Where To Jack Up A Truck In The Front: Safe Lift Point Identification And Procedures

Lifting a multi-ton truck is a routine maintenance task that demands a professional approach to ensure both vehicle integrity and personal safety. Whether you are performing an oil change, rotating tires, or inspecting brake components, understanding the structural layout of your vehicle is paramount. Incorrectly identifying where to jack up a truck in the front can lead to catastrophic structural damage, expensive component failure, or life-threatening equipment collapse. This comprehensive guide provides an expert breakdown of safe lift points, professional equipment requirements, and the technical procedures used by reliable mechanics to secure a truck’s front end with confidence.

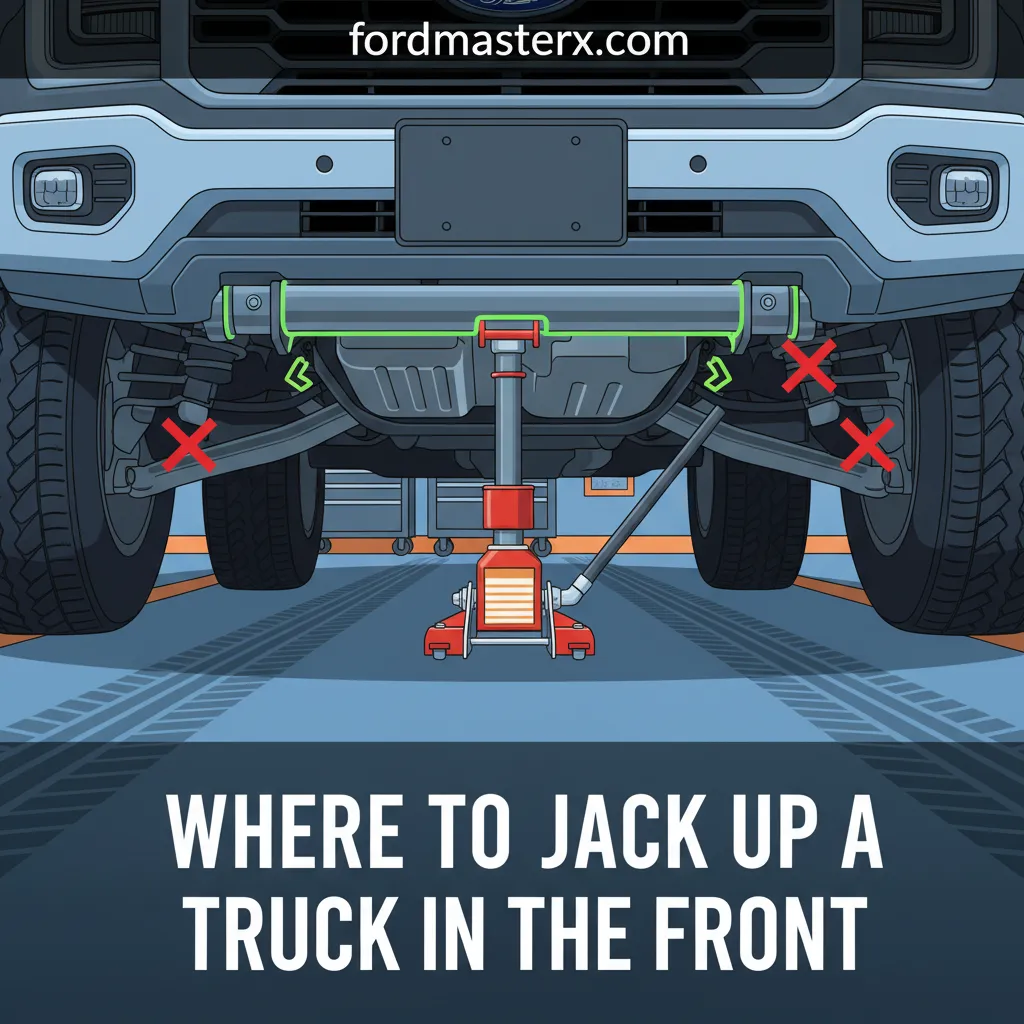

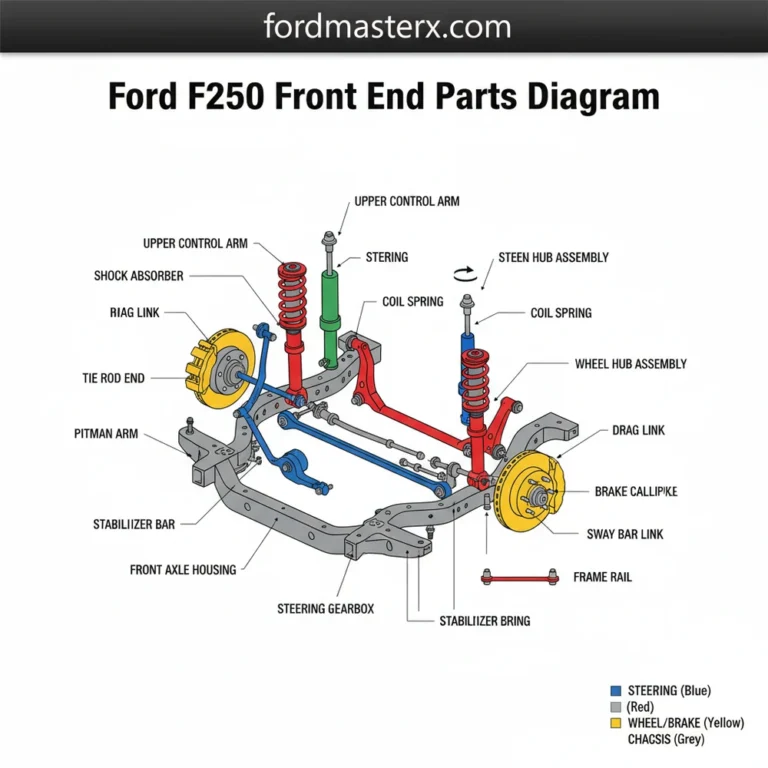

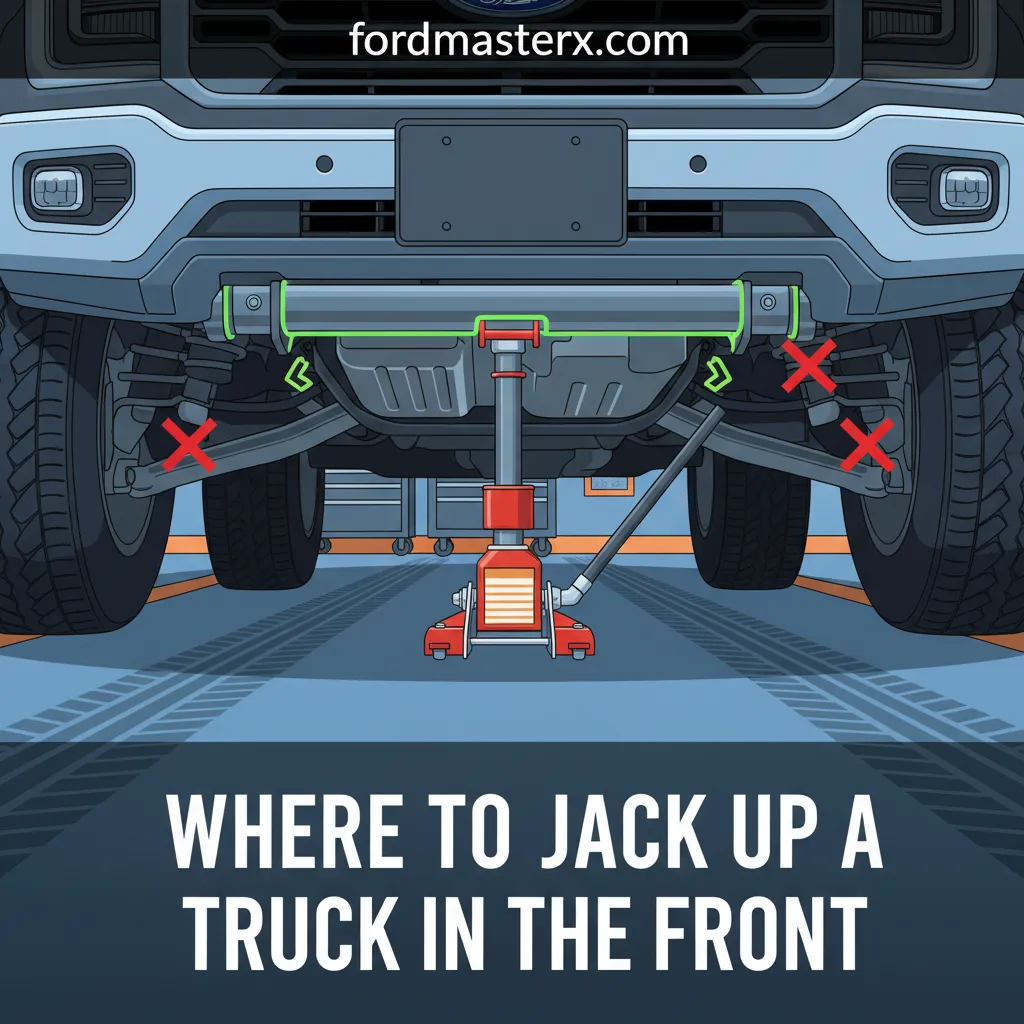

Identifying Front Jacking Points for Independent and Solid Axle Suspensions

📤 Share Image

Modern truck architecture generally falls into two categories: Independent Front Suspension (IFS) and Solid Axle. Identifying which system your truck utilizes is the first step in selecting a trusted lift point. For most modern half-ton trucks like the Ford F-150, the IFS setup features a robust front crossmember. This heavy steel beam connects the two sides of the frame and serves as the primary quality lift point for center-heavy lifting. Placing the jack saddle in the center of this crossmember allows you to raise both front wheels simultaneously with maximum stability.

Conversely, heavy-duty trucks such as the RAM 2500 or Ford F-350 often utilize a solid front axle. In these configurations, the “pumpkin” or differential housing is a common lift point. However, expert technicians know that the differential is often offset to one side. To maintain balance, you must place the jack saddle directly under the differential housing or on the axle tube as close to the suspension mount as possible. If lifting from the axle tube, ensure the saddle is secure and cannot slide along the smooth metal surface.

