Symptoms Of A Bad Timing Chain: Identification, Diagnostic Codes, And Mechanical Warning Signs

For any high-performance internal combustion engine, precision is the difference between reliable power and catastrophic mechanical failure. The timing chain serves as the mechanical heartbeat of your vehicle, ensuring that every valve opens and closes in perfect harmony with the movement of the pistons. When a timing chain begins to stretch or its guides deteriorate, the delicate synchronization of your engine is compromised, leading to poor performance, increased emissions, or total engine destruction. In this comprehensive guide, we will detail the auditory, visual, and electronic symptoms of a bad timing chain to help you identify issues before they necessitate an expensive engine replacement.

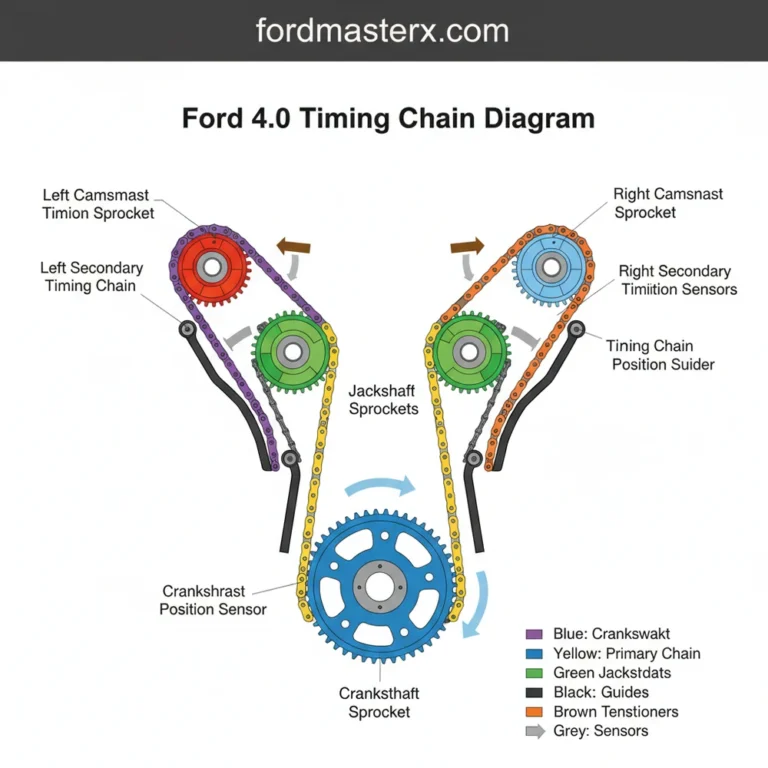

Understanding the Role of the Timing Chain in Internal Combustion Engines

📤 Share Image

The timing chain is a critical mechanical link that synchronizes the rotation of the crankshaft and the camshaft(s). This synchronization ensures that the engine’s intake and exhaust valves open and close at precise intervals during each cylinder’s intake and exhaust strokes. In a modern high-performance engine, such as a 3.5L V6 engine, the timing chain must manage complex geometry, often navigating multiple pulleys to maintain exact timing across dual overhead cams (DOHC). Even a fractional deviation in this timing can result in a significant loss of volumetric efficiency.

Mechanical Composition and Geometry

Most automotive manufacturers utilize either high-tensile steel roller chains or “silent” inverted-tooth chains. While roller chains are incredibly durable, silent chains are preferred in many luxury applications for their reduced harmonic resonance. These systems rely on hydraulic tensioners—which use engine oil pressure to maintain tension—and plastic or nylon-composite guides to direct the chain’s path. As the engine reaches operating temperature, thermal expansion occurs; the tensioning system is designed to compensate for this while preventing any slack that could lead to “whipping” or tooth-jumping.

Timing Chain vs. Timing Belt

Unlike rubber-composite timing belts, which are dry systems, the timing chain is fully lubricated by engine oil and resides behind a sealed timing cover. This makes maintaining consistent oil pressure and quality lubrication non-negotiable. In Variable Valve Timing (VVT) systems, the timing chain is the foundation upon which the phasers adjust cam timing. If the chain loses its structural integrity, the VVT system cannot function within its calibrated parameters.

