The Ultimate Ford Axle Code Chart & Decoder (All Models)

The Rosetta Stone for Your Truck: Why Your Ford Axle Code Matters

For any Ford truck owner, certain specifications are paramount: engine displacement, horsepower, and torque figures are often the first to be quoted. Yet, a small, unassuming code printed on a sticker in the driver’s door jamb holds the key to a vehicle’s true character and capability. This is the Ford axle code, and it serves as the DNA of the truck’s final drive system. It dictates critical performance attributes,

from the maximum weight a truck can safely tow to its fuel efficiency on a long highway journey, and its ability to maintain traction on a treacherous off-road trail. Understanding this code transforms an owner from a mere driver into an informed operator, capable of leveraging their vehicle’s full potential while ensuring its longevity.

What is a Ford Axle Code? (And What Does it Tell You?)

A Ford axle code is a simple alphanumeric shorthand that provides a wealth of information about the vehicle’s rear axle assembly (and front axle, on 4×4 models). This code is a direct reference to a specific combination of components installed at the factory. Primarily, the code identifies three critical specifications: the gear ratio, the differential type, and, in many cases, the axle model and its load-bearing capacity.

- Gear Ratio: This is perhaps the most crucial piece of information. Expressed as a ratio like

$3.73:1$, it represents the number of times the driveshaft must rotate to turn the wheels one full revolution. A higher number signifies a “shorter” gear, providing more torque multiplication, while a lower number indicates a “taller” gear, optimized for lower engine speeds during cruising. - Differential Type: The code reveals how the engine’s power is distributed between the two drive wheels. It specifies whether the vehicle is equipped with a standard “open” differential, a traction-enhancing limited-slip differential (LSD), or a robust electronic locking differential.

- Axle Model & Capacity: The code is also tied to the specific axle model installed, such as a Ford 8.8-inch, a Ford 9.75-inch, a heavy-duty Sterling, or a Dana axle. This implicitly defines the axle’s Gross Axle Weight Rating (GAWR), which is the maximum weight the axle is designed to support.

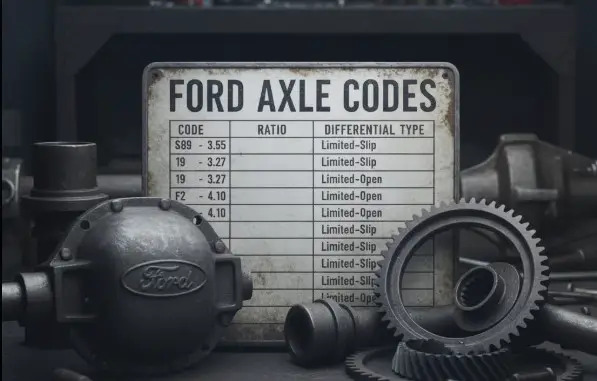

The Ultimate Ford Axle Code Infographic

Decode Your Truck’s Towing & Performance DNA

What is a Ford Axle Code?

A Ford axle code is a simple code, typically two or three characters, found on your truck’s Safety Compliance Certification Label. This single code is the key to understanding your vehicle’s differential type (like open, limited slip) and, most importantly, its axle gear ratio. Knowing this information is critical for determining your truck’s original towing capacity, performance characteristics, and what parts to buy for maintenance or upgrades.

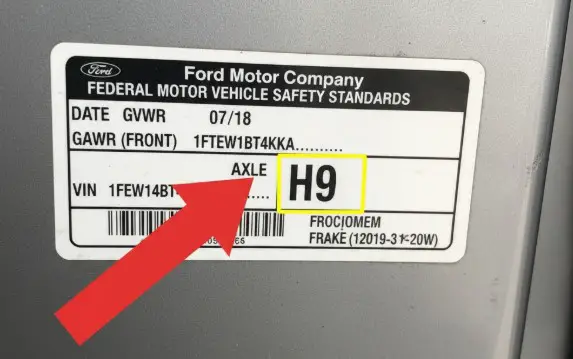

Where to Find Your Axle Code

Your code is located on the Safety Compliance (or “VC”) Label, which is almost always on the driver’s side door jamb or the edge of the door itself.

