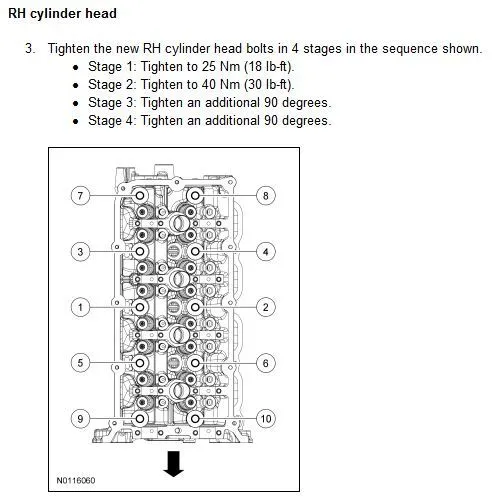

Ford 5.4 Head Bolt Torque Sequence: Ultimate Guide for Precision

For the Ford 5.4 engine, follow a specific head bolt torque sequence. Tighten bolts in three stages: 30, 60, and 85 ft-lbs.

The Ford 5. 4 engine is known for its durability and performance. Properly torquing the head bolts is crucial for maintaining engine integrity. Incorrect torque can lead to engine failure or gasket issues. Always follow the manufacturer’s recommended torque sequence and specifications.

This sequence ensures even pressure distribution and prevents warping. Use a quality torque wrench for accuracy. Following these guidelines will help maintain your engine’s performance and longevity. Regular maintenance and correct procedures are key to a well-functioning vehicle. Proper torque is essential for optimal engine operation.

Credit: www.ford-trucks.com

Tools And Materials

Working on the Ford 5.4 engine requires specific tools and materials. Proper preparation ensures a smooth and efficient process. Below, we’ll cover the essential tools and materials needed for the Ford 5.4 head bolt torque sequence.

Essential Tools

Having the right tools is critical. Here are the must-have tools:

- Torque Wrench – For precise torque settings.

- Socket Set – Includes various sizes for different bolts.

- Breaker Bar – Helps loosen tight bolts.

- Extension Bars – Reach hard-to-access bolts.

- Angle Gauge – Ensures accurate bolt angles.

Materials Needed

Gathering the right materials ensures the job is done correctly. Here’s a list of necessary materials:

- Head Bolts – New bolts are recommended.

- Head Gasket – A new gasket ensures a proper seal.

- Engine Oil – For lubricating bolts.

- Thread Locker – Prevents bolts from loosening.

- Anti-Seize Compound – Eases future bolt removal.

Proper tools and materials lead to successful engine work. Ensure everything is in place before starting the torque sequence.

Preparation Steps

Preparing your engine for the Ford 5.4 head bolt torque sequence is crucial. Follow these steps to ensure a smooth process. Proper preparation prevents issues and guarantees engine safety.

Safety Precautions

- Wear protective gloves to avoid injuries.

- Use safety glasses to protect your eyes.

- Ensure the engine is cool before starting.

- Disconnect the battery to prevent electric shocks.

- Work in a well-ventilated area to avoid inhaling fumes.

Engine Preparation

- Clean the engine area with a degreaser.

- Remove any debris around the head bolts.

- Refer to the manual for specific torque settings.

- Organize your tools and materials.

- Check that you have the correct head bolts.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensure proper torque settings |

| Socket Set | Remove and install bolts |

| Degreaser | Clean the engine area |

| Safety Gear | Protect yourself |

Important: Always double-check your torque wrench settings. Incorrect settings can cause engine damage.

With these steps, your engine is ready for the head bolt torque sequence.

