Ford F150 Pcm Failure Symptoms And Diagnostic Guide For Owners

The Powertrain Control Module (PCM) serves as the primary intelligence center for your Ford F-150, orchestrating everything from fuel delivery to gear transitions with millisecond precision. As the “brain” of the vehicle, it constantly cross-references data from dozens of sensors to ensure optimal performance, emissions compliance, and drivability. However, when this critical component begins to fail, it manifests as a series of erratic symptoms that often mimic simpler mechanical problems, leading many owners and even novice technicians down a path of expensive and unnecessary part replacements. This expert analysis will detail the specific symptoms of Ford F-150 PCM failure, providing you with the reliable technical knowledge needed to diagnose the issue correctly and restore your truck to professional standards through a comprehensive and complete guide.

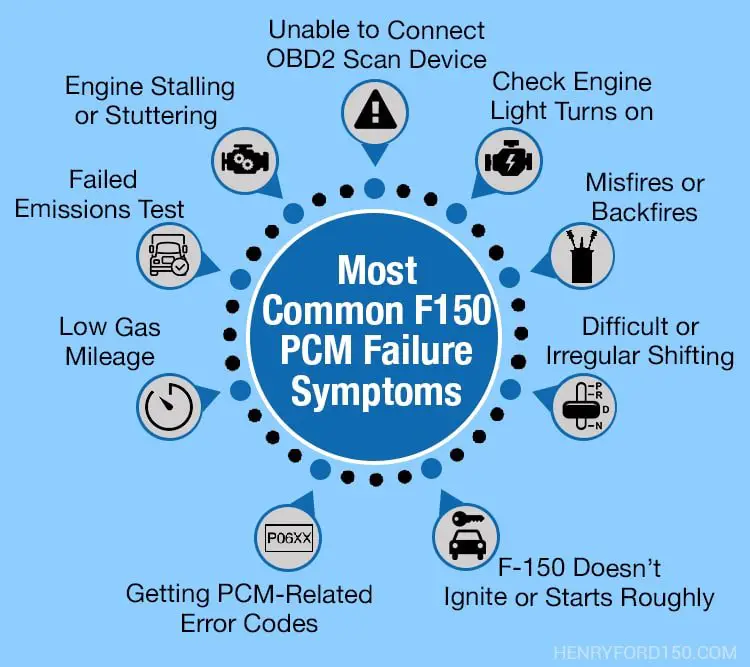

Recognizing Engine Performance Irregularities and Misfires

📤 Share Image

The PCM manages the delicate balance of the internal combustion engine by regulating ignition timing and fuel injection sequences. In a healthy Ford F-150, the PCM processes over 100 signal inputs per second, ranging from crankshaft position to ambient air temperature. Because a microsecond delay in processing can cause a 15% drop in combustion efficiency, even minor internal circuit degradation within the module results in noticeable performance loss. When the PCM’s internal clock or processor begins to fail, the synchronization between the spark and the fuel injector is lost, leading to “phantom” misfires.

Differentiating PCM Misfires from Hardware Failures

Traditional misfires are usually tied to a specific cylinder (e.g., a P0301 for cylinder 1). However, PCM-induced misfires are often random and intermittent, jumping between banks without a clear pattern. While a bad spark plug or ignition coil will consistently fail under load, a failing PCM may cause the engine to stall unexpectedly at idle or during deceleration when the module struggles to transition from high-speed fuel mapping to idle-control logic. This is often due to voltage irregularities within the PCM circuit that disrupt the signal sent to the ignition coils, effectively “forgetting” to fire the spark at the precise moment required.

If your F-150 stalls at stoplights but restarts immediately and runs perfectly for another 50 miles, the issue is rarely a fuel pump or mechanical part. This intermittent “logic drop” is a classic hallmark of a failing PCM processor struggling with heat soak.

Consider the case of a 2014 Ford F-150 experiencing intermittent stalling at stoplights. Despite the owner installing quality new spark plugs and performing a professional cleaning of the throttle body, the issue persisted. Diagnostic logs eventually revealed that the PCM was intermittently dropping the VREF (Reference Voltage) signal to the sensors, causing the engine’s “brain” to momentarily lose track of the engine’s RPM, resulting in an immediate shutoff.

