Definitive Technical Analysis: 2010 Ford F-150 Towing Capabilities, Engineering Specifications, and Performance Optimization

The 2010 Ford F-150 stands as a seminal platform in the history of light-duty trucks, representing the zenith of the twelfth-generation architecture’s reliance on the modular V8 powertrain family. As the automotive industry stood on the precipice of the EcoBoost revolution (which would arrive in 2011), the 2010 model year served as the final,

perfected iteration of the naturally aspirated, high-displacement towing philosophy. For fleet managers, heavy-duty towing operators, and automotive enthusiasts, the 2010 F-150 offers a unique case study in the application of low-end torque, rigid chassis engineering, and integrated stability control systems to achieve best-in-class capabilities.

This comprehensive research report provides an exhaustive technical breakdown of the 2010 Ford F-150’s towing infrastructure. It synthesizes data from official manufacturer towing guides, engineering specifications, and long-term reliability metrics to construct a definitive resource for understanding the vehicle’s Gross Combined Weight Rating (GCWR), Gross Vehicle Weight Rating (GVWR), and operational limits.

The analysis reveals that while the 2010 F-150 boasts a headline towing capacity of 11,300 pounds, achieving this figure requires a precise confluence of optional equipment—specifically the Max Trailer Tow Package and the Heavy-Duty Payload Package—which transforms the standard half-ton truck into a platform capable of rivaling entry-level three-quarter-ton vehicles.

2010 Ford F-150

Towing Capacity

The ultimate data-driven guide to the 2010 model year. Discover how the 5.4L Triton V8 and Heavy-Duty Payload Package unlock the legendary 11,300 lbs limit.

Under the Hood: Engine Performance

In 2010, the F-150 lineup was dominated by V8s. Before the EcoBoost era arrived in 2011, the 5.4L Triton was the king of the hill. Understanding your engine is the first step in knowing your tow limit.

Horsepower & Torque Comparison

Data Source: 2010 Ford F-150 Technical Specifications

4.6L 2V V8

The base workhorse. Reliable but limited towing capability (Max ~6,000 lbs). Found mostly in XL and STX trims.

4.6L 3V V8

A significant upgrade with 3-valve technology. Pushes horsepower to 292, offering a “sweet spot” for daily drivers who tow occasionally.

5.4L Triton V8

The towing champion. 310 HP and a massive 365 lb-ft of torque. This is the mandatory engine for reaching the 11,000+ lbs towing bracket.

Maximum Towing Capacity by Engine

Torque is nothing without the chassis to handle it. Here is the absolute maximum rating for each engine when properly equipped (Heavy Duty Payload Package & Max Tow Package).

The Axle Ratio Effect

The axle ratio is the “force multiplier” of towing. A higher number (e.g., 3.73) means the engine spins faster relative to the wheels, providing more torque for getting heavy loads moving.

- 3.15 / 3.31 Fuel economy focused. Lower tow ratings.

- 3.55 The standard balance. Good for everyday use.

- 3.73 / 4.10 Required for Max Towing.

Based on SuperCrew 5.4L V8 4×2 Configuration

SVT RAPTOR

The Off-Road Beast Exception

Introduced late in the 2010 model year, the 6.2L V8 Raptor is a powerhouse (411 HP), but it is NOT a towing machine. Its soft, long-travel Fox suspension is designed for desert running, not hauling heavy trailers.

Frequently Asked Questions

Can a 2010 F-150 tow 10,000 lbs?

Yes, but only if equipped with the 5.4L Triton V8, the 3.73 axle ratio, and the Heavy-Duty Payload/Max Tow packages. Most standard configurations tow between 7,000 and 9,000 lbs.

Where is the towing chart on the truck?

Check the white sticker on the driver’s side door jamb. It lists the GVWR and specific payload for your VIN. Never exceed the payload limit, which includes tongue weight.

Does the 4.6L V8 have good towing capacity?

The 4.6L 2-valve is limited (~6,000 lbs). The 4.6L 3-valve is much more capable, reaching up to 9,500 lbs in the right configuration, making it a solid choice for medium campers.

What is the payload capacity?

Payload varies wildly from 1,000 lbs to 3,030 lbs. Higher trim levels (Platinum, King Ranch) have heavy luxury features that reduce available payload for towing.