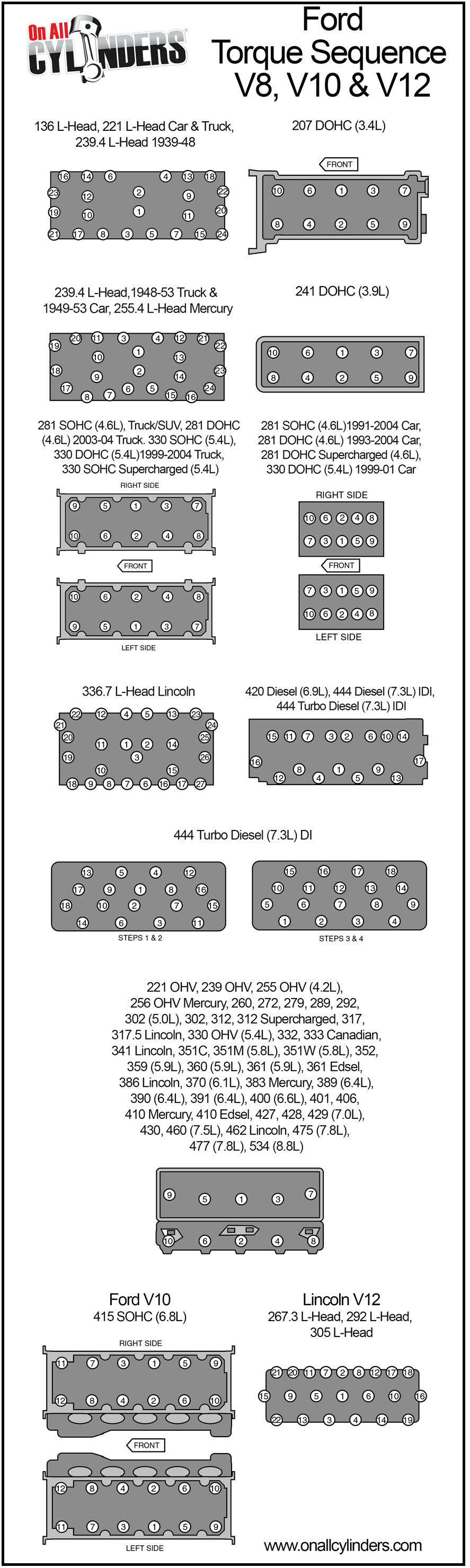

Torque Sequence Overview

Understanding the torque sequence for the Ford 5.4 head bolt is crucial. It ensures the engine head is properly secured. An incorrect sequence can lead to engine problems. Let’s dive into the details.

Bolt Placement

Correct bolt placement is vital for even pressure distribution. The Ford 5.4 engine has a specific order for its head bolts.

| Bolt Number | Position |

|---|---|

| 1 | Top Left |

| 2 | Bottom Right |

| 3 | Top Right |

| 4 | Bottom Left |

| 5 | Center |

Sequential Steps

Follow the sequential steps to ensure the head bolts are torqued correctly.

- Tighten bolts in the specified order.

- Use a torque wrench for accuracy.

- Initial torque should be 30 ft-lbs.

- Re-torque to 60 ft-lbs.

- Final torque should be 85 ft-lbs.

Repeat the sequence to ensure consistency. This avoids uneven pressure and engine issues.

Detailed Torque Steps

Properly torquing the head bolts on a Ford 5.4 engine is crucial. This ensures a secure and tight fit. Follow these detailed torque steps to avoid engine issues. We’ll break down the process into two main phases.

Initial Torque Phase

The initial torque phase involves a series of specific steps. Start by ensuring all bolts are clean and free from debris.

- Apply a thin coat of engine oil to the bolt threads.

- Insert the bolts into their respective holes.

- Use a torque wrench to tighten each bolt to 30 ft-lbs.

- Follow the correct sequence as shown in the table below:

| Bolt Number | Sequence |

|---|---|

| 1 | Center |

| 2 | Opposite Center |

| 3 | Top Left |

| 4 | Bottom Right |

| 5 | Top Right |

| 6 | Bottom Left |

| 7 | Next to Bolt 1 |

| 8 | Next to Bolt 2 |

Final Torque Phase

The final torque phase is equally important. Ensure you follow each step carefully.

- Rotate each bolt an additional 90 degrees.

- Follow the same sequence from the initial phase.

- Double-check each bolt to confirm they are secure.

After completing these steps, your Ford 5.4 engine head bolts should be properly torqued. This helps prevent leaks and engine damage.

Common Mistakes

Working on the Ford 5.4 engine requires precision, especially with the head bolt torque sequence. Mistakes can lead to costly repairs and engine damage. Here are some common pitfalls to avoid.

Over-tightening Issues

One major mistake is over-tightening the head bolts. Over-tightening can cause the bolts to stretch or break. This will compromise the engine’s integrity.

