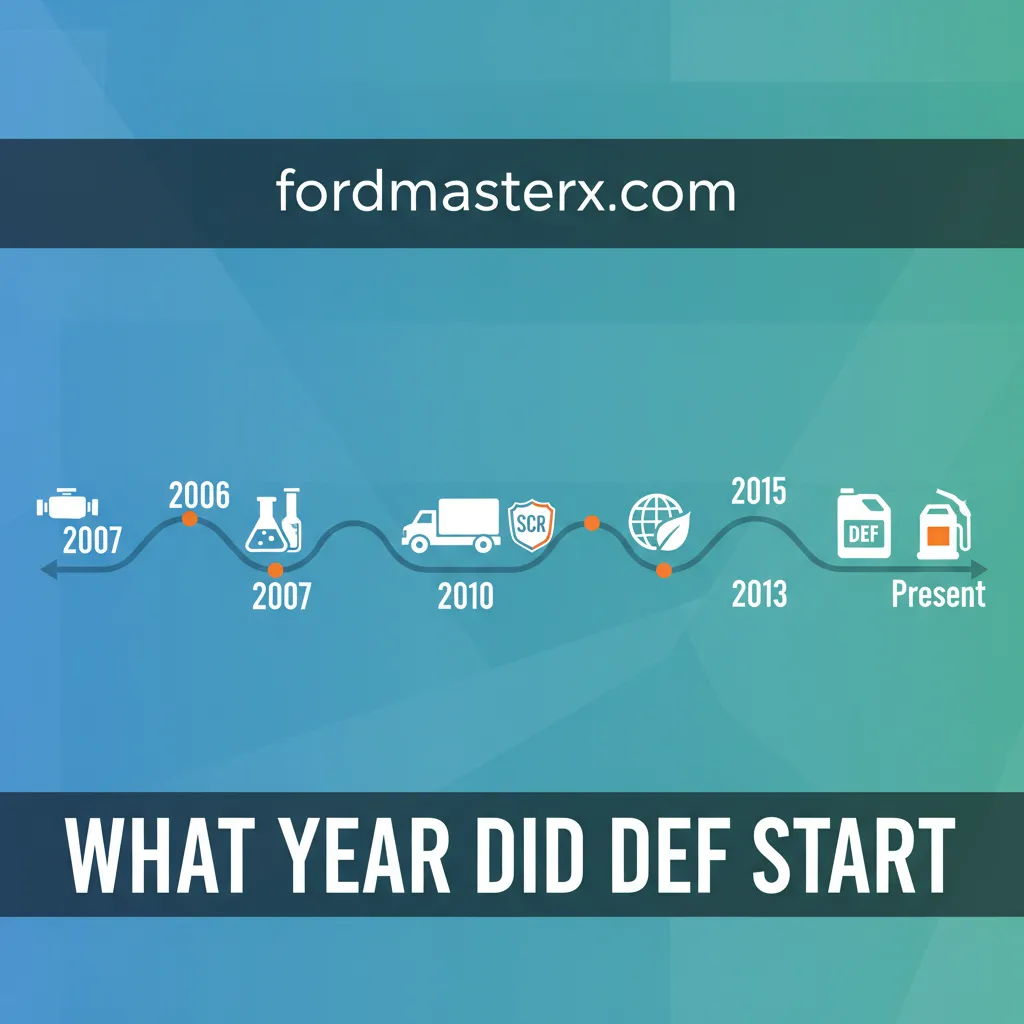

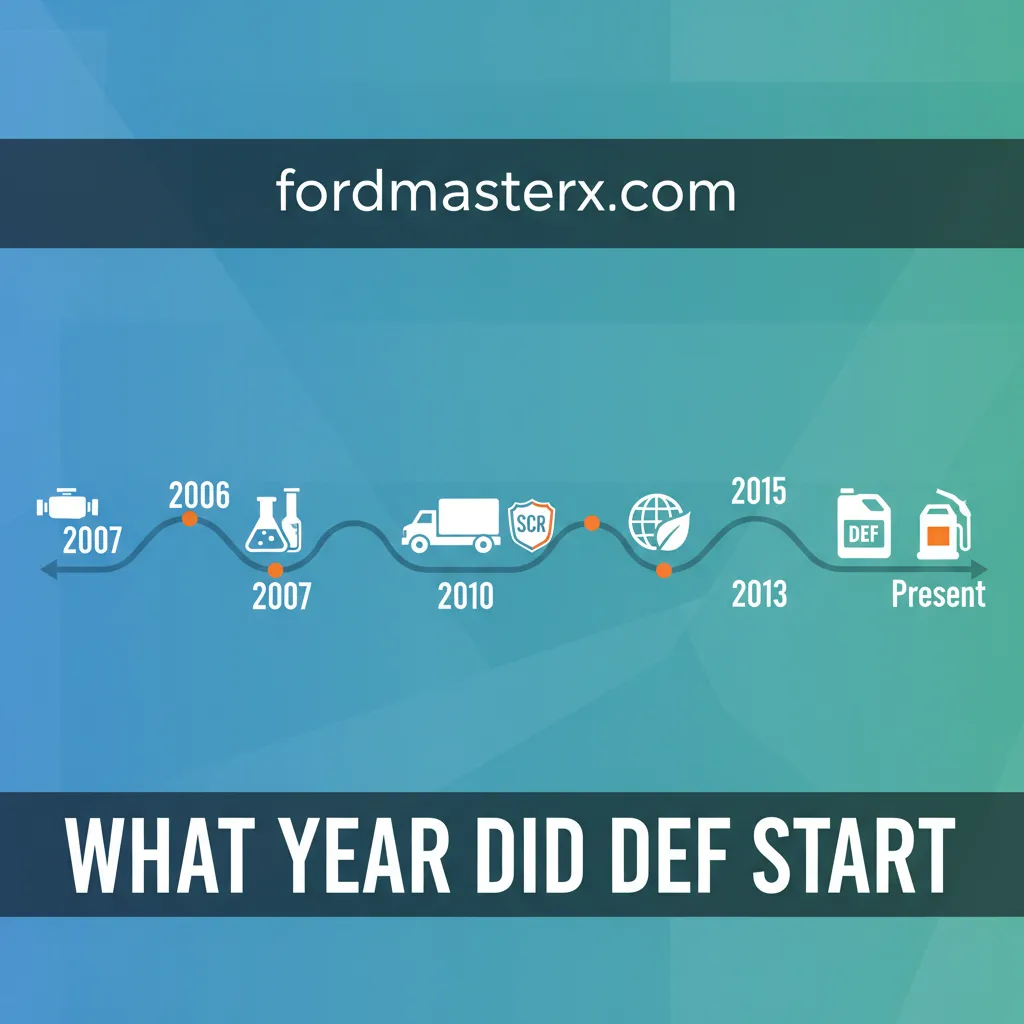

What Year Did Def Start? Timeline Of Diesel Exhaust Fluid And Scr Regulations

In the world of modern diesel engineering, the year 2010 stands as a definitive turning point that fundamentally changed the chemical composition of vehicle exhaust. While many operators recognize the DEF tank on their equipment, there remains significant confusion regarding exactly when these regulations began and why the technology was mandated. This expert analysis will detail the 2010 regulatory shift, the technical implementation of SCR technology, and the global standards that ensure the reliability of Diesel Exhaust Fluid today. By understanding this timeline, professionals can better manage their fleets and appreciate the comprehensive engineering required to meet today’s environmental benchmarks.

The Regulatory Genesis of Diesel Exhaust Fluid and EPA 2010 Standards

📤 Share Image

The implementation of DEF was not a voluntary innovation by manufacturers but a necessary response to the Environmental Protection Agency (EPA) Clean Air Act amendments. To understand the 2010 shift, one must first look at the “stepping stone” of 2007. The EPA 2007 standards primarily focused on Particulate Matter (PM), leading to the widespread adoption of Diesel Particulate Filters (DPF). However, the EPA 2010 mandate set its sights on Nitrogen Oxide (NOx), a major contributor to smog and acid rain.

The EPA 2010 standard was remarkably stringent, requiring NOx levels to drop to 0.20 grams per brake horsepower-hour (g/bhp-hr). To put this in perspective, this represented a staggering 90% reduction from the 2007 limits. For engine designers, reaching these levels through internal engine modifications alone—such as Exhaust Gas Recirculation (EGR)—became physically and thermodynamically impractical. Excessive EGR usage led to higher engine temperatures, decreased fuel efficiency, and increased engine wear due to soot loading in the oil.

The “Big Three” and the 2010 Model Year Shift

The transition of the ‘Big Three’ heavy-duty truck manufacturers (Ford, GM, and Ram) marked the definitive commercial debut for DEF-dependent vehicles. Between 2010 and 2011, these manufacturers moved away from EGR-only solutions.

