Ford F150 Fuel System Diagram: Component Layout Guide

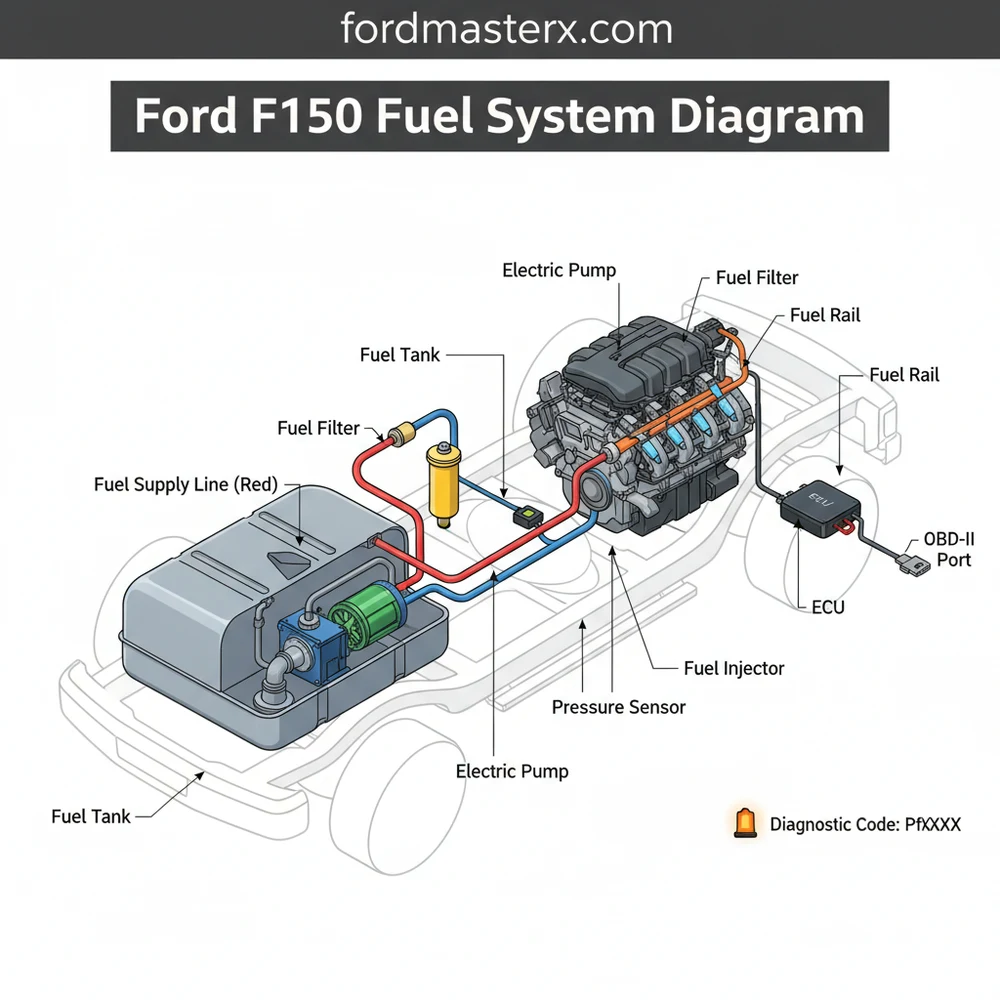

The Ford F150 fuel system diagram illustrates the path from the gas tank to the engine, including the fuel pump assembly, filter, fuel rails, and injectors. Managed by the ECU, this system ensures precise pressure delivery. It helps identify leak points or component failures when a check engine light or diagnostic code appears.

📌 Key Takeaways

- Provides a visual map of fuel flow from the tank to the fuel injectors

- Helps identify the Fuel Pump Driver Module as a common failure point

- Always relieve fuel system pressure before disconnecting any fuel lines

- Use a fuel pressure gauge at the schrader valve to verify pump health

- Essential for diagnosing hard starts, stalling, or poor engine performance

Understanding the intricacies of a ford f150 fuel system diagram is essential for any truck owner looking to maintain peak performance or perform their own repairs. Whether you are dealing with a rough idle, a sudden loss of power, or a persistent “crank but no start” condition, the fuel system is the lifeblood of your vehicle. This comprehensive guide provides a detailed roadmap of the components that move gasoline from your tank to the combustion chamber. You will learn how to identify key modules, interpret the flow of fuel, and use diagnostic data from the ECU to pinpoint failures before they lead to expensive shop bills.

