The Leviathan of Lima: A Comprehensive Technical Analysis of the Ford 460 V8 (1968–1997)

In the pantheon of American automotive engineering, few powerplants command the sheer physical presence and historical weight of the Ford 460. Known internally as the “Lima” engine—named for the Ohio plant where it was forged—and part of the broader “385 Series” family, the 460 cubic inch (7.5L) V8 represents the zenith of Ford’s displacement wars. Introduced in 1968, ostensibly to power the brand’s rapidly growing luxury liners, the engine’s architecture was a clean-sheet departure from the “FE” (Ford-Edsel) big-blocks that preceded it.

While the FE 390s, 427s, and 428s were legendary for their racing pedigree, they were complex, heavy, and expensive to manufacture. The 460 was designed with a different philosophy: effortless, turbine-like torque delivery, utilizing modern thin-wall casting techniques to reduce weight while maximizing structural rigidity for sustained load-bearing applications.

The 460’s lifecycle, spanning three tumultuous decades from the height of the muscle car era to the twilight of the pushrod V8 in heavy-duty trucks, offers a perfect case study in automotive adaptation. It began as a 10.5:1 compression monster in the Lincoln Continental, evolved into a smog-choked survivor in the mid-1970s, and enjoyed a fuel-injected renaissance in the 1990s as the backbone of Ford’s heavy-duty truck and motorhome fleet.

This report provides an exhaustive analysis of the 460’s horsepower and torque evolution, dissecting the mechanical nuances—from cylinder head combustion chamber geometry to camshaft timing retard strategies—that dictated its performance across thirty years of production.

Ford 460 “Big Block”

The Ultimate Horsepower & Torque Chart Guide (1968-1997)

The 7.5L V8 was a torque monster that powered everything from Lincoln Continentals to F-350s. Explore the history, the smog-era crash, and the massive potential hidden inside the 385 Series engine.

Why the Numbers Confuse Everyone

If you look at a Ford 460 chart, you’ll see a massive drop in 1972. In 1971, the engine was rated at 365 HP. In 1972, it plummeted to 212 HP. Did the engine break? No. This was the shift from SAE Gross (engine on a stand, no accessories) to SAE Net (engine in a car, with mufflers/pumps). While compression did drop, the “real” power difference wasn’t as drastic as the charts suggest.

The Rollercoaster Timeline

Comparing Horsepower vs. Torque output across the engine’s lifespan.

The 460 was never about high-revving horsepower; it was built for torque. Even during the “Smog Era” lows of the late 70s, torque remained respectable, making it a favorite for towing and heavy trucks. Note the stability in the EFI years (1988+).

Peak Gross Power

1968 Model Year (High Compression)

Cylinder Bore

Massive pistons define the 385 series.

Stroke

The namesake dimension of the engine family.

1971 vs. 1972: The “Fake” Drop?

In 1972, the industry changed how HP was measured. SAE Gross measured the engine in a lab with no drag. SAE Net measured it as installed in a vehicle. This chart visualizes the dramatic shift in reported numbers, though actual road performance dropped less severely.

Unlocking the Beast

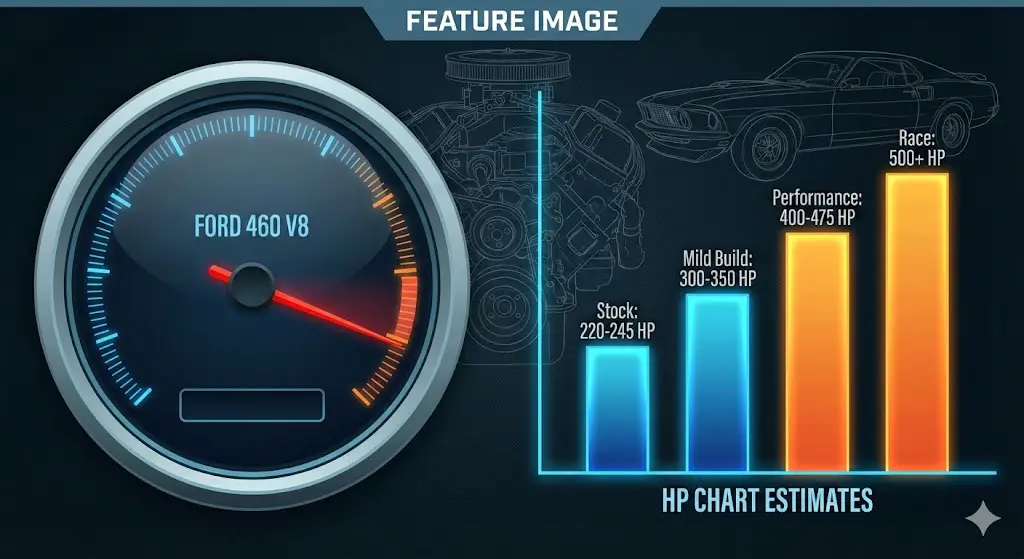

The 460 is severely restricted in stock form, especially cylinder heads and exhaust. Because it is a large displacement engine, it responds exceptionally well to airflow modifications. Here is a projection of power based on common aftermarket build recipes.

