A Comprehensive Analysis of Ford TPMS Activation and Relearn Protocols Without Specialized Diagnostics

The automotive industry’s shift toward integrated safety telematics has fundamentally altered the relationship between the driver, the mechanic, and the vehicle’s maintenance ecosystem. At the forefront of this digital transformation is the Tire Pressure Monitoring System (TPMS). While often viewed by consumers as a mere dashboard convenience or an annoyance, the TPMS is a federally mandated safety architecture born from significant historical automotive failures.

For the Ford Motor Company, the implementation of TPMS is inextricably linked to the Transportation Recall Enhancement, Accountability, and Documentation (TREAD) Act of 2000, legislation passed in the wake of the Firestone/Ford Explorer rollover controversy.

This report serves as an exhaustive technical resource for automotive technicians, fleet managers, and advanced enthusiasts seeking to understand the activation and relearn procedures for Ford TPMS sensors, specifically focusing on methods that circumvent the need for specialized 125 kHz triggering tools. The core inquiry driving this research is whether the “pressure drop” method—a legacy protocol allowing sensor activation via rapid deflation—remains viable in modern Ford architectures, and how “Auto-Relearn” technologies are reshaping the service landscape.

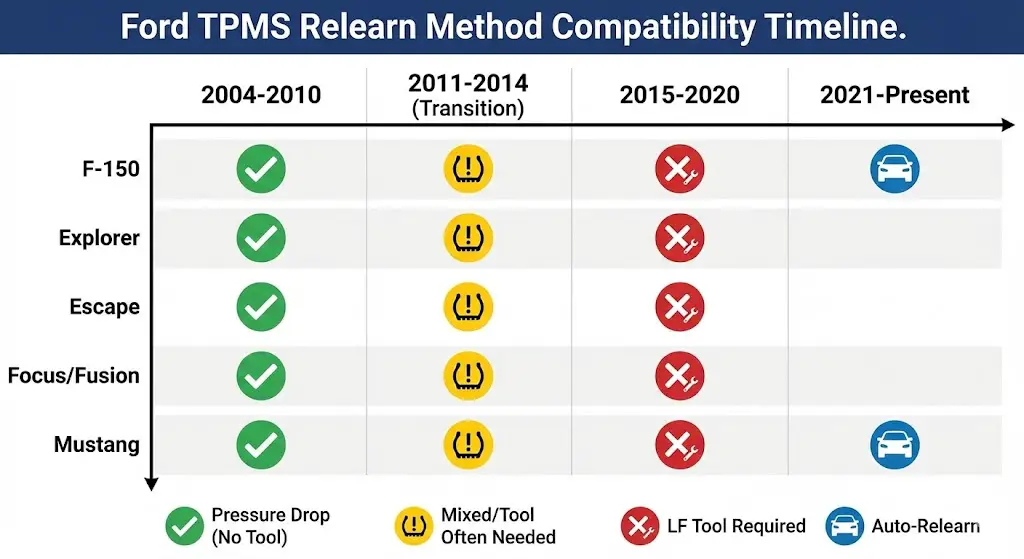

The analysis reveals a complex dichotomy in Ford’s engineering evolution. While early iterations of the system (circa 2004–2010) were designed with “no tool” field serviceability in mind, enabling the “Delta P” (pressure change) trigger, subsequent generations (2011–present) have largely deprecated this feature in favor of Low-Frequency (LF) activation tools and, more recently, advanced Auto-Location logic. Understanding these distinctions is not merely a matter of convenience but of technical necessity to avoid diagnostic missteps.

The Operational Imperative of the Relearn Process

A fundamental misunderstanding often persists regarding the distinction between a functioning sensor and a recognized sensor. A new TPMS sensor installed in a wheel is, from the perspective of the vehicle’s Body Control Module (BCM), a ghost. Although it may be physically transmitting data (pressure, temperature, and acceleration), the vehicle will ignore this data until the sensor’s unique hexadecimal identification code is registered to a specific position (e.g., Left Front). This registration process is known as “Training” or “Relearning”.

Failure to perform this procedure correctly results in the “Tire Pressure Sensor Fault” warning, a solid or flashing tally light, and the disablement of the safety system. This report will demonstrate that while “no tool” methods exist, their applicability is strictly bounded by model year and platform architecture.

