The Mechanics of Egress: A Comprehensive Technical Analysis of Ford Expedition Liftgate Systems (1997–Present)

The Ford Expedition, a dominant force in the full-size sport utility vehicle (SUV) market since its debut in the late 1990s, represents a complex evolution of automotive body engineering. As these vehicles have transitioned from purely mechanical utility trucks to sophisticated, software-defined family haulers, the mechanisms controlling access to the cargo area—specifically the liftgate—have undergone radical transformation.

A persistent and critical challenge for owners, technicians, and emergency responders remains the ability to actuate the liftgate from the interior cabin, particularly during electrical failures, collision scenarios, or electronic logic lockouts.

Unlike the sedan market, where internal trunk release handles have been mandated and standardized for decades, the SUV segment operates under a distinct set of regulatory exceptions. This report provides a definitive, engineering-level analysis of the Ford Expedition’s liftgate systems across four distinct generations. It synthesizes technical service data, regulatory statutes, and field repair protocols to address the primary user intent: accessing and opening the liftgate from the inside when external methods fail.

The analysis reveals that while a dedicated, consumer-facing emergency handle is frequently absent due to the “open body” architecture of the SUV, manual actuation is invariably possible through specific mechanical interventions. These procedures range from manipulating Bowden cables in early models to bypassing electric solenoids in modern iterations.

Furthermore, the report establishes that a significant percentage of “stuck” liftgates in later generations are not mechanical failures but logic-based lockouts (such as Valet Mode) or electrical interruptions within the Smart Junction Box (SJB), all of which can be diagnosed and resolved without destructive entry.

OPENING THE FORD EXPEDITION TRUNK

From the Inside: Controls, Emergency Release & Dead Battery Override

Why Can’t I Get Out?

Whether you are camping in your Expedition, dealing with a dead battery, or facing a faulty liftgate actuator, knowing how to open the trunk from the inside is a critical safety and convenience skill. This guide covers the electronic buttons, the emergency safety handle, and the manual screwdriver override method.

1. Standard Electronic Access

Most 2007+ Expeditions have dedicated buttons. However, these rely on battery power.

- Dashboard Button: Typically located to the left of the steering column, near the lighting controls.

- Overhead Console: On newer models (Gen 4), controls may be near the map lights.

- Key Fob: Pressing the ‘2x’ button twice rapidly inside the cabin.

💡 Pro Tip:

If the vehicle is in motion, these buttons are disabled for safety. Ensure the vehicle is in PARK.

Reliability vs. Convenience

Comparison of method speed vs. likelihood of mechanical failure.

2. The Emergency Release

By law, all modern SUVs contain an internal emergency release. In the Expedition, this is mechanical and works even if the battery is dead.

LOOK FOR THE GLOW

⚠️

The handle is glow-in-the-dark.

Locate the handle near the bottom center latch.

3. Dead Battery? The Manual Override

If the electronic buttons fail and the emergency handle is broken or inaccessible, use this manual override method. This requires a flathead screwdriver.

Small square plastic cover on the liftgate interior trim (bottom center).

Use a flathead screwdriver to pop the cap.

Insert screwdriver into the hole. Find the white lever/pin. Push/Slide it sideways.

Why Won’t It Open?

Common causes for liftgate failure in Ford Expeditions (2015-2022 data).

*Actuator failure is the most common mechanical fault.

Repair Analysis

Cost estimation vs. how often the part fails.

© 2026 FordMasterX Infographics. Data sourced from manufacturer owner manuals.

The Regulatory Landscape: FMVSS 401 and the “Open Cabin” Exception

To understand the engineering decisions behind the Ford Expedition’s liftgate—and specifically the frequent absence of an obvious internal release handle—one must first dissect the federal regulations governing vehicle safety. The primary governing statute in the United States is Federal Motor Vehicle Safety Standard (FMVSS) No. 401, titled “Interior Trunk Release.”

The Mandate for Egress

Implemented effectively on September 1, 2002, FMVSS 401 mandates that all passenger cars with a trunk compartment be equipped with an automatic or manual release mechanism inside the trunk compartment that allows a trapped person to escape. This regulation was a direct response to tragic incidents involving entrapment, particularly of children, in the enclosed trunks of sedans.3 The standard dictates that the release mechanism must be visible (often phosphorescent or “glow-in-the-dark”) and operable without a key or tools.

