Best Cold Air Intake For 6.7 Powerstroke: Ranked Performance Systems For Ford Diesel Engines

The Ford 6.7L Powerstroke is a relentless workhorse, yet it is often throttled by a factory airbox designed more for silence than for maximum airflow. These stock intake systems prioritize noise suppression and cost-effective manufacturing, which can lead to high Exhaust Gas Temperatures (EGTs) and sluggish turbo response when the engine is under load. This guide provides a ranked analysis of the best cold air intake systems for the 6.7 Powerstroke, focusing on a curated selection of options that improve CFM, reduce heat soak, and enhance overall engine efficiency.

Section 1: Essential Metrics for Ranking 6.7 Powerstroke Cold Air Intakes

📤 Share Image

Evaluating an intake system for the 6.7L platform requires looking past marketing jargon and focusing on technical performance indicators. The primary metric is airflow volume, measured in Cubic Feet per Minute (CFM). The factory 6.7L airbox is notoriously restrictive, particularly in the 2011-2016 model years. While Ford redesigned the stock units for the 2017+ models to be higher capacity, even these struggle to provide the volume required when the engine is modified or under heavy strain. A recommended aftermarket system typically provides a 40% to 50% increase in airflow over stock, which is essential for maximizing the volumetric efficiency of the Garrett VGT turbocharger.

Filtration efficiency is the second pillar of our evaluation. We prioritize systems that adhere to ISO 5011 standards. This ensures that while you are increasing the volume of air, you aren’t inviting fine particulates into the precision-machined combustion chambers of your diesel engine. For the 6.7 Powerstroke, high-quality filtration is a non-negotiable requirement for engine longevity.

Heat Soak and Thermal Management

In a dense engine bay like the Super Duty’s, heat soak is a constant threat. Enclosed airbox designs are superior to open-element filters because they isolate the intake charge from the radiant heat of the engine. This directly impacts Exhaust Gas Temperatures (EGTs), which is a must-know factor for anyone using their truck for heavy towing or high-torque applications. By keeping Intake Air Temperatures (IATs) low, the system prevents the ECU from pulling timing or reducing boost to protect the engine.

By The Numbers: Airflow Reality

Avg. CFM Increase

Filtration Efficiency

Installation Time

Section 2: The Ranked List: Top Performance Intakes for the Ford 6.7L Diesel

Our curated collection of the best intake systems highlights manufacturers who have invested heavily in R&D specifically for the 6.7L Powerstroke engine architecture.

1. S&B Filters Enclosed Intake (Ranked #1 for Daily/Towing)

S&B remains the industry standard for a reason. Their systems, such as Part Number 75-5121 for 2017-2019 models, utilize high-quality silicone components that withstand extreme temperatures better than rubber. These kits often exceed a 50% airflow improvement over the stock 2011-2016 units. The clear lid allows for easy filter inspection, and the fitment is virtually identical to OEM standards.

2. Banks Power Ram-Air System

Gale Banks is synonymous with diesel performance. The Banks Ram-Air is engineered to eliminate the ‘bellows’ found in stock tubes, which are notorious for causing air turbulence. By smoothing the path to the turbo, these systems have been dyno-tested to provide up to 50% more air volume than the 2011-2016 factory configuration, significantly improving spool-up time.

3. No Limit Fabrication Stage 2

For competition-level builds and high-horsepower 6.7L setups, No Limit is the go-to popular choice. Their Stage 2 system uses massive 5-inch mandrel-bent piping. This is not for the faint of heart; it is designed for trucks that have been deleted or tuned to handle significant boost increases where the standard 4-inch diameter becomes a bottleneck.

4. Mishimoto Performance Intake

Mishimoto focuses on velocity. Their system features a powder-coated heat shield and a custom-engineered intake tube designed to maintain air speed. It’s an excellent middle-ground option for owners who want a more robust look and sound without moving to a full 5-inch race setup.