How to Activate Ford TPMS Without a Tool

Installed new sensors? Rotating tires? Your Ford needs to “relearn” their positions. Before buying a $50 tool or paying a dealer $100, try the “Delta Pressure” Method.

Will It Work For My Car?

Not all Ford TPMS sensors are created equal. Older “Band” sensors and early valve-stem sensors (approx 2007–2016) often respond to a rapid drop in air pressure to trigger the signal. Newer models (2017+) are increasingly reliant on 125kHz activation tools, though some feature “Auto-Relearn” by driving.

The “Delta Pressure” Concept

When in “Training Mode,” a rapid change in tire pressure (releasing air for 5-10 seconds) wakes the sensor up, forcing it to send a signal to the car’s computer.

Success Probability by Method

Estimation based on Ford models 2007-2023

The Activation Sequence

Follow this “Ford Dance” precisely to enter Training Mode.

Prep the Vehicle

Make sure all tires are inflated to the recommended PSI. Ensure the vehicle is in Park (P) and the ignition is OFF. Close all doors.

Brake & Cycle

1. Press and release the Brake Pedal once.

2. Cycle Ignition: OFF to

RUN (Engine Off) 3 times. End in

RUN.

Brake & Cycle Again

1. Press and release the Brake Pedal once.

2. Turn Ignition OFF.

3. Cycle Ignition: OFF to RUN 3

times again.

Listen for Horn

The horn should honk ONCE. The dashboard message center will display “TRAIN LF TIRE” (Left Front). You are now in Training Mode.

Trigger LF Sensor

Go to the Left Front tire. Unscrew the valve cap. Use a key or tool to depress the valve core and let air out for 10-15 seconds. Wait for the horn to HONK.

Repeat Clockwise

Move clockwise: RF (Right Front) → RR (Right Rear) → LR (Left Rear). Once the final horn honks, the display will say “TRAINING COMPLETE”.

Cost Comparison: TPMS Reset Methods

Is it worth the hassle?

Entering “Training Mode” manually is free. The only variable is how you trigger the sensors.

-

FREE

Pressure Drop Method Costs $0, but requires an air compressor to refill tires afterwards. Success rate varies by year.

-

$15-40

Activation Tool (TPMS19) A small “clicker” tool. Highly reliable. Saves having to let air out of tires.

-

$100+

Dealer Service The “I don’t want to think about it” option. Most expensive.

Troubleshooting the Process

| Symptom | Possible Cause | Solution |

|---|---|---|

| Horn honks TWICE during training | Training failed for that sensor. | Try releasing air again or move sensor closer (if loose). |

| Cannot enter Training Mode | Timing is off or Brake Pedal switch issue. | Repeat “The Dance” faster or slower. Check brake lights. |

| Sensor won’t trigger with air loss | Sensor is 315MHz/433MHz mismatch or Sleep Mode. | Ensure sensor frequency matches VIN. Drive car to wake sensors. |

© 2026 FordMasterX Infographics. Data sourced from manufacturer owner manuals.

Technical Architecture of Ford Direct TPMS

To navigate the “no tool” workarounds, one must first comprehend the hardware constraints of the system. Ford utilizes a Direct TPMS architecture, distinguishing it from the Indirect systems (iTPMS) used by some European manufacturers that rely on ABS wheel speed differentials.

