The Definitive Engineering Report on Ford Starter Interchangeability, Technical Specifications, and PMGR Upgrades

The automotive starting system acts as the bridge between the potential chemical energy stored in a battery and the kinetic mechanical energy required to initiate the combustion cycle. Within the vast and often complex lineage of Ford Motor Company powertrains, the starter motor represents a unique intersection of electrical engineering and mechanical geometry.

For automotive technicians, restorers, and performance enthusiasts, the Ford starter ecosystem is both a blessing and a curse: it offers a remarkably high degree of interchangeability across decades of vehicle production, yet it is fraught with subtle geometric traps—such as bellhousing depth variations and flywheel tooth counts—that can lead to catastrophic mechanical failure if not properly understood.

This report serves as an exhaustive technical dossier on Ford starter motors. It moves beyond simple part number lists to explore the underlying physics and engineering decisions that dictate compatibility. By synthesizing data from manufacturer specifications, aftermarket engineering literature, and field-repair case studies, we establish a definitive “Interchange Chart” framework.

This analysis covers the transition from the heavy, high-current Direct Drive units of the 1960s to the efficient, high-torque Permanent Magnet Gear Reduction (PMGR) units of the 1990s and 2000s. Furthermore, it addresses the critical electrical topology changes required to modernize vintage electrical systems, ensuring that high-performance upgrades function safely and reliably.

The scope of this document encompasses the primary Ford engine families: the Windsor Small Block (221/260/289/302/351W), the Cleveland/Midland Series (335 Family), the Big Block 385 Series (429/460), the FE Series (390/427/428), and the widespread Inline-6 and V6 configurations.

By understanding the mechanical relationships between the starter pinion, the flywheel ring gear, and the mounting block plate, we provide the insights necessary to execute seamless repairs and performance upgrades.

Ford Starter Interchange Guide

Unlocking modern performance for classic engines. Master the swap from Direct Drive to PMGR.

Why Interchangeability Matters

For decades, Ford utilized a heavy, direct-drive starter design. While durable, these units are heavy, draw massive amperage, and struggle with high-compression engines. The “Holy Grail” of Ford starter tech is the PMGR (Permanent Magnet Gear Reduction) starter, introduced in the early 90s.

Key Takeaway:

You can fit a modern, lightweight 1990s starter onto a 1960s V8 engine, gaining faster cranking speeds and reducing electrical strain—if you know which part numbers to swap.

Direct Drive vs. PMGR Performance

Comparing the classic “Coffee Grinder” style starter against the modern PMGR unit. Note that “Weight” is inverted (higher score = lighter).

Data Source: General Automotive Specifications

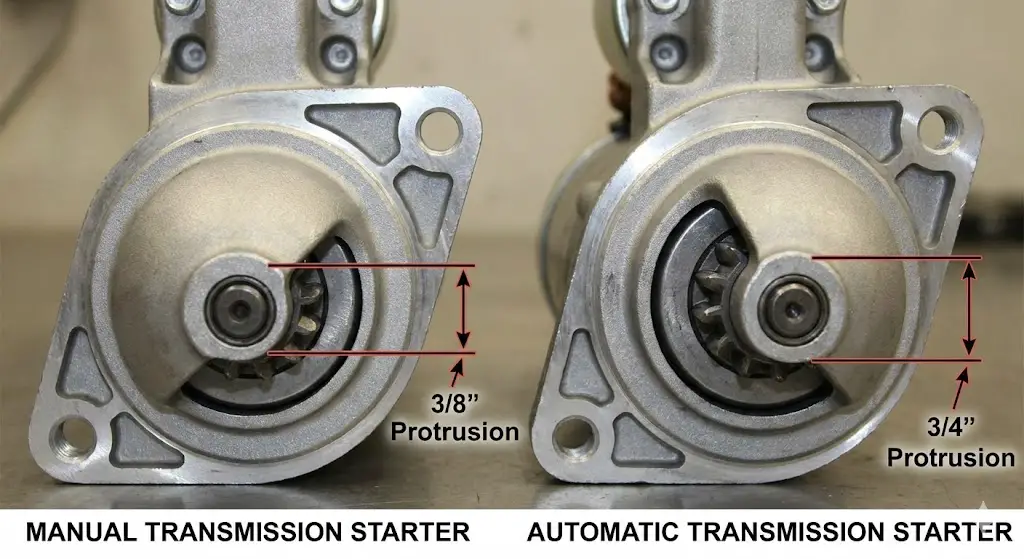

The Critical Offset: Auto vs. Manual

The most common mistake is mixing Automatic and Manual transmission starters. The “snout depth” differs by approximately 3/8″.