- Over-tightening can warp the cylinder head.

- It may damage the bolt threads.

- This can lead to oil leaks.

Over-tightening also stresses the gasket. This reduces its lifespan and effectiveness. Always follow the recommended torque specifications to avoid these issues.

Under-tightening Risks

Another common mistake is under-tightening the head bolts. Under-tightening can lead to improper sealing. This allows gases and fluids to escape.

- Under-tightening can cause head gasket failure.

- This may result in engine overheating.

- It could also lead to reduced engine performance.

Under-tightening can cause the bolts to loosen over time. This leads to more serious engine problems. Use a torque wrench to ensure proper tightening.

| Common Mistake | Potential Consequences |

|---|---|

| Over-Tightening | Warped Cylinder Head, Damaged Bolt Threads, Oil Leaks |

| Under-Tightening | Head Gasket Failure, Engine Overheating, Reduced Performance |

Credit: www.onallcylinders.com

Tips For Accuracy

Ensuring accurate torque on your Ford 5.4 head bolts is crucial. Follow these tips for precision and reliability.

Using Torque Wrenches

Torque wrenches are essential for accuracy. They help apply the correct force. Follow these steps:

- Set the torque wrench to the specified value.

- Use a click-type wrench for easier use.

- Apply the wrench smoothly and steadily.

Digital torque wrenches offer more precision. They display the exact torque applied. This reduces errors.

Double-checking Work

Double-checking your work ensures each bolt is torqued correctly. Follow these tips:

- Recheck each bolt after the initial torque.

- Use a checklist to track each bolt.

- Ensure all bolts are tightened in the correct sequence.

Re-torquing is sometimes necessary. After the engine runs, recheck the bolts. This ensures they remain tight.

Maintenance Advice

Maintaining your Ford 5.4 engine’s head bolt torque sequence is crucial. Proper maintenance extends the engine’s life and ensures optimal performance. Regular checks help prevent costly repairs and improve reliability.

Regular Inspections

Regular inspections are essential for your Ford 5.4 engine. Check the head bolts for tightness and wear. Use a torque wrench to ensure bolts meet manufacturer specifications. Inspect every 10,000 miles or during oil changes.

- Inspect head bolts for corrosion and damage.

- Use the correct torque pattern during inspections.

- Check for oil leaks around the head gasket.

- Listen for unusual noises indicating loose bolts.

Long-term Care

Long-term care involves more detailed maintenance tasks. Regularly replace head bolts as part of the long-term care plan. Always use bolts recommended by Ford for the best results.

- Replace head bolts every 100,000 miles.

- Use a high-quality torque wrench for accuracy.

- Follow the specified torque sequence without skipping steps.

- Keep a maintenance log for tracking replacements.

Pay attention to the head bolt torque sequence. It ensures even pressure distribution across the engine head. Proper maintenance keeps your Ford 5.4 engine running smoothly for years.

Credit: www.f150forum.com

Frequently Asked Questions

What Is The Best Sequence Of Tightening Cylinder Head Nuts?

The best sequence for tightening cylinder head nuts is to start from the center and work outward in a spiral pattern. This method ensures even pressure distribution and prevents warping. Always follow the manufacturer’s torque specifications for best results.

What Is The Correct Tightening Torque For The Cylinder Head?

The correct tightening torque for the cylinder head is usually specified in the vehicle’s service manual. Generally, it ranges from 60 to 80 ft-lbs. Always refer to the manufacturer’s specifications for the exact value. Proper torque ensures engine performance and prevents damage.

Why The Correct Cylinder Head Bolts Tightening Sequence Is Important?

The correct cylinder head bolts tightening sequence prevents engine damage, ensures even pressure distribution, and maintains a proper seal.

What Is The Head Bolt Torque On A 302 Ford?

The head bolt torque for a 302 Ford engine is 70-100 ft-lbs. Always check your vehicle’s manual for specifics.

Conclusion

Mastering the Ford 5. 4 head bolt torque sequence ensures engine reliability and performance. Follow the steps closely for optimal results. Proper torque application prevents engine damage and costly repairs. Keep your Ford running smoothly by adhering to these guidelines.

Your vehicle will thank you with enhanced longevity and efficiency.