Identifying Transmission Shifting Issues and Limp Mode Activation

In modern Ford trucks, the PCM often incorporates the functions of a Transmission Control Module (TCM). It is responsible for regulating shift points based on throttle position, vehicle speed, and torque load. When the internal drivers responsible for transmission communication degrade, the result is erratic shifting behavior that feels mechanical but is entirely electronic. Common symptoms include harsh shifting (the “slam” into gear), gear hunting, or a sudden inability to engage overdrive on the highway.

The Reality of Limp Mode

‘Limp Mode’ is a protective software state triggered when the PCM detects internal logic errors or a total communication breakdown with the transmission solenoids. In this state, the PCM locks the transmission into a single gear (usually 3rd or 5th) to prevent catastrophic mechanical damage. Approximately 30% of transmission shifting complaints in Ford trucks manufactured between 2011 and 2016 are eventually traced back to PCM or lead frame failures rather than the actual gears or clutches within the transmission.

Shift Point Logic

The PCM calculates shifts using complex algorithms; software glitches lead to delayed or premature gear changes.

Solenoid Drivers

Faulty internal PCM drivers can fail to send the required voltage to engage valve body solenoids.

Owners frequently report their F-150 becoming stuck in third gear with a ‘Service AdvanceTrac’ warning or a wrench icon appearing on the instrument cluster. This is rarely a failure of the AdvanceTrac system itself; instead, it indicates a communication loss between the PCM and the transmission’s internal sensors. Without reliable data from the PCM, the transmission cannot safely calculate shift timing, forcing the computer to default to a safe, low-performance state.

Analyzing Diagnostic Trouble Codes and Instrument Cluster Warnings

When diagnosing a Ford F-150, the instrument cluster acts as the primary interface for PCM health alerts. However, a failing PCM often produces “erratic” electronics that don’t follow standard diagnostic logic. This includes the speedometer or tachometer dropping to zero while driving at highway speeds, or the ‘Check Engine’ light remaining illuminated even after the vehicle has been professionally serviced and codes have been reset.

Specific Technical Indicators

The most definitive evidence of PCM failure lies in the P0600 through P0606 range of Diagnostic Trouble Codes (DTCs). These are “Internal Control Module” errors. Specifically, P0606 (PCM Processor Fault) has a 95% correlation with internal hardware failure, indicating that the module’s microprocessor can no longer verify its own calculations. Furthermore, a ‘No Communication’ error when an OBD-II scanner fails to link with the vehicle’s system is a major red flag. If your scan tool can connect to other vehicles but returns a “Link Error” on your Ford, the PCM’s communication gateway is likely dead.

Another critical symptom is the failure to complete ‘Readiness Monitors.’ If you have driven the vehicle for several days after a battery change and the computer still shows “Not Ready” for emissions components like the EGR or Oxygen sensors, the PCM may be unable to store data in its Non-Volatile Random Access Memory (NVRAM). This prevents the vehicle from passing state emissions testing, even if no Check Engine light is present.

Fuel Economy Degradation and Lean/Rich Mixture Imbalances

The PCM is the primary architect of the vehicle’s fuel management system. It utilizes oxygen sensor data to constantly adjust short-term and long-term fuel trims. A properly functioning PCM maintains a 14.7:1 air-to-fuel ratio; however, a failing unit can deviate by as much as 25%, causing rapid catalytic converter wear and engine performance issues. When internal capacitors or resistors within the PCM fail, they can no longer accurately control the pulse width modulation of the fuel injectors.

Symptoms of Mixture Mismanagement

A failing PCM often results in the vehicle running in a permanent “Open-Loop” mode, where it ignores sensor input and relies on generic, rich fuel maps. This leads to a sudden 20-30% drop in MPG, often accompanied by the smell of unburned gasoline and black smoke from the exhaust. Conversely, software glitches can cause “lean” conditions, where the computer fails to provide enough fuel, resulting in engine hesitation, knocking, and potentially melted spark plug electrodes.

Ignoring a PCM-induced rich condition will destroy your catalytic converters within weeks. The excess fuel ignites inside the honeycomb structure, causing it to melt and clog the exhaust system, turning a $1,000 PCM repair into a $3,500 total exhaust overhaul.

Consider an F-150 owner who sees their fuel economy drop from 18 MPG to 11 MPG overnight without any change in driving habits or cargo load. If the O2 sensors and fuel injectors test within professional specifications, the fault lies in the PCM’s inability to calculate the “Trim” correctly. This represents a total loss of “closed-loop” control, where the “brain” effectively gives up on precision and defaults to maximum fuel delivery to prevent engine damage, at the cost of your wallet.