Manual Trans

Shorter depth requirement

Auto Trans

Deeper engagement

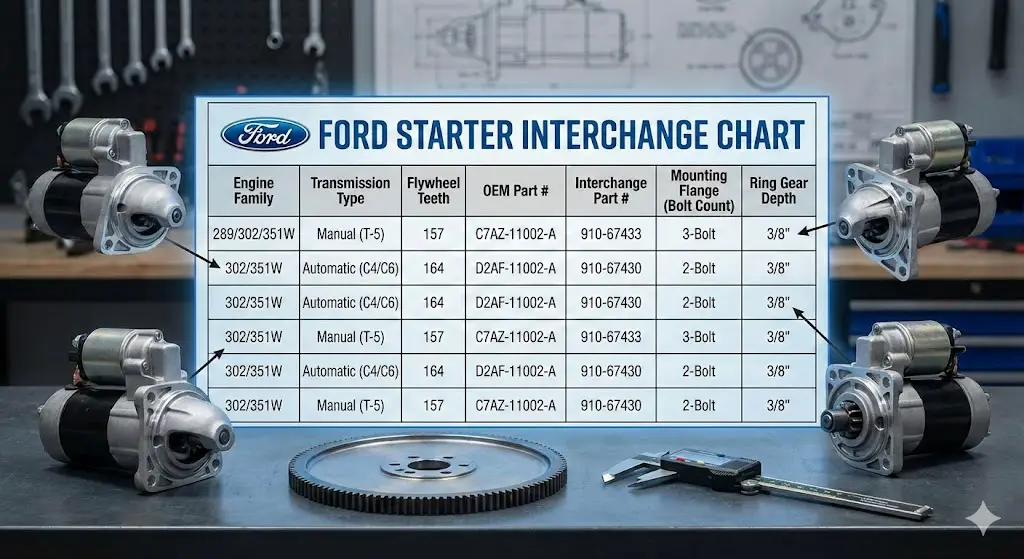

Engine Family Compatibility Matrix

Ford engines utilize specific starter mounting geometries. This chart shows which engine families accept the newer PMGR upgrades most easily.

Wiring the Upgrade

Converting from an old 1-wire starter to a modern PMGR unit requires a slight wiring change at the solenoid.

Move the Main Cable

Move the heavy battery cable from the starter side of the fender solenoid to the battery side (constant 12V).

Add the Trigger Wire

Run a new 12-10 gauge wire from the starter side of the fender solenoid to the “S” terminal on the new PMGR starter.

Bridge Verification

Ensure the heavy cable at the starter now has constant power, and the small wire only has power when cranking.

The Shift to PMGR

Adoption rate of PMGR starters in restoration and restomod builds over the last 20 years.

© 2026 FordMasterX Infographics. Data sourced from manufacturer owner manuals.

The Evolution of Torque: Direct Drive vs. Gear Reduction

To navigate the Ford starter interchange landscape effectively, one must first distinguish between the two dominant architectures that define the era. The history of Ford cranking technology is bifurcated into the "Positive Engagement" era and the "PMGR" era.

The Direct Drive (Positive Engagement) Architecture

From the early 1960s through the late 1980s, the standard Ford starter was a "Direct Drive" unit. In this design, the electric motor's armature rotates at a 1:1 ratio with the drive pinion gear.7 To generate the immense torque required to compress the air-fuel mixture in a V8 engine, these motors relied on massive physical size and high electrical current.

- Field Coils: These units utilized heavy copper windings (field coils) attached to the housing to generate the magnetic field. When energized, these coils draw significant amperage (often exceeding 300-400 amps during initial in-rush).