© 2026 FordMasterX Infographics. Data sourced from manufacturer owner manuals.

The 2010 F-150 in the Landscape of Heavy-Duty Half-Tons

The context of the 2010 model year is critical for understanding the engineering choices made by Ford Motor Company. Released in the wake of the 2008 financial crisis and amidst volatile fuel prices, the 2010 F-150 had to satisfy two divergent market demands: the need for relentless, “Built Ford Tough” capability for commercial sectors that kept the economy moving, and the growing demand for fuel efficiency and refinement from the personal-use segment.

Unlike its competitors, which were experimenting with coil-spring rear suspensions or cylinder deactivation technologies at different rates, Ford doubled down on structural rigidity and proven powertrain architectures. The 2010 F-150 utilized the fully boxed frame introduced in 2009, a hydroformed high-strength steel skeleton that provided the torsional stiffness necessary to manage heavy trailer loads without the chassis flex that plagued earlier generations.1 This structural integrity allowed engineers to tune the suspension for load-bearing capacity without sacrificing the unladen ride quality, a perennial compromise in pickup truck design.

Furthermore, the 2010 model year is significant as it predates the SAE J2807 towing standard adoption across the industry. Consequently, the towing ratings cited in this report reflect Ford’s internal durability testing standards of the era, which were notoriously rigorous but distinct from the standardized metrics used today. Understanding these ratings requires a nuanced analysis of the powertrain’s torque curves, the axle ratios’ mechanical leverage, and the chassis’ thermal management capabilities.

Powertrain Engineering: The Heart of the Tow Vehicle

The towing capability of any vehicle is fundamentally limited by its ability to generate tractive force and dissipate the heat generated during that process. The 2010 F-150 lineup was powered exclusively by the Modular Engine family, a SOHC (Single Overhead Cam) design architecture that prioritized durability and torque delivery over high-RPM horsepower.

The 5.4L 3-Valve Triton V8: The Towing Flagship

The apex predator of the 2010 lineup was the 5.4-liter (330 cubic inch) 3-Valve Triton V8. This engine is the mandatory powerplant for achieving the maximum towing capacity of 11,300 pounds.

Architectural Analysis:

The “Triton” moniker denotes a specific configuration of the modular V8 featuring a tall deck height and a long stroke (4.165 inches). This long-stroke design is crucial for towing applications. In internal combustion physics, a longer stroke increases the leverage the connecting rod exerts on the crankshaft journal, thereby increasing torque production at lower engine speeds. The 5.4L engine produces its peak torque of 365 lb-ft at a relatively low 3,500 RPM 1, allowing the vehicle to initiate movement of heavy loads without requiring excessive engine speeds that increase wear and thermal stress.

The 3-Valve Head Design:

The 2010 iteration featured aluminum cylinder heads with three valves per cylinder—two intake valves and one exhaust valve. This configuration, combined with Variable Cam Timing (VCT), allowed for optimized intake air velocity. At low RPMs, the intake charge velocity is maintained to improve mixing and torque; at higher RPMs, the dual intake valves provide sufficient volume for horsepower generation.

- Performance Metrics:

- Horsepower: 310 hp @ 5,000 RPM (Gasoline).

- Torque: 365 lb-ft @ 3,500 RPM (Gasoline).

- Flex Fuel Capability: The engine was E85 capable. When running on E85 (85% ethanol), the evaporative cooling effect of the alcohol allowed for more aggressive ignition timing, boosting output to 320 hp and 390 lb-ft of torque. For dedicated towing operators in regions with E85 availability, this fuel offered a tangible performance advantage, albeit at the cost of fuel range.

The 4.6L 3-Valve V8: The Balanced Mid-Range

Serving as the mid-tier option, the 4.6L 3-Valve V8 shared the advanced head design of its larger sibling but utilized a shorter stroke and deck height.

- Performance Metrics:

- Horsepower: 292 hp @ 5,700 RPM.

- Torque: 320 lb-ft @ 4,000 RPM.

