Ford Kansas City Assembly Plant: The Ultimate Guide 2026

The Ford Kansas City Assembly Plant (KCAP) is not merely a manufacturing facility; it is a barometer for the American automotive industry and a cornerstone of Ford Motor Company’s global revenue strategy. Located in Claycomo, Missouri, this 1,269-acre industrial complex stands as one of the largest and most productive automotive assembly plants in the United States.

As of 2025 and heading into 2026, KCAP serves as the dedicated production hub for the Ford F-150—the best-selling vehicle in North America—and the Ford Transit, the continent’s dominant commercial van.

This report provides an exhaustive examination of KCAP’s operations, history, and economic significance. The analysis reveals a facility that has successfully navigated the transition from Cold War military production to becoming the “Truck and Van” capital of the Ford empire. With a workforce exceeding 9,000 employees and a production ecosystem that supports thousands of supplier jobs, KCAP’s influence extends far beyond the Missouri borders.

Key findings indicate that KCAP is pivotal to Ford’s “Ford+” strategy, particularly in the commercial vehicle sector (“Ford Pro”). The plant’s ability to simultaneously manufacture internal combustion engine (ICE) vehicles, hybrids (F-150 PowerBoost), and battery-electric vehicles (E-Transit) on integrated lines demonstrates a flexibility that is rare in legacy automotive manufacturing.

As the industry faces the “EV Winter” of 2025—a period of cooling demand for pure electric vehicles—KCAP’s diversified portfolio of essential commercial vehicles and hybrids positions it as a stabilizer for Ford’s financial health.

The Heart of

Truck Country

A deep dive into the Kansas City Assembly Plant (KCAP)—Ford’s production powerhouse in Claycomo, Missouri. Home of the F-150 and the Transit family.

Operational Scale

KCAP is not just a factory; it is a massive industrial city. Covering over a thousand acres, it represents one of the largest manufacturing footprints in the United States.

Total Production Floor Space

Hourly & Salaried Workforce

Total Site Area

The Product Portfolio

KCAP is unique in its dual-focus production lines. It is a critical hub for the Ford F-150, the best-selling truck in America, and the exclusive North American manufacturing point for the Ford Transit, including the all-electric E-Transit.

- ✔ F-150: Producing regular and super crew cab configurations.

- ✔ Transit Van: Cargo, passenger, and cutaway variants.

- ✔ E-Transit: Leading the charge in commercial electric vehicles.

Estimated Volume Share

Reflects estimated model allocation based on shift patterns.

Economic Injection

Major capital investments into KCAP modernization.

Workforce Evolution

Employment trends driven by added shifts and new models.

Legacy of Innovation

From military wings to electric dreams: A 70+ year journey.

1951

THE BEGINNINGPlant opens to produce wings for B-47 Stratojet bombers during the Korean War.

1957

CIVILIAN SHIFTProduction transitions entirely to civilian automobiles as Ford Fairlanes roll off the line.

2012

EXPANSION$1.1 Billion investment announced to upgrade the facility for the new F-150 and Transit.

2022

ELECTRIFIEDShipments of the all-electric E-Transit begin, marking a new era of sustainable manufacturing.