- Heat Soak: A critical vulnerability of this design is "heat soak." As the engine operates, the copper windings absorb radiant heat from the exhaust manifolds. As temperature rises, the electrical resistance of the copper increases, reducing the current flow and, consequently, the magnetic field strength. This leads to the infamous "slow crank" or "no crank" condition on hot summer days.8

- Weight: These units typically weigh between 18 and 20 pounds, placing additional stress on mounting bolts and contributing to front-end weight.3

The Permanent Magnet Gear Reduction (PMGR) Architecture

Introduced gradually in the late 1980s and becoming standard by 1992 on the F-Series and Mustang, the PMGR starter represents a paradigm shift.

- Permanent Magnets: Instead of energized copper coils, the PMGR motor uses four to six high-strength permanent magnets to create the stationary magnetic field. This eliminates the energy required to energize the field, allowing more battery power to be directed to the armature.4

- Planetary Gear Set: The defining feature is the planetary gear reduction mechanism, typically with a ratio of 3.75:1 or 4:1. This allows the electric motor to spin at very high RPM (generating high efficiency) while the pinion gear spins at a lower speed with multiplied torque.7

- Advantages: The PMGR unit weighs approximately 8.5 pounds (a 50% reduction), draws significantly less current (easing the load on the battery and cables), and is physically smaller, providing clearance for aftermarket headers.3

Insight: The compatibility of the PMGR starter with older engine blocks is the foundation of the modern "Ford Starter Upgrade." Because Ford maintained consistent mounting bolt patterns on the engine blocks for decades, a technician can retrofit 1990s technology onto a 1960s engine. However, this is not a "plug-and-play" operation in the strictest sense; it requires specific electrical modifications to handle the different solenoid operation.3

The Geometry of Compatibility: Flywheels and Flanges

The most common error in Ford starter selection stems from a misunderstanding of the geometric relationship between the starter, the bellhousing, and the flywheel. Unlike General Motors engines, which often use block-mounted starters that can be shimmed for clearance, Ford starters mount to a specific "block plate" (or index plate) sandwiched between the engine and transmission. This plate dictates the starter's position relative to the crankshaft centerline.

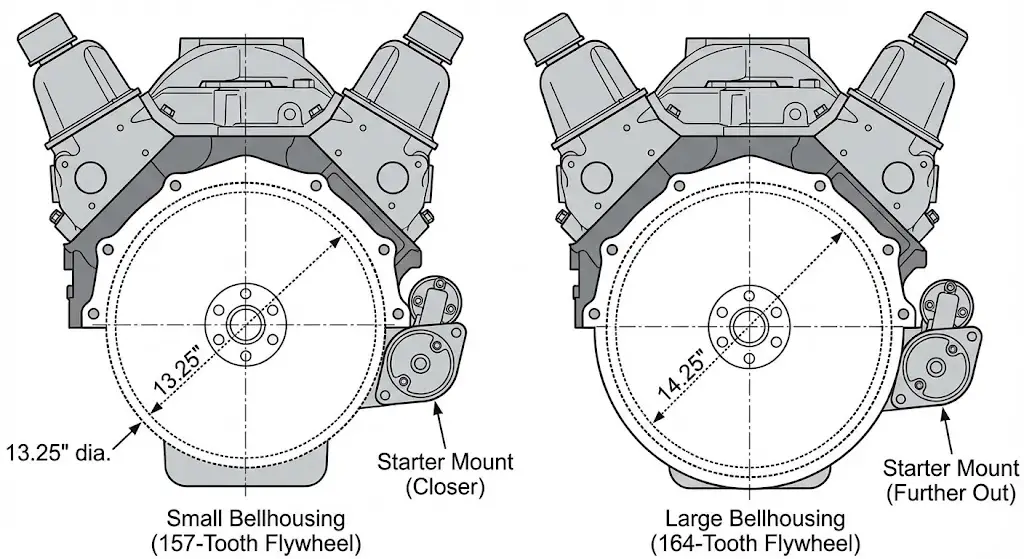

The Critical Divide: 157-Tooth vs. 164-Tooth Flywheels

For the Ford Small Block (Windsor) family, compatibility is primarily determined by the bellhousing size, which dictates the flywheel size. There are two main standards:

- 157-Tooth Flywheel (Small Bellhousing):

- Diameter: Approximately 13.25 inches.