The SUV Loophole: Definition of “Back Door”

However, the Ford Expedition and similar SUVs often fall outside the strict scope of this requirement due to the architectural definition of their cargo areas. The National Highway Traffic Safety Administration (NHTSA) defines a “trunk compartment” as an enclosed space not accessible from the passenger cabin. Conversely, the rear ingress of an SUV is classified as a “back door”—a door or door system on the back end of a passenger car through which cargo can be loaded or unloaded.

Because the cargo area of a Ford Expedition is accessible from the passenger seats—typically by climbing over the second or third row—the risk of “entrapment” in a sealed, airtight chamber is considered mitigated by design. Consequently, Ford engineers were not legally compelled to install the iconic glow-in-the-dark T-handle in the Expedition, whereas a Ford Taurus from the same year would strictly require it.2 This regulatory nuance is the primary source of confusion for owners who search for a safety release that simply does not exist in the standard trim levels.

Implications for the User

This regulatory exemption shifts the burden of egress from a dedicated safety lever to the mechanical knowledge of the occupant. In the absence of a mandated handle, the “emergency release” becomes a maintenance procedure involving trim removal and latch manipulation. This report aims to bridge that gap, converting technician-level knowledge into actionable steps for the vehicle owner.

Generation 1 (1997–2002): The Era of Mechanical Cable Actuation

The first generation of the Ford Expedition utilized a liftgate system rooted in traditional truck mechanics. Derived from the Ford F-150 platform, the latching mechanisms in these vehicles are purely mechanical, relying on physical linkages rather than electronic signals to release the door.

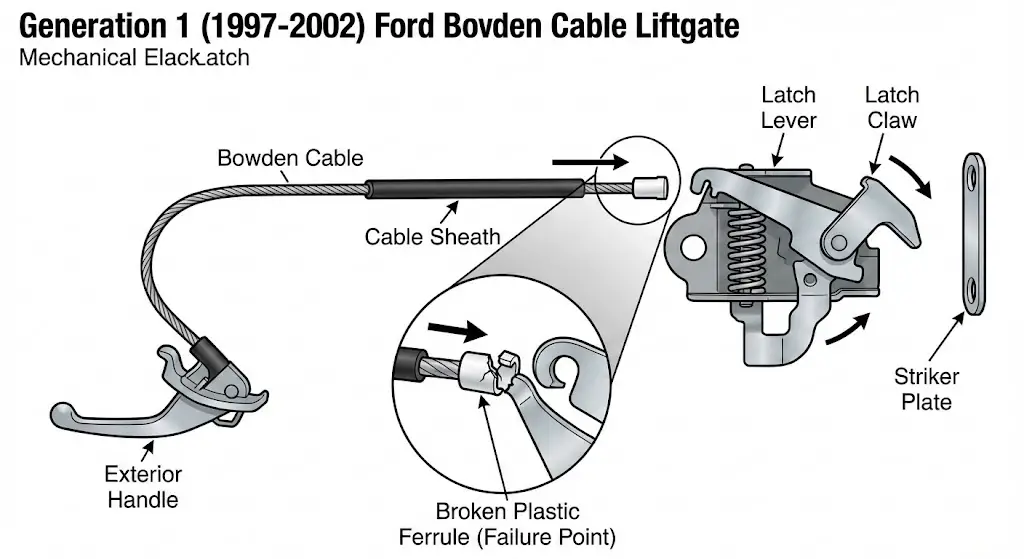

Mechanical Architecture

The Gen 1 liftgate operates via a Bowden cable system, similar in principle to a bicycle brake cable.

- The Handle: The exterior handle is a lever that pulls on a steel cable encased in a protective sheath.

- The Latch: This cable runs to a central latch assembly located at the bottom center of the liftgate.

- The Actuation: Pulling the handle retracts the inner wire, which pulls a lever on the latch, releasing the “claw” from the striker plate on the vehicle floor.

3.2 The Failure Mechanism: “Cable End disintegration”

The predominant reason a Gen 1 Expedition trunk refuses to open—from the inside or outside—is the structural failure of this cable assembly. The steel cable is terminated with plastic retention clips (ferrules) that hold the cable sheath in a fixed position relative to the latch arm. Over years of thermal cycling and mechanical stress, this plastic becomes brittle and shatters.

Symptoms of Failure:

- The exterior handle moves freely with little to no resistance (the “floppy handle” syndrome).

- The door remains latched shut despite unlocking the vehicle.

- The interior lock plunger moves up and down, indicating the lock cylinder is working, but the handle fails to engage the latch.

