7.3 Powerstroke Fuel Bowl Diagram: Diagnosis & Fix Guide

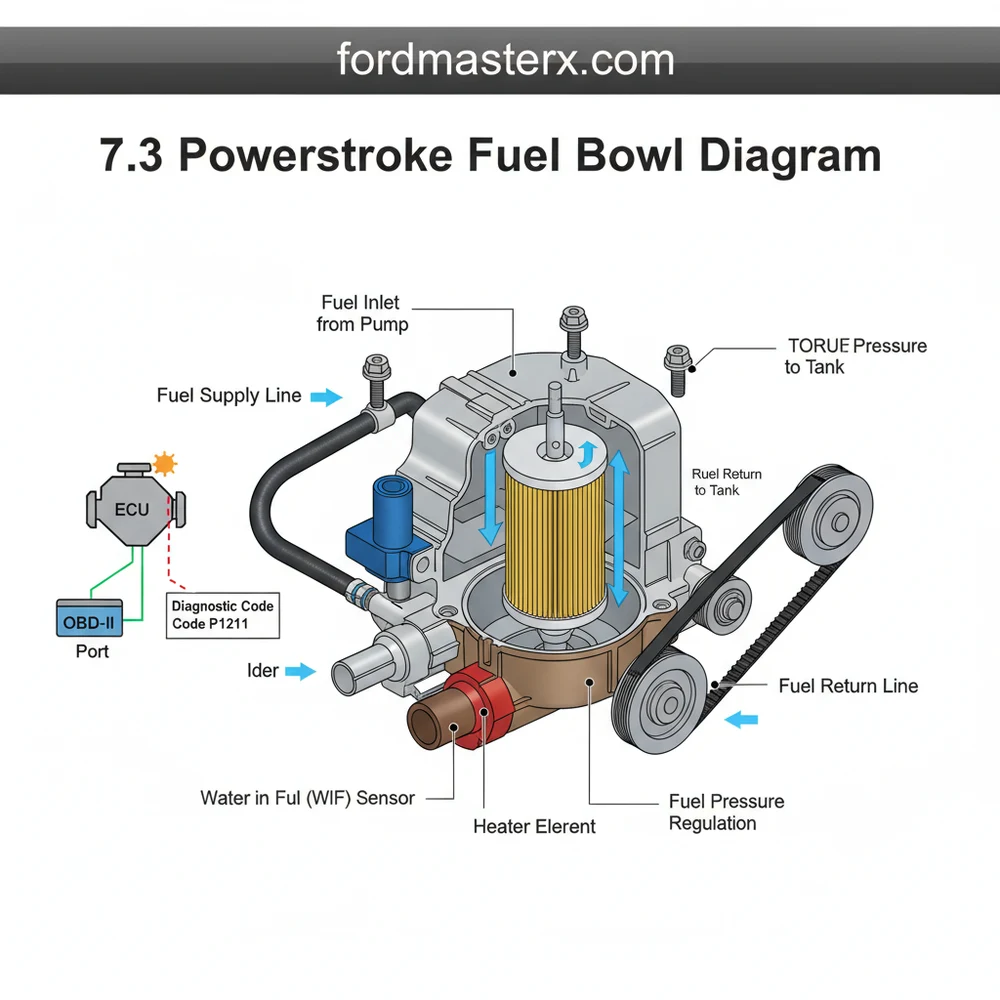

The 7.3 Powerstroke fuel bowl diagram illustrates the fuel filter housing, including the pressure regulator, heater element, and drain valve. It serves as a visual guide for replacing filters or seals to prevent air intrusion and ensure the ECU receives consistent fuel pressure for optimal engine performance.

📌 Key Takeaways

- Visualizes internal fuel flow and component placement

- Most important to identify the Fuel Pressure Regulator (FPR)

- Always relieve pressure before opening the fuel bowl

- Use the diagram to identify potential leak points at the drain valve

- Essential for filter changes and seal replacements

Understanding the 7.3 Powerstroke fuel bowl diagram is a critical first step for any truck owner looking to maintain engine longevity and performance. Whether you are dealing with a stubborn leak, a “Water in Fuel” light, or a complete no-start condition, the fuel bowl serves as the central hub for filtration and pressure regulation. This article provides a comprehensive breakdown of the internal and external components of the fuel filter housing, offering clear guidance on how to interpret the 7.3 powerstroke fuel bowl diagram. By mastering this component, you will gain the confidence to perform your own repairs, ensuring your legendary diesel engine remains reliable for hundreds of thousands of miles.

Understanding the 7.3 Powerstroke Fuel Bowl Components

The fuel bowl on a 7.3-liter Powerstroke engine is more than just a container for a filter; it is a sophisticated manifold that manages fuel heating, water separation, and pressure regulation. When looking at a 7.3 powerstroke fuel bowl diagram, you will notice several distinct ports and electrical connections that interface with the engine’s management system.