- Applications: Most Mustangs (1965-1995), Falcons, and early Fairlanes. Typically paired with C4 automatics (case-fill) and T5 manual transmissions.12

- Starter Position: The starter is mounted closer to the engine centerline.

- 164-Tooth Flywheel (Large Bellhousing):

- Diameter: Approximately 14.25 inches.

- Applications: Trucks (F-Series), large cars (Galaxie, LTD), and high-performance applications. Standard for C6 automatics, AOD (Automatic Overdrive), and heavy-duty manual transmissions (Tremec 3550/TKO in some conversions, Truck 4-speeds).13

- Starter Position: The starter is mounted further out from the engine centerline to accommodate the larger ring gear.

The Interchange Trap: A starter motor itself does not "know" if it is spinning a 157-tooth or 164-tooth flywheel. The mounting holes in the bellhousing and block plate determine the position. Consequently, the same physical starter part number often fits both applications, provided the nose cone geometry clears the bellhousing opening.2 However, the snout depth becomes the differentiating factor, specifically when moving between automatic and manual transmissions.

The Snout Depth Variable: Automatic vs. Manual

Perhaps the most persistent source of confusion and mechanical failure is the distinction between Automatic and Manual transmission starters. On many vehicles, these are interchangeable. On older Fords, they are mechanically distinct.

Research indicates a specific variance in the "depth of engagement." According to technical data from Speedway Motors and interchange experts, the starter drive (pinion) on an Automatic Transmission starter protrudes approximately 3/8 inch (0.375") deeper into the bellhousing than the Manual Transmission starter.2

- Automatic Transmissions: The flexplate ring gear is often welded to the torque converter side or positioned further aft (away from the engine block) to clear the converter housing geometry. The starter snout must reach deeper to engage it. The distance from the mounting flange to the tip of the pinion (at rest) is often greater.

- Manual Transmissions: The flywheel ring gear is press-fit onto the outer edge of the flywheel, which sits closer to the block face to align with the clutch mechanism. A starter with a longer "Auto" nose would cause the pinion gear to constantly grind against the flywheel face or ring gear even when retracted. Conversely, a "Manual" starter on an Automatic might not extend far enough to fully engage the teeth, stripping the very edge of the ring gear.2

Measurement Verification:

- Manual Transmission Snout Depth: ~3/8" protrusion from the mounting face.

- Automatic Transmission Snout Depth: ~3/4" protrusion from the mounting face.

The PMGR Exception: Modern PMGR starters (1992+) often feature a "universal" clearance design where the pinion is retracted fully inside the nose cone, or the throw (travel distance) is longer, allowing some PMGR units to bridge this gap. However, for the purpose of accurate interchange, one must assume the distinction remains valid unless the specific aftermarket part states otherwise.16

Comprehensive Interchange Analysis by Engine Family

This section provides a granular breakdown of starter interchangeability, organized by engine family. It synthesizes Lester catalog numbers (the industry standard for rotating electrical identification) with OEM Ford engineering numbers.

The Windsor Small Block V8 (221, 260, 289, 302, 351W)

The Windsor family is the most common application for starter swaps. The interchangeability here is robust, covering vehicles from 1962 through 2001.

Automatic Transmission Interchange (1964-2001)

For vehicles equipped with C4, C6, FMX, or AOD automatic transmissions.

| Era | Technology | Lester No. | Ford Part Ref. | Description & Notes |

| 1964-1991 | Direct Drive | 3124 | C4OZ-11002-A | The standard "Long Nose" starter. Heavy (18lbs). 4.5" magnet housing length. Fits almost all RWD auto setups. Prone to heat soak. |

| 1992-1995 | PMGR | 3205 | E9SZ-11002-A | The Premier Upgrade. Stock on '92-'93 Mustang 5.0L Auto and Lincoln Mark VII. Fits 1964-1991 applications perfectly. High torque, 8.5lbs. |

| 1996-2001 | PMGR | 3268 | F7SZ-11002-AA | Evolution of the 3205. Used on Explorer 5.0L. Identical mounting and function; often superseded by 3205 in aftermarket catalogs. |