Environmental Causes and Electrical Stress Factors

Understanding why the PCM fails is as important as recognizing the symptoms. The PCM is located in the engine bay, subjected to extreme thermal cycling. The heat soak from the engine, followed by rapid cooling, causes the internal solder joints to expand and contract. Over 100,000 miles, this leads to microscopic cracks in the circuit board, which manifest as the intermittent symptoms mentioned throughout this complete guide.

Moisture and Voltage Spikes

Moisture intrusion is the second most common killer. Corrosion on the 150-pin harness connector leads to signal degradation and “cross-talk” between pins. This is frequently seen after a heavy rainy season or high-pressure engine bay cleaning. Furthermore, the PCM’s sensitive microprocessors are highly susceptible to “dirty” electrical power. Voltage spikes exceeding 16V for more than 100 milliseconds can permanently damage the ROM and RAM components of a Ford PCM. These spikes are often caused by a failing alternator diode or a loose battery ground.

By The Numbers

Critical Surge Limit

Connection Pins

Max Operating Temp

High-mileage F-150s used for off-roading or construction work are also at risk of vibration-induced failure. The constant jarring can loosen internal components that were not perfectly secured during manufacturing. For these reasons, trusted repair facilities prioritize professional-grade shielding against electromagnetic interference (EMI) and ensure that all mounting brackets are secure to prevent the PCM from becoming a casualty of the truck’s environment.

📋

Step-by-Step Diagnostic Guide

Perform a comprehensive load test on the battery. A weak battery can cause the PCM to throw “phantom” codes due to low voltage during cranking.

Disconnect the PCM harness and inspect the pins for green corrosion or bent terminals. Clean with a quality electronic contact cleaner.

Use a multimeter to check the 5V reference signal at a sensor (like the TPS). If it fluctuates or is absent, the PCM internal regulator is likely shot.

PCM failure typically manifests through erratic engine behavior, transmission limp mode, and specific P06 series diagnostic codes that indicate internal processor distress. Environmental factors like heat and moisture remain the leading causes of physical PCM degradation in Ford trucks, necessitating a thorough physical inspection before concluding the module is at fault. Accurate diagnosis requires distinguishing between simple sensor failures and deep-seated internal processor errors to ensure a trusted and cost-effective repair. If you suspect your Ford F-150 is suffering from these symptoms, consult a certified technician to perform a professional pin-out test or PCM reflash before committing to a full module replacement.

Frequently Asked Questions

Can I drive my Ford F-150 with a failing PCM?

Driving with a failing PCM is not recommended and can be dangerous. A faulty module can cause the engine to stall unexpectedly at highway speeds or trigger ‘limp mode,’ which limits your vehicle’s power and speed. Continued operation may also lead to permanent damage to the transmission and catalytic converters, resulting in much higher repair costs.

Does a replacement Ford PCM need to be programmed?

Yes, a replacement PCM must be programmed with your vehicle’s specific VIN, odometer mileage, and the latest software calibration files from Ford. Additionally, the PATS (Passive Anti-Theft System) must be synchronized so that your existing keys will start the vehicle. This process requires professional diagnostic tools such as the Ford Integrated Diagnostic System (IDS).

What is the average cost to replace a Ford F-150 PCM?

The cost of replacing a Ford F-150 PCM typically ranges between $800 and $1,500. This estimate includes the price of the module itself, which can be $500 to $1,000, and the labor for installation and specialized programming. Choosing a reliable, remanufactured unit with a warranty can sometimes reduce the hardware cost significantly while maintaining professional performance.

Can a bad battery cause PCM failure symptoms?

Low voltage or a failing battery can definitely mimic PCM failure symptoms. Modern Ford electronics are highly sensitive to voltage drops; if the battery cannot maintain a steady 12.6V, the PCM may produce erratic signals or throw ‘lost communication’ codes. Experts always recommend testing the battery and alternator health before concluding that the PCM is the source of the problem.

How do I know if my PCM just needs a software update?

If your truck is experiencing minor shifting issues or slightly decreased fuel economy, it may simply require a PCM ‘reflash.’ Ford frequently releases Technical Service Bulletins (TSBs) containing software updates that fix known logic bugs. A professional diagnostic scan will reveal if your current software version is outdated and if a flash is a viable alternative to replacement.