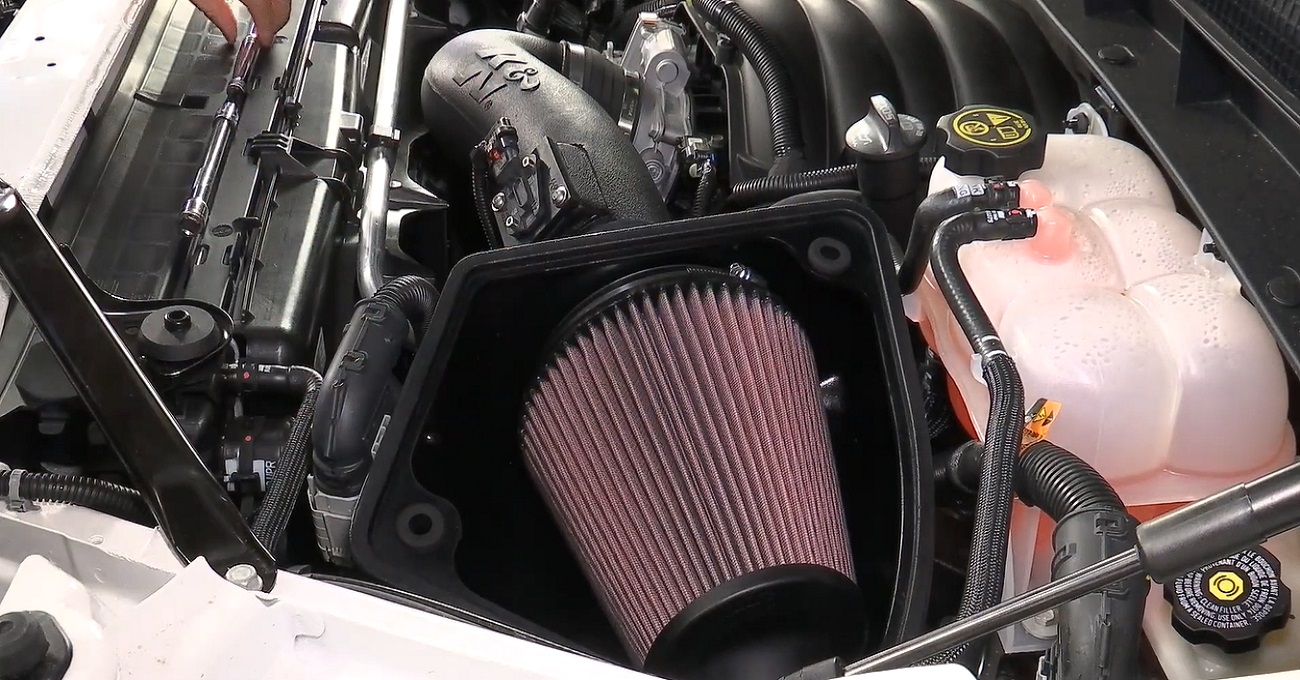

5. K&N 71 Series Blackhawk

The Blackhawk series is favored by those who prioritize a more aggressive engine note. Utilizing mandrel-bent aluminum piping, it provides a distinct “whistle” that many Powerstroke owners find appealing, while still offering significant performance gains over the stock plastic tubing.

Section 3: Must-Know Comparison: Oiled vs. Dry Filtration Systems

Choosing between oiled and dry filter media is often a matter of maintenance preference and the environment in which you operate your Super Duty. S&B, for example, offers both Cleanable (8-layer cotton) and Extendable (Dry) options for the same intake housing, allowing for a personalized selection based on need.

Oiled cotton gauze filters generally offer the highest airflow. They are essentially ‘lifetime’ components, as they can be washed, re-oiled, and reused indefinitely. However, they require a nuanced touch; over-oiling can lead to Mass Air Flow (MAF) sensor fouling, which triggers check engine lights and poor performance. Dry extendable filters, on the other hand, achieve upwards of 99% filtration efficiency. They are the recommended choice for trucks operating in dusty, agricultural, or construction environments. While they may trade a fraction of a percent in CFM compared to oiled filters, the ease of maintenance—simply blowing them out with low-pressure air or replacing them—is a significant advantage.

✅ Oiled Filters

- Highest potential CFM

- Lower long-term cost (reusable)

- Excellent for street use

- Deep induction sound

❌ Dry Filters

- Slightly lower airflow than oiled

- Limited lifespan (disposable)

- Best for extreme dust

- No risk of MAF sensor oiling

Section 4: Popular Installation Challenges and Essential Calibration Notes

Most bolt-on 6.7L intakes can be installed in under 60 minutes with basic hand tools like a 10mm socket and a flathead screwdriver. However, the process requires attention to detail. Handling the factory Mass Air Flow (MAF) and Intake Air Temperature (IAT) sensors is the most critical step. These are sensitive components; damaging the internal pins or the sensor element itself will lead to immediate drivability issues.

Never touch the actual sensor element of the MAF sensor. Even the oils from your skin can cause inaccurate readings. Always use specialized MAF cleaner if the sensor appears dirty during the transfer to the new intake tube.