The primary body is typically cast aluminum, housing the fuel filter element in the center. On the side of the bowl, you will find the Fuel Pressure Regulator (FPR), which maintains the necessary 45-65 PSI required for the injectors to function correctly. The diagram also highlights the fuel heater element at the bottom of the bowl. This heater is vital for preventing paraffin wax buildup in cold climates, though it is a common point of electrical failure.

[DIAGRAM_PLACEHOLDER – A detailed technical illustration showing the 7.3 Powerstroke Fuel Bowl. Key labels include: 1. Fuel Inlet Port, 2. Fuel Pressure Regulator (FPR), 3. Fuel Bowl Cap, 4. Drain Valve (Yellow Lever), 5. Fuel Heater Element, 6. Water-in-Fuel Sensor, 7. Outlet to Cylinder Heads.]

Key variations exist between the early “OBS” (Old Body Style) models and the later Super Duty models. Early versions use a mechanical fuel pump located in the valley, while later versions utilize an electric pump mounted on the frame rail. Despite these differences, the internal flow of the bowl remains similar: fuel enters the outer diameter of the filter, passes through the media to the center, and exits through the top or sides toward the cylinder heads.

The fuel bowl is located in the “valley” of the engine, situated between the two cylinder heads. This area is also a common collection point for oil or coolant if other components fail, so always verify that fluid in the valley is indeed diesel before assuming the fuel bowl is leaking.

Step-by-Step Guide to Using the Diagram for Maintenance

Navigating the fuel system requires precision. Using the 7.3 powerstroke fuel bowl diagram as your roadmap, follow these steps to perform a standard reseal or inspection. This process is essential if you notice fuel pooling in the engine valley or if your check engine light illuminates due to fuel delivery issues.

- ✓ Step 1: Preparation and Safety. Ensure the engine is completely cool. Unlike engines with a timing chain that are fully enclosed, the 7.3 valley is open, and you will be working near the accessory belt. Disconnect the batteries to prevent any electrical shorts, especially since the fuel heater circuit is often live.

- ✓ Step 2: Drain the Bowl. Locate the yellow drain lever on the back of the fuel bowl. Place a catch pan beneath the drain tube (located near the front passenger side of the engine). Flip the lever to allow fuel and any trapped water to exit the system.

- ✓ Step 3: Remove the Cap and Filter. Using a large socket or a specialized fuel cap wrench, unscrew the lid. Remove the old filter and inspect the bottom of the bowl for debris or “algae” (asphaltene). This is a great time to check the integrity of the fuel heater element.

- ✓ Step 4: Inspect the Fuel Pressure Regulator (FPR). Referencing your diagram, locate the FPR on the side of the bowl. If you are experiencing low power, you may need to clean the small screen inside the FPR housing. Be careful not to lose the internal spring or plunger.

- ✓ Step 5: Replace O-Rings and Seals. Most leaks occur at the drain valve or the FPR mounting points. Use high-quality Viton O-rings to ensure they can withstand modern ultra-low sulfur diesel. Lubricate the new O-rings with a small amount of clean diesel or engine oil before installation.

- ✓ Step 6: Reassembly and Torque. Reinstall the filter and cap. It is vital to follow the correct torque spec for the FPR bolts (typically 8-10 lb-ft) to avoid stripping the aluminum threads. Over-tightening the fuel bowl cap can also lead to cracked lids and vacuum leaks.

- ✓ Step 7: Priming the System. For Super Duty models, cycle the key to the “On” position for 30 seconds several times without cranking. This allows the electric pump to purge air from the bowl. For OBS models, you will need to crank the engine in short bursts to allow the mechanical pump to fill the reservoir.

Failure to properly seat the fuel filter O-ring can cause a massive high-pressure leak. Always double-check that the bevelled edge of the O-ring is facing the correct direction as indicated in your specific 7.3 powerstroke fuel bowl diagram.

Common Issues and Troubleshooting

The fuel bowl is frequently the source of the dreaded “crank but no start” condition. One of the most common issues is a shorted fuel heater element. When the heater shorts out, it typically blows a specific fuse (Fuse 22 in many Ford trucks) which also provides power to the ECU (Engine Control Unit). When the ECU loses power, the OBD-II port will fail to communicate with scanners, and the truck will not start.

If your check engine light is on, use a high-quality scanner to look for a diagnostic code such as P1211 (Injection Control Pressure) or P0251 (Injection Pump Fuel Metering). While these codes often point toward the high-pressure oil system, they can also be triggered by severe fuel starvation caused by a clogged fuel bowl screen or a failing pressure regulator.

If your truck dies while driving and won’t restart, try disconnecting the electrical plug on the back of the fuel bowl. If the truck then starts, your fuel heater has shorted. This simple trick can save you a costly tow bill.