VEHICLE CERTIFICATION LABEL

Look for the “AXLE” box on the sticker!

How to Read the Code

Once you have your code, you cross-reference it with a Ford axle chart for your truck’s model and year. The code instantly tells you two things: the gear ratio and the differential type. A numeric-only code (like ’19’) typically indicates an open differential, while an alphanumeric code (like ‘H9’) indicates a limited-slip or locking differential.

Your Axle Code

Equals:

Common F-150 Axle Ratios

The axle ratio is a major factor in performance and fuel economy. A higher number (e.g., 3.73) means better “off-the-line” acceleration and towing power, but generally lower highway fuel economy. A lower number (e.g., 3.31) is better for highway cruising and efficiency, but offers less towing muscle. The 3.55 ratio is often considered the best all-around compromise.

Common Differential Types

The differential allows your wheels to spin at different speeds when turning. An ‘open’ differential is standard, but a ‘Limited Slip’ (LSD) or ‘Electronic Locking’ differential provides significantly better traction in slippery conditions (mud, snow, rain) by sending power to both rear wheels.

Axle Models by Truck Series

Ford uses different axle models based on the truck’s intended workload. Lighter-duty F-150s typically use the durable Ford 8.8″ or 9.75″ axles. Heavy-duty F-250 and F-350 Super Duty trucks use much larger, more robust axles from manufacturers like Dana (e.g., Dana 60, Dana 80) to handle extreme towing and payload demands.

The Great Trade-Off: How Axle Ratio Defines Your Truck’s Personality

The axle ratio is the final stage of gearing in a vehicle’s powertrain, and its selection involves a fundamental trade-off between raw power and operational efficiency. This choice fundamentally shapes a truck’s performance profile.

- Higher Numerical Ratio (e.g.,

$4.10:1$): Often referred to as a “shorter” or “lower” gear, a higher numerical ratio provides superior torque multiplication. This means the engine has greater leverage over the wheels, resulting in quicker acceleration from a standstill and a significantly increased ability to pull heavy loads. This is the preferred choice for trucks dedicated to serious towing and hauling. The compromise, however, is that the engine must run at a higher RPM to maintain a given highway speed. This increased engine speed leads to greater fuel consumption and potentially more engine noise and wear over time. - Lower Numerical Ratio (e.g.,

$3.31:1$): Known as a “taller” or “higher” gear, a lower numerical ratio requires fewer engine revolutions to turn the wheels. This allows the engine to operate at a much lower, more relaxed RPM during highway cruising. The direct benefit is improved fuel economy, making it an ideal choice for trucks that spend most of their time on the open road without a heavy trailer. The trade-off is a reduction in pulling power and slower acceleration, as the engine has less mechanical advantage.

While this core principle remains true, the starkness of the trade-off has been softened by modern powertrain technology. In the era of 3- and 4-speed automatic transmissions, the axle ratio was the primary determinant of a truck’s specialized duty cycle. Today, with advanced 10-speed automatic transmissions becoming standard, the dynamic has shifted. These modern transmissions feature an incredibly wide spread of gear ratios, including multiple low gears for pulling power and several tall overdrive gears for efficiency.

This allows powertrain engineers to use the transmission’s own gearing to achieve the torque multiplication once reserved for a short axle ratio. A truck with a fuel-efficient $3.31:1$ axle can use its lower transmission gears to get a heavy load moving effectively, then shift into its higher gears to cruise efficiently once up to speed. Consequently, the axle ratio, while still critically important, is now one component in a highly integrated system. Its role has evolved, and its impact must be considered in the context of the entire powertrain, especially in late-model vehicles.