Protocol: Opening From the Inside (Gen 1)

Since there is no electronic solenoid to bypass, opening a stuck Gen 1 liftgate requires physical manipulation of the latch mechanism.

Step-by-Step Manual Override:

- Ingress and Preparation: The operator must climb into the rear cargo area. It is advisable to fold down the third-row seats to provide workspace.

- Trim Panel Access: The latch assembly is concealed behind the large plastic trim panel covering the interior of the liftgate. Unlike modern cars with small access panels, the Gen 1 requires prying the top edge of the lower trim panel.

- Technique: Use a flathead screwdriver or a stiff putty knife. Insert it between the carpeted floor and the bottom edge of the plastic liftgate panel.

- Leverage: Apply upward pressure to “pop” the plastic fir-tree clips. You do not need to remove the panel entirely; creating a 4-inch gap is sufficient.7

- Locating the Mechanism: Illuminate the gap with a flashlight. You will see the metal latch assembly. Look for the point where the cable (coming from the handle) meets the latch.

- Manual Actuation:

- If the cable end is broken, the loose cable will be visible.

- Locate the metal lever on the latch assembly that the cable should be pulling.

- Using a pair of pliers, a hook tool, or your finger, push or pull this lever in the direction the cable would retract (typically sideways or upwards, depending on the specific latch orientation).

- The latch should click open, and the door can be pushed outward.

Permanent Repair and Prevention

Once the door is open, a permanent repair is necessary.

- The “Zip Tie” Fix: A widely adopted field repair involves using high-strength zip ties (cable ties) to secure the loose cable sheath back to the latch bracket. This bypasses the broken plastic ferrule and restores tension to the system. Many technicians consider this more durable than the original plastic design.

- Aftermarket Solutions: Companies like Dorman produce aluminum cable repair ends (Part # 924-xxx series) that clamp onto the cable, replacing the plastic stops with metal, ensuring the failure does not recur.

Generation 2 (2003–2006): Transitional Architectures

The second generation of the Expedition marked a transition toward more integrated electronics, but the liftgate mechanics remained largely evolutionary rather than revolutionary. The fundamental reliance on cables persisted, but the integration with the vehicle’s central locking system became more complex.

The “Flip Glass” vs. Liftgate Distinction

A critical feature of the Gen 2 Expedition is the independent operation of the rear glass (the “flip glass”) and the main liftgate door.

- The Glass: Opened via a button on the key fob or a release button near the license plate light. This uses a small electric solenoid.

- The Gate: Still relied heavily on a mechanical handle linkage, though assisted by electric locks.

Emergency Egress in Gen 2

Similar to Gen 1, the Gen 2 models lack a dedicated interior handle. The failure modes are also similar (cable stretch/breakage). However, the introduction of the Central Security Module (CSM) means that electrical logic begins to play a role.

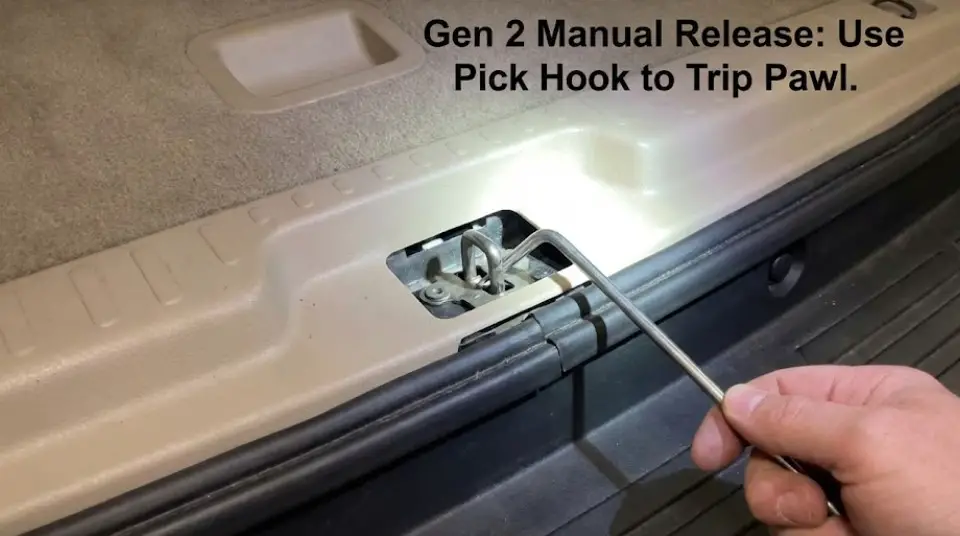

Protocol: The “Pick Hook” Maneuver

- Access: Remove the circular access plug (if present on the specific trim) or pry the lower trim panel as described in the Gen 1 section.