Insight: The Lester 3205 is the "Gold Standard" for automatic Small Block Fords. It is a direct bolt-on for the older 3124 unit, offering massive weight savings and cranking speed improvements. It clears most long-tube headers due to its compact solenoid orientation.3

Manual Transmission Interchange (1964-1995)

For vehicles equipped with Toploader 4-speeds, 3-speed manuals, and T5 5-speeds.

| Era | Technology | Lester No. | Ford Part Ref. | Description & Notes |

| 1964-1991 | Direct Drive | 3132 | C2OZ-11002-B | The standard "Short Nose" starter. Cannot be interchanged with the 3124 Auto starter (nose is too long). |

| 1992-1997 | PMGR | 3223 | F2TZ-11002-A | The Manual Upgrade. Stock on '92-'97 F-Series/Bronco with 5.0L/5.8L & Manual Trans. Fits vintage manual cars (Mustang/Falcon) perfectly. |

| Note: | 3241 | F7PZ-11002-FA | Variant often listed for late model trucks. Functionally similar to 3223 for interchange purposes. |

Crucial Warning: Do not attempt to use a 1993 Mustang 5.0L starter on a 1965 Mustang if the 1993 starter was sourced from an automatic car. You must source the starter for a 1992-1996 Ford F-150 5.0L Manual Transmission (Lester 3223) to guarantee the correct pinion depth for a vintage manual flywheel.3

The 335 Series (351C, 351M, 400) and 385 Series (429/460)

This group shares the "Big Block" bellhousing bolt pattern (except for the 351C, which shares the Small Block pattern but often uses specific flywheels). However, for starter purposes, the 351M/400 and 429/460 are virtually identical.

The 351 Cleveland (351C) Nuance

The 351C (1970-1974) uses the Small Block Windsor bellhousing pattern. Therefore, it typically utilizes the Small Block starters (Lester 3124 for Auto, 3132 for Manual).

- Upgrade Path: Use the Lester 3205 (Auto) or 3223 (Manual) PMGR units intended for the 5.0L Windsor. They bolt right up to the Cleveland.12

The 351M, 400, 429, and 460

These engines use the larger 385-series bellhousing pattern.

| Trans | Type | Lester No. | Notes |

| Auto | Direct Drive | 3153 / 3180 | Heavy-duty unit found on 1970s Lincolns and F-Series. Notorious for "hot start" failure on 460s. |

| Auto | PMGR | 3226 | The Big Block Upgrade. Stock on 1992-1997 F-Series 7.5L (460). Massive torque increase. Solves hot start issues permanently. |

| Manual | Direct Drive | 3154 | Specific snout depth for truck transmissions (NP435, T18, ZF5). |

| Manual | PMGR | 3225 | From late model F-Series Manual 460. The correct upgrade for manual big block trucks. |

Analysis: The 460 engine is a high-compression, large-displacement platform that stresses the electrical system significantly. The original Direct Drive starters (3153/3180) were barely adequate when new. Upgrading to the Lester 3226 PMGR unit is widely considered a mandatory reliability modification for any 460-powered motorhome, tow rig, or muscle car. It draws nearly 40% less amperage while delivering superior torque.3