How to Find Your Ford Axle Code: A Step-by-Step Guide

Before the comprehensive charts in this guide can be utilized, the vehicle’s specific axle code must be identified. Ford provides two primary methods for this, one easily accessible from the driver’s seat and another requiring a closer inspection of the axle hardware itself.

Method 1: The Door Jamb Sticker (Safety Compliance Certification Label)

For the vast majority of Ford owners, the quickest and most reliable method is to consult the Safety Compliance Certification Label, commonly known as the door jamb sticker. This label serves as the vehicle’s “birth certificate,” containing a wealth of information including the VIN, paint codes, and the all-important axle code.

The process is straightforward:

- Open the driver’s side door of the vehicle.

- Locate the large white or silver sticker affixed to the door frame or the edge of the door itself.

- On this label, look for a section with printed vehicle specifications, often located below a barcode.

- Find the heading labeled “AXLE” or “AX.”

- The two- or three-character alphanumeric code directly below this heading is the vehicle’s factory-installed axle code.

Locating the Axle Code on a Door Jamb Sticker

A graphic would be inserted here, showing a sample Ford Safety Compliance Certification Label. An arrow or highlighted box would clearly point to the “AXLE” field and the corresponding two-digit code (e.g., “H9”), making it instantly recognizable for the reader.

Method 2: The Axle Identification Tag

For older vehicles, or in cases where an axle may have been swapped from another vehicle, the door jamb sticker may be missing, illegible, or inaccurate. In these situations, the definitive source of information is the physical Axle Identification Tag bolted directly to the differential housing.

This small metal tag was the standard method of identification for decades.

- Location: The tag is typically found secured by one of the differential cover bolts, often in the 3 o’clock position when viewing the axle from the rear of the vehicle. It may be covered in dirt, grease, or rust and require cleaning to be read.

- Decoding the Tag: The information stamped on this tag is often more detailed than the door sticker code. The format evolved over the years, but a common layout includes two lines of code:

- Top Line: This line often starts with the axle model prefix and suffix, followed by a date code.

- Bottom Line: This line contains the most critical information. It typically begins with the gear ratio. If the differential is a limited-slip unit, an “L” will be placed within the ratio numbers (e.g.,

$3 L 55$for a$3.55:1$limited-slip). This is followed by the ring gear diameter (e.g., “8.8” or “9.75”), and finally a plant code.

The format and content of these tags provide a historical record. Early tags from before 1963 might only show the gear ratio, while later versions became progressively more informative. Over time, these durable metal tags were phased out in favor of adhesive labels applied to the axle tube, primarily for reasons of cost and manufacturing efficiency.

For restorers and mechanics working on classic Fords, the specific format of the tag can help date the component and verify its originality. Discrepancies between the door sticker, axle tag, and a vehicle’s build sheet could indicate that parts have been replaced during the vehicle’s service life, making direct identification of the hardware essential.

The Definitive Ford Axle Code Charts

The following charts provide a comprehensive resource for decoding Ford axle codes. It is essential to use the chart that corresponds to the specific model and generation of the vehicle in question. Ford has frequently reused codes over the years, meaning a code like “H9” on a 1980s truck signifies a different configuration than the same code on a modern F-150. Always cross-reference the code with the vehicle’s year to ensure accurate identification.

Ford F-150 Axle Code Chart

As America’s best-selling truck, the F-150 has seen numerous axle configurations. The charts below are divided by key generations to simplify identification.

Table 1: 2010-Present F-150 Axle Codes

This chart covers the most recent generations of the F-150, which feature more streamlined and consistent coding, often related to the availability of electronic locking differentials.12

| Axle Code | Gear Ratio | Differential Type |

| 15 | $3.15:1$ | Open |

| L5 | $3.15:1$ | Electronic Locking |

| 27 | $3.31:1$ | Open |

| L3 | $3.31:1$ | Electronic Locking |

| 19 | $3.55:1$ | Open |

| H9 | $3.55:1$ | Limited-Slip (Traction-Lok) |

| L9 | $3.55:1$ | Electronic Locking |

| 26 | $3.73:1$ | Open |

| B6 | $3.73:1$ | Limited-Slip (Traction-Lok) |

| L6 | $3.73:1$ | Electronic Locking |

| L4 | $4.10:1$ | Electronic Locking |

Table 2: 1980-2009 F-150 & Bronco Axle Codes

This period covers several F-150 generations and the popular Bronco models, featuring a wider array of codes and axle types, including the legendary Ford 9-inch and the robust 8.8-inch axles.