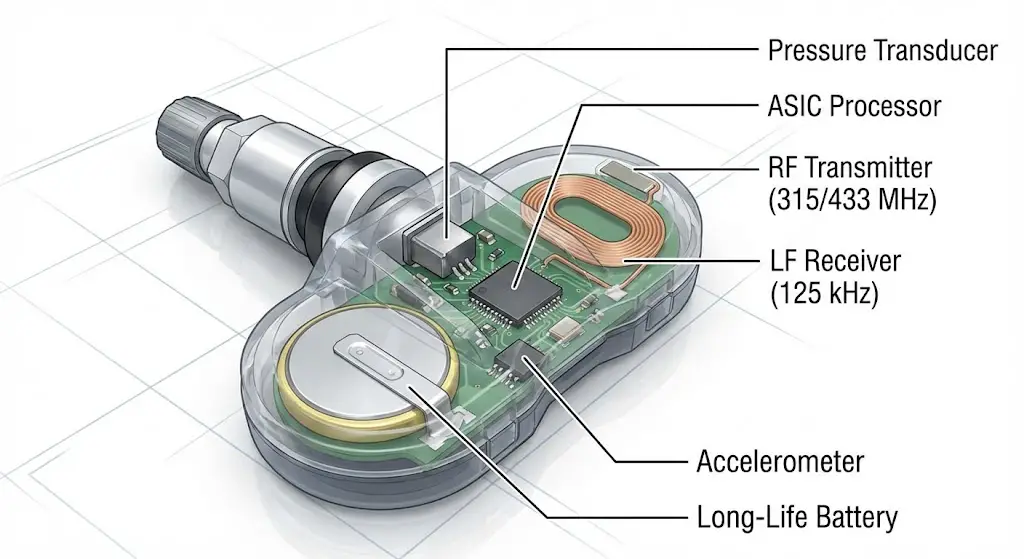

The Sensor: An Embedded Telemetry Station

The Ford TPMS sensor (manufactured primarily by Schrader, VDO/Continental, or Huf, depending on the era) is a sophisticated micro-electromechanical system (MEMS). It comprises:

- Pressure Transducer: A piezoelectric element that converts physical air pressure into a voltage signal.

- ASIC (Application-Specific Integrated Circuit): The processor that manages data transmission logic.

- RF Transmitter: Broadcasts data to the vehicle on Ultra High Frequency (UHF) bands, typically 315 MHz or 433 MHz.

- LF Receiver: A copper coil antenna tuned to 125 kHz, designed to “listen” for a wake-up signal from a trigger tool.

- Accelerometer: A motion sensor that detects wheel rotation to manage battery life, switching the sensor between “Park Mode” (slow transmission) and “Drive Mode” (active transmission).

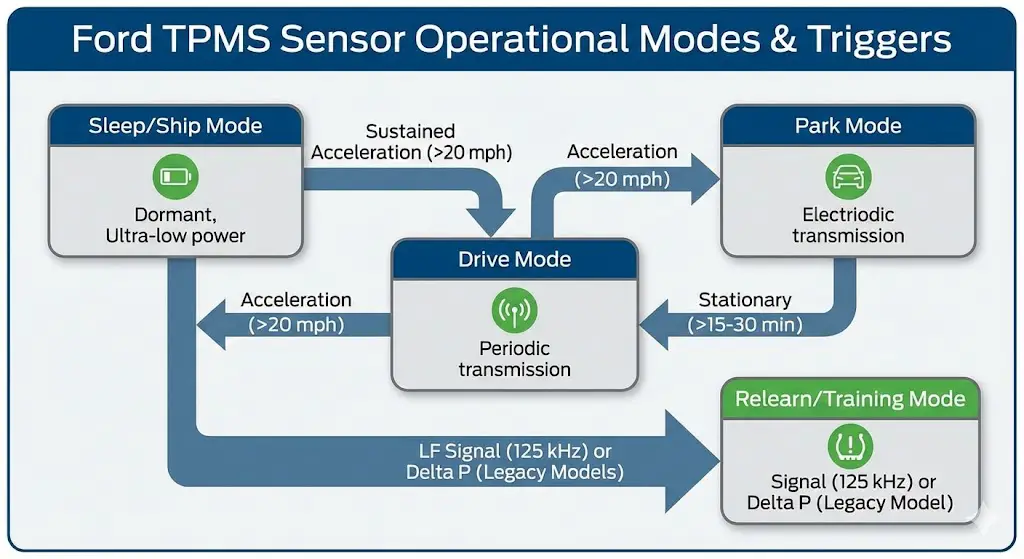

Modes of Operation and Transmission Triggers

The sensor is not a continuous broadcasting device; continuous transmission would deplete the non-replaceable lithium-ion battery (typically a CR2032 or CR2450 variant) within months. Instead, the sensor operates on a rigid logic of “States” or “Modes”.

- Sleep/Ship Mode: The state in which new replacement sensors are often shipped. The sensor is essentially dormant to prevent battery drain on the shelf. It requires a specific wake-up event (usually sustained acceleration or a high-power LF signal) to activate.

- Park Mode: When the vehicle is stationary for more than 15-30 minutes, the sensor reduces its transmission rate (e.g., once every 13 hours or only upon significant pressure change) to conserve energy.