Technical Specifications Breakdown

385 SERIES| Spec Category | Early (1968-1971) | Smog Era (1973-1986) | EFI Era (1988-1997) |

|---|---|---|---|

| Compression Ratio | 10.5:1 (High) | 8.0:1 (Low) | 8.5:1 |

| Fuel Delivery | 4-Barrel Carb | 4-Barrel Carb | Electronic Fuel Injection |

| Cylinder Heads | C8VE / C9VE (Small Chamber) | D2VE / D3VE (Open Chamber) | E7TE / F3TE (High Swirl) |

| Primary Usage | Luxury Cars (Lincoln) | Trucks, RVs, Vans | F-250/F-350 Heavy Duty |

| Stock Timing | Straight Up | Retarded 4-8° (Emission) | Computer Controlled |

Police Interceptors

Used in 1970s cruisers for high-speed pursuit capabilities.

Heavy Haulers

Standard in F-250, F-350, and Econoline vans for decades.

Motorhomes

The class-A RV standard engine due to massive low-end torque.

The Legacy Lives On

While production ended in 1997 (replaced by the V10 Triton), the 460 remains a legend in drag racing, jet boats, and mud trucks. It represents the pinnacle of “No Replacement for Displacement.”

© 2026 FordMasterX Infographics. Data sourced from manufacturer owner manuals.

The "385 Series" Nomenclature and Design Philosophy

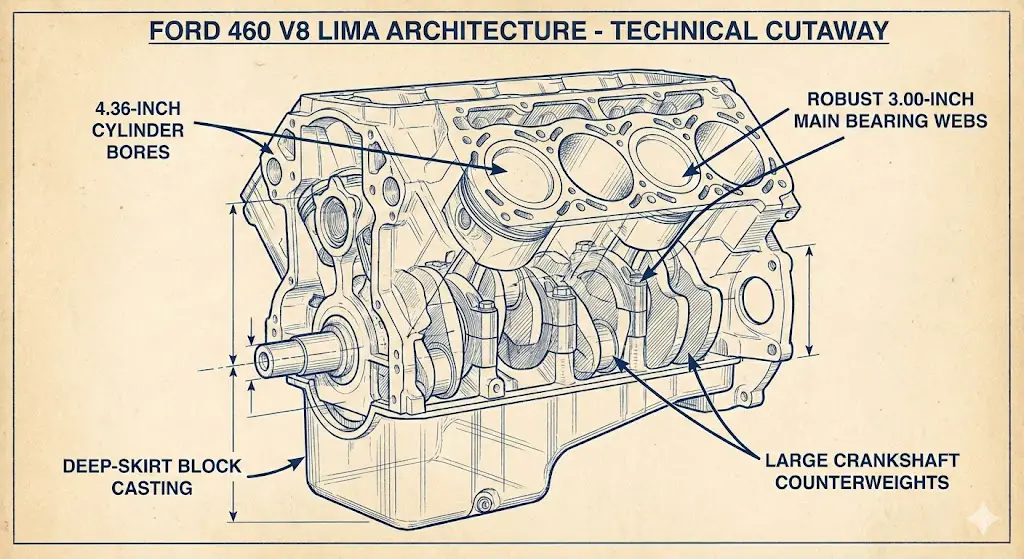

The designation "385 Series" is frequently misunderstood by enthusiasts as a reference to a specific displacement. In reality, the name is derived from the 3.85-inch crankshaft stroke of the 460 engine, which was the primary displacement planned during the design phase. This stroke, combined with a massive 4.36-inch cylinder bore, created a square-ish architecture that favored low-end torque without sacrificing piston speed reliability.

The engineering mandate for the 460 was durability under load. Unlike the FE engines, which utilized a deep-skirt block where the crank sat high in the casting, the 385 Series utilized a skirtless block design similar to the small-block Windsor, but on a massive scale. The engine featured 3.00-inch main bearing journals, a robust cast-iron crankshaft (nodular iron in later years), and massive connecting rods. This overbuilt bottom end allowed the engine to serve not only in luxury cars but also in industrial irrigation pumps, 60kW standby generators, and jet boats, where it would run at wide-open throttle for hours.