Another must-know consideration is the ‘No-Tune Required’ vs. ‘Tuning Recommended’ debate. For standard-diameter intake tubes (like those from S&B and Banks), the factory ECU can easily calibrate for the increased airflow. However, once you move to a 5-inch system like the No Limit Stage 2, the MAF sensor readings will be skewed because the air is moving through a larger volume at a different velocity. In these cases, custom tuning is required to recalibrate the sensor scaling. Additionally, ensure your system carries a CARB (California Air Resources Board) Executive Order (EO) sticker if you reside in a state that follows California emission standards, as you will need this to pass smog inspections.

📋

Installation Checklist

Disconnect the batteries (6.7L has two) to prevent any electrical surges when unplugging the MAF and IAT sensors.

Carefully remove sensors from the factory box. Ensure the O-rings are intact before seating them into the new aftermarket intake tube.

Tighten all T-bolt or worm-gear clamps. Double-check clearance around secondary cooling reservoirs and dual-alternator setups.

Section 5: Real-World Impact on Fuel Economy and Turbo Spool Response

The benefits of a cold air intake on a 6.7 Powerstroke are most evident when the truck is working. Drivers will notice a marked reduction in turbo lag. This is due to the decreased pressure drop across the filter media, allowing the turbocharger to reach target boost levels more rapidly. For many users, this manifests as a more “snappy” throttle response during city driving.

In terms of fuel economy, users frequently report a 0.5 to 1.5 MPG increase when combining a high-flow intake with a quality exhaust system. This improvement comes from enhanced volumetric efficiency—the engine doesn’t have to work as hard to pull in air, reducing pumping losses. However, the most critical essential benefit is during towing. Imagine a scenario involving a 15,000-lb trailer pull up a steep grade. In stock form, the high IATs might cause the ECU to de-rate power to protect the turbo. An engineered intake like the Banks Ram-Air keeps those temperatures in check, allowing for sustained speed and lower EGTs throughout the climb.

If you enjoy the audible “whistle” of the 6.7L turbo, look for a system with a metal intake tube. Plastic and silicone tend to dampen the sound, whereas aluminum or steel tubes amplify the induction noise significantly.

Quicker Turbo Spool

Reduced restriction allows the turbo to reach boost threshold faster, improving low-end torque.

Lower EGTs

Denser, cooler air results in lower exhaust temperatures, which is critical for the longevity of the turbo and DPF.

Upgrading the 6.7L intake is an essential first step for any owner looking to reduce EGTs and improve turbo spool response. Whether you choose the high-value silicone design of S&B or the precision engineering of Banks, moving away from the stock airbox unlocks the latent potential of the Powerstroke platform. Choosing between oiled and dry filters depends largely on your maintenance schedule and operating environment, but both represent a significant leap over factory performance. Select the intake that matches your specific model year and filtration needs to unlock the hidden potential of your Super Duty today.

Frequently Asked Questions

Will a cold air intake void my 6.7 Powerstroke warranty?

Generally, no. Under the Magnuson-Moss Warranty Act, a dealer cannot void your warranty simply because you installed an aftermarket part. They must prove the intake caused a specific failure. However, for total peace of mind, many owners choose CARB-exempt intakes which are recognized as safe, high-quality replacements for the factory equipment.

Do I need a tuner to run an aftermarket intake on my 6.7L Ford?

Most standard cold air intakes from reputable brands like S&B or Banks are designed to work with the factory ECU calibration. These ‘no-tune’ intakes maintain the factory MAF sensor housing diameter. However, larger 5-inch ‘Stage 2’ intakes usually require custom tuning to recalibrate the MAF sensor scaling to prevent lean conditions or check engine lights.

How often should I clean my 6.7 Powerstroke air filter?

For oiled filters, a cleaning interval of every 20,000 to 30,000 miles is standard, though this should be shorter if you frequently drive on dirt roads. Dry filters should be inspected every 10,000 miles and either blown out with low-pressure air or replaced once the filter monitor indicates a restriction in airflow.

What is the difference between an enclosed and an open airbox?

An enclosed airbox, like those from S&B, seals the filter away from the hot engine bay, drawing air only from outside vents. This results in lower Intake Air Temperatures (IATs). Open designs offer more ‘turbo whistle’ and aggressive sound but can suffer from heat soak in stop-and-go traffic or high-heat environments.

Is the performance gain from an intake actually noticeable?

While horsepower gains on a stock truck are modest (typically 5-15 HP), the real benefit is in throttle response and EGT reduction. Drivers usually notice the turbo spools up faster (less lag) and the engine doesn’t feel as ‘stifled’ during heavy acceleration, especially when the truck is equipped with a larger exhaust.