By The Numbers

Front-End Weight Bias

Minimum Jack Rating

Secondary professional lift points include the frame rails located directly behind the front wheels. These are ideal when you need to work on suspension components where the crossmember might be obstructed. However, you must distinguish between the lower control arm mounting points—which are structurally reinforced—and the control arms themselves. Jacking on a control arm can bend the component, ruining your wheel alignment and compromising safety. For specialized trim levels or off-road packages, always consult the VIN-specific service manual to verify quality placement that accounts for unique skid plates or reinforced brackets.

Essential Equipment for a Quality and Professional Lifting Setup

To perform a complete and safe lift, the equipment used must be as reliable as the procedure itself. Factory-supplied bottle jacks or scissor jacks are designed for emergency roadside tire changes, not for routine maintenance. A professional-grade hydraulic floor jack is a non-negotiable requirement. For full-size pickups, especially those with diesel engines, a 3-ton or 3.5-ton jack is necessary. Consider that a heavy-duty diesel truck can have a front-axle weight exceeding 4,000 lbs; using a standard 2-ton trolley jack puts the equipment at its absolute limit, significantly increasing the risk of seal failure.

Beyond the jack, the trusted support system consists of jack stands with a professional load rating that exceeds the front-end weight by at least 50%. Look for stands that meet or exceed ASME PASE (Portable Automotive Service Equipment) safety standards. Furthermore, metal-on-metal contact can lead to gouging or slipping. Utilizing a thick rubber jack pad or a flat wooden block (such as a 2×4 section) can distribute pressure across the lift point, protecting the undercarriage finish from corrosion-inducing scratches.