By The Numbers

Standard Service Life (Miles)

Stretch Threshold for DTCs

Interference Engine Ratio

Common Auditory Symptoms of a Bad Timing Chain and Mechanical Slack

Sound is often the first warning a technician receives regarding timing component degradation. In my expert experience, the human ear is one of the most effective diagnostic tools for early detection. However, timing chain noises are frequently nuanced and require a professional understanding of engine harmonics to distinguish from other mechanical failures.

The ‘Cold Start Rattle’

The most classic symptom of a failing timing system is a harsh metallic clatter that occurs immediately after ignition and lasts for approximately 2 to 5 seconds. This occurs because the hydraulic tensioner has bled down or the chain has stretched to a point where the tensioner cannot immediately take up the slack until oil pressure reaches its peak. This “death rattle” is a clear indicator that the chain is physically slapping against the timing cover or the guides.

Continuous Slapping and Ticking

As the wear progresses, the noise may transition from a start-up rattle to a continuous ticking or slapping sound that increases in frequency with engine RPM. Unlike a lifter tick—which is typically light and rhythmic—timing chain noise is often heavier and more chaotic. Imagine the sound of “marbles in a tin can”; this is the sound of a chain that has lost its tension, frequently reported in high-mileage luxury sedans with sophisticated hydraulic systems.

Studies show that up to 40% of timing chain noises are initially misdiagnosed as accessory drive belt or pulley issues. To isolate the noise, a trusted technician will briefly remove the serpentine belt to see if the rattle persists. If it does, the source is internal.

Engine Performance Indicators and Visual Warning Signs in the Lubrication System

Beyond acoustics, a deteriorating timing chain will manifest in physical symptoms within the engine’s fluids and its operational output. When a chain stretches—even by as little as 0.5%—the relationship between the crankshaft and camshaft becomes “retarded.” This slight delay in valve opening significantly impacts the combustion cycle.

Debris in the Oil and Filtration System

During routine maintenance, a complete inspection of the oil filter can reveal the health of the timing system. A failing chain will often shave off microscopic bits of the metal timing cover or the chain links themselves, appearing as fine “glitter” or metal shavings in the oil pan. Furthermore, finding shards of plastic or nylon in the oil pickup tube is a definitive sign that the timing chain guides have shattered under the impact of a loose chain.

Performance Degradation and Misfires

Because the Engine Control Module (ECM) relies on exact sensor data to time the spark and fuel injection, a stretched chain causes the timing to drift outside of acceptable parameters. Common performance symptoms include:

- Rough Idling: The camshaft position sensor detects the out-of-sync rotation, causing the engine to struggle to find a steady idle speed.

- Reduced Fuel Efficiency: Inefficient valve timing prevents the engine from extracting maximum energy from the fuel-air mixture.

- Engine Stalling: In severe cases of slack, the ECM may shut down the engine to prevent catastrophic interference if the correlation between sensors becomes too erratic.

Reliable Power

Precise timing ensures optimal compression and power delivery across the entire RPM range.

System Longevity

Properly tensioned chains prevent wear on camshaft phasers and sensitive VVT solenoids.

Interpreting Diagnostic Trouble Codes (DTCs) Related to Timing Inaccuracy

Modern vehicles are equipped with sophisticated onboard diagnostics that monitor the phase relationship between the crankshaft and camshaft sensors. When the timing chain stretches, the physical position of the camshaft lags behind the crankshaft. The ECM detects this “phase shift” and triggers specific reliable fault codes.

The Critical P0016 and P0011 Codes

The P0016 code (Crankshaft Position – Camshaft Position Correlation) is arguably the most definitive electronic indicator of a mechanical timing issue. While a P0011 code might point toward a VVT solenoid or oil flow issue, P0016 specifically tells the technician that the two sensors are not “seeing” the expected tooth count on their respective wheels at the same moment. The ECM uses ‘look-up tables’ programmed during manufacturing to determine if the timing is within trusted tolerances; once those tolerances are exceeded, the Check Engine Light is illuminated.

📋

Professional Diagnostic Workflow

Connect a professional-grade scanner to check for P0016, P0017, or P0300 (Random Misfire) codes.