Modern Ford F-150 trucks often utilize a “returnless” fuel system. Unlike older designs that pumped excess fuel back to the tank, these systems use the ECU to vary the pump speed, maintaining precise pressure and reducing evaporative emissions.

Decoding the Ford F-150 Fuel System Diagram

A comprehensive ford f150 fuel system diagram serves as a visual schematic of the mechanical and electronic path fuel takes within the vehicle. At the rear of the truck, the diagram identifies the fuel tank and the Fuel Delivery Module (FDM). The FDM is a critical unit that houses the electric fuel pump, the fuel level sender, and a preliminary “sock” filter. From the tank, the diagram traces the supply line moving forward along the frame rail. In many F-150 configurations, particularly those with EcoBoost engines, you will see a distinction between the low-pressure system (tank to engine) and the high-pressure system (engine-mounted pump to injectors).

The diagram also highlights the Fuel Pump Driver Module (FPDM). This is a common point of failure often located on the crossmember above the spare tire. It receives signals from the ECU (Engine Control Unit) to modulate the voltage sent to the pump. Further up the line, the diagram will show the fuel rail, which acts as a manifold for the fuel injectors. On Direct Injection models, a High-Pressure Fuel Pump (HPFP) is driven by the camshaft, which significantly boosts pressure to facilitate efficient combustion. Understanding these color-coded or labeled lines helps you differentiate between vapor lines (part of the EVAP system) and high-pressure liquid lines.

[DIAGRAM_PLACEHOLDER: Detailed Ford F-150 Fuel System Schematic showing Fuel Tank, FPDM, Fuel Lines, HPFP, and Fuel Rail Interface]

Step-by-Step Guide to Reading and Applying the Diagram

Interpreting a fuel system diagram requires a systematic approach to ensure safety and accuracy. Because the fuel system is under high pressure, especially in modern fuel-injected engines, you must follow a specific sequence before attempting any physical inspection or part replacement.

Step 1: Relieve System Pressure

Before you even touch a wrench, you must depressurize the lines. Locate the fuel pump fuse or relay in the power distribution box (consult your owner’s manual for the specific location). Start the engine and then pull the fuse. The engine will stumble and die as it consumes the remaining fuel in the lines. This ensures that when you disconnect a fitting, fuel does not spray at high velocity into your eyes or onto hot engine components.

Step 2: Identify the Low-Pressure Side

Using your ford f150 fuel system diagram, locate the lines running from the fuel tank toward the engine. In many trucks, these are nylon or stainless steel lines held by plastic “quick-connect” clips. Trace these lines to ensure there are no kinks or leaks. This is also where you would typically find the inline fuel filter on older models, whereas newer models have the filter integrated into the tank assembly.

Step 3: Locate the Fuel Pump Driver Module

The FPDM is a small electronic box that translates the ECU commands into physical pump action. On your diagram, this is the intermediary between the battery and the pump. If your truck has no fuel pressure but the pump is functional, the FPDM is often the culprit. Visually inspect the module on your truck for corrosion or cracks in the housing, which are common issues in regions that use road salt.

Step 4: Inspect the High-Pressure Fuel Pump (EcoBoost Only)

If you own an EcoBoost F-150, the diagram will show an additional pump located on the engine valve cover. This pump is mechanical and is located near the timing chain assembly at the rear of the engine. It takes the low-pressure fuel (approx. 50-70 PSI) and cranks it up to over 2,000 PSI for direct injection. Do not attempt to service this side of the system without specialized tools and high-pressure-rated seals.

Step 5: Check the Fuel Rail and Injectors

The final stop on the diagram is the fuel rail. This sits atop the engine intake manifold. Ensure the injectors are seated properly. If you are replacing injectors, pay close attention to the torque spec for the fuel rail mounting bolts. Over-tightening can crack the manifold, while under-tightening can lead to dangerous fuel leaks directly onto the engine block.

Fuel systems are under extreme pressure. Always wear safety goggles and keep a fire extinguisher nearby. Ensure the engine is completely cool to the touch, as fuel contact with a hot exhaust manifold can cause an immediate fire.