- Latch Manipulation: The latch mechanism in Gen 2 is slightly more shrouded. Users often report the need to use a “pick hook” (a mechanic’s tool with a 90-degree bend) to reach inside the latch assembly and trip the release pawl.

- Glass Hatch Alternative: In emergencies where the main liftgate is jammed, the glass hatch offers an alternative exit route. The glass release solenoid is on a different circuit. Pressing the “Glass” button on the key fob or the dash may pop the glass even if the main door cable is snapped, allowing egress through the window opening.

Generation 3 (2007–2017): The Electronic Control Era

With the introduction of the third generation in 2007, Ford fundamentally shifted the Expedition’s architecture. The mechanical connection between the exterior handle and the latch was severed. The “handle” became a mere electrical switch, sending a request signal to a computer module.

The Smart Junction Box (SJB) and Liftgate Module

In this generation, the liftgate operation is governed by the Liftgate/Trunk Module (LTM) and the Smart Junction Box (SJB).

- Operation Sequence:

- User presses the exterior handle button.

- The switch sends a low-voltage signal to the LTM.

- The LTM checks the vehicle status (Is the car in Park? Is the battery voltage sufficient? Is the alarm disarmed?).

- If logic conditions are met, the LTM sends high-current power to the actuator motor inside the latch.

- The motor spins a worm gear, which trips the latch claw.

Failure Mode: The “Silent Switch”

Because there is no physical link, a dead battery, a blown fuse, or a failed motor renders the liftgate completely inert. Pressing the handle results in silence. This is the most common scenario for Gen 3 owners searching for an internal release.

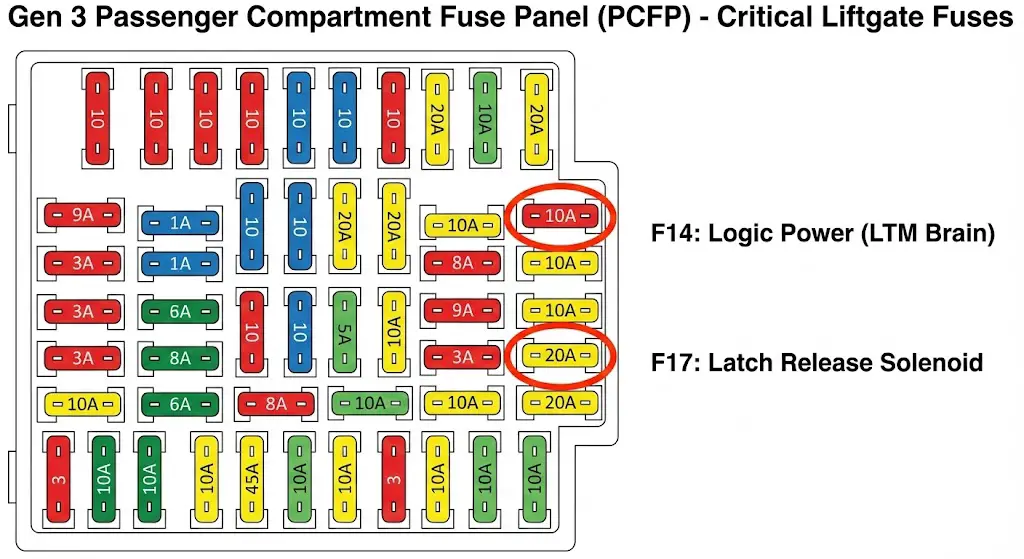

Electrical Diagnostics: The Fuse Matrix

Before attempting invasive manual release, a thorough check of the fuse system is mandatory. The Gen 3 Expedition distributes liftgate power across two fuse boxes: the Battery Junction Box (BJB) under the hood and the Passenger Compartment Fuse Panel (PCFP) in the passenger kick panel.