| Axle Code | Year Range (Approx.) | Gear Ratio | Axle Model / Capacity | Differential Type |

| 13 | 1981-1983 | $2.75:1$ | Ford 9″ / 3750 lbs | Open |

| 13 | 1985-1986 | $4.11:1$ | Ford 8.8″ | Open |

| 14 | 1981-1986 | $3.00:1$ | Ford 9″ / 3750 lbs | Open |

| 16 | 1981-1987 | $3.50:1$ | Ford 9″ / 3750 lbs | Open |

| 18 | 1983-1986 | $3.08:1$ | Ford 8.8″ / 3800 lbs | Open |

| 19 | 1983-2009 | $3.55:1$ | Ford 8.8″ / 3800 lbs | Open |

| H3 | 1981-1982 | $2.75:1$ | Ford 9″ / 3750 lbs | Limited-Slip |

| H3 | 1985-1986 | $4.11:1$ | Ford 8.8″ / 3800 lbs | Limited-Slip |

| H4 | 1981-1986 | $3.00:1$ | Ford 9″ / 3750 lbs | Limited-Slip |

| H6 | 1981-1987 | $3.50:1$ | Ford 9″ / 3750 lbs | Limited-Slip |

| H8 | 1983-1986 | $3.08:1$ | Ford 8.8″ / 3800 lbs | Limited-Slip |

| H9 | 1983-2009 | $3.55:1$ | Ford 8.8″ / 3800 lbs | Limited-Slip |

| B6 | 1997-2009 | $3.73:1$ | Ford 8.8″ or 9.75″ | Limited-Slip |

Ford Super Duty (F-250/F-350) Axle Code Chart

Super Duty trucks are built for work, and their axle codes reflect heavy-duty components from manufacturers like Sterling and Dana.

Table 3: Modern Super Duty Axle Codes (c. 2020)

This chart details the codes for a representative modern Super Duty, highlighting the options for single rear wheel (SRW) and dual rear wheel (DRW) configurations.

| Rear Axle Ratio | Non-Limited Slip Code | Limited-Slip Code | Electronic Locking Code |

$3.73:1$ | 37 | Not Available | 3E |

$4.10:1$ | 41 | 4N / 4W¹ | Not Available |

$4.30:1$ | Not Available | 4L / 4X² | 4M |

$4.88:1$ | 48 | 8L | Not Available |

Table 4: Older Super Duty & Heavy-Duty Axle Codes (1980s-2000s)

This era saw a mix of heavy-duty axles, including the transition from Dana axles to the Ford-built Sterling axles.

| Axle Code | Year Range (Approx.) | Gear Ratio | Manufacturer / Model | Differential Type |

| 23 | 1980s | $3.54:1$ | Dana 60 | Open |

| 24 | 1980s | $3.73:1$ | Dana 60 | Open |

| 35 | 1985+ | $4.10:1$ | Sterling 10.25″ (SRW) | Open |

| 39 | 1985+ | $3.55:1$ | Sterling 10.25″ (SRW) | Open |

| B5 | 1985+ | $4.10:1$ | Sterling 10.25″ (SRW) | Limited-Slip |

| B9 | 1985+ | $3.55:1$ | Sterling 10.25″ (SRW) | Limited-Slip |

| C5 | 1985+ | $4.10:1$ | Sterling 10.25″ (SRW) | Limited-Slip |

| C9 | 1985+ | $3.55:1$ | Sterling 10.25″ (SRW) | Limited-Slip |

| D3 | 1983-1985 | $3.54:1$ | Dana 70 | Limited-Slip |

Ford Ranger & Explorer Axle Code Chart

The Ford Ranger and Explorer platforms are popular not only with their owners but also with a wider community of off-road enthusiasts who often use their durable 8.8-inch axles for swaps into other vehicles.