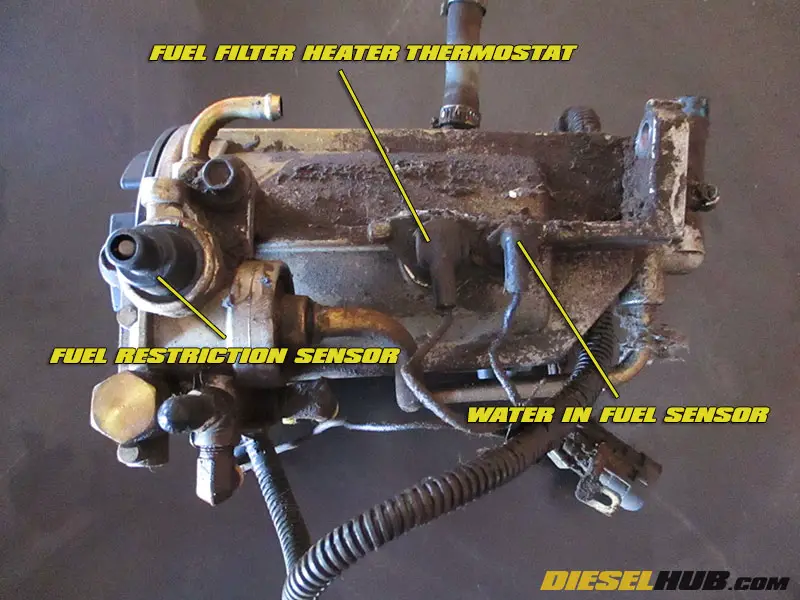

Another frequent problem involves the yellow drain valve. Over time, the internal O-rings shrink and harden, leading to a constant drip of diesel into the engine valley. This can be mistaken for a leak in the coolant flow system or an oil leak from the HPOP (High Pressure Oil Pump). Using the diagram to identify the valve’s structure allows you to rebuild the valve with new seals rather than replacing the entire expensive housing.

Maintenance Tips and Best Practices

To keep your fuel system running at peak efficiency, preventive maintenance is key. Always use OEM-quality fuel filters, such as those from Motorcraft or Racor. These filters include a built-in water separator and the correct lid seal, which are essential for maintaining the pressure integrity shown on the 7.3 powerstroke fuel bowl diagram.

- ✓ Drain Water Monthly: Even if the light isn’t on, flick the drain lever for a few seconds once a month to remove any moisture that has settled at the bottom of the bowl.

- ✓ Monitor Fuel Pressure: Installing a mechanical or electronic fuel pressure gauge at the FPR test port is one of the best upgrades for a 7.3 owner. It allows you to see real-time performance and catch a failing pump before it leaves you stranded.

- ✓ Clean the Valley: Every time you change your filter, use a degreaser to clean the engine valley. This makes it much easier to spot new leaks from the fuel bowl, HPOP, or turbocharger pedestals.

While the 7.3 Powerstroke does not utilize a timing chain (it is gear-driven), the synchronization between fuel delivery and engine timing is managed by the ECU. Keeping your fuel bowl clean and pressurized ensures that the fuel injectors receive the volume they need to maintain this precise timing. If you find yourself frequently replacing filters or seeing sediment in the bowl, consider inspecting your fuel tanks for “delamination,” a common issue where the interior lining of the tank flakes off and clogs the system.

By following this 7.3 powerstroke fuel bowl diagram guide and maintaining your fuel system components, you ensure that your engine remains the workhorse it was designed to be. Consistent inspections and using the right torque spec on all fittings will prevent the most common points of failure, saving you thousands of dollars in professional repair costs over the life of the vehicle.

Frequently Asked Questions

Where is the fuel bowl located?

The fuel bowl is located in the center valley of the engine block, directly behind the High-Pressure Oil Pump (HPOP). It is positioned under the plastic decorative engine cover and is easily accessible for filter changes and seal maintenance to ensure proper fuel delivery.

What does the fuel bowl diagram show?

This diagram provides a detailed breakdown of the fuel filter housing, including the internal standpipe, heating element, water-in-fuel sensor, and the fuel pressure regulator assembly. It identifies the exact path fuel takes from the pump through the filter and out to the cylinder heads.

How many connections does the fuel bowl have?

The 7.3 Powerstroke fuel bowl typically features four main fluid connections: the fuel inlet from the pump, two outlets leading to the cylinder heads, and a return line to the fuel tank. It also includes electrical connectors for the heater and water-in-fuel sensor.

What are the symptoms of a bad fuel bowl?

Common symptoms include hard starts, stalling, or a check engine light. If the internal heater shorts, it can blow the fuse that powers the ECU, resulting in a no-start condition. External leaks are often caused by degraded O-rings on the drain valve.

Can I replace the fuel bowl seals myself?

Yes, replacing seals or the fuel pressure regulator is a common DIY task. Using a diagnostic code via OBD-II can help confirm pressure issues, but physical inspection for leaks or a shorted heater is straightforward for most diesel owners with basic hand tools.

What tools do I need for fuel bowl maintenance?

You will need a fuel filter wrench or large pliers, a socket set for the mounting bolts, and a torque wrench. Ensuring the housing lid meets the correct torque spec prevents cracks and maintains a proper seal under high fuel pressure during engine operation.