- Towing Implications: While the horsepower figure is close to the 5.4L, the torque deficit (45 lb-ft) and the higher RPM required to access it (4,000 vs 3,500) make this engine less suited for maximum GCWR applications. It requires more frequent transmission downshifts to maintain momentum on grades, increasing thermal load. However, for loads under 8,000 lbs, it provides a compelling balance of capability and unladen fuel economy.

The 4.6L 2-Valve V8: The Legacy Workhorse

The entry-level V8, found primarily in XL trim work trucks, utilized the older 2-valve head design.

- Performance Metrics:

- Horsepower: 248 hp @ 4,750 RPM.

- Torque: 294 lb-ft @ 4,000 RPM.

- Engineering Context: This engine prioritized simplicity and fleet reliability over peak output. Its restricted airflow limited high-end power, and its pairing with the older 4-speed automatic transmission significantly handicapped its towing utility compared to the 3-valve variants.

Thermal Management Systems

Towing is an exercise in thermodynamics; the engine must convert fuel into work while shedding the immense waste heat generated by pulling heavy loads up grades. The 2010 F-150 equipped with the Trailer Tow Package (535) or Max Trailer Tow Package (53M) featured an upgraded radiator and an auxiliary transmission fluid cooler.

The auxiliary transmission cooler is particularly vital. Located in front of the A/C condenser, this heat exchanger operates in series with the radiator’s internal cooler. It utilizes airflow to reduce transmission fluid temperatures, preventing the fluid from oxidizing (burning) and ensuring the clutch packs within the transmission retain their frictional properties. For the 5.4L engine towing near its 11,300 lb limit, this cooling capacity is not merely an option but a mechanical necessity to prevent catastrophic driveline failure.

Transmission and Driveline Architecture

The transmission serves as the torque multiplier, converting engine rotation into wheel movement. The 2010 model year was pivotal as it marked the widespread adoption of 6-speed automatic transmissions in the half-ton segment.

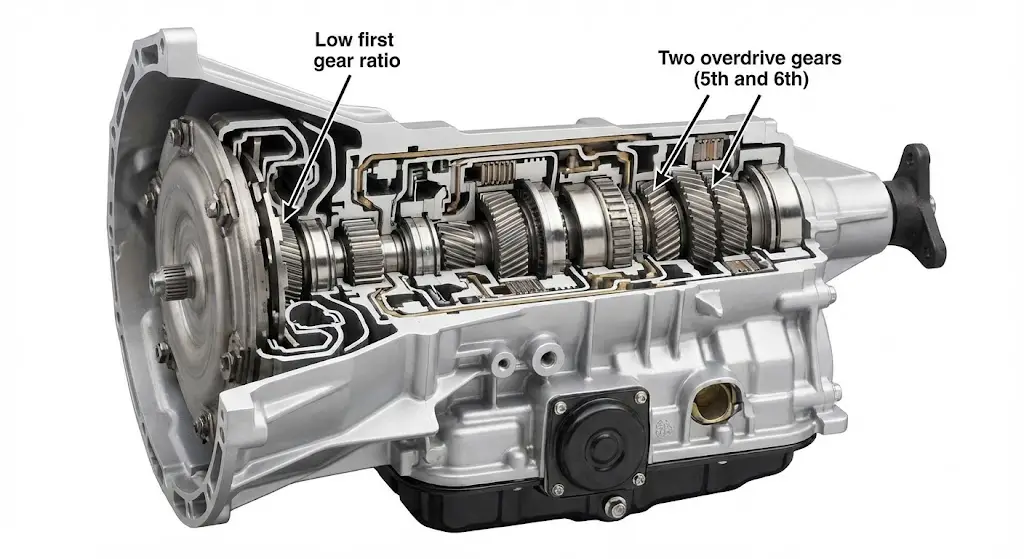

The 6R80 6-Speed Automatic Transmission

Standard with the 5.4L and 4.6L 3-Valve engines, the 6R80 transmission is a defining component of the 2010 F-150’s towing prowess. Based on a ZF design and built by Ford under license, this transmission offered a significantly wider gear ratio spread than the outgoing 4-speed units.

- First Gear Leverage: The 6R80 features a low 4.17:1 first gear ratio. This provides immense mechanical leverage for launching a heavy trailer from a standstill, reducing the strain on the torque converter and allowing the engine to quickly reach its power band.