- Ford: Introduced the 6.7L Power Stroke in 2011, which utilized SCR and DEF from its inception.

- GM: Updated the Duramax 6.6L (LML) in 2011 to include SCR technology.

- Ram: While chassis cab models adopted SCR in 2010, the 2500/3500 pickups followed suit shortly after, ensuring the entire heavy-duty lineup met the 0.20 g/bhp-hr NOx target.

This move allowed the engines to be tuned for better combustion efficiency, effectively “offloading” the emissions cleanup to the exhaust system rather than choking the engine with its own spent gases.

By The Numbers: EPA 2010 Impact

Reduction in NOx from 2007

g/bhp-hr NOx Limit

Fuel Economy Improvement

How Selective Catalytic Reduction (SCR) Integration Defined the DEF Launch

The debut of DEF was synonymous with the integration of Selective Catalytic Reduction (SCR). This is an active after-treatment system where DEF—a trusted mixture of high-purity urea and deionized water—is injected into the exhaust stream. When this fluid meets the hot exhaust gases, it decomposes into ammonia (NH3). Inside the SCR catalyst, the ammonia reacts with NOx to convert it into nitrogen (N2) and water vapor (H2O), both of which are harmless components of the air we breathe.

Manufacturers faced a significant choice: continue with high-rate EGR or adopt SCR. The professional consensus quickly shifted toward SCR. Despite the added complexity of a secondary fluid tank, dosing valves, and sensors, SCR allowed the engine to operate in a more efficient “sweet spot.” By reducing the amount of EGR, engines ran cooler, experienced fewer oil contamination issues, and saw a 3-5% increase in fuel economy compared to previous EGR-only systems.

Early Adoption: The Case of Daimler Trucks

Daimler Trucks North America (Freightliner) was a pioneer in this space, being among the first to successfully integrate BlueTec SCR technology in 2010. Their expert engineering proved that while the “secondary tank” was a hurdle for driver acceptance, the long-term mechanical benefits and reliable performance outweighed the inconvenience of refilling the fluid. However, this launch required the rapid establishment of a distribution infrastructure to ensure DEF was available at every major truck stop in the country.

The success of the 2010 rollout relied on the professional calibration between the Engine Control Unit (ECU) and the dosing valve. If the ECU injects too much DEF, it can lead to “ammonia slip” or crystallization; too little, and the vehicle fails its emissions targets, often resulting in an immediate “de-rate” or limp mode.

The Global Context: Euro V Standards and International ISO 22241 Quality Benchmarks

While 2010 was the benchmark for North America, the comprehensive history of DEF begins earlier in Europe. Under the Euro IV and Euro V standards, European manufacturers had already begun utilizing a urea solution branded as AdBlue as early as 2005-2006. The North American “DEF” and European “AdBlue” are chemically identical, but the branding differs due to trademarking by the German Association of the Automotive Industry (VDA).

To ensure the complete success of this global rollout, the industry established the ISO 22241 standard. This is the expert-defined benchmark that dictates the exact composition of DEF. Without this international standard, the sensitive SCR catalysts would be prone to “poisoning” from impurities.

- Composition: Exactly 32.5% high-purity urea and 67.5% deionized water.

- Precision: The 32.5% concentration is the “eutectic point,” providing the lowest possible freezing point for the solution.

- Quality Control: ISO 22241-1 through ISO 22241-4 covers everything from chemical specs to handling and storage procedures.

Evolution to Tier 4 Final: DEF Expansion into Off-Road and Agricultural Machinery

Following the 2010 highway mandate, the regulatory focus shifted to non-road diesel engines. This transition was categorized under “Tier” standards. While Tier 4 Interim (starting in 2011) saw some DEF adoption, it was the Tier 4 Final regulations in 2014 that truly solidified DEF as the industry standard for construction and agriculture.

Industry giants like Caterpillar, John Deere, and Case IH had to integrate SCR systems into mid-sized and large machinery (typically the 75-175 hp range and above). This presented unique logistical challenges. Unlike highway trucks that visit centralized fuel stations, a combine harvester or an excavator may remain on a remote job site for weeks. This necessitated a professional-grade approach to bulk DEF storage and transport to maintain a reliable supply in the field.