- Drive Mode: Activated by centrifugal force (usually >20 mph). The sensor transmits periodically (e.g., every 60 seconds).

- Relearn/Training Mode: The critical state for this report. When the vehicle is placed in “Training Mode” (indicated by the horn chirp), the BCM listens exclusively for new sensor IDs. The sensor must be forced to transmit immediately during this window.

Table 1: Ford TPMS Transmission Logic

| Trigger Event | Mechanism | Outcome | “No Tool” Viability |

| LF Signal (125 kHz) | Inductive coupling via Trigger Tool (TPMS-19) | Immediate Wake-up & Data Burst | Low (Requires Tool) |

| Delta P (Pressure Drop) | Rapid change in pressure (>3 PSI in <10 sec) | Emergency Burst (Leak Detection) | High (Legacy Models Only) |

| Centrifugal Force | Accelerometer detects rotation (>20 mph) | Switch to Drive Mode | High (Auto-Relearn Models) |

| Magnetism | Reed switch activation | Switch Closure | Zero (Obsolete on Ford) |

The “Delta P” Mechanism (The Pressure Drop Method)

The primary mechanism relied upon for “no tool” activation is the Delta P logic. In older firmware iterations (Pre-2011), the sensor was programmed to interpret a rapid drop in pressure not just as a puncture warning, but as a deliberate trigger for relearning when the vehicle was in Training Mode. By manually releasing air from the valve stem, the user mimics a leak. The sensor detects the steep pressure gradient and transmits its ID. The BCM, seeing the vehicle is in Training Mode, captures this ID and assigns it to the current position (e.g., Left Front).

However, this feature has been systematically removed from newer sensors. Modern Original Equipment (OE) sensors for platforms like the S550 Mustang or the Aluminum-body F-150 prioritize LF activation to prevent accidental relearning of adjacent vehicles’ sensors in busy service bays and to enhance system security.

Comprehensive Analysis of “No Tool” Relearn Procedures

The research identifies three distinct methodologies for sensor activation that do not rely on the standard diagnostic scan tool (OBD-II). However, the viability of each is contingent on the vehicle’s production era.

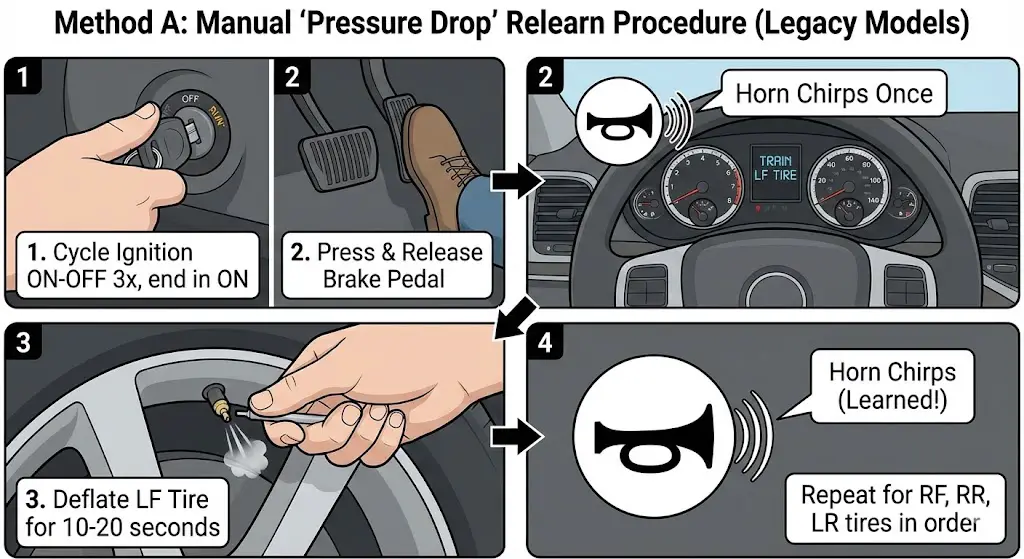

Method A: The Manual “Pressure Drop” Relearn

This method is the “Holy Grail” for DIY enthusiasts but is becoming increasingly archaic. It relies on the vehicle having a user-accessible “Training Mode” and the sensors supporting the Delta P trigger.

