Ford Lower Ball Joint Replacement Costs, Diagnostics, and Repair Engineering Guides 2026

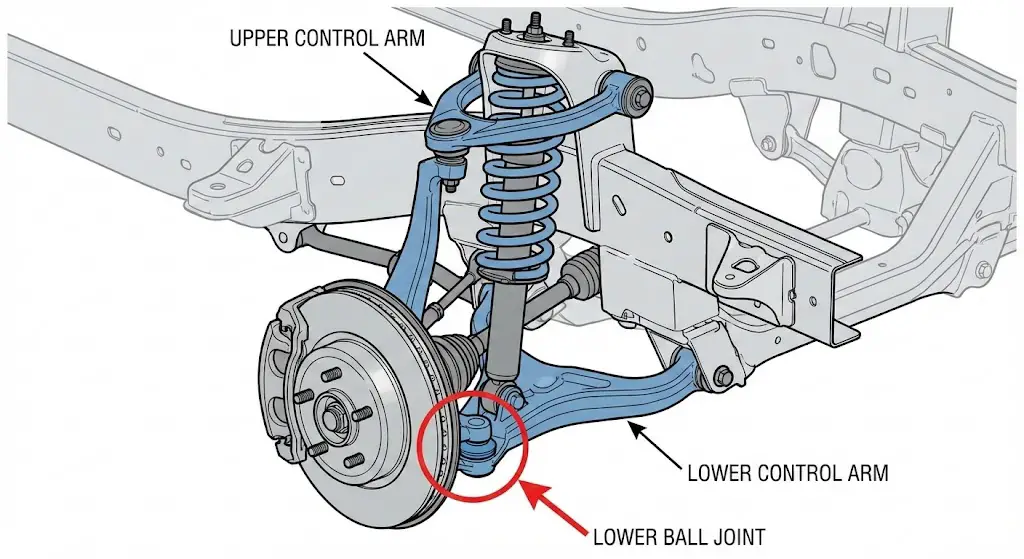

The automotive suspension system is a complex network of linkages, damping units, and structural members designed to reconcile two opposing forces: the chaotic, vertical energy of the road surface and the driver’s demand for stability and control. Within this architectural framework, particularly in the independent front suspension (IFS) systems utilized by Ford Motor Company, the lower ball joint serves as the linchpin.

It is not merely a pivot; it is a load-bearing articulation point that acts as the primary interface between the vehicle’s chassis (via the control arm) and the road (via the steering knuckle and wheel assembly).

When a lower ball joint fails, it does not fail in isolation. It compromises the structural integrity of the entire front end. The steering geometry—specifically camber and toe—becomes fluid rather than fixed, leading to accelerated tire decomposition, unpredictable handling, and, in catastrophic scenarios, the separation of the wheel assembly from the vehicle at velocity.

This report serves as an exhaustive resource for Ford owners, mechanics, and fleet managers. We will dissect the economics of replacement costs across various models, analyze the engineering differences between Original Equipment Manufacturer (OEM) and aftermarket components, and provide a technical deep dive into the diagnostic and repair procedures required to maintain these critical safety systems.

The Anatomy of Articulation

At its core, a ball joint is a spherical bearing. It consists of a hardened steel stud with a spherical head enclosed within a housing (socket). This design allows for multi-axial rotation:

- Vertical Articulation: Accommodating the up-and-down movement of the suspension as the wheel tracks over bumps.

- Horizontal Rotation: Allowing the steering knuckle to pivot left and right as the driver turns the steering wheel.

In Ford’s double-wishbone suspension designs (common in the F-150 and Ranger), the lower ball joint typically carries the weight of the vehicle (load-carrying), placing it under immense continuous compression or tension depending on the spring mounting location. This contrasts with MacPherson strut designs (Focus, Fusion, modern Explorer), where the strut bearing often carries the vertical load, and the ball joint serves primarily as a follower joint to control lateral positioning. Understanding this distinction is crucial for both diagnostics and safe repair procedures.