| Axle Code | Year Range (Approx.) | Gear Ratio | Axle Model / Spline | Differential Type |

| 82 | 1990s | $3.08:1$ | Ford 7.5″ / 28-spline | Open |

| 84 | 1990s | $3.45:1$ | Ford 7.5″ / 28-spline | Open |

| 86 | 1990s | $3.73:1$ | Ford 7.5″ / 28-spline | Open |

| 87 | 1990s | $4.10:1$ | Ford 7.5″ / 28-spline | Open |

| 92 | 1990s | $3.08:1$ | Ford 8.8″ / 28-spline | Open |

| 96 | 1990s | $3.73:1$ | Ford 8.8″ / 28-spline | Open |

| R5 | 2000s | $4.10:1$ | Ford 8.8″ / 31-spline | Limited-Slip (Torsen) |

| R6 | 2000s | $3.73:1$ | Ford 8.8″ / 28-spline | Limited-Slip |

| R7 | 2000s | $4.10:1$ | Ford 8.8″ / 28-spline | Limited-Slip |

Modern Ford Bronco (2021+) Axle Code Chart

The revived Ford Bronco has captured the attention of a new generation of enthusiasts. Its axle codes are specific to its unique off-road-focused packages.

| Rear Axle Ratio | Non-Limited Slip Code | Electronic Locking Code |

$3.73:1$ | 73 | Not Available |

$4.27:1$ | Not Available | 2L |

$4.46:1$ | 46 | 4L |

$4.70:1$ | Not Available | 7L |

Beyond the Code: An Investigator’s Guide to Axle Identification

There are common scenarios where the factory codes are simply not available. The door jamb sticker may have been removed during bodywork, the metal tag on an older axle may have rusted away or been discarded during a repair, or the entire axle assembly may have been swapped from a donor vehicle. In these cases, a vehicle owner must become an investigator, using direct physical methods to identify the hardware.

Method 1: The Rotation Test

This low-tech but highly accurate method allows for the direct measurement of the gear ratio without disassembling the differential.

- Safety First: Park the vehicle on a level surface, chock the front wheels, and safely raise the rear axle with a jack, supporting it securely on jack stands. The transmission should be in neutral.

- Mark References: Place a visible mark (using chalk, tape, or a paint pen) on the driveshaft and on the sidewall of one of the rear tires. Position both marks at a convenient starting point, such as the 12 o’clock position.

- Rotate and Count: Slowly and carefully rotate the marked tire by hand for exactly one complete revolution, bringing the mark back to its starting position. While doing this, have an assistant count the number of full rotations the driveshaft makes.

- Interpret the Result: The number of driveshaft rotations corresponds to the gear ratio. For example, if the driveshaft turns approximately three and a half times, the axle has a

$3.55:1$ratio. If it turns just over four times, it’s a$4.10:1$ratio. For greater accuracy, one can rotate the tire ten times and divide the driveshaft rotations by ten.

Method 2: Visual Identification Guide

The physical shape and construction of an axle housing are direct results of its engineering design, strength, and serviceability. Learning to recognize these visual cues allows for confident identification even without codes. The shape of the differential cover is often the most telling feature.

- Ford 9-Inch: This legendary axle is easily identified by its “drop-out” third member design. The gear assembly is housed in a carrier that unbolts from the front of the axle housing. The definitive tell-tale sign is that the two bottom nuts securing this carrier are inaccessible with a standard socket and require a wrench. This is a direct consequence of the straddle-mounted pinion bearing design that gives the 9-inch its renowned strength.