Applicability:

- High probability of success: Ford models 2004–2010 (e.g., Edge, Escape, F-150 12th Gen early years).

- Mixed success: 2011–2012 transition models.

- Low probability: 2013+ models (requires LF tool).

Detailed Procedure:

- Preparation: Park the vehicle in a radio-quiet zone. Inflate all tires to the placard pressure. Ensure the ignition is OFF.

- Mode Entry (Ignition Cycling):

- Turn the ignition switch to the ON (Run) position (Engine Off).

- Turn to OFF.

- Repeat this On-Off cycle three times, ending in the ON position.

- Press and release the Brake Pedal. (This clears the BCM logic).

- Turn the ignition to OFF.

- Repeat the On-Off cycle three times, ending in the ON position.

- Confirmation: The horn will chirp once, and the TPMS indicator will flash. The message center (if equipped) will read

TRAIN LF TIRE. - The Trigger (The “No Tool” Step):

- Proceed to the Left Front (LF) tire.

- Remove the valve cap and use a tool (pen, key, fingernail) to depress the valve core.

- Release air continuously for 10 to 20 seconds.

- Critical Insight: You are waiting for the sensor to detect the pressure change rate (dP/dt). If you release air too slowly, the sensor may not trigger.

- Response:

- If successful: The horn chirps once. This confirms the LF sensor is learned.

- If unsuccessful: No chirp occurs after 30 seconds, or the horn chirps twice (indicating a fault/retry).

- Sequence: Repeat the process for Right Front (RF), Right Rear (RR), and Left Rear (LR). The order is mandatory as the BCM steps through the positions sequentially.

- Finalization: After the LR tire is trained, the horn chirps twice to signal

TRAINING COMPLETE. Turn the ignition off and immediately reinflate tires to safe levels.

Method B: The “Hazard Button” Entry Sequence

For vehicles equipped with Push-Button Start (Intelligent Access), the ignition cycling method is physically impossible or unreliable. Ford introduced a secondary entry method utilizing the Hazard Flasher switch.

Applicability:

- Standard on most Ford vehicles 2015+ (F-150 13th/14th Gen, Fusion, Mustang, Explorer).

- Also works on many Key-Start vehicles from 2011–2014 as a backup method.

Detailed Procedure:

- Power On: With the key fob inside the vehicle, press the START button once (without touching the brake) to enter Accessory/Run Mode. The engine must remain off.

- The Code: Press the Hazard Flasher button six times typically within 5–10 seconds.

- Nuance: Some documentation suggests toggling it On/Off three times (6 presses total). The system is looking for the switch state change.

- Confirmation: The horn chirps once, and the

TRAIN LF TIREmessage appears. - Triggering: At this point, the user must activate the sensors. On newer vehicles (2015+), the pressure drop method described in Method A often fails here because the sensors require an LF signal. Thus, while the entry to the mode requires no tool, the activation often does.

Method C: The “Auto-Relearn” (Drive-to-Learn)

A growing number of modern Ford platforms, particularly those sharing architecture with European models (Global C2 platform, Transit), support automatic sensor location. This effectively meets the “without tool” requirement by utilizing the vehicle’s driving physics.

Applicability:

- Ford Transit (2016+).2

- Ford Mustang Mach-E.

- Ford Edge (Select Years).

- Some newer F-150s (14th Gen, though mixed reports exist regarding tire rotation vs. new sensor ID learning).

Mechanism of Action:

The vehicle uses Phase Angle Location (PAL) or signal strength triangulation. By monitoring the RF signal’s arrival time relative to the ABS wheel speed sensor’s position data, the BCM can algorithmically determine that “Sensor ID X” is rotating in phase with the “Left Front” wheel speed.

Procedure:

- Install the new sensors.

- Inflate to placard pressure.

- Leave the vehicle stationary for 20 minutes (to ensure sensors enter Sleep/Park mode and reset counters).

- Drive the vehicle at speeds above 20 mph (32 km/h) for at least 15–20 minutes.

- Result: The TPMS light should extinguish automatically. No horn chirps or special modes are involved.

Model-Specific Compatibility and “Cutoff” Analysis

A critical component of this research is determining when the “pressure drop” method became obsolete. The transition was not uniform across the Ford lineup but rolled out with platform updates.