The Displacement Siblings: 370, 429, and 460

While the 460 is the focus of this analysis, its performance context cannot be understood without referencing its stablemates. The 385 family architecture was modular, allowing Ford to vary displacement primarily through crankshaft stroke changes while maintaining the same block deck height (10.300 to 10.322 inches depending on the year).

| Engine Displacement | Bore (Inches) | Stroke (Inches) | Primary Application | Production Era | Notes |

| 370 cu in (6.1L) | 4.05 | 3.59 | Medium-Duty Trucks (F-600) | 1977–1991 | Commercial use only; smaller bore. |

| 429 cu in (7.0L) | 4.36 | 3.59 | Passenger Performance (Mustang, Torino) | 1968–1973 | Short-stroke variant; higher revving capabilities. |

| 460 cu in (7.5L) | 4.36 | 3.85 | Luxury Cars, Light/Heavy Trucks, Marine | 1968–1997 | The definitive long-stroke torque monster. |

The Golden Era: High Compression Dominance (1968–1971)

The initial four years of 460 production represent the engine in its purest, most undiluted form. Before the onset of the 1973 oil crisis and the stranglehold of the EPA, the 460 was tuned for gross output. These engines are characterized by high compression ratios, aggressive ignition timing, and cylinder heads that prioritized flow volume over emissions turbulence.

The 1968–1971 Horsepower and Torque Landscape

When the 460 debuted in the 1968 Lincoln Continental Mark III, it was rated at 365 gross horsepower and a staggering 485 to 500 lb-ft of torque. It is crucial to distinguish that these were SAE Gross ratings—measured on a stand with no accessories, optimized timing, and open exhaust. However, even accounting for the optimistic rating standards of the day, these engines were formidable.

The primary driver of this performance was the 10.5:1 compression ratio. This high static compression allowed for high thermal efficiency and snappy throttle response, necessitating the use of premium leaded fuel. The torque curve of these early engines was essentially flat; the peak torque arrived at a low 2,800 RPM, providing immediate acceleration for the 5,000-pound vehicles they propelled.

Cylinder Head Analysis: The "Straight-Up" Years

The cylinder heads from this era—specifically castings C8VE, C9VE, and D0VE—are today considered the "Holy Grail" of stock Ford big-block parts. Mechanically, these heads are virtually identical in terms of performance potential, featuring:

- Combustion Chamber Size: Approximately 75cc to 77cc. This small volume was the key to the high compression ratio.

- Valve Sizes: Standard 2.08-inch intake and 1.65-inch exhaust valves.

- Port Design: Generous intake runners that flowed significantly better than the later "smog" heads.

- Rail Rockers: These heads utilized a rail-style rocker arm system with screw-in studs (on some performance 429s) or press-in studs (standard 460s), which offered decent valvetrain stability.

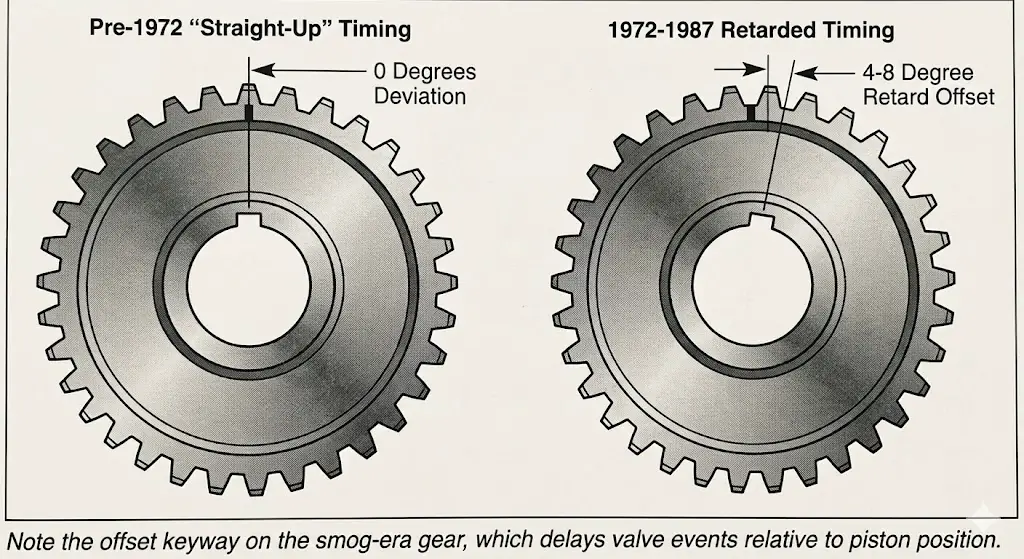

Mechanical Insight: One of the most critical aspects of the pre-1972 engines was the timing set. The camshaft and crankshaft gears were aligned "straight up" (0 degrees of deviation). This synchronized the valve events perfectly with the piston motion for maximum cylinder filling and power generation. In later years, Ford would alter this relationship to reduce combustion temperatures for emissions, costing significant power.