Lower Ball Joint Replacement Cost

Don’t overpay at the shop. We’ve analyzed market data to break down parts, labor, and hidden fees. Is that $500 quote fair? Find out below.

National Average Cost

Per wheel (Parts + Labor)

Why is this repair unavoidable?

The lower ball joint is the critical pivot point connecting your vehicle’s suspension to the wheel hub. It bears the weight of the car while allowing the wheel to steer and move up and down. When it fails, your wheel can physically separate from the suspension—a catastrophic failure you want to avoid.

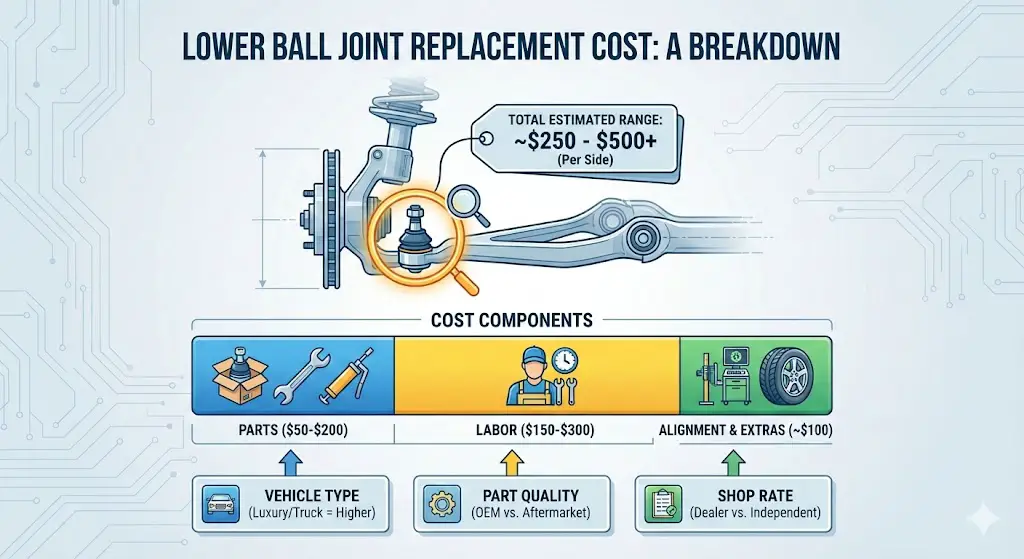

Cost varies significantly based on whether you drive a compact sedan (MacPherson strut) or a heavy-duty truck (Control arm assembly). Below, we visualize where your money goes.

Where Does Your Money Go?

The Mechanic’s Bill DeconstructedFor most professional replacements, labor dominates the bill. Ball joints are often press-fit or riveted, requiring specialized tools and time to remove.

- Labor (50-60%): Usually 1.5 to 2.5 hours of shop time per side.

- Parts (20-30%): The ball joint itself is relatively cheap, but quality varies.

- Alignment (15-20%): CRITICAL: You almost always need an alignment after suspension work.

Total Invoice Composition

*Based on national average shop rates of $100-$150/hr.

Cost by Vehicle Class

Not all ball joints are created equal. A Honda Civic’s ball joint is a simple bolt-on or press-in part. A Ford F-150 often requires replacing the entire Lower Control Arm (LCA), tripling the part cost.

Compact/Sedan

$220 – $350

Often simple press-in joints.

SUV/Crossover

$350 – $600

Heavier suspension, harder labor.

Trucks/4×4

$500 – $900+

Often requires full control arm.

Symptoms: Is it Time?

Ignoring these symptoms can lead to wheel separation. If you experience these, the “cost” of waiting is far higher than the repair bill.

Clunking Noise

A faint, intermittent clunk coming from a corner of the vehicle when going over bumps.