- Double Overdrive: Gears 5 and 6 are overdrive gears (ratios less than 1:1), allowing for lower engine RPMs during highway cruising, which improves fuel economy when not under heavy load.

- Tow/Haul Mode: This software calibration alters the shift strategy. When engaged, the transmission holds lower gears longer to prevent “hunting” on inclines and aggressively downshifts when the brake pedal is tapped to provide engine braking—using engine compression to slow the vehicle and save the service brakes.

The 4R75E 4-Speed Automatic Transmission

Paired exclusively with the 4.6L 2-Valve engine, the 4R75E was a legacy unit. Its wide gaps between gears meant that the engine often had to operate outside its optimal RPM range during towing. For example, a downshift from 4th to 2nd on a steep hill might result in excessive RPMs, whereas the 6-speed could drop from 6th to 5th or 4th, maintaining optimal torque delivery.

Differential Gearing and Axle Ratios

The final drive ratio in the rear differential acts as the last torque multiplier in the drivetrain. The 2010 F-150 offered a spectrum of axle ratios, each dictating the truck’s personality.

- 3.15 and 3.31: Tailored for fuel economy. These “tall” gears reduce engine RPM at highway speeds but significantly reduce the torque available at the wheels. Consequently, trucks with these axles have the lowest tow ratings, often capped below 8,000 lbs.

- 3.55: The general-purpose ratio. It strikes a compromise, suitable for towing moderate loads (boats, small campers) while maintaining respectable unladen efficiency.

- 3.73: The towing standard. Required for the Max Trailer Tow Package ratings. The “short” gearing increases torque at the wheels by approximately 5% over the 3.55, crucial for moving the full 11,300 lb rating.

- 4.10: Typically reserved for the SVT Raptor or FX4 trims, this ratio provides extreme acceleration and crawling capability but limits top-speed efficiency.

Electronic Locking Rear Differential (E-Locker):

Available on FX4 and Max Tow equipped trucks, the E-Locker (Axle Code L6) allows the driver to mechanically lock the rear axle shafts together. This ensures that both rear wheels turn at the same speed, providing maximum traction on slippery boat ramps or muddy jobsites—a critical feature for extracting a heavy trailer from low-traction environments.7

Chassis and Structural Dynamics

The “Built Ford Tough” slogan rests on the foundation of the truck’s chassis. The 2010 F-150 utilizes a fully boxed frame constructed from hydroformed high-strength steel.

Hydroformed Frame Technology

Prior to 2009, many trucks used C-channel rails in the rear of the frame. C-channels are open on one side, allowing for significant torsional flex. While this flex can improve ride quality on uneven terrain, it is detrimental to towing stability.

- The Boxed Advantage: The 2010 F-150’s boxed rails (closed on all four sides) resist twisting forces. When a 30-foot travel trailer is hit by a crosswind, it exerts a lateral torque on the truck’s hitch. A flexible frame acts as an undamped spring, storing and releasing this energy in the form of sway. The rigid boxed frame of the 2010 model transmits these forces directly to the suspension, where the springs and shock absorbers can effectively manage them.

Suspension Geometry

- Front Suspension: Independent double-wishbone coil-over-shock. This setup separates steering forces from suspension loads, providing the precise steering input required to make micro-corrections during towing.

- Rear Suspension: Hotchkiss-type live axle with leaf springs. Crucially, the 2010 F-150 features outboard-mounted shock absorbers. By moving the shock mounting points outside the frame rails (closer to the wheels), engineers increased the mechanical advantage of the dampers. This effectively controls “axle wrap” (the axle twisting under torque) and body roll, providing a planted feel even with high-center-of-gravity loads.

Braking Systems

Stopping power is as important as pulling power. The 2010 F-150 features 4-wheel vented disc brakes with large rotors.

- Thermal Capacity: The venting helps dissipate the immense heat generated when braking a combined load of 16,000+ lbs (truck + trailer).

- ABS Integration: The Anti-lock Braking System is integrated with the Trailer Sway Control software, allowing the truck to pulse individual brakes to counteract trailer oscillation.

Decoding the Towing Packages

To the untrained eye, two F-150s may look identical, but their towing capabilities can differ by over 4,000 pounds based on the installed packages. Identifying these packages via option codes or physical inspection is essential.