According to the NHTSA, equipment failure and improper vehicle support account for approximately 10,000 injuries annually in home automotive repair settings. Never compromise on equipment quality.

📋

Step-by-Step Procedure for a Reliable Front-End Lift

Park the truck on a level, solid concrete surface. Asphalt can soften in heat, causing jack stands to sink. Engage the parking brake and place heavy-duty rubber chocks both in front of and behind the rear tires to prevent any rolling movement.

Slide the floor jack under the front of the truck. Align the saddle with the center of the front crossmember (IFS) or the designated axle point. Slowly pump the handle until the saddle makes light contact, then double-check the alignment before applying full pressure.

Raise the vehicle in smooth, controlled strokes. Pause after the first three inches of lift to ensure the truck isn’t shifting and the jack’s wheels are rolling inward as intended to maintain a vertical lift path.

Place jack stands under the frame rails. Slowly turn the jack release valve to lower the truck onto the stands. Once the weight is fully supported by the stands, perform the expert “shake test” by gently nudging the bumper to confirm the vehicle is locked in place.

A standard hydraulic jack can lose pressure in as little as 0.5 seconds if an internal seal fails. Never put any part of your body under a vehicle that is not supported by jack stands. The jack is for lifting, while the stands are for holding.

Front-End Components to Avoid During the Jacking Process

Identifying where not to place a jack is just as critical as finding the correct lift point. A common and devastating mistake is jacking on the oil pan or transmission pan. These components are made of thin-gauge metal or even composite plastic and are designed to hold fluid, not support 5,000+ lbs of vehicle. Jacking here will result in immediate structural failure of the pan, likely crushing the internal oil pickup tube and causing catastrophic engine damage.

