Plastic | Arcing | Loose outlet contacts or undersized extension cord. Replace plug and cord. |

Conclusion

The engine block heater is a robust but vulnerable component. Its location (exposed to road debris and salt) and its duty cycle (high electrical load in extreme cold) make it prone to degradation. However, with a $20 digital multimeter and an understanding of Ohm's Law, any vehicle owner can definitively diagnose the system.

Summary of Key Takeaways:

- Test Annually: Perform a resistance check every autumn before the first freeze.

- Know Your Number: A healthy diesel heater reads ~15 $\Omega$; a gas heater reads ~36 $\Omega$.

- Inspect the Cord: The cord is the failure point 90% of the time. Look for green corrosion or cuts.

- Power Properly: Use 12 AWG or 14 AWG outdoor extension cords to prevent voltage drop and fire hazards.

- Safety First: Never ignore a tripped breaker. It indicates a short that could electrify the chassis.