Common Issues and Diagnostic Troubleshooting

When the check engine light illuminates on your dashboard, it is often the first sign of a fuel system malfunction. By using an OBD-II scanner, you can retrieve a specific diagnostic code that points you toward the failing component in the diagram. For instance, codes P0171 or P0174 indicate a “lean” condition, meaning there is too much air and not enough fuel, often caused by a failing pump or clogged injectors.

Common issues include:

- ✓ FPDM Corrosion: The aluminum backing of the driver module reacts with the steel frame, leading to electrical failure.

- ✓ Clogged Fuel Sock: Debris in the tank restricts flow, causing the pump to whine or overheat.

- ✓ Leaking Injectors: Can cause “hard starting” because the fuel rail loses pressure while the truck is parked.

If your diagnostics suggest a fuel issue but the fuel pressure is within spec, check for interference from other systems. Sometimes a slipping accessory belt can affect the alternator’s output, leading to low voltage at the fuel pump, or an issue with coolant flow can cause the engine to run in a “limp mode” that mimics fuel starvation.

Pro Tips and Maintenance Best Practices

Maintaining your F-150’s fuel system is far more cost-effective than replacing a high-pressure pump or a set of injectors. Follow these professional tips to extend the life of your components:

Never let your fuel tank drop below a quarter tank. The fuel in the tank actually acts as a coolant for the electric fuel pump. Running the tank near empty consistently allows the pump to run hot, significantly shortening its lifespan.

Maintain Clean Connections

Whenever you are working near the engine, ensure that the fuel lines are kept away from moving parts like the timing chain cover or the accessory belt. Vibrations can cause these parts to rub against fuel lines, leading to catastrophic leaks over time. Additionally, ensure that your electrical connectors for the injectors and FPDM are clean and free of dielectric grease (unless specified by the manufacturer), as poor connections can trigger false OBD-II codes.

Use Quality Components

When replacing parts identified in your ford f150 fuel system diagram, always prioritize OEM (Motorcraft) parts. The fuel system operates on very specific voltage and pressure parameters defined by the ECU. Aftermarket pumps or injectors may not communicate perfectly with the truck’s computer, leading to persistent check engine light issues or poor fuel economy.

Finally, always double-check the torque spec for any fuel system fastener. Whether it is the bolts holding the fuel tank straps or the small screws on the fuel rail, proper tension prevents leaks and ensures the long-term integrity of the system. Regular maintenance, such as using a high-quality fuel system cleaner every 5,000 miles, can also help keep the “spray pattern” of your injectors optimal, ensuring your Ford F-150 remains the reliable workhorse it was designed to be.

Frequently Asked Questions

Where is the fuel pump located?

The Ford F150 fuel pump is located inside the fuel tank. To access it, you must either lower the tank from under the vehicle or remove the truck bed. The fuel filter is typically mounted along the frame rail on the driver’s side for easier maintenance and replacement.

What does the fuel system diagram show?

A Ford F150 fuel system diagram provides a visual map of how fuel travels from the reservoir to the fuel injectors. It highlights the fuel pump, lines, pressure regulator, and filter, allowing you to trace the flow and identify potential blockage points or leaks during a repair.

How many connections does the fuel pump have?

The fuel pump module typically features three primary connections: a high-pressure outlet line, a vapor return line for the EVAP system, and a multi-pin electrical connector. This connector links directly to the fuel pump driver module and the ECU to regulate pressure based on engine demand.

What are the symptoms of a bad fuel system component?

Common symptoms include engine sputtering at high speeds, loss of power while towing, and a persistent check engine light. You may also notice a loud whining noise from the gas tank area or retrieve a specific diagnostic code through the OBD-II port indicating low fuel rail pressure.

Can I replace the fuel pump myself?

Replacing components like the fuel filter or pump driver module is a straightforward DIY task. However, replacing the internal fuel pump is more difficult as it requires specialized tools to disconnect lines and either dropping a heavy fuel tank or lifting the truck bed to gain access safely.

What tools do I need for fuel system repair?

You will need a set of fuel line disconnect tools, a socket set for tank straps, and a torque wrench for final assembly. Additionally, an OBD-II scanner is essential for reading a diagnostic code and clearing the check engine light once the fuel system repair is complete.