1968–1971 Specification Matrix

| Model Year | Compression | HP (Gross) | Torque (Gross) | Head Casting | Carburetor | Notes |

| 1968 | 10.5:1 | 365 @ 4600 | 485 @ 2800 | C8VE-A | Autolite 4300 | Debut year; Lincoln exclusive. |

| 1969 | 10.5:1 | 365 @ 4600 | 500 @ 2800 | C9VE-A | Autolite 4300 | Peak torque rating. |

| 1970 | 10.5:1 | 365 @ 4600 | 500 @ 2800 | D0VE-C | Autolite 4300 | The most common "performance" casting. |

| 1971 | 10.5:1 | 365 @ 4600 | 500 @ 2800 | D0VE-C | Autolite 4300 | Last year of high compression. |

The Great Depression: Smog, Safety, and the Drop (1972–1978)

The transition from 1971 to 1972 marked the single most dramatic shift in the 460’s history. A convergence of federal regulations—the Clean Air Act requiring lower NOx emissions and the mandate for unleaded fuel compatibility—forced Ford to radically detune the Lima engine. Simultaneously, the industry switched from SAE Gross to SAE Net horsepower ratings, which measured engine output as installed in the vehicle with all accessories (alternator, power steering, water pump) and the full exhaust system attached. This change in measurement methodology, combined with the mechanical detuning, caused advertised horsepower to plummet by over 150 ponies on paper.

The 1972 D2VE Cylinder Head Disaster

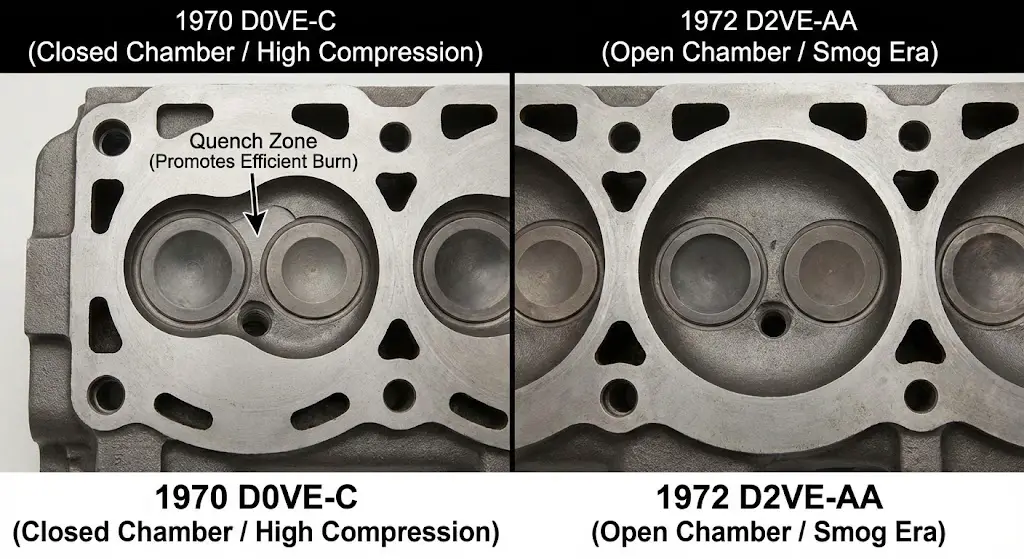

In an attempt to lower the compression ratio to 8.5:1 to accept regular unleaded fuel, Ford engineers redesigned the cylinder head for the 1972 model year. The result was the D2VE-AA casting. This head is unique in the 385 Series lineage for having large, round, open combustion chambers that measured approximately 100cc.

While this successfully lowered compression, it eliminated the "quench" area—the flat portion of the head that comes in close proximity to the piston at Top Dead Center (TDC). The quench area is vital for creating turbulence in the air/fuel mixture, which promotes a complete and controlled burn. Without it, the D2VE heads were prone to "detonation" or "pinging," even with low-compression pistons and low-octane fuel. Consequently, the 1972 engines are often regarded as the nadir of 460 performance engineering, with ignition timing often having to be pulled back further to prevent engine-destroying knock.