The F-Series (F-150 / Super Duty)

- 11th Gen (2004–2008): Typically supported the pressure drop method. Sensors were often “banded” (attached to the wheel barrel with a steel strap) rather than valve-mounted.

- 12th Gen (2009–2014):

- 2009–2010: High success rate with pressure drop.

- 2011–2014: Mixed. Many users report the pressure drop method works for entering the mode, but the sensors fail to trigger without an LF tool. This coincides with the switch to different BCM suppliers.

- 13th Gen (2015–2020): Tool Required. The pressure drop method is almost universally disabled. The vehicle enters training mode (via Hazard button), but bleeding air does not trigger the horn. The Motorcraft TPMS-19 tool is essential here.

- 14th Gen (2021+): Tool Required / Auto-Learn. These vehicles use a new electrical architecture (SYNC 4, OTA capable). While some support auto-learning, manual relearns definitively require an LF tool, and the frequency may have shifted to 433 MHz.

The Explorer and SUV Lineup

- Explorer (Pre-2010): Supported pressure drop. Often required checking the spare tire.

- Explorer (2011–2015): Similar to the F-150, this era phased out the pressure drop trigger. By 2013, the LF tool was standard equipment for dealership technicians.

- Explorer (2016+): The shift to 433 MHz in some markets and the introduction of “Auto-Relearn” on the dashboard menu (in some trims) changed the dynamic. However, for manual resets, the tool remains mandatory.

- Escape (2013+): The redesign in 2013 (Global C platform) largely standardized the LF tool requirement. Pressure drop is rarely successful on 2013+ Escapes.

The “Ship Mode” Anomaly

A common source of failure for the “no tool” approach on new sensors is “Ship Mode.” New sensors from Motorcraft or aftermarket suppliers are shipped in a deep sleep state to preserve the battery (shelf life of 10 years). In this state, the sensor will not respond to a pressure drop, and sometimes not even to a tool, until it is “woken up.”

The “No Tool” Wake-Up Hack:

The wake-up signal is often a centrifugal switch (accelerometer). If a new sensor fails to train:

- Install the sensor.

- Drive the vehicle for 15 minutes at highway speeds. This spins the internal accelerometer, breaking the “Ship Mode” lock.

- Park and immediately attempt the relearn procedure (Method A or B). The sensor is now “awake” and may respond to triggers it previously ignored.

The LF Activation Tool: Why It Is Often Unavoidable

While the premise of this report is to avoid tools, intellectual honesty demands acknowledging that for post-2015 Ford owners, the “no tool” path is fraught with failure. The pressure drop method was deprecated not to annoy customers, but for safety and efficiency.

The Safety Argument

Using the pressure drop method requires a technician to significantly deflate all four tires. If the procedure is interrupted or if the technician forgets to reinflate a tire, the vehicle is left in a dangerous state. The LF tool (TPMS-19) allows the sensors to be trained without altering the air pressure, maintaining the vehicle’s readiness.

The Economic Reality

The “tool” required for Fords is not a $1,000 diagnostic tablet. The Motorcraft TPMS-19 (and its generic equivalents) is a simple RF transmitter.

- Frequency: 125 kHz (Tx) / 315 or 433 MHz (Rx).

- Cost: Market analysis shows these tools retail for approximately $15–$30 USD.

- Comparison: This cost is often lower than a single diagnostic fee at a dealership. For owners of 2015+ vehicles, purchasing this tool is arguably the most efficient “repair” strategy, as the “pressure drop” method is functionally obsolete for their VINs.

Frequency Compatibility: The Hidden Barrier

A successful activation depends entirely on the sensor speaking the same language as the receiver. “No tool” methods cannot bridge a frequency mismatch.

The 315 MHz vs. 433 MHz Split

Historically, North American Fords used 315 MHz, while European Fords used 433 MHz. However, with the “One Ford” global strategy and recent platform consolidations, this distinction has blurred.

