7.3 Idi Vs 7.3 Powerstroke: A Technical Comparison Of Ford’S Legendary Diesel Engines

For diesel enthusiasts and truck owners, the “7.3” badge represents a pinnacle of American engineering reliability and longevity. Often cited as the engine that built Ford’s modern reputation in the heavy-duty market, the 7.3L displacement actually spans two distinct eras of technology. Deciding between the vintage, purely mechanical 7.3 IDI and the more modern, electronically controlled 7.3 Powerstroke requires an understanding of complex fuel systems and performance trade-offs. This expert analysis will break down the technical differences in injection technology, maintenance requirements, and real-world performance to help you identify which legend belongs in your driveway.

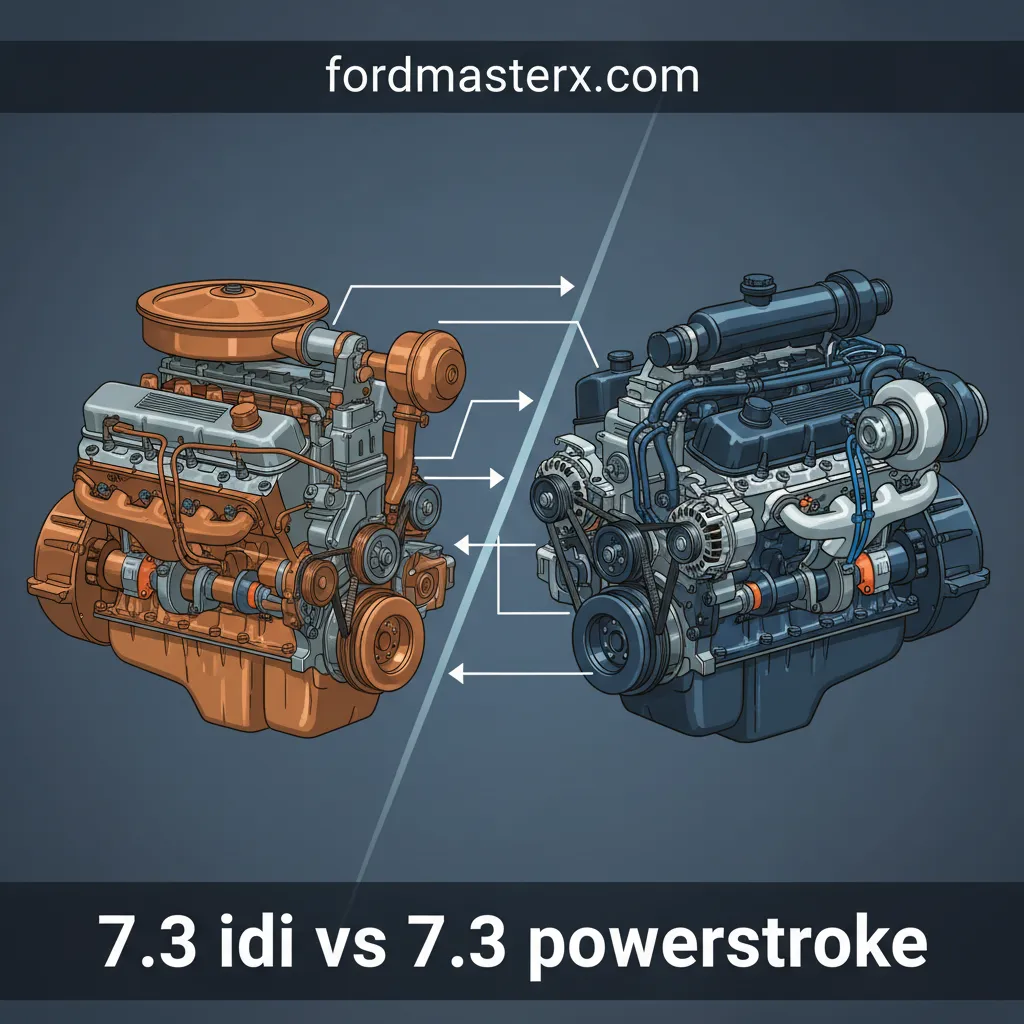

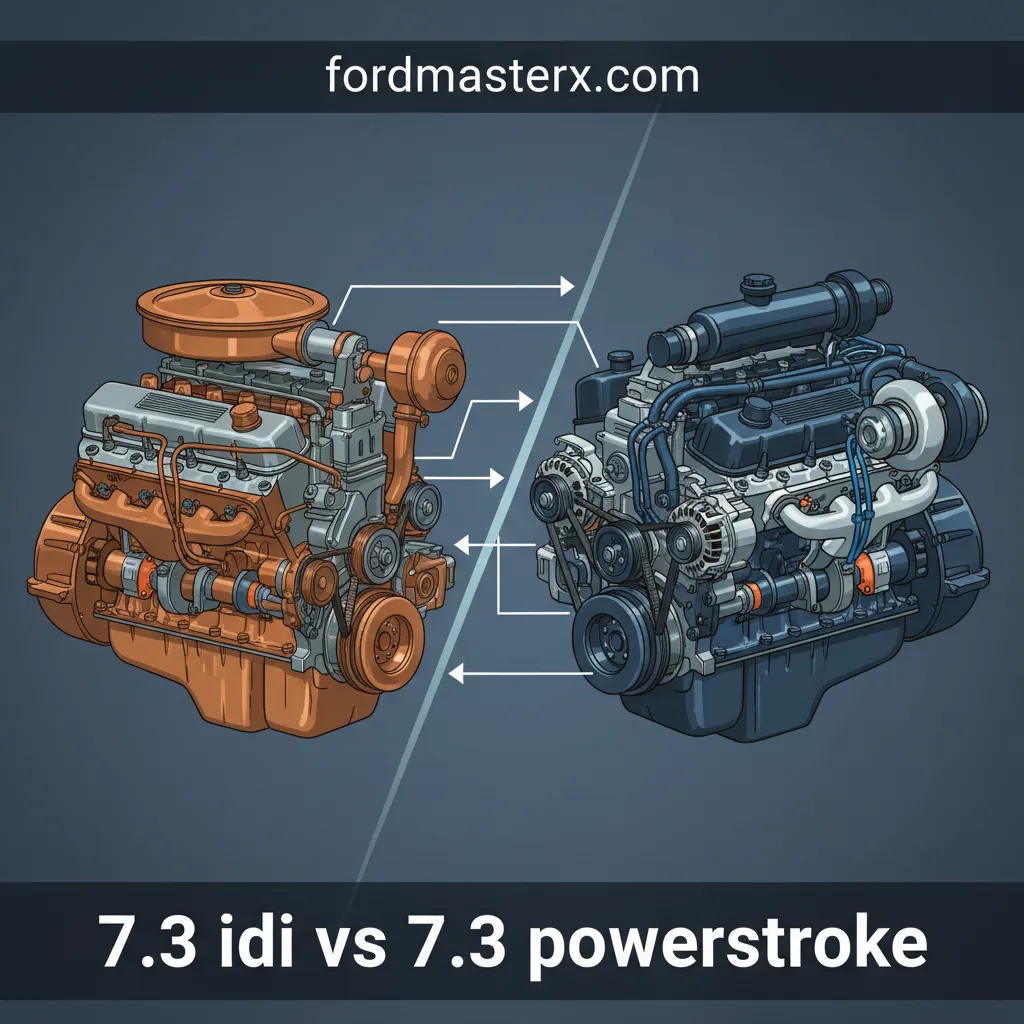

Engineering Origins: Comparing the International Harvester IDI and the 7.3 Powerstroke T444E

📤 Share Image

The history of Ford’s heavy-duty dominance is inextricably linked to International Harvester (later Navistar). From 1988 to 1994, the 7.3 IDI (Indirect Injection) served as the workhorse of the Ford F-Series. This engine was a purely mechanical design, devoid of any computer management. It relied on high compression and mechanical timing to operate, earning it a reputation as a “tractor engine” for the road. Its design prioritized durability and ease of repair over sheer horsepower, making it a trusted companion for farmers and fleet operators.

In mid-1994, a seismic shift occurred with the introduction of the 7.3 Powerstroke. While it shared the same 7.3L displacement, the Powerstroke (internally designated as the T444E by International) was a clean-sheet redesign in several critical areas. The transition marked the move from ‘tractor-like’ simplicity to high-output automotive diesel technology. The Powerstroke introduced the Hydraulic Electronic Unit Injection (HEUI) system, which utilized a powertrain control module (PCM) to manage engine parameters.

Structural Redesign for Higher Pressures

The Powerstroke block was significantly reinforced compared to its IDI predecessor. Because the Powerstroke was designed to handle higher cylinder pressures from factory turbocharging and direct injection, the casting included additional webbing and thicker cylinder walls. The 1988-1994 IDI trucks featured a simpler block design that was adequate for its 185 horsepower rating, but the Powerstroke platform eventually peaked at 275 horsepower in late-model manual transmission configurations, requiring a more robust architecture. This structural evolution was necessary to maintain quality and long-term durability under the increased stress of modern performance demands.