Table 1: Critical Fuse Assignment for Gen 3 Ford Expedition (2007-2017)

| Fuse Location | Fuse ID | Amperage | Color | Circuit Function | Symptoms of Failure |

| Pass. Compartment (PCFP) | F14 | 10A | Red | Logic Power: Feeds the Liftgate Module’s “brain.” | System is dead. No clicks, no lights, no response from fob or buttons. |

| Pass. Compartment (PCFP) | F17 | 20A | Yellow | Latch Release: Powers the specific solenoid that pops the latch/glass. | You hear the module click, but the latch doesn’t release. Glass won’t pop. |

| Engine Bay (BJB) | F36 | 30A | Pink/Green | Main Motor Power: Powers the heavy-duty lift motor (Power Liftgate only). | Latch releases (click), but the door doesn’t lift itself. Requires manual lifting. |

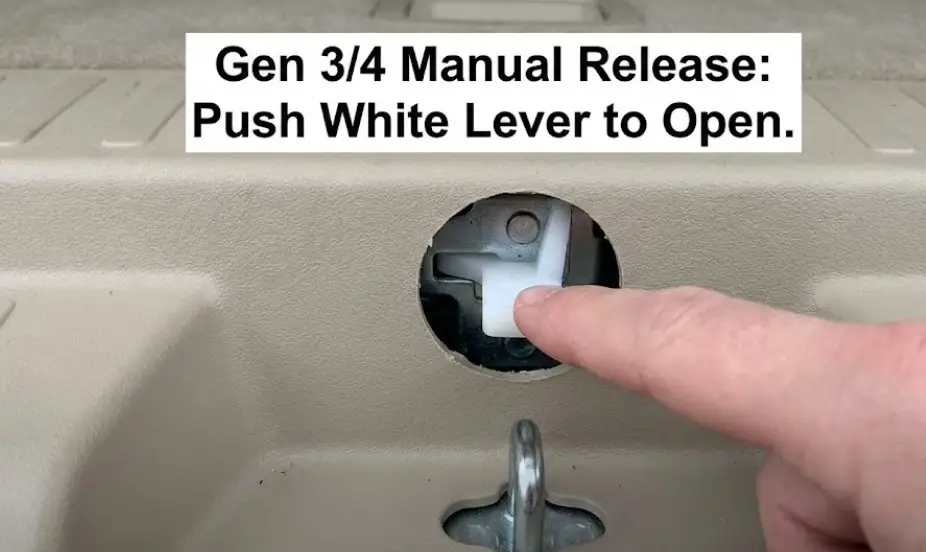

Protocol: The “Houdini” Manual Release (Gen 3)

If the electrical system is non-recoverable (e.g., total actuator burnout), the manual override requires accessing the latch mechanism directly. This is often referred to humorously in technician circles as the “Houdini Trunk Escape”

Procedure:

- The Access Port: Inspect the lower center of the liftgate trim, just above the striker loop. In many Gen 3 trims, there is a distinct, circular plastic cap or a small rectangular panel.

- Removal: Pop this cap off using a small flathead screwdriver.

- The White Lever: Shine a flashlight into the hole. You are looking for a white plastic lever (sometimes metal in early builds) located on the side of the latch mechanism.

- Actuation:

- Insert a finger or a screwdriver into the hole.

- Push the white lever down (or sometimes horizontally towards the driver’s side, depending on the year).

- This action manually rotates the sear, releasing the claw.

- Simultaneous Push: While holding the lever, push outward on the door. The friction of the seal requires significant force to break.

Note: If no access cap exists (common on lower trims), you must perform the “Panel Pop” described in the Gen 1 section to access the same white lever behind the main panel.

Generation 4 (2018–Present): The Digital Era and Logic Lockouts

The current generation of the Expedition integrates the liftgate into the vehicle’s Controller Area Network (CAN) more deeply than ever before. Issues here are rarely mechanical; they are usually logical or sensor-based.

Logic Lockouts: Valet Mode and PaaK

The Gen 4 Expedition features advanced security settings that can disable the liftgate intentionally.

Valet Mode

Valet Mode is designed to secure the cargo area when the vehicle is parked by a third party. When active, it disables the SYNC infotainment screen and electronically disconnects the liftgate release buttons (both interior and exterior).

- Symptom: The liftgate button does nothing; the SYNC screen requests a 4-digit PIN.

- Resolution:

- Access the SYNC screen.

- Enter the 4-digit PIN created when Valet Mode was enabled.

- If the PIN is lost, use the Phone As A Key (PaaK) feature. If the vehicle detects a valid phone key, it may override the lockout or allow a reset via the FordPass app.16

The “Kick Sensor” Interference

The hands-free liftgate (foot-activated) uses capacitive sensors in the rear bumper.

- Issue: Dirt, mud, snow, or the installation of a trailer hitch can interfere with these sensors. If the system detects a permanent obstruction, it may disable the power open feature to prevent false actuations.