Wandering

Steering feels loose or the vehicle drifts to the left or right without input.

Vibration

Excessive vibration in the steering wheel or floorboards at highway speeds.

Uneven Wear

The inside or outside edge of your front tires is wearing down faster than the center.

The DIY Route

Can you do this yourself? Yes, but it is physically demanding. You save 100% of the labor cost, but you must factor in tool rental.

Required Tools:

- • Floor Jack & Jack Stands

- • Ball Joint Press (Rentable)

- • Pickle Fork / Separator

- • Torque Wrench

- • Snap Ring Pliers

Cost Comparison: DIY vs Shop

Comparing the cost for replacing BOTH front lower ball joints (Parts + Labor/Tools).

Part Quality: You Get What You Pay For

Which brand should you choose?

-

OEM / Premium

Moog, AC Delco Pro, Spicer

Best for daily drivers and trucks. usually greaseable (serviceable) and built with sintered metal bearings. Life expectancy: 50k+ miles.

-

Budget

White Box, Store Brand Economy

Okay for selling a car, but risky for long term. Often use plastic inserts instead of metal bearings. Life expectancy: < 20k miles.

The Replacement Process

What are you paying for?Diagnosis & Lift

Mechanic verifies play in the joint using a pry bar while the car is lifted.

Removal

Cotter pin removal, castle nut removal. Using a separator or press to force the old joint out of the knuckle/arm.

Installation

Pressing the new joint in straight. Installing snap rings and torquing the castle nut to spec.

Alignment

Crucial Step. Suspension geometry changes during install. Alignment prevents rapid tire ruin.

© 2026 FordMasterX Infographics. Data sourced from manufacturer owner manuals.

Economic Analysis: The Cost of Replacement

The financial outlay for replacing a lower ball joint is highly variable, influenced by vehicle architecture, regional labor rates, and parts selection. The following analysis synthesizes data from 2024-2025 repair databases to provide accurate cost expectations.

Global Cost Averages

Across the Ford lineup, the average cost to replace a single lower ball joint ranges significantly.

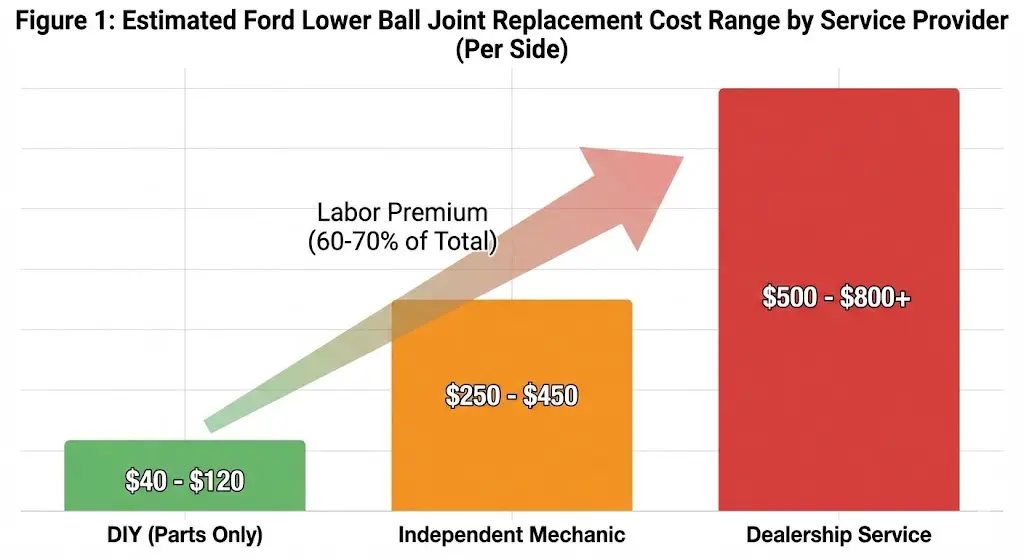

Figure 1: Estimated Cost Range by Service Provider (Data Visualization Description)

