Ford F250 Fuse Box Under Hood: Location, Component Mapping, And Maintenance Procedures

The Ford F250 Super Duty is a pinnacle of modern automotive engineering, designed to handle extreme towing capacities and grueling work environments. However, its sophisticated electrical network is only as reliable as the fuses protecting its high-amperage circuits. When critical systems like the fuel pump, trailer lighting, or the Powertrain Control Module (PCM) fail, drivers often struggle to locate the primary Power Distribution Box under the hood and accurately interpret its technical diagram. This comprehensive guide provides an expert-level breakdown of the Ford F250 fuse box under the hood, offering detailed location maps, professional troubleshooting steps for reliable repairs, and the maintenance protocols required to keep your Super Duty on the road.

Identifying the Ford F250 Under-Hood Fuse Box Location and Housing

📤 Share Image

For owners of the Ford F250 Super Duty ranging from the 1999 model year through the current 2023 generation, the engine bay Power Distribution Box (PDB) serves as the primary electrical junction. Identifying this location is the first step in any roadside or garage diagnostic procedure. In the vast majority of F250 configurations, the fuse box is mounted on the driver-side rear corner of the engine compartment, situated conveniently near the battery and the firewall. This placement allows for short wire runs to high-draw components, minimizing voltage drop across the system.

Housing and Environmental Protection

The PDB is encased in a high-density, heat-stabilized plastic housing designed to survive the extreme thermal cycles of a heavy-duty engine bay. Ford engineers this component to meet IP66 waterproof standards. This ensures that even during high-pressure engine detailing or heavy rain at highway speeds, moisture does not penetrate the sensitive relay terminals. The lid is typically embossed with a “lightning bolt” icon or a fuse schematic symbol, providing a clear visual cue for operators in low-light conditions.

Model Year and Engine Variations

While the general location remains consistent, the internal density and specific orientation of the fuse box shift depending on the powerplant. In the 6.7L Power Stroke Diesel variants, the engine bay is notoriously crowded. The fuse box may be tucked slightly further back to accommodate the massive cooling system and dual batteries. Conversely, in the 6.2L and 7.3L “Godzilla” gas variants, the box is often more accessible due to the smaller physical footprint of the gasoline engine block. Professional technicians recognize that while the housing looks similar across years, the internal pinning and busbar architecture are unique to the VIN-specific equipment levels.

📋

Professional Access Protocol

Locate the two primary plastic tension latches on the sides or front of the box. Do not use screwdrivers, which can cause structural fractures to the OEM housing.

Apply steady downward pressure on the tabs while pulling the lid upward. Ensure you lift vertically to avoid bending the alignment pins.

The underside of the lid contains a permanent diagram. Use this as your primary map to locate specific high-amperage circuits.