By The Numbers: Evolution of Power

IDI Peak HP

Powerstroke Peak HP

The “Split” Year

Fuel Injection Mechanics: Indirect Injection vs. HEUI Direct Injection Systems

The defining technical difference between these two engines lies in how they deliver fuel. The 7.3 IDI utilizes a pre-combustion chamber. In this setup, fuel is injected into a small chamber separate from the main cylinder, where it begins to ignite before expanding into the main combustion area. This results in a “softer” combustion event, which historically reduced diesel “clatter” but significantly hampered thermal efficiency and cold-start capability.

The 7.3 Powerstroke revolutionized this with Direct Injection via the HEUI system. Instead of a mechanical pump timing the injection, the Powerstroke uses high-pressure engine oil to fire the injectors. A High-Pressure Oil Pump (HPOP) creates the force necessary to atomize fuel directly into the cylinder. This allow for precise electronic timing, multi-shot injection events, and vastly improved fuel atomization. While the IDI’s Stanadyne DB2 mechanical injection pump is a marvel of simplicity, it cannot match the over 20,000 PSI injection pressures achieved by the Powerstroke’s HEUI system.

The Complexity of Cold Starts

Reliable cold starting is a frequent topic of professional diagnostic discussion. The IDI relies heavily on high-amperage glow plugs and massive cylinder compression. If the glow plug relay or even a single plug fails, the IDI becomes notoriously difficult to start in sub-zero temperatures. Conversely, while the Powerstroke also uses glow plugs, its startability is equally dependent on oil viscosity. Because the injectors require high-pressure oil to fire, using the wrong oil weight in winter can prevent the engine from starting even if the electrical system is perfect. This nuanced understanding of oil-fired injection is vital for any expert technician working on the T444E platform.

On the 7.3 Powerstroke, if the truck cranks but won’t fire in the cold, check your oil level and weight first. HEUI injectors cannot build the 500 PSI of ICP (Injection Control Pressure) required to start if the oil is too thick or low.

Performance and Towing: Horsepower and Torque Output Analysis

From a complete performance perspective, the Powerstroke is the clear victor, but the comparison requires nuance. Most IDIs found in the wild are naturally aspirated. They are essentially “momentum” engines—they will pull almost anything, but they will do it slowly. The 7.3 IDI produced a modest 338 lb-ft of torque, which was respectable for the late 80s but pales in comparison to modern standards. The lack of a factory turbocharger on most units means that power drops off significantly at higher altitudes.

The 7.3 Powerstroke was turbocharged from the factory, which fundamentally changed its torque curve. With up to 525 lb-ft of torque in later models, the Powerstroke provides a wider, more accessible power band. This makes it the professional choice for heavy-duty towing and hauling. When pulling a 10,000lb gooseneck trailer over a mountain pass, the Powerstroke’s wastegated turbocharger maintains boost levels and EGT (Exhaust Gas Temperature) stability far better than the IDI.

Tuning Potential and the “Factory Turbo” IDI Bridge

One cannot discuss 7.3 performance without mentioning tuning. The Powerstroke is an electronic engine, meaning its performance can be vastly improved with simple plug-and-play chips like the TS6 or Hydra. These can add 60-100+ horsepower safely. The IDI, however, is limited by its mechanical pump. While you can “turn up the fuel” by adjusting the internal screw on the DB2 pump, you are quickly limited by airflow unless you add an aftermarket turbo kit. A rare bridge between these technologies exists in the 1993-1994 “Factory Turbo” IDI, which offered a glimpse into the Powerstroke’s future performance but still utilized the mechanical injection system.

Maintenance and Reliability: Addressing Cavitation and Electronic Failures

Both the IDI and the Powerstroke share a “million-mile” reputation, but achieving that milestone requires specific maintenance practices. The most critical issue shared by both engines is cylinder wall cavitation. This is a phenomenon where tiny vacuum bubbles form on the outside of the cylinder liners during the combustion stroke. When these bubbles collapse, they act like tiny jackhammers, eventually pitting a hole through the wall into the combustion chamber. To prevent this, owners must professionally maintain Supplemental Coolant Additives (SCA) such as Fleetguard DCA4. Failure to do so can result in a perforated block, rendering the engine a total loss.