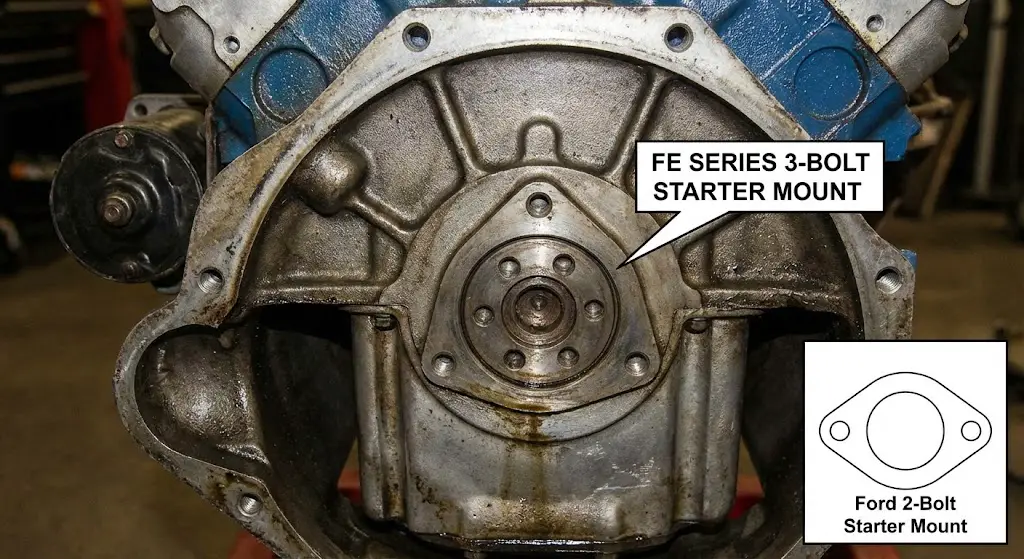

The FE Series (360, 390, 427, 428)

The FE engine family (1958-1976) is the outlier in the Ford ecosystem. It utilizes a unique 3-bolt mounting flange where the starter bolts directly into the bellhousing/transmission adapter, rather than a 2-bolt flange on the block plate.18

- Standard Starter: Lester 3131 (Direct Drive).

- The PMGR Challenge: Because the FE engine was discontinued in 1976—long before PMGR technology became standard in the 1990s—there is no "junkyard swap" available. You cannot go to an auto parts store and ask for a 1995 F-150 starter and expect it to fit an FE.

- The Solution: Aftermarket companies (e.g., Powermaster, TCI, PA Performance) manufacture custom-engineered starters that mate a modern PMGR motor to a custom 3-bolt mounting block designed for the FE. These are the only way to get PMGR performance on a 390 or 428 engine.18

V6 and Inline-4 Applications

Often ignored, these engines benefit massively from parts bin upgrades.

- 2.3L Lima (Pinto/Mustang II/Fox): The older Direct Drive units are sluggish. The PMGR starter from a 1991-2001 Ford Ranger 2.3L/2.5L (Lester 3231) is a direct bolt-on upgrade. It is significantly smaller, helping with intake manifold clearance on turbo 2.3L builds.3

- 3.8L Essex V6: The starter from a 1990s Thunderbird Super Coupe or Mustang V6 (Lester 3204) is a high-torque PMGR unit that fits older 3.8L applications.3

Technical Deep Dive: The PMGR Wiring Conversion

While the mechanical interchange of a PMGR starter is often a direct bolt-on affair, the electrical integration is not. The PMGR starter functions fundamentally differently than the Direct Drive unit, and failing to update the wiring can lead to hazardous "run-on" conditions.

The Physics of the "Run-On" (Generator Effect)

In a Direct Drive starter, the solenoid is on the fender (the "Starter Relay"). A single heavy cable runs from this relay to the starter motor. When the relay opens, power is cut, and the motor stops instantly.

In a PMGR starter, a solenoid is mounted directly on the starter motor. This solenoid serves two purposes:

- It acts as a high-current switch to power the motor.

- It mechanically pushes the bendix gear out to engage the flywheel.

The Problem: The PMGR motor uses permanent magnets. When the engine starts and spins the starter gear (before it retracts), the starter motor briefly acts as a generator, producing voltage. If the installer simply bridges the heavy battery cable to the small 'S' terminal on the starter (a common lazy hack), the current generated by the spinning motor can feed back into its own solenoid coil. This keeps the solenoid energized even after the driver releases the key. The starter will stay engaged, grinding loudly against the flywheel, potentially exploding the armature due to over-speed.3