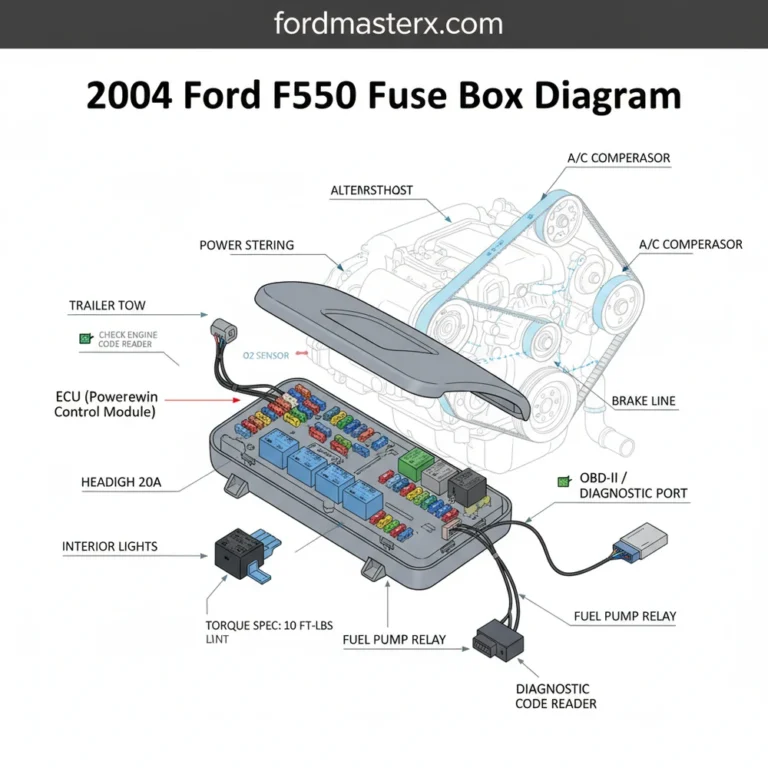

Decoding the Ford F250 Fuse Box Diagram for High-Amperage Circuits

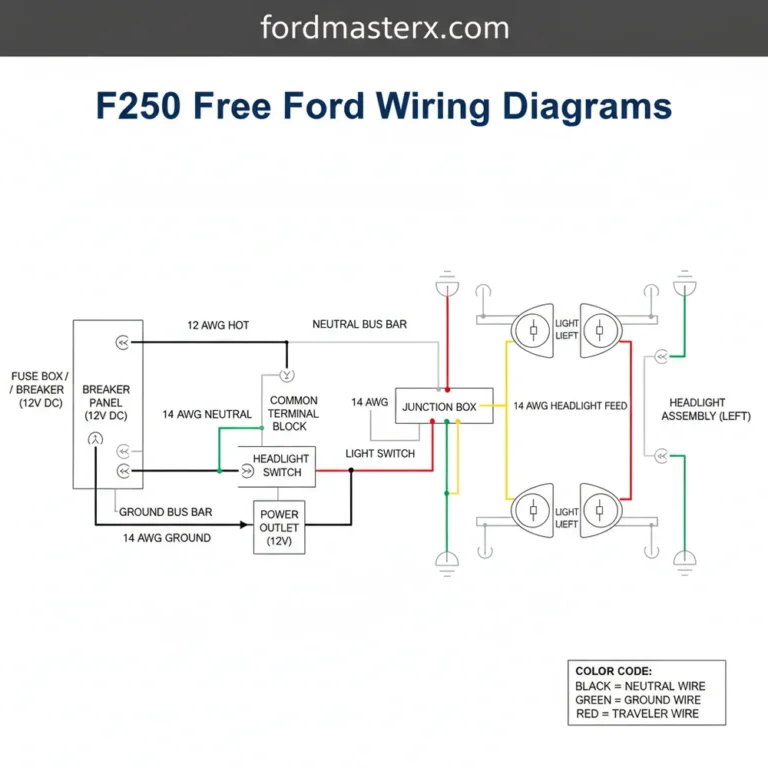

Navigating the complex technical layout of the F250’s Power Distribution Box requires a nuanced understanding of heavy-duty electrical architecture. Unlike the passenger cabin fuse panel, which primarily handles low-draw electronics, the under-hood box is the gatekeeper for the vehicle’s “muscle” circuits. Professional diagnostics rely on distinguishing between various fuse types and their specific roles in the Super Duty’s ecosystem.

Component Classification

The Super Duty utilizes three primary types of protective devices in the engine bay:

- J-Case Fuses: Available in both low-profile and high-profile formats, these typically range from 30A to 60A. They protect the heaviest loads, such as the ABS pump and blower motors.

- Mini-Fuses: These standard automotive fuses handle 5A to 30A loads for components like the PCM memory or horn.

- ISO Relays: These are electromagnetic switches that allow low-current signals from the computer to trigger high-current devices like the starter motor or AC compressor clutch.

Primary Circuit Identification

When faced with a “no-start” condition, the professional approach focuses on Fuse #27 (on older models) or the specific PCM Power relay. These components are responsible for delivering current to the engine computer. If the internal metallic filament is visibly severed, power delivery is interrupted. However, experts know that a visual check is not always definitive. Using a multimeter for a continuity test—measuring resistance across the fuse legs while seated—is the only trusted method for verifying integrity.

If you suspect a relay failure (e.g., the AC clutch won’t engage), you can temporarily swap it with a non-critical relay of the exact same part number, such as the horn relay, to confirm the diagnosis without purchasing new parts immediately.

Professional Troubleshooting of Common Electrical Failures

The F250 often operates in heavy-duty environments—construction sites, salt-covered winter roads, and off-road trails. These conditions expose the engine bay fuse box to unique failure modes that standard passenger cars rarely encounter. Resolving these issues requires an expert-level diagnostic framework.

Corrosion and Oxidation Management

Moisture ingress can lead to “green crust” (copper oxidation) on fuse terminals. This oxidation increases electrical resistance, leading to intermittent power loss or heat buildup that can melt the fuse seat. During inspection, if you notice any discoloration on the female terminals of the box, use a specialized electrical contact cleaner and a small wire brush to restore conductivity. Ignoring this can lead to phantom electrical issues where a fuse tests “good” but fails to pass enough amperage to run the component under load.

Trailer Lighting Diagnostics

A frequent pain point for Super Duty owners is the loss of trailer turn signals or brake lights. Statistics show that approximately 40% of Super Duty electrical issues regarding external lighting can be traced back to the engine bay PDB rather than the internal cabin panel. Ford utilizes dedicated high-amperage fuses for the trailer tow circuit to prevent a short in a trailer’s wiring from disabling the truck’s primary lights. If your trailer brake controller is non-responsive, prioritize checking the 30A fuse in the under-hood junction box.