Standard Towing Equipment

Every 2010 F-150 includes basic wiring provisions. However, without a specific tow package, the vehicle is limited to 5,000 lbs towing capacity (bumper pull) and lacks the auxiliary cooling necessary for longevity.

Trailer Tow Package (Option Code 535)

This is the baseline requirement for serious towing.

- Includes: Class IV hitch receiver, 7-pin/4-pin wiring harness, auxiliary transmission oil cooler, and upgraded radiator.

- Capability: Enables towing up to the rated capacity of the standard axle/engine combination (typically 8,000–9,800 lbs).

Max Trailer Tow Package (Option Code 53M)

Available only with the 5.4L engine, this package is engineered for the upper limits of the half-ton class.

- Key Upgrades:

- Upgraded Rear Bumper: Reinforced structure to handle higher static tongue weights.

- Class IV Receiver: Rated for higher weight distribution limits.

- Integrated Trailer Brake Controller (TBC): A factory-installed unit that provides smoother, proportional braking compared to aftermarket time-delay controllers.

- Telescoping Tow Mirrors: Large mirrors with convex spotters to cover the blind spots created by wide trailers.

- Performance: This package is mandatory to unlock tow ratings above 10,000 lbs and GCWRs up to 17,100 lbs.

Heavy-Duty Payload Package (Option Code 627)

This package is the “unicorn” of the F-150 lineup, transforming the truck into a heavy hauler.

- Visual Identifier: 7-Lug Wheels. Standard F-150s have 6 lugs. The HD Payload package uses 7 lugs to secure the heavy-duty wheels to the upgraded axle.

- Structural Upgrades:

- LT245/75R17E Load Range E tires (stiffer sidewalls for load support).

- Heavy-duty shock absorbers and springs.

- Thicker frame rail gauge in high-stress areas.

- 9.75-inch gear set with 3.73 Limited Slip axle.

- Capacity Boost: Increases GVWR to 8,200 lbs (vs ~7,200 standard). This provides the massive payload capacity (up to 3,030 lbs) needed to handle the heavy tongue weights of fifth-wheels or large travel trailers.

Comprehensive Analysis of Towing Capacities

The following data sets are reconstructed from the 2010 Ford RV & Trailer Towing Guide. These figures represent the maximum allowable weights. Real-world capacity is often lower due to vehicle options and passenger weight.

- Note: All towing capacities over 5,000 lbs require a Weight Distributing Hitch.

Conventional Towing Matrix (Bumper/Receiver)

5.4L 3-Valve V8 Conventional Towing Capabilities

| Cab Style | Drive | Wheelbase (in) | Axle Ratio | GCWR (lbs) | Max Trailer Wt (lbs) | Requirement/Notes |

| Regular Cab | 4×2 | 126 | 3.15 | 13,200 | 8,400 | |

| 126 | 3.31 | 13,000 | 8,000 | |||

| 126 | 3.55 | 15,000 | 9,800 | |||

| 126 | 3.73 | 15,000 | 9,800 | |||

| 145 | 3.73 | 17,100 | 11,300 | Requires HD Payload Pkg & Max Tow Pkg | ||

| SuperCrew | 4×2 | 145 | 3.15 | 13,200 | 8,000 | |

| 145 | 3.55 | 15,000 | 9,800 | |||

| 145 | 3.73 | 17,100 | 11,300 | Requires Max Tow Pkg | ||

| 4×4 | 145 | 3.31 | 13,200 | 7,700 | ||

| 145 | 3.55 | 15,100 | 9,600 | |||

| 145 | 3.73 | 17,100 | 11,200 | Requires Max Tow Pkg | ||

| SuperCab | 4×4 | 145 | 3.73 | 15,200 | 9,300 | |

| 163 | 3.73 | 17,100 | 11,100 | Requires HD Payload Pkg & Max Tow Pkg |

Interpretation:

The data illustrates the profound impact of axle gearing. For a SuperCrew 4×4, switching from a 3.31 axle to a 3.73 axle (with the Max Tow package) increases towing capacity from 7,700 lbs to 11,200 lbs—a 45% increase. This underscores that engine displacement alone does not dictate capacity; mechanical advantage is equally critical.