The Introduction of “Inducements”

To ensure compliance, the EPA mandated “inducements”—commonly known as limp mode. If a machine runs out of DEF or if the sensors detect fluid that does not meet quality standards, the ECU will progressively de-rate the engine’s power. In extreme cases, the machine may be limited to idle speed only. This expert design ensures that the vehicle cannot be operated without functional emissions controls, protecting the environment but requiring trusted fluid management from the operator.

Off-Road Integration

By 2014, almost all diesel engines over 75hp required DEF to meet Tier 4 Final standards.

Emissions Targets

Tier 4 Final achieved a 90% reduction in PM and NOx compared to Tier 3 levels.

Maintaining System Integrity: Expert Best Practices for DEF Handling

As an industry veteran, I have seen more SCR failures caused by poor handling than by mechanical defects. Maintaining the integrity of your DEF system is paramount for long-term reliability. Because the SCR catalyst is highly sensitive, any contamination can lead to repairs costing upwards of $5,000–$10,000.

📋

Professional Handling Guide

Always look for the API (American Petroleum Institute) Certification Mark or ISO 22241 compliance on the packaging. This ensures the fluid is not “home-brewed.”

DEF has a shelf life of 12-36 months. However, it degrades rapidly if stored above 86°F (30°C). Avoid leaving jugs in direct sunlight.

Never reuse funnels or containers that have touched oil, fuel, or coolant. Even a teaspoon of motor oil can ruin an entire tank of DEF.

A common pitfall is attempting to dilute DEF or clean the system with tap water. Tap water contains minerals (calcium, magnesium) that will permanently coat the SCR catalyst, rendering it useless. Only deionized water—already found in certified DEF—should ever be in that system.

Operational Considerations: Freezing and Filtration

One technical nuance often misunderstood is DEF’s behavior in cold weather. DEF freezes at 12°F (-11°C). However, SCR systems are professionally designed with heating elements in the tank and lines. The ECU allows the engine to start and run without DEF for a short period until the heaters melt enough fluid for dosing. Expert recommendation: Always check your DEF dosing filter during annual maintenance; a clogged filter can cause pump failure and system fault codes.

DEF became a commercial reality in North America in 2010 following EPA mandates for a 90% reduction in NOx emissions. The technology relies on SCR systems and high-purity ISO 22241 certified fluid to maintain environmental and mechanical integrity. Modern diesel performance is inextricably linked to the professional handling and storage of quality DEF. For fleet managers and owner-operators, maintaining a reliable supply of certified Diesel Exhaust Fluid is essential for maximizing uptime and protecting your investment in modern diesel technology. By staying committed to expert maintenance standards and using only trusted, certified fluid, you ensure your equipment remains efficient and compliant for years to come.

Frequently Asked Questions

Was DEF required before 2010?

In North America, DEF was not a standard requirement for highway diesel engines until the EPA 2010 regulations took effect. However, European markets adopted similar technology earlier, starting around 2005 under Euro IV and V standards. Before 2010, US manufacturers primarily relied on Exhaust Gas Recirculation (EGR) and Diesel Particulate Filters (DPF) to meet less stringent emissions targets.

What happens if I run out of DEF while driving?

Modern SCR systems are professionally programmed with an ‘inducement’ strategy. If the DEF tank is empty, the engine control unit will initially provide warnings, followed by a reduction in engine speed and power (limp mode). Eventually, the vehicle may be restricted to speeds as low as 5 mph to ensure emissions compliance, requiring an immediate refill of quality fluid to restore full performance.

Does Diesel Exhaust Fluid have an expiration date?

Yes, DEF is a perishable product. When stored in ideal conditions (between 23°F and 68°F), it can remain stable for up to two years. However, exposure to direct sunlight or temperatures consistently above 86°F can reduce its shelf life to approximately six months. To ensure a reliable system, always source fluid from a trusted supplier and check for an expiration or batch date.

Can I use water instead of DEF in an emergency?

Absolutely not. Using water or a low-quality urea solution will trigger immediate sensor faults and can cause permanent damage to the SCR catalyst. The SCR system requires the precise 32.5% concentration of high-purity urea defined by ISO 22241. Water does not have the chemical properties to reduce NOx, and minerals in tap water will contaminate the expensive catalyst components.

Is DEF toxic or hazardous to handle?

DEF is a non-toxic, non-flammable, and non-hazardous solution consisting of synthetic urea and deionized water. While it is safe to handle, it is corrosive to certain metals like copper, brass, and aluminum. It is expert practice to rinse any spills on vehicle paint or skin with water immediately to prevent white salt crystals from forming as the water evaporates.