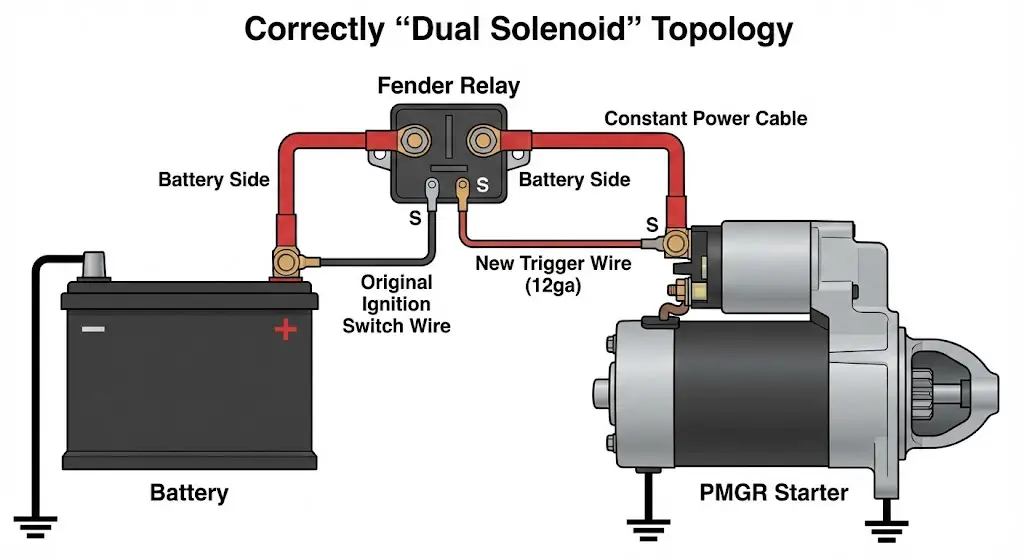

The Correct "Dual Solenoid" Topology

To safely install a PMGR starter on a vintage Ford with a fender-mounted relay, you must adopt a "Dual Solenoid" wiring strategy. This utilizes the original fender relay as a low-current switch to trigger the starter-mounted solenoid.

Step-by-Step Wiring Modification:

- Constant Power Supply: Move the heavy starter cable (that goes down to the starter) from the "switched" side of the fender relay to the "battery" side of the fender relay. Now, the cable at the starter has constant 12V power, regardless of key position.

- Alternative: Run a completely new, heavy-gauge (4 AWG or larger) cable directly from the battery positive terminal to the large post on the new starter.

- Trigger Wire: Install a new 12-gauge wire. Connect one end to the "switched" side of the fender relay (the post that used to hold the heavy starter cable). Connect the other end to the small "S" (Start) terminal on the PMGR starter solenoid.11

- The Sequence of Operation:

- Driver turns key to START.

- Ignition switch triggers the Fender Relay.

- Fender Relay closes, sending 12V down the new 12-gauge wire.

- The 12-gauge wire triggers the PMGR Solenoid.

- The PMGR Solenoid engages the gear and bridges the high-current contacts.

- The Starter motor draws power from the Constant Heavy Cable and cranks the engine.

- Driver releases key -> Fender Relay opens -> Trigger wire loses power -> PMGR Solenoid disengages instantly.

This topology ensures that the "generator effect" cannot feedback into the trigger circuit, preventing run-on. It also retains the factory Neutral Safety Switch functionality, which is wired into the control side of the fender relay.22

Diagnostics and Troubleshooting

Even with the correct part numbers, installation issues can arise due to the age of the vehicles and the variances in aftermarket parts manufacturing.

The Grinding Noise: Diagnosis and Repair

A high-pitched grinding noise during cranking usually indicates improper gear mesh.

- Depth Mismatch: As discussed, using a Manual starter on an Auto (or vice versa) is the #1 cause. If the noise sounds like the starter is "whizzing" but not turning the engine, the drive is not extending far enough (Manual starter on Auto application). If it crunches loudly, it is extending too far or hitting the ring gear face (Auto starter on Manual application).24

- Worn Block Plate: The starter aligns via the circular pilot hole in the block plate. If this plate is worn, bent, or missing, the starter will not center on the flywheel.