4.6L 3-Valve V8 Conventional Towing Capabilities

| Cab Style | Drive | Axle Ratio | GCWR (lbs) | Max Trailer Wt (lbs) |

| Regular Cab | 4×2 | 3.15 | 11,900 | 7,200 |

| 3.73 | 14,000 | 9,400 | ||

| SuperCrew | 4×4 | 3.55 | 14,100 | 8,900 |

| 3.73 | 14,500 | 9,300 |

While the 4.6L 3V is a competent engine, its lower GCWR limits restrict the amount of cargo that can be carried in the truck while towing near the limit.

Fifth-Wheel and Gooseneck Capabilities

Fifth-wheel towing offers superior stability by placing the trailer’s pivot point directly over the rear axle. However, the 2010 F-150 presents specific geometric challenges.

The Short Bed Dilemma (5.5ft Box):

Many SuperCrew models are equipped with the 5.5-foot bed. Ford and aftermarket manufacturers urge extreme caution here. The short distance between the cab and the rear axle means that during a 90-degree turn (such as backing into a campsite), the nose of a fifth-wheel trailer is highly likely to impact the truck’s cab structure (C-pillar).

- The Solution: Towing a fifth wheel with a 5.5ft bed requires a Sidewinder pin box (which moves the pivot point back) or an Auto-Slider Hitch (which automatically slides the hitch rearward during turns).10 Without these specialized (and heavy) hitches, the 5.5ft bed is functionally incompatible with fifth-wheel towing.

Weight Limits:

Fifth-wheel trailers typically have a pin weight of 15-25% of the trailer’s total weight (vs 10-15% for conventional trailers).

- Example: A 10,000 lb fifth wheel has a pin weight of ~2,000 lbs.

- Limitation: A standard F-150 Lariat SuperCrew may only have 1,400 lbs of available payload. Thus, it is impossible to tow this trailer legally, despite the 11,000+ lb “tow rating.”

- The HD Payload Necessity: Only the Heavy-Duty Payload Package (Option 627) with its 8,200 lb GVWR prvides the necessary payload buffer (2,000-3,000 lbs) to accommodate true fifth-wheel pin weights.

Payload: The Governing Variable

In the real world, 90% of half-ton trucks will run out of payload capacity long before they reach their maximum towing capacity. Understanding this distinction is vital for safety and legal compliance.

GVWR vs. Payload

- GVWR (Gross Vehicle Weight Rating): The maximum allowable weight of the truck, including fuel, passengers, cargo, and trailer tongue weight.

- Curb Weight: The actual weight of the empty truck.

- Payload Formula: Payload = GVWR – Curb Weight.

The Impact of Trim Levels

Luxury features add mass. A panoramic sunroof, power running boards, heated leather seats, and premium sound systems all increase the curb weight, thereby decreasing payload.

- Scenario: An XL Regular Cab (low curb weight) might have a payload of 2,000 lbs. A Platinum SuperCrew 4×4 (high curb weight) might have a payload of only 1,250 lbs.

- Implication: If you have a travel trailer with a 1,000 lb tongue weight, the XL has 1,000 lbs left for driver and gear. The Platinum has only 250 lbs left—barely enough for the driver. Towing any passengers or gear in the Platinum would exceed the GVWR, rendering the setup illegal.12

Operational Dynamics and Safety Technologies

The 2010 F-150 introduced active safety technologies that fundamentally changed the towing experience.

Trailer Sway Control (TSC)

Standard on all 2010 models, TSC is a software extension of the AdvanceTrac® Roll Stability Control (RSC®) system.

- Mechanism: The system utilizes gyroscopic sensors to detect yaw (rotational movement) that doesn’t match steering input. If it detects the rhythmic oscillation characteristic of trailer sway, it acts immediately.

- Action: It applies braking force to individual wheels (e.g., left front, then right front) to counter the sway forces and simultaneously cuts engine torque.

- Significance: This is a reactive system. It does not replace a proper weight distribution hitch with sway control, but it serves as a critical safety net of last resort to prevent jackknifing.

Integrated Trailer Brake Controller (TBC)

Included in the Max Tow Package, this device represented a quantum leap over aftermarket “pod” controllers.