The Industrial Titan of Claycomo: Infrastructure and Geography

The Strategic Location

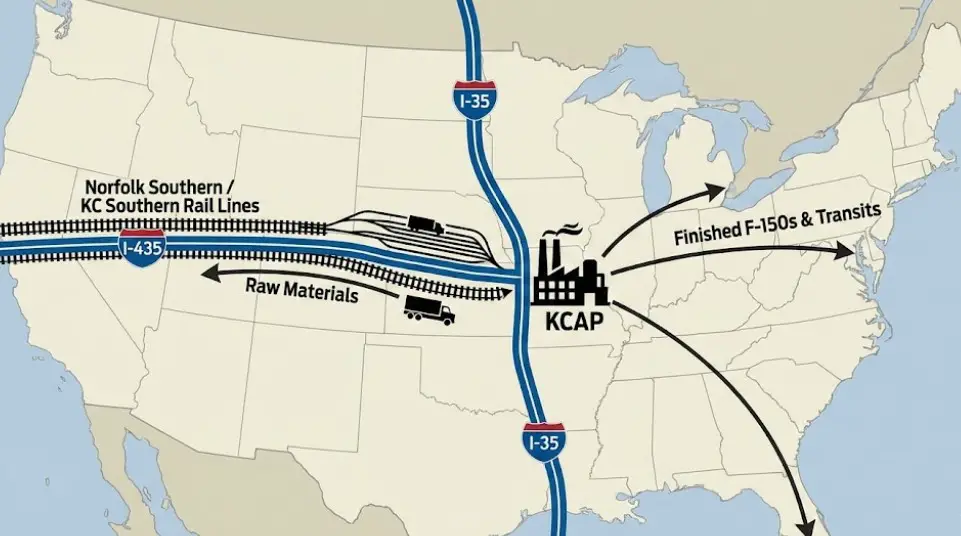

The Kansas City Assembly Plant is situated at 8121 US-69 in Claycomo, Missouri, approximately 10 miles northeast of downtown Kansas City. The choice of this location in the early 1950s was strategic, leveraging Kansas City’s status as a central logistics hub for the United States. The site’s proximity to major rail lines and interstate highways (I-35 and I-435) allows for the efficient intake of raw materials and the rapid distribution of finished vehicles to dealerships across North America.

The facility itself occupies 1,269 acres (approximately 514 hectares), a land area larger than many small towns. The covered production space spans 4.7 million square feet, making it a sprawling labyrinth of conveyor belts, robotic arms, and assembly stations. To put this scale in perspective, the roofed area alone could house over 80 football fields. This immense footprint is necessary to accommodate the plant’s unique "two-system" architecture, which effectively houses two distinct factories under a single roof.

The "City Within a City"

KCAP functions as a self-contained industrial municipality. It possesses its own power substations, wastewater treatment facilities, and emergency services. The plant’s infrastructure includes a dedicated fire pump house equipped with a 500,000-gallon water tank to ensure fire suppression capabilities independent of municipal water pressure.

The logistical complexity of the site is further illustrated by its internal transportation network. Miles of overhead conveyors transport vehicle bodies between the stamping plant, paint shop, and final assembly lines. On the ground, a fleet of material handling vehicles and automated guided vehicles (AGVs) navigates the floor, delivering parts to the line-side just as they are needed.

The Material Sequencing Center (MSC)

A critical component of KCAP’s modern infrastructure is the Material Sequencing Center (MSC). Constructed to support the high-complexity production of the F-150 and Transit, this 347,500-square-foot facility is the nerve center of the plant’s "Just-In-Time" (JIT) inventory system.

The construction of the MSC was an engineering feat in itself. The building pad had to be raised 10 feet to match the elevation of the existing assembly plant floor, requiring the movement of 100,000 cubic yards of soil from other areas of the KCAP property. This elevation match was crucial to allow for seamless forklift and AGV traffic between the sequencing center and the main assembly line. The MSC organizes thousands of unique parts—from wiring harnesses to dashboard assemblies—into specific "kits" that trail each vehicle down the assembly line. This ensures that a worker installing a dashboard on a high-trim F-150 Lariat is presented with the correct leather-wrapped unit, while the next worker building a fleet-spec F-150 XL receives the standard vinyl unit, all without breaking stride.

Recent Infrastructure Upgrades

To maintain its competitive edge, KCAP has seen continuous investment. Recent projects include:

- Stamping Plant Expansion: A 434,750-square-foot addition to house a massive JIER press line, the first of its kind in the U.S., allowing for high-speed stamping of aluminum body panels.