- Ford 8.8-Inch & 9.75-Inch: These are “integral” or “Salisbury-style” axles. The differential is accessed by removing a stamped steel cover on the rear of the housing. The 8.8-inch has a 10-bolt cover with a somewhat squared-off oval shape. The larger 9.75-inch axle, found on many F-150s, has a 12-bolt cover with a more rounded, octagonal shape.

- Sterling Axles (10.25″ & 10.5″): Used in Super Duty trucks, these massive axles are identified by their 12-bolt differential cover. A key way to distinguish between the two generations is by their brakes and model years. The earlier 10.25-inch axle (1985-1997) was equipped with drum brakes, while the later 10.5-inch axle (1999-present) uses disc brakes.

Differential Cover Comparison Chart

A visual chart would be presented here with clear images of the rear differential covers for the Ford 9-inch (showing the front-loading carrier), Ford 8.8-inch, Ford 9.75-inch, Sterling 10.5-inch, and a common Dana 60. Each image would be labeled with its name, bolt count, and key identifying features.

Method 3: Decoding Dana Axles

Many Ford 4×4 and Super Duty trucks, particularly older models, were factory-equipped with axles manufactured by Dana-Spicer. These axles use a separate identification system. The most important identifier is the Bill of Material (BOM) number. This number, which acts as a specific VIN for the axle assembly, is typically stamped on the long axle tube.

The BOM number can be entered into the Dana Aftermarket expert lookup tool to retrieve the exact specifications of the axle, including the gear ratio, differential type, and a complete list of component parts. This is an invaluable resource when sourcing parts for a Dana axle.28

The Heart of the Axle: Open, Limited-Slip, or Locking Differentials

The differential type specified by the axle code determines how the truck behaves when traction is uneven between the left and right wheels. This has a profound impact on performance in various conditions, from wet city streets to rugged mountain trails.

Table 5: Differential Type Comparison Matrix

| Feature | Open Differential | Limited-Slip Differential (LSD) | Locking Differential (Locker) |

| How it Works | Allows wheels to turn at different speeds with no connection. Power follows the path of least resistance. | Uses clutches or gears to automatically send more torque to the wheel with more traction when slip is detected. | Mechanically locks both axle shafts together, forcing both wheels to rotate at the exact same speed. |

| Best For | Everyday on-pavement driving in good conditions. | Performance driving, wet/snowy roads, light to moderate off-roading. A good all-around compromise. | Extreme off-roading, rock crawling, deep mud/sand where maximum traction is essential. |

| Pros | Simple, inexpensive, smooth and predictable operation on pavement. | Improves traction automatically without driver input. Enhances stability and performance. | Provides 100% power to both wheels, offering the ultimate traction in low-grip situations. |

| Cons | Loses all forward momentum if one wheel has zero traction (the “one-tire fire”). | More complex and expensive than an open diff. Clutches can wear out over time. | Can cause tire scrubbing, binding, and unpredictable handling on high-traction surfaces like pavement. |

Open Differential: The Standard for Daily Driving

The open differential is the most common type found in passenger cars and trucks. Its design allows the outer wheel to spin faster than the inner wheel during a turn, which is essential for smooth, predictable handling on pavement. Its primary weakness becomes apparent in low-traction environments. Because it sends equal torque to both wheels and power follows the path of least resistance, if one wheel is on ice or in the air, that wheel will receive all the engine’s power and spin uselessly, leaving the vehicle stranded.

Limited-Slip Differential (LSD): The Smart Compromise

A limited-slip differential addresses the main flaw of an open differential. Using a system of clutches or helical gears, an LSD can detect when one wheel begins to spin faster than the other. When this happens, it automatically transfers a portion of the torque away from the slipping wheel and directs it to the wheel that has more grip.

This provides a significant traction advantage on wet roads, gravel, snow, and in light off-road situations. It offers a seamless and automatic enhancement to performance and safety, making it a popular option for trucks that serve as both daily drivers and weekend adventurers.