- Hydraulic Integration: Unlike aftermarket controllers that use inertia accelerometers (which can be tricked by road bumps), the Ford TBC reads the hydraulic pressure in the truck’s master cylinder.

- Proportionality: The harder the driver presses the brake pedal, the more voltage is instantly sent to the trailer brakes. This eliminates the “push-pull” sensation and allows for smooth, confident stops, even in panic situations.2

Tow/Haul Mode

The Tow/Haul button on the shift lever is not a gimmick; it fundamentally re-maps the transmission strategy.

- Upshifts: It holds gears longer, allowing the engine to rev higher before shifting, ensuring the truck doesn’t bog down after a shift.

- Downshifts: It aggressively downshifts when decelerating to utilize engine compression braking.

- Lock-up: It locks the torque converter clutch in lower gears to reduce heat generation and provide a direct mechanical connection between the engine and wheels.2

Maintenance and Reliability for High-Duty Cycles

Towing places “severe duty” stress on the vehicle. Owners utilizing the 2010 F-150 for regular towing must adhere to accelerated maintenance schedules to preserve the 5.4L powertrain.

5.4L Triton Specifics

- Cam Phasers: The 3-valve engine uses oil pressure to adjust cam timing. Dirty or degraded oil can cause the phaser solenoids to stick or the phasers themselves to fail (manifesting as a diesel-like rattle). Recommendation: Change oil every 3,000-5,000 miles using high-quality 5W-20 synthetic, especially when towing.13

- Spark Plugs: While the 2010 model utilizes an updated cylinder head design that largely mitigated the “broken plug” issue of earlier years, plug changes can still be difficult. It is recommended to change plugs every 60,000 miles to prevent seizing.

- Exhaust Manifolds: High exhaust gas temperatures (EGTs) from towing can cause the exhaust manifolds to warp or the mounting studs to shear, creating an exhaust leak (ticking sound). This is a common failure point on work trucks.13

Transmission and Driveline Care

- Fluid Intervals: The 6R80 transmission fluid is officially “filled for life” for normal use, but for towing, it should be changed every 30,000 to 60,000 miles. Heat degrades the fluid’s frictional modifiers, which can lead to torque converter shudder.

- Rear Differential: Limited Slip (LSD) differentials utilize clutch packs that wear over time. If the rear end begins to “chatter” during turns, the fluid requires changing with the addition of a friction modifier additive.

Aftermarket Considerations and Hitching

Weight Distribution Hitches (WDH)

Ford specifies that any trailer over 5,000 lbs requires a weight distribution hitch.

- Physics: A heavy tongue weight lifts the front of the truck, reducing steering traction and braking effectiveness. A WDH uses spring bars to leverage that weight, transferring it back to the truck’s front axle and the trailer’s axles.

- Compliance: Towing 8,000 lbs on the bumper without a WDH is not only unsafe; it violates the hitch receiver’s rating (usually 5,000 lbs weight-carrying / 10,500 lbs weight-distributing).

Tires

Standard F-150s come with P-metric (Passenger) tires. These have flexible sidewalls for ride comfort. For heavy towing, upgrading to LT-metric (Light Truck) Load Range E tires (standard on the HD Payload package) is highly recommended. The stiffer sidewalls reduce squirm and sway, providing a much more stable towing platform.

Conclusion

The 2010 Ford F-150 represents a high-water mark for the modular V8 era. It combines the raw, low-end torque of the 5.4L Triton with a chassis architecture that was arguably over-engineered for its time. With a properly equipped configuration—specifically the 5.4L V8, 3.73 Axle Ratio, Max Tow Package, and Heavy-Duty Payload Package—it offers a towing capacity of 11,300 lbs and a payload of over 3,000 lbs, figures that remain competitive even against modern trucks.

However, the “11,300 lb” figure is not a blanket capability. It is a specific ceiling achievable only by a narrowly defined configuration. The vast majority of 2010 F-150s on the road are rated for significantly less (typically 7,000–9,000 lbs). For the prospective buyer or operator, the safety and legality of the tow depend entirely on reading the door jamb stickers and understanding the interplay of GVWR, Axle Code, and Payload. When respected and maintained, the 2010 F-150 is a formidable towing machine, embodying the durability that defined the “Built Ford Tough” era.