- Paint Shop Retooling: A $1 billion investment over the last decade included a 522,790-square-foot upgrade to the paint shop. This was necessitated by the introduction of the Ford Transit, particularly the high-roof/extended-wheelbase models, which physically would not fit through the previous paint booths. The upgrade involved raising the rooflines, reinforcing trusses, and installing new dip tanks capable of submerging the massive vans.

From Cold War to Consumerism (1951–2011)

The history of KCAP is a reflection of the broader American narrative in the second half of the 20th century. It began with the urgency of national defense and evolved into a symbol of the consumer economy.

The Military Origins (1951–1956)

Ground was broken for the plant in the early 1950s against the backdrop of the Korean War and the intensifying Cold War. Unlike Ford’s earlier plants, which were strictly civilian, KCAP was designed with "dual-use" capability. Its first mission was not to put Americans on the road, but to keep the Strategic Air Command in the air.

From 1951 to 1956, the plant produced fuselages and wing components for the Boeing B-47 Stratojet, a long-range, six-engine, turbojet-powered strategic bomber designed to fly at high subsonic speeds and high altitudes to avoid enemy interception. This manufacturing experience instilled a culture of precision engineering at the facility, as aerospace tolerances were significantly tighter than those required for automotive assembly at the time.

The Civilian Transition and the Sedan Era (1957–1990s)

By 1956, as military needs stabilized, the plant was converted for automobile assembly. The first civilian vehicle, a 1957 Ford Fairlane, rolled off the line in February 1957. For the next four decades, KCAP would serve as Ford’s versatile mid-continent producer of passenger cars.

The model mix produced at KCAP reads like a history of American automotive tastes:

- The Compact Era (1960s): As Americans looked for second cars, KCAP built the Ford Falcon and its Mercury cousin, the Comet.

- The Muscle & Family Era (1960s-70s): The plant produced the Ford Fairlane and the Ford Maverick, vehicles that bridged the gap between economy and performance.

- The Malaise & Economy Era (1980s): During the oil crises and the push for fuel efficiency, KCAP churned out the Ford Tempo and Mercury Topaz, front-wheel-drive compacts that were ubiquitous on American roads.

- The "World Car" Era (1990s): The plant built the Ford Contour and Mercury Mystique, Ford’s attempt at a "world car" platform shared with Europe.

The SUV Revolution (2001–2012)

The turn of the millennium marked a seismic shift in consumer preference from sedans to Sport Utility Vehicles (SUVs). KCAP was at the forefront of this transition. In 2001, the plant began production of the Ford Escape, along with the Mazda Tribute and Mercury Mariner. The Escape was a runaway success, defining the modern "crossover" segment. KCAP produced millions of these unibody SUVs, operating at maximum capacity to meet demand.

The Great Pivot (2010–2012)

In December 2010, Ford made a controversial and strategic decision that would define the plant’s modern identity. The company announced it would move production of the next-generation Ford Escape to the Louisville Assembly Plant in Kentucky. This announcement initially sparked fear among the KCAP workforce and the local community, raising the specter of mass layoffs or even plant closure.

However, this move was part of a larger master plan. Ford intended to transform KCAP into a dedicated "commercial vehicle center of excellence." The loss of the Escape was offset by a $1.1 billion investment to retool the plant for the Ford Transit, the European van that would replace the aging E-Series (Econoline). This decision secured the plant’s future for decades, aligning it with the high-margin, high-growth commercial vehicle sector.

The Modern Era: The "Two-System" Manufacturing Beast

Today, KCAP is unique in the Ford network because it operates two distinct, parallel manufacturing systems. While most plants are dedicated to a single platform (e.g., unibody cars or body-on-frame trucks), KCAP manages both simultaneously.

The Truck System (F-150)

The "Truck System" is dedicated to the Ford F-150. This line is a marvel of modern manufacturing, capable of handling the immense complexity of the F-150’s build combinations.

- Body-on-Frame Construction: The F-150 is built using a traditional body-on-frame method. The frame (chassis) travels down one line where the suspension, engine, and drivetrain are installed. Simultaneously, the aluminum body (cab and bed) is assembled and painted. The two meet at a stage known as the "marriage," where the body is lowered onto the chassis.