This chart would depict a bar graph comparing three distinct cost tiers:

- DIY (Parts Only): $40 - $120

- Independent Mechanic: $250 - $450

- Dealership Service: $500 - $800+The visualization would highlight the massive labor premium associated with professional repair, which accounts for 60-70% of the total bill.

| Vehicle Model | Independent Shop Cost (Per Side) | Dealership Cost (Per Side) | DIY Parts Cost (Per Side) | Labor Difficulty (1-10) |

| Ford F-150 (2004-2014) | $270 - $405 | $450 - $650 | $40 - $90 | 8 (Press Required) |

| Ford F-150 (2015+) | $423 - $543 | $600 - $900 | $150 - $250* | 6 (Control Arm Swap) |

| Ford Ranger (1998-2011) | $206 - $319 | $400 - $550 | $30 - $70 | 7 (Torsion Bars) |

| Ford Explorer (2011+) | $258 - $382 | $500 - $750 | $40 - $100 | 7 (CV Axle/Strut) |

| Ford Focus / Fusion | $305 - $495 | $530 - $650 | $100 - $180* | 5 (Control Arm Swap) |

The "Rust Belt" Factor: A Geographic Multiplier

Standard labor guides (Book Time) assume a "clean" vehicle where bolts turn freely and parts separate with standard force. However, real-world data indicates a severe bifurcation in cost based on geography.

- The Corrosion Bond: In states utilizing road salt (e.g., New York, Michigan, Minnesota), the steel ball joint stud chemically fuses to the iron steering knuckle, and control arm bolts seize within their metal bushings.

- The "Torch Tax": Mechanics in these regions often add a "corrosion contingency" to their quotes. A job booked for 2 hours can easily expand to 6 hours if bolts require induction heating, oxy-acetylene torching, or cutting with a reciprocating saw.

- Cost Impact: A quote for an F-150 ball joint replacement in Texas might be $350, while the same job in New Jersey could be quoted at $600+ due to anticipated labor complications.

The "While You're In There" Efficiency

The most significant "hidden" cost is not the ball joint itself, but the overlapping labor for related components.

- Wheel Alignment ($100 - $168): Replacing a ball joint fundamentally alters the suspension geometry (camber and toe). An alignment is mandatory immediately following the repair. Failure to align will destroy tires in under 1,000 miles.

- Tie Rod Ends: The outer tie rod connects to the same steering knuckle. If the ball joint is worn, the tie rod is likely tired. Since the labor to remove the tie rod is already part of the ball joint process, replacing it adds only the part cost ($20-$40). Doing this separately later would incur a second labor charge and a second alignment fee.

- Sway Bar Links: These thin connecting rods often have to be removed to access the lower control arm. In rust-prone areas, they rarely survive disassembly and must be cut off. It is standard practice to budget $40-$80 for a new pair.

The Engineering of Longevity

The market for replacement ball joints is vast, ranging from high-precision OEM components to "white box" economy parts. Understanding the metallurgical and design differences is critical for ensuring safety and value.

OEM: Motorcraft (The Baseline)

Motorcraft parts are designed by Ford engineers to meet the exact specifications of the vehicle as it left the factory.

- Design Philosophy: Typically "Sealed for Life." They utilize a highly polished steel ball stud rotating within a synthetic polymer (plastic) bearing race.

- Pros: Guaranteed fitment; predictable durability (typically 100k+ miles in normal conditions); no maintenance required.

- Cons: Once the internal grease degrades or the boot cracks, the plastic race wears quickly. They cannot be serviced.

- Cost: Premium pricing (~$70 - $120 per unit).

Premium Aftermarket: Moog "Problem Solver"

Moog is a dominant player in the aftermarket, famous for their "Problem Solver" line which claims to address OEM design weaknesses.