- Shimming: Unlike Chevy starters, Ford starters are hub-centric and typically do not require shims. If a shim is needed, it is usually to correct a manufacturing tolerance error in an aftermarket starter. Dorman shim kit #02359 is available for 2-bolt Ford starters to push the unit slightly away from the flywheel if the mesh is too tight (binding).26

Voltage Drop and "Click-No-Start"

PMGR starters are sensitive to voltage. While they draw less current, they require a strong trigger signal.

- The Symptom: You hear the fender relay click, but the starter does nothing.

- The Cause: High resistance in the new trigger wire or a corroded "battery side" connection on the fender relay.

- The Fix: Perform a voltage drop test. Place a multimeter lead on the battery positive and the other on the starter's large post while cranking. A drop of more than 0.5V indicates a bad cable. Ensure the trigger wire is at least 12-gauge; using thin 16 or 18-gauge wire may not provide enough "in-rush" current to snap the PMGR solenoid closed.23

Heat Soak Mitigation

While PMGR starters are resistant to heat soak, they are not immune.

- Clocking: Many aftermarket PMGR starters (e.g., from Powermaster) feature a "clockable" mounting block. This allows the installer to rotate the motor body relative to the mounting flange, moving the solenoid away from headers or exhaust pipes. This is a critical adjustment for high-performance Mustangs with long-tube headers.27

- Heat Shields: For big block (460) applications where the exhaust is inches from the starter, a reflective heat wrap or metal shield is still recommended even with a PMGR unit.

Master Interchange Tables

The following tables serve as the primary reference for identifying the correct starter for your application.

Table 6.1: Small Block Windsor (289, 302, 351W) Interchange

| Engine | Trans | Flywheel | Recommended Starter (PMGR) | Lester No. | OEM Source Application |

| 289 / 302 / 351W | Automatic | 157 or 164 Tooth | High Torque PMGR | 3205 | 1992-1995 Mustang 5.0L Auto |

| 289 / 302 / 351W | Manual | 157 Tooth (10.5" Clutch) | High Torque PMGR | 3223 | 1992-1996 F-150 5.0L Manual |

| 289 / 302 / 351W | Manual | 164 Tooth (11" Clutch) | High Torque PMGR | 3223 | 1992-1996 F-150 5.0L Manual |

Table 6.2: Big Block (385 Series) & Modified Interchange

| Engine | Trans | Notes | Recommended Starter (PMGR) | Lester No. |

| 351M / 400 | Automatic | Standard 2-Bolt | High Torque PMGR | 3226 |

| 429 / 460 | Automatic | Standard 2-Bolt | High Torque PMGR | 3226 |

| 429 / 460 | Manual | Truck Trans (T18/NP435) | High Torque PMGR | 3225 |

Table 6.3: Specialized & V6/I4 Interchange

| Engine | Application | Direct Drive (Old) | PMGR Upgrade (New) | Lester No. |

| 2.3L I4 | Pinto / Mustang II / Fox | Lester 3139 / 3149 | 1993 Ranger 2.3L Starter | 3231 |

| 3.8L V6 | Fox Body / T-Bird | Lester 3166 | 1995 Mustang 3.8L Starter | 3204 |

| FE (390/428) | All | Lester 3131 | Aftermarket Only | N/A |

| 7.3L Diesel | IDI / Powerstroke | Lester 16560 | 1999+ Super Duty (Gear Red.) | 17250 |

Conclusion

The Ford starter interchange landscape, while complex, follows a predictable logic grounded in the geometry of bellhousings and transmission types. The shift from Direct Drive to PMGR technology stands as one of the most effective upgrades for any vintage Ford vehicle, offering reduced weight, increased reliability, and superior cranking power.

For the technician or enthusiast, the key to success lies in three verification steps:

- Confirm the Transmission Type: Do not assume an Auto starter fits a Manual.

- Verify the Mounting Flange: Identify 2-bolt vs. 3-bolt configurations immediately.

- Execute the Wiring Upgrade: Never install a PMGR starter without adding the dedicated trigger wire circuit.

By strictly adhering to these engineering principles and utilizing the cross-reference data provided in this report, the "click-no-crank" frustration of the past can be permanently engineered out of the vehicle's future.