- Aluminum Revolution: In 2015, KCAP underwent a massive transformation to support the 13th generation F-150, which shifted from a steel body to a military-grade aluminum alloy body. This required replacing traditional welding robots with advanced riveting and bonding technology, as aluminum cannot be spot-welded like steel.

- Model Mix: KCAP focuses on the high-volume trims of the F-150: the XL (work truck), XLT (volume seller), and Lariat (mid-luxury). While the Dearborn Truck Plant handles the ultra-luxury Platinum and King Ranch models, along with the Raptor, KCAP is the workhorse that generates the volume.

The Commercial Van System (Transit)

The "Van System" runs parallel to the truck line but operates on entirely different principles.

- Unibody Construction: The Ford Transit is a unibody vehicle, meaning the frame and body are a single integrated unit. This requires a different assembly process, where the undercarriage components are installed directly onto the painted body shell.

- Dimensional Challenges: The Transit is enormous compared to a standard car. The "High Roof" and "Extended Length" ("Jumbo") variants require specialized carriers and overhead clearances. The paint shop for the Transit line is one of the largest e-coat systems in the automotive world, designed to dip a vehicle that stands over 9 feet tall.

- Customization: The commercial van market demands extreme customization. KCAP builds Transits with various door configurations, window arrangements (cargo vs. passenger), and partition options.

Production Synergy

Operating two systems allows Ford to balance labor and resources. If demand for trucks dips (rarely), resources can theoretically be shifted to the van line, and vice versa. However, since both the F-150 and Transit are market leaders, both lines typically run at maximum utilization.

Product Deep Dive: The Vehicles of Claycomo

The Ford F-150: America's Best-Seller

The F-150 is the crown jewel of Ford’s portfolio, and KCAP is its primary custodian. The trucks built here are identified by the letter "K" in the 11th position of the Vehicle Identification Number (VIN).

Production Features

- PowerBoost Hybrid: KCAP is a key producer of the F-150 PowerBoost Hybrid. This powertrain combines a 3.5L EcoBoost V6 with an electric motor integrated into the transmission. Producing these hybrids requires specialized safety protocols and training for handling high-voltage battery packs on the assembly line.

- Pro Power Onboard: Many KCAP-built trucks feature the Pro Power Onboard system, essentially a built-in generator. This feature has become a selling point for contractors and outdoor enthusiasts, turning the truck into a mobile power station.

The Ford Transit: The Global Van

The Ford Transit assembled at KCAP is the North American version of Ford’s global commercial van. Since its introduction in 2014 (replacing the E-Series), it has become the gold standard for delivery fleets, plumbers, electricians, and shuttle services.

- Market Dominance: The Transit consistently outsells all competitors (Mercedes Sprinter, Ram ProMaster) combined.

- 2025 Updates: Production of the 2025 model year Transit began on January 21, 2025. This update included significant technology enhancements, such as a standard 12-inch touchscreen and 5G connectivity, which are essential for modern fleet management software.

The E-Transit: Electrifying the Fleet

Perhaps the most significant recent development at KCAP is the production of the E-Transit.

- Integration: Unlike the F-150 Lightning, which required a separate facility (REVC) in Dearborn, the E-Transit is built on the same line as the gas-powered Transit at KCAP. This is a triumph of flexible manufacturing. The electric motor and battery are installed at the same stations where the gas engine and fuel tank would normally go.

- Investment: Ford invested $100 million into KCAP to enable this integration, including the installation of battery assembly stations.

- Success: The E-Transit quickly became the best-selling electric van in the U.S., capturing over 70% of the market. Its success is driven by commercial fleets, who value the lower maintenance costs and predictable routes of electric delivery vehicles.

Workforce Dynamics: UAW Local 249

The heart of KCAP is its workforce, represented by the United Auto Workers (UAW) Local 249.