- Design Philosophy: "Gusher Bearing" technology. They often use a sintered metal-on-metal bearing design rather than plastic. This allows grease to flow through the bearing surface.

- Greaseable: Almost all Moog joints feature a Zerk fitting, allowing the owner to inject fresh grease. This flushes out contaminants and extends life—if maintained.

- Pros: Extremely durable under impact loads (potholes); serviceable; often feature oversized housings to fit worn control arms (knurled bodies).

- Cons: If you fail to grease them every oil change, the metal-on-metal friction will destroy the joint faster than an OEM sealed unit. Recent forum discussions suggest inconsistent quality control.

- Cost: Mid-range (~$60 - $90 per unit).

Heavy Duty Aftermarket: Mevotech TTX

Mevotech's "Terrain Tough Extreme" (TTX) line is marketed specifically towards working trucks and fleets.

- Design Philosophy: Over-engineering. They feature thicker flanges, highly durable boots (often the first point of failure), and advanced corrosion-resistant coatings (Repel-TEK) to prevent the "rust welding" issue common in Fords.

- Pros: Excellent boot durability; superior rust protection; often includes new hardware (snap rings, nuts).

- Cons: Stiffer ride break-in period.

- Cost: Competitive (~$50 - $80 per unit).

Economy Parts: The False Economy

Brands like Detroit Axle or unbranded eBay kits often sell two ball joints, two tie rods, and control arms for less than the price of one Motorcraft joint.

- Risk: These parts often use inferior steel alloys and poor-quality rubber boots that crack within months.

- The Math: Installing a $20 ball joint that fails in 12 months requires paying the $300 labor and $100 alignment fee twice. It is mathematically irrational to use economy parts for labor-intensive suspension work.

Model-Specific Analysis: Ford F-150

The F-150 has undergone several generational shifts in suspension architecture, each bringing unique repair challenges.

The Steel Era (2004-2014)

- Suspension Type: Coil-over-shock double wishbone (2WD/4WD).

- Repair Method: Press-In. The lower ball joint is pressed into a steel lower control arm.

- The Challenge: The factory ball joint is often staked or rusted into place. Removing it requires a heavy-duty C-clamp press (not the lightweight ones often rented at auto parts stores) and specific adapter cups to fit the Ford knuckle.

- Snap Rings: These models use a snap ring to retain the joint. It is often buried under layers of road grime and rust, making it invisible to the uninitiated DIYer. Attempting to press the joint without removing this ring will bend the control arm.

- IWE System (4WD Only): The Integrated Wheel End (vacuum hub) is fragile. To remove the knuckle, the CV axle must be disengaged. If the IWE actuator is reinstalled without properly meshing the splines (or pulling a vacuum to retract it), the hub will grind itself to pieces within miles, adding ~$300 to the repair bill.

The Aluminum Era (2015-Present)

- Suspension Type: Aluminum lower control arms and knuckles on many trims.

- Repair Method: Assembly Replacement. While it is theoretically possible to press a ball joint out of an aluminum arm, it is fraught with risk. The force required to remove a steel joint can crack or deform the softer aluminum arm.

- Recommendation: Most shops and the dealer will refuse to replace just the ball joint. They will insist on replacing the entire Lower Control Arm (LCA) assembly. This increases parts cost ($200+ per arm) but ensures the integrity of the aluminum structure and provides fresh control arm bushings simultaneously.

- Recall Alert (F-150 Lightning): Owners of the 2023-2024 F-150 Lightning must be aware of Recall 24S76. A manufacturing defect may have left the upper control arm ball joint nut loose. While this is the upper joint, any front-end clunk should be immediately inspected by a dealer under this recall before paying for independent repairs.

Model-Specific Analysis: Ford Ranger

The Ranger holds a unique place in the Ford lineup, with a distinct split between the compact "old gen" and the midsize "new gen."