Use a dual-trace scope to visualize the square waves of the CKP and CMP sensors. A 10-degree phase shift on the screen confirms mechanical chain stretch.

Live Data Monitoring

By monitoring “live data” streams, an expert technician can observe “camshaft desired” vs. “camshaft actual” angles. If the “actual” angle cannot meet the “desired” setpoint despite full VVT solenoid duty cycle, the mechanical integrity of the chain or its guides is almost certainly the culprit.

The Risks of Ignoring Symptoms in Interference vs. Non-Interference Engines

The urgency of timing chain repair cannot be overstated, particularly in modern engine designs. To understand the risk, one must understand the “interference” engine design. In these engines, the space occupied by an open valve overlaps with the space occupied by the piston at the top of its stroke. The only thing preventing a collision is the timing chain.

Catastrophic Failure Consequences

If a timing chain snaps or “jumps a tooth” under load, the valves will remain open as the piston travels upward at thousands of revolutions per minute. The resulting impact causes bent valves, shattered piston crowns, and often, a cracked cylinder head. In a recent case study, a driver ignored a persistent rattle in their high-performance SUV; the chain eventually failed at highway speeds, leading to a total engine loss and a repair bill exceeding $10,000.

Over 70% of modern production engines are interference designs. While a timing chain replacement might cost between $1,500 and $2,500, a complete engine rebuild following a failure typically costs $6,000 to $9,000. Acting on early symptoms is the only financially responsible choice.

Maintenance as Prevention

The longevity of a timing chain is intrinsically linked to oil hygiene. Oil sludge—the byproduct of extended oil change intervals—clogs the small orifices of hydraulic tensioners and causes premature wear on the chain’s pins and bushings. Using high-grade synthetic lubricants and quality filters is the most effective way to reach the 300,000-mile potential of these systems.

In summary, identifying a bad timing chain requires a multi-faceted approach. Early detection of rattle and metallic ticking is essential for preventing catastrophic chain failure. Monitoring oil quality and using high-grade lubricants remains the most reliable way to extend chain life and protect your investment. Furthermore, electronic diagnostic codes like P0016 provide definitive evidence of timing synchronization issues that should never be ignored. This complete guide has outlined the roadmap to identification; if you suspect your vehicle is exhibiting these symptoms, consult a trusted, professional technician immediately to perform a comprehensive timing system inspection. Early intervention is the only way to ensure the long-term health and safety of your engine.

Frequently Asked Questions

How long should a quality timing chain typically last?

A high-quality timing chain is engineered to be a ‘lifetime’ component, often lasting between 150,000 and 300,000 miles. However, its longevity depends heavily on the use of professional-grade synthetic oils and regular maintenance. Neglecting oil changes can lead to sludge buildup, which restricts hydraulic tensioners and causes premature chain stretching or guide failure.

Can I drive my vehicle if I hear a timing chain rattle?

Driving with a known timing chain rattle is extremely risky and not recommended. The noise indicates that the chain has excessive slack or the tensioner has failed. In an interference engine, a jumped or broken chain will cause the pistons to strike the valves, leading to catastrophic engine damage that often costs thousands of dollars more than a proactive chain replacement.

Why do metal shavings appear in the oil when a timing chain is bad?

As a timing chain stretches or its guides wear down, the chain may begin to vibrate or ‘slap’ against the internal engine timing cover or other metal components. This friction grinds off small metallic particles which are then circulated through the lubrication system. Finding ‘glitter’ or shavings in your oil filter is a reliable indicator of severe internal mechanical wear.

What is the average cost for a professional timing chain replacement?

A professional timing chain replacement typically costs between $1,200 and $2,500, depending on the vehicle’s make, model, and engine complexity. This price includes the chain, new tensioners, guides, and gaskets. While expensive, it is a necessary investment to protect the engine’s core components and ensure the long-term reliability of your vehicle’s powertrain.

Does a check engine light always come on for a bad timing chain?

Usually, yes. In modern vehicles, the ECM constantly monitors the correlation between the crankshaft and camshaft sensors. If the chain stretches by even a few degrees, the computer will detect the timing offset and trigger a P0016 or P0017 code. However, mechanical symptoms like a rattle may appear before the stretch is significant enough to trigger an electronic warning.