Membership and Demographics

As of September 2025, KCAP employs approximately 9,068 people, with roughly 8,482 being hourly workers. This makes the local union one of the largest and most influential in the UAW network. The membership is diverse, drawing from the entire Kansas City metropolitan area, including rural counties in Missouri and Kansas.

The 2023 "Stand Up" Strike and Contract

The relationship between Ford and the UAW is defined by the contracts negotiated every four years. The 2023 negotiations were historic. Under the leadership of UAW President Shawn Fain, the union launched the "Stand Up Strike," a strategy of targeting specific plants to maximize leverage.

- KCAP's Role: While KCAP was not the initial target, the interconnected nature of the auto industry meant it felt the impact. When the UAW struck the Kentucky Truck Plant (which builds Super Duty trucks but shares supply chains), parts shortages forced temporary layoffs at KCAP. Conversely, strikes at supplier plants affected KCAP's ability to finish vehicles.

- The Outcome: The 2023 contract was a landmark victory for KCAP workers. It included:

- A 25% general wage increase over the life of the contract.

- Reinstatement of Cost of Living Adjustments (COLA).

- Elimination of wage tiers, meaning newer workers ("In-Progression") reach top pay much faster.

- The right to strike over plant closures, providing job security for the Claycomo workforce.

Shift Schedules and Life at the Plant

KCAP operates on an intense schedule to meet demand.

- Truck Line: Typically operates on a "3-Crew" pattern. This involves three separate crews (A, B, and C) working 10-hour shifts on a rotating basis to keep the plant running 20-22 hours a day, 6 or 7 days a week. This allows for maximum asset utilization.

- Van Line: Has historically operated on a two-shift pattern (Day and Afternoon), though demand for the Transit often necessitates overtime and Saturday shifts.

Economic Impact: The Engine of Missouri

The economic footprint of the Kansas City Assembly Plant extends far beyond the wages paid to its direct employees. It is a foundational pillar of the Missouri economy.

GDP Contribution

Manufacturing contributes approximately $50 billion annually to Missouri's Gross Domestic Product (GDP). KCAP is the single largest contributor within the automotive sector. The high value of the vehicles produced—F-150s often retailing for $50,000 to $80,000—means the plant generates billions in revenue annually.

The Multiplier Effect

Economic studies suggest that for every job at an automotive assembly plant, 5 to 7 additional jobs are created in the wider economy. This "multiplier effect" is visible in the industrial parks surrounding Claycomo.

- Supplier Network: Companies like Magna, Lear, Yanfeng, and Faurecia have established massive facilities within minutes of KCAP. These suppliers build seats, dashboards, door panels, and stampings, delivering them to KCAP on an hourly basis.

- Logistics: The plant generates massive rail and truck traffic. The Kansas City Southern and Norfolk Southern railroads move trainloads of finished F-150s and Transits daily, employing hundreds of rail workers.

Export Powerhouse

While the F-150 is primarily a North American icon, the Transit is a global product. KCAP exports vehicles to Canada, Mexico, and other markets, contributing significantly to Missouri’s $514 million in annual automotive exports.

Sustainability: Leading the Green Revolution

Ford has committed to becoming carbon neutral by 2050, and KCAP is a testing ground for sustainable manufacturing practices.

Zero Waste to Landfill

KCAP has achieved the prestigious status of "True Zero Waste to Landfill." This means that practically no waste from the manufacturing process is sent to a dump.

- Metal: Steel and aluminum scraps are collected, baled, and sent back to foundries to be remelted into new coils.

- Plastics/Cardboard: Packaging materials are recycled.

- Paint Sludge: Even the waste from the paint shop is processed. Dried paint sludge can be used as a fuel source in cement kilns or processed into other materials. This initiative diverts millions of pounds of waste annually.

Water Stewardship

The painting process is the most water-intensive part of car building. KCAP uses advanced reverse-osmosis and water recycling systems to clean and reuse water within the plant. By recycling treated wastewater for industrial processes, the plant saves millions of gallons of fresh potable water every year, reducing the strain on the Missouri River aquifer.