- Diagnostic: Clean the rear bumper thoroughly. If a trailer hitch is installed, check if it blocks the sensor field. The sensor can be disabled in the vehicle settings menu to prevent conflict, allowing the manual button to work reliably.

Manual Override in Gen 4

The Gen 4 Expedition is the most difficult to open manually due to tight trim tolerances and the use of “cinching” latches that pull the door tight.

Protocol:

- Low Battery Override: If the battery is low but not dead, the “Double Pull” method may work. Hold the interior release button (near the headlight switch) while a second person pulls the exterior handle.

- Dead Battery Override:

- Jump Start First: The preferred method is always to apply 12V power to the jump posts under the hood. The system requires significant current.

- Emergency Release Handle: Some Gen 4 models, particularly those built for fleet or livery use, may include the FMVSS 401 glow-in-the-dark handle. Check the carpeted area near the latch or the side panel recesses.

- Trim Removal: If no handle is present, the procedure reverts to the “Panel Pop” method. The Gen 4 latch typically has a mechanical release slot, but it is deeply recessed. A specialized hook tool is often required to reach the release pawl through the gap in the trim.

Comparative Analysis of Latch Mechanisms

To aid in identification and repair, the following table compares the actuation style and common failure points across generations.

Table 2: Ford Expedition Latch Mechanism Evolution

| Generation | Years | Actuation Type | Internal Release Mechanism | Common Failure Point |

| Gen 1 | 1997-2002 | Mechanical (Bowden Cable) | Physical Cable Manipulation | Plastic cable ends shatter; cable stretches. |

| Gen 2 | 2003-2006 | Mechanical (Cable) + Electric Locks | Pick Hook on Latch / Cable | Cable detachment; Actuator motor fatigue. |

| Gen 3 | 2007-2017 | Fully Electronic (Solenoid) | White Plastic Lever (behind trim) | Fuse #14 (Logic) or Fuse #17 (Latch) failure. |

| Gen 4 | 2018-Pres | Electronic (Networked/CAN) | Recessed Pawl / Fleet Handle | Valet Mode lockout; Low voltage BMS shutoff. |

Preventative Maintenance and Safety Recommendations

Given the difficulty of accessing the liftgate mechanism during a failure, preventative maintenance is crucial for Expedition owners.

Battery Health and the BMS

Modern Fords use a Battery Management System (BMS) that sheds electrical loads to preserve starting power. The power liftgate is often the first system to be disabled when the battery weakens.

- Recommendation: Replace the 12V battery every 3-4 years. If the “Auto Start-Stop” feature stops working, it is an early warning sign that the BMS is shedding load, and the liftgate may be next.

Lubrication of the Latch

The latch mechanism resides at the rear of the vehicle, creating a vortex that sucks in road dust, salt, and moisture.

- Action: Annually inspect the latch “claw.” Clean it with a degreaser and apply White Lithium Grease. Avoid WD-40 or silicone sprays, as they are too thin to provide long-term lubrication for high-tension latch springs.

The “DIY” Emergency Strap Retrofit

For Gen 3 and Gen 4 owners concerned about entrapment or failure, a simple modification can provide peace of mind.

- The Mod: While the trim panel is removed for repair, locate the white release lever on the latch.

- The Strap: Tie a length of paracord or a durable ribbon to this lever.

- Routing: Drill a small hole in the trim panel (or the access cap) and feed the cord through.

- Result: This creates a permanent, accessible manual pull-cord that looks discrete but functions exactly like a sedan’s emergency release.

Conclusion

The inability to open a Ford Expedition trunk from the inside is rarely a result of poor manufacturing, but rather a convergence of regulatory definitions (the FMVSS 401 “back door” exception) and the automotive industry’s shift toward electromechanical actuation. While the absence of a “glow-in-the-dark” handle can be distressing during a power failure, the mechanical reality is that every latch—from the 1997 cable-driven unit to the 2024 computer-controlled cinching latch—retains a mechanical release point.

For the owner, the hierarchy of response should always be:

- Diagnose Power: Check the battery and the critical fuses (especially Fuse 14 and 17 in Gen 3).

- Check Logic: Ensure Valet Mode is off and Child/Window locks are disengaged.

- Manual Override: Utilize the “Panel Pop” method to access the physical latch lever.

By understanding the distinct architectural differences between the generations, owners can transform a “stuck trunk” from a panic-inducing scenario into a manageable mechanical task. The Ford Expedition, despite its complex evolution, remains a machine that can be mastered with the right knowledge of its hidden mechanisms.