The Achilles’ Heel of Each Platform

While the IDI is mechanically bulletproof, it has its own minor annoyances, specifically air intrusion in the fuel lines. A simple leak in a return line O-ring can cause the truck to lose prime, making it impossible to start. On the other hand, the Powerstroke’s Achilles’ heel is its Camshaft Position Sensor (CPS). When this sensor fails—which it often does without warning—the engine will simply shut off and refuse to restart. Fortunately, this is a $30 part and a 10-minute fix, but it is a failure mode that simply doesn’t exist on the mechanical IDI.

Never run standard “green” automotive coolant in these engines without checking the SCA levels with test strips. A comprehensive cooling system service every 30,000 miles is the only way to ensure your engine block doesn’t succumb to cavitation pitting.

✅ Pros: Powerstroke

- Higher horsepower/torque for towing

- Easily tuned for more power

- Better parts availability today

- Superior cold-weather reliability

❌ Cons: Powerstroke

- Injection system is expensive to fix

- Dependent on electronic sensors

- Higher initial purchase price

- Complex high-pressure oil system

Value Assessment: Choosing the Right Engine for Your Application

Choosing between these two icons often comes down to budget and intended use. The 7.3 IDI is the ideal choice for the “prepper,” the farmer, or the budget-conscious owner. Because it requires no electricity to stay running once started, it is effectively EMP-proof. It is a simple, reliable machine that can be maintained with basic hand tools. A full set of IDI injectors can often be purchased for under $500, making it an incredibly affordable platform for long-term ownership.

The 7.3 Powerstroke, however, is the premier choice for modern highway driving and serious work. It offers significantly better fuel economy, better throttle response, and the power required to keep up with modern traffic while hauling heavy loads. This utility is reflected in the resale value. Clean 7.3 Powerstroke-equipped trucks, especially the 1999-2003 Super Duty models, frequently command a significant premium, often selling for $15,000 to $25,000. In contrast, IDI trucks generally occupy the $5,000 to $10,000 bracket.

📋

Buyer’s Inspection Guide

With the engine running, flip the oil fill cap upside down over the hole. If it dances around, that’s normal; if it’s blown off by pressure, the rings are worn.

Look for oil in the coolant or “slugde” under the radiator cap. This is a sign of oil cooler failure or, worse, cavitation damage.

Always insist on seeing the engine start from a “dead cold” state. This reveals the health of the glow plugs and, on Powerstrokes, the high-pressure oil system.

In summary, the 7.3 IDI offers unmatched mechanical simplicity and ‘EMP-proof’ reliability for those on a budget. The 7.3 Powerstroke provides superior torque, horsepower, and modern drivability through its advanced HEUI electronic injection. Both engines require diligent cooling system maintenance to prevent cavitation and ensure they reach their legendary high-mileage potential. Whether you choose the mechanical IDI or the electronic Powerstroke, ensure you perform a professional coolant analysis and oil sample test before purchasing one of these iconic Ford diesels. With proper care, either engine will likely outlast the truck it was built in.

Frequently Asked Questions

Is the 7.3 IDI or 7.3 Powerstroke more reliable?

Reliability is subjective; the IDI is more reliable in terms of simplicity because it has no sensors or computers to fail. However, the Powerstroke is professionally regarded as more reliable for long-distance towing due to its robust internal components and better heat management. Both can easily exceed 300,000 miles with proper maintenance of SCAs and oil changes.

Can I swap a 7.3 Powerstroke into an IDI truck?

While physically possible, it is not a direct bolt-in swap. The Powerstroke requires a complex wiring harness, an Engine Control Module (ECM), an IDM (Injector Driver Module), and a different fuel system. Most professional builders recommend buying a factory Powerstroke truck rather than attempting the conversion due to the extensive electronic integration required.

What does IDI stand for in the 7.3 engine?

IDI stands for Indirect Injection. In this design, fuel is injected into a small pre-combustion chamber rather than directly into the cylinder. This creates a softer combustion event, which was quieter and easier on engine components during an era when diesel technology was transitioning from industrial use to consumer pickup trucks.

Does the 7.3 IDI have a turbocharger?

Most 7.3 IDI engines produced between 1988 and 1993 were naturally aspirated (non-turbo). However, in 1993 and 1994, Ford offered a factory-turbocharged IDI version. While it improved performance, it still used the mechanical DB2 injection pump and lacked the power levels found in the later 7.3 Powerstroke direct-injection engines.

Why is the 7.3 Powerstroke so expensive today?

The 7.3 Powerstroke is highly valued for its lack of complex modern emissions equipment like EGR, DPF, or DEF. This makes it a trusted choice for those wanting a ‘forever truck’ that is relatively easy to work on compared to modern diesels, while still offering enough power to keep up with modern traffic and towing demands.