Third Generation (1998-2011)

- Suspension Type: Torsion Bar (4WD/Edge) or Coil Spring (2WD).

- The Torsion Bar Trap: On 4WD models, the suspension spring is a torsion bar connected to the lower control arm. It exerts massive downward pressure.

- Safety Warning: You cannot simply unbolt the ball joint. The torsion bar must be unloaded using a special tool or by carefully releasing the tension key. Failure to do this can result in the control arm snapping down with lethal force when the ball joint nut is removed.

- Parts: The upper ball joints are integral to the upper control arm (UCA) and must be replaced as a unit. The lower ball joints are press-in.

- DIY Difficulty: High (8/10). The combination of torsion bar danger and rusted press-fit parts makes this a challenging driveway repair.

Fourth Generation (2019-Present)

- Suspension Type: Modern coil-over strut.

- Repair Profile: Similar to the modern F-150. Labor times are standard (approx 2.5 hours per side).

- Parts Cost: OEM parts are readily available, but aftermarket support (Mevotech/Moog) offers robust alternatives for off-road builds.

Model-Specific Analysis: Ford Explorer

The Unibody Transition (2011-Present)

The shift from a truck-based chassis (pre-2011) to a unibody car-based platform (D4 platform) changed the repair landscape.

- Suspension Type: MacPherson strut.

- Repair Method: The lower ball joint is pressed into the steering knuckle (on some configurations) or bolted to the control arm.

- Rear Toe Link Recall (21B14): While this report focuses on the front suspension, Explorer owners must be aware of the rear toe link recall. These ball joints are prone to seizure and fracture in corrosion states. If you hear a clunk from the rear, it is a safety-critical recall issue.

- Cost: Independent shops typically charge around $300-$380 per side. The complex labor involves managing the CV axle on 4WD models, which can seize in the hub.

Model-Specific Analysis: Ford Focus & Fusion

Integrated Simplicity (and Cost)

For Ford's sedans, the repair philosophy is "remove and replace."

- Design: The lower ball joint is permanently riveted or cast into the stamped steel or aluminum lower control arm.

- Serviceability: You do not replace the ball joint. You replace the entire Lower Control Arm (LCA).

- Pros: You get new control arm bushings (the rubber pivots) for "free" with the new arm. These bushings often fail at the same rate as the ball joint (around 80k-100k miles), so replacing the whole unit restores the entire lower suspension feels.

- Cons: Higher parts cost compared to a single joint, though stamped steel arms for the Focus are relatively cheap ($50-$100 aftermarket).

- Fusion "Hack": On certain engine configurations (like the 3.5L V6), the front bolt of the lower control arm is blocked by the transmission pan or A/C compressor.

- The "Book" Way: Lower the subframe or lift the engine (4+ hours labor).

- The "Mechanic" Way: Cut the bolt head off, slide it out, and install a new bolt from the reverse direction. This saves massive amounts of time. DIYers should be prepared with a reciprocating saw and new high-grade hardware.

Diagnostics: The "Ford Pry Bar" Test

Identifying a worn ball joint on a Ford truck requires a specific technique due to the suspension design.

The Pre-Load Problem

On vehicles where the spring (or torsion bar) pushes down on the lower control arm (F-150, Ranger), the ball joint is constantly under tension.

- The Mistake: If you jack the truck up by the frame and let the wheels hang, the spring pressure will force the ball stud tight against the socket. If you grab the wheel and shake it, it will feel tight even if the joint is completely worn out.

- The Solution: You must jack the vehicle up by the Lower Control Arm (as close to the wheel as possible). This compresses the spring and relieves the tension on the ball joint, allowing it to "float." Only then can you test for play.

The Pry Bar Test

- Lift: Raise the vehicle safely, supporting the lower control arm.

- Leverage: Insert a large pry bar (36"+) between the bottom of the tire and the ground (or between the control arm and the knuckle).

- Action: Lift the tire upwards with the pry bar while watching the ball joint.