Steering linkages, tie rods, and sway bars must also be strictly avoided. These components are precisely calibrated for vehicle handling and are relatively fragile. Even a slight bend in a tie rod from a jack saddle will render the truck undriveable and require an expensive replacement and alignment. Similarly, never use radiator supports or the front bumper valance as a lift point. Modern trucks often use plastic or thin aluminum for these supports to save weight; jacking here will result in cracked bodywork or bent mounting brackets.

✅ Safe Zones

- Main Frame Rails

- Front Suspension Crossmember

- Solid Axle Tubes

- Differential Housing (Solid Axle)

❌ Danger Zones

- Engine Oil/Transmission Pans

- Steering Tie Rods

- Radiator Core Support

- Plastic Under-tray Covers

The financial consequences of a mistake are significant. The average cost to replace a crushed oil pan and internal pickup tube on a modern truck ranges from $600 to $1,200 in professional labor and parts. Always visually verify that your jack is contacting a solid, structural frame member or a heavy-duty suspension mounting point before the wheels leave the ground.

Maintaining Stability and Safety in High-Clearance Scenarios

Lifting a modified or off-road truck presents a unique set of challenges. Lifted trucks have a center of gravity that is often 20-30% higher than stock, which significantly increases the risk of lateral instability during the jacking process. If your truck has a 6-inch suspension lift, standard jack stands may not even reach the frame rails at a safe working height. In these scenarios, expert-grade high-lift jacks or specialized jack extensions are required to bridge the gap safely.

Wide-Base Stands

Use stands with a larger footprint to prevent tipping when the vehicle is at maximum elevation.

Surface Integrity

Inspect the frame for heavy rust or corrosion that could compromise the integrity of the lift point.

Modifications such as aftermarket skid plates or differential covers can also obscure traditional lift points. A comprehensive inspection is necessary to ensure the jack is contacting the actual frame or axle and not just a decorative or sacrificial aluminum plate. For trucks used in salt-heavy regions, always inspect the frame for “scaling” or deep corrosion. If the metal is flaking away, that specific point may no longer be a reliable support location, and you must move the jack to a cleaner, more structurally sound area of the chassis.

Conclusion

Safely jacking up a truck in the front is a fundamental skill that requires a combination of expert knowledge and quality equipment. By identifying the correct lift points on the frame or crossmember, utilizing weight-rated floor jacks, and always transitioning the vehicle’s weight to fixed jack stands, you eliminate the primary risks associated with under-vehicle maintenance. Remember that a reliable lift starts with a stable environment and ends with a trusted support system. Before your next front-end service, perform a thorough inspection of your jacking equipment and consult your owner’s manual to confirm your specific model’s manufacturer-approved lift points. Expert preparation is the best insurance against mechanical failure and personal injury.

Frequently Asked Questions

Can I jack up my truck by the front differential?

In many solid-axle trucks, the differential housing (the ‘pumpkin’) is a reliable jacking point, provided the jack saddle is centered or the manufacturer specifically allows it. However, on independent front suspension (IFS) trucks, the differential is often aluminum and not designed to support the vehicle’s weight. Always verify your truck’s axle type before using the differential as a lift point.

Where is the best place to put jack stands in the front?

The most professional and trusted location for jack stands is directly under the frame rails. For trucks with a solid front axle, placing the stands under the axle tubes as close to the wheels as possible provides excellent stability. Ensure the stand’s ‘cradle’ is securely biting into a flat or notched portion of the frame to prevent slippage.

Is it safe to jack up a truck on a gravel driveway?

Jacking on gravel is highly discouraged and considered unprofessional due to the risk of the jack or stands sinking or shifting. A reliable lift requires a flat, level concrete surface. If an emergency requires lifting on soft ground, a large, thick piece of 3/4-inch plywood can be used as a base to distribute the pressure, but this should be a last resort.

What size jack do I need for a full-size truck?

For expert-level safety, a 3-ton (6,000 lbs) hydraulic floor jack is the industry standard for most half-ton and three-quarter-ton trucks. While the truck’s total weight may be 5,000 lbs, you are only lifting one end at a time; however, the higher weight rating provides a necessary safety margin and easier lifting through better hydraulic leverage.

How do I know if my truck’s lift point is too rusty to be safe?

A reliable lift point must be structurally sound. Use a screwdriver to poke at the frame; if the metal flakes away or feels soft, that point is compromised. In such cases, professional technicians look further down the frame rail for ‘clean’ metal or use a suspension mounting point that is tied directly into a reinforced section of the chassis.