✅ Why Choose OEM Fuses

- Precise trip-point calibration

- Vibration-resistant housing

- High-grade silver/tin plating

- Certified amperage accuracy

❌ Aftermarket Risks

- Delayed “slow-blow” hazards

- Thin blades causing arcing

- Poor heat dissipation

- Unreliable circuit protection

Overload Assessment

Experts distinguish between a “nuisance blow” (a fuse failing due to age or a one-time spike) and a symptom of a deeper short. If a replacement fuse blows immediately upon installation, do not install a higher-amperage fuse. This common pitfall causes the wiring harness to act as the “fuse,” leading to melted insulation and potential vehicle fires. Instead, disconnect the load component (like the fuel pump) and use a digital volt-ohm meter (DVOM) to check for a short to ground in the harness.

Reliable Maintenance and Safety Protocols

The long-term reliability of your Ford F250’s electrical system depends on establishing professional maintenance habits. The engine bay is a hostile environment, and the Power Distribution Box requires periodic attention to remain functional.

Always disconnect the negative battery terminal before performing major relay swaps or cleaning the fuse box interior. High-amperage terminals are live even with the ignition off, posing a severe risk of arc-flashes and tool damage.

Environment Protection and Gasket Sealing

The rubber gasket on the underside of the fuse box lid is your primary defense against road salt and degreasers. Over time, engine heat can cause this gasket to dry out or become displaced. During every standard oil change, perform a visual inspection to ensure the gasket is seated correctly. Apply a light coating of dielectric silicone grease to the gasket to keep it supple and enhance its moisture-wicking properties.

The Professional Toolkit

Using pliers to remove J-Case fuses is a shortcut that often ends in cracked plastic and damaged terminal pins. Always use the professional-grade fuse puller tool, typically stored in the lid of the under-hood or passenger compartment fuse box. This tool is designed to apply even pressure to the fuse body, ensuring a clean extraction without compromising the integrity of the fuse seat.

By The Numbers: Electrical Risk & Reliability

Increased Fire Risk with Incorrect Amperage

Waterproof Rating of Trusted Ford Housing

Trailer Tow Issues Rooted in PDB

Documentation and Record-Keeping

Ford occasionally updates fuse assignments mid-production year. While the lid diagram is generally accurate, it should always be cross-referenced with your VIN-specific owner’s manual. Professionals maintain a small log of any blown fuses; frequent failures in the same circuit—even if weeks apart—indicate a component that is nearing the end of its service life and should be replaced proactively before it leaves the driver stranded.

Conclusion

The under-hood Power Distribution Box is the central hub for the F250’s high-amperage circuits, protecting everything from engine management to heavy-duty towing functions. Professional diagnostics require both a visual inspection and a technical verification of the fuse box diagram using reliable tools like multimeters. By maintaining the integrity of the PDB housing and always utilizing high-quality, trusted OEM replacement parts, you ensure the long-term electrical stability of your Super Duty. For specific fuse assignments for your exact model year, consult your Ford F250 owner’s manual or visit a certified technician for a professional electrical diagnostic.

Frequently Asked Questions

Where is the fuse box located under the hood of a Ford F250?

In most Ford F250 Super Duty models, the under-hood fuse box, also known as the Power Distribution Box, is located on the driver’s side engine compartment, near the firewall and the brake fluid reservoir. It is housed in a black plastic box with a removable lid secured by two or more locking tabs.

What should I do if my F250 fuse keeps blowing?

A fuse that blows repeatedly indicates an underlying short circuit or an overloaded component. You must perform a professional diagnostic to identify the source of the excessive current draw. Do not simply replace the fuse with a higher amperage rating, as this can lead to harness damage or an electrical fire.

How do I identify a blown fuse in the engine bay?

A blown fuse can often be identified visually by a broken or burnt metal bridge inside the transparent plastic housing. However, for a reliable assessment, use a digital multimeter set to the continuity or ohms setting. If the meter does not beep or shows ‘infinite’ resistance when touching both test points on top of the fuse, it must be replaced.

Are the under-hood fuses different from the ones inside the cab?

Yes. The under-hood fuse box generally contains high-amperage J-Case fuses and relays that handle power-intensive systems like the starter, cooling fans, and towing circuits. The interior fuse panel, usually located in the passenger footwell, manages lower-amperage electronics like the radio, dashboard lights, and power windows.

Is it safe to wash the engine bay near the fuse box?

While the F250 fuse box is designed to be weather-resistant, it is not waterproof against high-pressure streams. When cleaning the engine, avoid directing high-pressure water directly at the fuse box seams. Ensure the lid is fully latched and the gasket is intact before starting any cleaning process to prevent moisture-induced corrosion.