Locking Differential: Maximum Traction for Off-Road Dominance

A locking differential, or “locker,” is the ultimate solution for traction. When engaged, it mechanically locks the two axle shafts together, forcing both wheels to rotate at the same speed, regardless of traction conditions. This ensures that even if one wheel is completely off the ground, the other wheel will continue to receive 100% of the available torque for that axle, propelling the vehicle forward. This capability is indispensable for serious off-roading.

However, this same feature makes lockers ill-suited for pavement driving. Because the wheels cannot differentiate speed in a turn, a locked differential will cause the tires to scrub and chirp, leading to increased tire wear and unpredictable handling characteristics. Most modern trucks, like the F-150 and Bronco, use selectable electronic lockers that function as an open differential until the driver activates the locking feature with the press of a button.

Frequently Asked Questions (FAQ)

What is the best Ford axle ratio for towing?

For heavy and frequent towing, a higher numerical ratio like $3.73:1$ or $4.10:1$ is generally best. These ratios provide superior torque multiplication, making it easier to get a heavy load moving and maintain speed on inclines.8 However, on modern trucks with 10-speed transmissions, even a $3.55:1$ ratio can offer excellent towing performance while providing better fuel economy when unloaded.11 The best choice depends on balancing the weight of the trailer with the amount of unloaded highway driving the truck will perform. Always consult the official(https://www.ford.com/support/towing-guides/) for your vehicle’s specific ratings.

How do I know if I have a limited-slip differential?

The easiest way is to check the axle code. On the door jamb sticker, codes that include a letter (e.g., H9) or are alphanumeric (e.g., L9) typically indicate a limited-slip or locking differential, whereas purely numerical codes (e.g., 19) often signify an open differential. On the physical axle tag, the presence of an “L” in the ratio (e.g., $3 L 55$) is the definitive indicator.6 If all tags are missing, a mechanic can perform a simple test by lifting the rear axle and spinning one wheel; on an LSD, the other wheel will typically turn in the same direction with some resistance.

Can I change my truck’s axle ratio?

Yes, the axle ratio can be changed by replacing the ring and pinion gear set inside the differential. This is a common upgrade for truck owners who want to improve towing performance or compensate for the installation of larger tires. It is a complex job that requires specialized tools and expertise to set the correct gear mesh and bearing preload, and it is best left to an experienced differential specialist. On a 4×4 vehicle, it is absolutely critical that the gear ratios in both the front and rear axles are changed to match perfectly to avoid catastrophic driveline damage.

Will bigger tires affect my axle ratio?

Installing larger-diameter tires does not change the physical gears in the axle, but it does change the effective final drive ratio. A taller tire covers more ground per revolution, which has the same effect as swapping to a lower numerical gear ratio (e.g., from $3.73:1$ to $3.55:1$). This will result in slower acceleration, reduced towing performance, and an inaccurate speedometer. To restore lost performance and correct the speedometer, owners who install significantly larger tires often need to “re-gear” the axles with a higher numerical ratio.

What does a Ford 8.8 or 9.75 axle mean?

These numbers refer to the diameter of the ring gear, measured in inches. The ring gear is the large gear within the differential that is turned by the smaller pinion gear (which is connected to the driveshaft). A larger ring gear diameter generally corresponds to a stronger axle assembly capable of handling more torque and weight. For example, the Ford 9.75-inch axle is a more robust unit than the Ford 8.8-inch axle and is used in F-150s with higher payload and towing packages.

Conclusion

The Ford axle code is far more than a simple production number; it is a concise summary of a truck’s core capabilities. It translates directly to real-world performance, dictating how a vehicle tows a trailer, accelerates onto a highway, grips a slippery road, or claws its way over an obstacle. By using this guide to locate and decode this critical piece of information, a Ford owner can gain a deeper understanding of their vehicle’s design and purpose. This knowledge empowers them to make informed decisions about proper vehicle use, maintenance, and potential modifications, ensuring that their truck performs exactly as needed for any task at hand.