Visualizing the Frequency Shift:

| Vehicle | 315 MHz Era | 433 MHz Era |

| Ford F-150 | 2004 – 2020 | 2021 – Present (Mixed) |

| Ford Edge | 2007 – 2014 | 2015 – Present |

| Ford Escape | 2001 – 2012 | 2013 – Present (Often 315, newer 433) |

| Ford Transit | N/A | 2015 – Present (High incidence of 433) |

| Ford Maverick | N/A | 2022 – Present (Mixed 315/433) 27 |

Insight: 2021+ F-150 and Maverick owners face a unique challenge. Reports indicate that some trucks use 315 MHz while others use 433 MHz, sometimes dependent on the Gross Vehicle Weight Rating (GVWR) or the specific assembly plant (Dearborn vs. Kansas City). Using a “no tool” auto-relearn will fail indefinitely if a user installs 315 MHz sensors on a 433 MHz truck. Checking the VIN or the old sensor’s casing is mandatory before attempting any relearn.

Troubleshooting and Diagnostics

When the relearn procedure fails, it rarely provides a detailed error code. The failure is usually binary: the horn doesn’t chirp.

Common Points of Failure

- RF Interference: LED headlights, dash cams, and phone chargers emit “noise” in the radio spectrum that can drown out the sensor’s weak signal. Solution: Unplug all accessories and move the vehicle away from metal buildings or other cars.

- The “Double Chirp”: If the horn chirps twice during training, the BCM has rejected the sensor. This usually means the sensor ID was received but deemed invalid (wrong protocol) or that there was a signal collision (two sensors triggered simultaneously).

- Sensor Protocol Mismatch: Installing a “Universal” sensor (e.g., Autel MX, Schrader EZ) without programming it first. These sensors are blank slates. A “no tool” relearn cannot write the software to the sensor; it can only read what is there. If the sensor is blank, it will never trigger. Solution: Pre-programmed “Direct Fit” sensors must be used if no programming tool is available.

Conclusion: The Verdict on “No Tool” Activation

The landscape of Ford TPMS activation is not monolithic. It is a timeline of evolving engineering standards.

- For the owner of a 2008 F-150: The Pressure Drop Method is a valid, reliable, and cost-effective way to activate sensors without a tool. The system was designed for this.

- For the owner of a 2018 F-150: The Pressure Drop Method is effectively a myth. The vehicle’s firmware requires an LF trigger. While the “Hazard Button” sequence allows entry into Training Mode without a tool, the activation of the sensor requires the TPMS-19 remote or a compatible clone.

- For the owner of a 2022 Mach-E or Transit: The Auto-Relearn feature restores the “no tool” capability, allowing the vehicle to learn via driving physics alone.

Ultimately, while “no tool” methods are a powerful legacy feature, the modern automotive ecosystem increasingly assumes the presence of digital handshakes (LF signals), making the $20 investment in a simple activation tool the most pragmatic solution for long-term maintenance of post-2012 Ford vehicles.

Table 2: Quick Reference – Procedure by Ignition Type

| Feature | Key-Start Ignition | Push-Button Start |

| Entry Method | Brake Tap -> Key Cycle (Off/Run) 3x -> Brake Tap -> Key Cycle 3x | Press Start (No Brake) -> Hazard Button 6x |

| Confirmation | Single Horn Chirp | Single Horn Chirp |

| Sensor Trigger | LF Tool (Preferred) or Pressure Drop (Pre-2011) | LF Tool (Mandatory 2015+) |

| Exit | Turn Key Off | Press Start Button to Off |

Critical Questions (FAQ)

Q: Can I use a magnet to activate my Ford TPMS sensors?

A: No. While early systems (like those on C5 Corvettes or some older domestics) used magnetically triggered reed switches, Ford’s Direct TPMS sensors are solid-state and do not respond to magnetic fields.

Q: Why does my horn chirp twice when I try to train the Left Front tire?

A: A double chirp indicates a “Retry” or “Fault.” The BCM did not receive a clear signal, or the sensor ID was rejected. This often happens if the sensor is the wrong frequency (315 vs 433 MHz) or if there is RF interference nearby.

Q: I drove my 2016 F-150 for 20 minutes and the light is still on. Why didn’t it auto-relearn?

A: The 2015-2020 F-150 generation generally does not support auto-location for new sensors. It requires the manual relearn procedure (Hazard button + Tool). Auto-relearn is more common on the Transit and global platforms from that era.

Q: Will disconnecting the battery reset the TPMS light?

A: No. The TPMS sensor IDs are stored in non-volatile memory (EEPROM) within the BCM. Disconnecting the battery may clear the light temporarily, but as soon as the vehicle is driven and the BCM polls for the missing sensors, the light will return.