- Observation:

- Radial Play (Side-to-Side): Any visible side-to-side wiggle of the knuckle relative to the arm is a failure.

- Axial Play (Up-and-Down): Some older Ford specs allowed for very minor axial movement, but modern consensus and TSBs suggest that any visible "clunk" or movement exceeding 1/32" is grounds for replacement. A "pop" or visible separation indicates imminent failure.

The Noise Test

- Clunk: Deep, metallic thud over bumps. Indicates structural play.

- Squeak: "Old mattress" sound when turning steering. Indicates dry/rusted joint. This is often a precursor to snapping.

DIY Repair Guide: Tooling and Techniques

For the ambitious owner, replacing ball joints is achievable but physically demanding.

The "Must-Have" Tool List

Attempting this repair with basic hand tools is a recipe for frustration.

- Ball Joint Press Kit: A heavy-duty C-clamp press is mandatory. Do not use the lightweight aluminum ones; they will bend. Ensure the kit has the specific Ford Adapter Cups (angled cups for F-150s).

- Impact Wrench: A high-torque impact gun (1/2" drive) is essential for removing the axle nut (often torqued to 220+ ft-lbs) and the ball joint nut.

- Penetrating Catalyst: Products like Kroil or PB Blaster are superior to WD-40. Start soaking the nuts and snap rings 24 hours before the job.

- Snap Ring Pliers: Heavy-duty pliers are needed to remove the rusted retention clips.

- Pickle Fork vs. Separator: A pickle fork destroys the boot. Only use it if you are replacing the joint. If you are just removing the knuckle to access something else, use a screw-type separator.

Critical Safety Warnings

- Spring Energy: On coil-spring trucks (F-150), verify the shock/strut limits the travel. On torsion bar trucks (Ranger), you must unload the torsion bar key before separating the ball joint.

- Torque Specs: The ball joint nut pulls the tapered stud into the knuckle. It must be torqued to spec (typically 111-150 ft-lbs depending on model). Under-torquing leads to the stud shearing off; over-torquing stretches the threads.

- Cotter Pins: Always install a new cotter pin. Never reuse the old one.

Conclusion:

The lower ball joint is a small component with a massive responsibility. For Ford owners, particularly those with F-Series trucks and Rangers, it is a wear item that demands respect.

Summary of Recommendations:

- Diagnose Correctly: Use the "Unloaded/Pry Bar" method to avoid false negatives.

- Respect the Region: If you live in the Rust Belt, budget for double the labor time or seek a shop with induction heating tools.

- Choose Quality: Install Motorcraft for peace of mind or Moog/Mevotech TTX for serviceable durability. Avoid unbranded economy parts.

- Align Immediately: Factor the $100 alignment into your total cost estimate. It is not optional.

Frequently Asked Questions (FAQ)

Q: Can I drive with a bad ball joint?

A: No. While a "clunking" joint might last for a few weeks, a "squeaking" joint is often on the verge of snapping. If the ball joint separates, the control arm drops, the wheel folds into the fender, and you lose steering control. This can happen at highway speeds.

Q: Should I replace both sides at the same time?

A: Yes. Ball joints typically experience the same mileage and road conditions. If the left side has failed, the right side is likely close behind. Doing both at once saves on the "setup" time and requires only one alignment.

Q: Why does my F-150 have a "Death Wobble" or Shimmy?

A: While true "Death Wobble" is a solid-axle trait (Super Duty), a severe shimmy in an F-150 is often caused by vertical play in the lower ball joints allowing the wheel to bounce uncontrollably. A steering stabilizer will not fix this; replacing the joints will.

Q: Is the F-150 Lightning ball joint issue different?

A: The Lightning uses a similar suspension design but carries more weight. The specific Recall 24S76 relates to a loose upper control arm nut. However, the increased weight of the EV battery accelerates wear on all suspension components, making regular inspection even more critical.