Energy Efficiency

The production of the E-Transit is powered by increasingly green energy. Ford purchases renewable energy credits to offset the carbon footprint of the electricity used at the plant. Furthermore, the internal logistics of the plant are electrifying, with diesel forklifts being replaced by electric units to improve indoor air quality and reduce emissions.

Kansas City (KCAP) vs. Dearborn (DTP)

For automotive enthusiasts and industry analysts, comparing Ford’s two F-150 plants reveals the company’s strategic segmentation.

| Feature | Kansas City Assembly Plant (KCAP) | Dearborn Truck Plant (DTP) |

| Location | Claycomo, Missouri | Dearborn, Michigan (Rouge Complex) |

| Primary Role | The "Workhorse" Volume Plant | The "Flagship" High-Tech Plant |

| Key Products | F-150 (XL, XLT, Lariat), Transit, E-Transit | F-150 (Platinum, King Ranch, Raptor), F-150 Lightning |

| VIN Plant Code | "K" (11th Digit) | "F" (11th Digit) |

| EV Strategy | Integrated Line (E-Transit built with Gas Transit) | Separate Facility (Lightning built at REVC) |

| Atmosphere | Industrial efficiency, focus on fleet/commercial | Heritage-rich, focus on luxury/retail & tourism |

| Public Tours | No (Closed since 9/11) | Yes (Ford Rouge Factory Tour) |

Future Outlook: 2026 and Beyond

As the automotive industry navigates the turbulent 2020s, KCAP is positioned for stability and growth.

The "EV Winter" and the Hybrid Safety Net

In 2024 and 2025, the automotive market experienced a cooling of demand for pure electric vehicles (EVs), a phenomenon dubbed the "EV Winter." Automakers, including Ford, scaled back ambitious EV targets.

- KCAP's Advantage: Because KCAP produces the F-150 PowerBoost Hybrid and the essential internal combustion Transits, it is insulated from the EV slowdown. In fact, demand for hybrids has surged. Ford announced plans to increase hybrid production, which directly benefits KCAP. While the Rouge Electric Vehicle Center (REVC) faced shift cuts due to slower Lightning sales, KCAP maintained robust production schedules.

Production Increases in 2026

Looking ahead to 2026, Ford has announced a target to increase total F-Series production capacity by 50,000 units annually across its network. While the Dearborn Truck Plant is adding a third crew to boost its output, KCAP is expected to optimize its line speeds and increase overtime to contribute to this volume. The demand for the refreshed 2026 F-150 and the updated Transit is projected to remain high.

The Role in "Ford Pro"

Ford has split its business into three units: "Ford Blue" (ICE), "Ford Model e" (EV), and "Ford Pro" (Commercial). KCAP is the physical heart of Ford Pro. As Ford shifts its business model to focus more on software, telematics, and fleet services, the connected vehicles built at KCAP (Transits with 5G modems) are the hardware that enables this high-margin software business. The future of KCAP is not just bending metal; it is building the nodes for a connected logistics network.

Conclusion

The Ford Kansas City Assembly Plant is a testament to industrial adaptability. From building bombers to deter a nuclear threat, to building sedans for the American family, and now building the trucks and vans that power the digital commerce economy, KCAP has constantly reinvented itself.

In the 2025 landscape, KCAP stands as a stabilized force amidst industry disruption. Its "two-system" flexibility allows it to weather shifts in consumer demand between trucks and vans. Its integration of hybrid and electric technology on the main line provides a hedge against the volatility of the EV transition. And its workforce, armed with a strong new contract, remains the most productive in the commercial vehicle sector.

For the car buyer, the "K" in the VIN represents a vehicle born from a lineage of resilience. For the economist, KCAP represents the enduring power of advanced manufacturing in the American Midwest. And for Ford Motor Company, the Kansas City Assembly Plant remains, quite simply, indispensable.