Performance Impact: The 1972 460 was rated at 212 SAE Net horsepower, a shocking drop from the previous year's 365 Gross rating. While some of this was purely mathematical due to the SAE standard change, the mechanical efficiency of the engine was severely compromised.

The Mechanical Retard of 1972

To combat Nitrogen Oxide (NOx) emissions, which form at high combustion temperatures, Ford implemented a strategy of retarding the camshaft timing. Starting in 1972, the timing chain gear on the crankshaft was machined with the keyway slot retard by approximately 4 to 8 degrees relative to the camshaft lobes.

- The Mechanism: By opening the exhaust valve later and closing the intake valve later, the dynamic compression was reduced, and some exhaust gas dilution occurred.

- The Result: This lowered peak combustion temperatures (reducing NOx) but devastated throttle response and low-end torque.

- The Fix: Enthusiasts quickly learned that installing a "pre-1972" or aftermarket "straight-up" timing set on a 1973–1987 engine would instantly recover 20–30 horsepower and significantly improve fuel economy.

The D3VE Stabilization (1973–1978)

Ford recognized the deficiencies of the D2VE head almost immediately. For the 1973 model year, they introduced the D3VE-A2A cylinder head. This design became the standard for the carbureted 460 era.

- Design Correction: The D3VE returned to a "closed" chamber design but with a larger volume (approx. 95–97cc) to maintain the lower 8.0:1 compression ratio without sacrificing the quench area. This restored combustion stability.

- Valvetrain Change: The D3VE heads moved to a pedestal-mount rocker arm system (non-adjustable), which was cheaper to manufacture but limited high-performance camshaft upgrades without machining for screw-in studs.

Migration to Trucks

As the 1970s progressed, rising fuel prices made big-block sedans dinosaurs. By 1978, the 460 was discontinued in Ford passenger cars (Lincoln and Mercury). However, it found a new and permanent home in the Ford F-Series trucks (F-150 through F-350) and E-Series vans. In these applications, the 460’s durability was paramount. It became the towing engine of choice, replacing the 390 FE in the truck lineup.

1972–1978 Specification Matrix (SAE Net)

| Model Year | Horsepower (Net) | Torque (Net) | Compression | Head Casting | Key Application |

| 1972 | 212 @ 4400 | 342 @ 2800 | 8.5:1 | D2VE-AA | Lincoln/T-Bird (Detonation prone) |

| 1973 | 200-219 | 350-360 | 8.0:1 | D3VE-A2A | F-100/F-250 intro. Better heads. |

| 1974 | 220 @ 4000 | 355 @ 2600 | 8.0:1 | D3VE-A2A | Truck focus increases. |

| 1975 | 218 @ 4000 | 369 @ 2600 | 8.0:1 | D3VE-A2A | Catalytic converters added to light duty. |

| 1976 | 200 @ 4000 | 350 @ 2600 | 8.0:1 | D3VE-A2A | Peak emissions choking. |

| 1977 | 197 @ 4000 | 355 @ 2600 | 8.0:1 | D3VE-A2A | Lowest rated HP in history. |

| 1978 | 200-220 | 380 | 8.0:1 | D3VE-A2A | Truck-only availability begins. |

The Workhorse Era: Carbureted Trucks (1979–1987)

From 1979 to 1987, the 460 existed solely as a truck engine. This era is characterized by incremental improvements in drivability and "hot fuel" handling, as engineers fought to make the carbureted beasts reliable in extreme heat conditions typical of towing.

Block Evolution: The D9TE "Truck" Block

In 1979, Ford introduced a revised engine block casting, the D9TE-AB. This block featured cylinders that were slightly longer (deeper) than the passenger car blocks.

- Why deeper cylinders? The piston design was changed to a different compression height, and the longer cylinder skirts provided better piston stability at the bottom of the stroke, reducing piston slap and wear in high-mileage heavy-duty applications.

- Crankshaft: This block was paired with an externally balanced crankshaft/flywheel assembly, distinguishing it from the internally balanced pre-1979 engines. Restorers must be careful not to mix flywheels/flexplates between these eras, or severe vibration will occur.

The "Hot Fuel" Problem and the 4180 Carburetor

A major issue with 460s in E-Series vans and heavy trucks was vapor lock. The immense heat generated by the engine under load would boil the fuel in the carburetor bowls.

- The Holley/Motorcraft 4180: To combat this, Ford worked with Holley to develop the 4180C carburetor. It featured "bowl vents" that were plumbed into the charcoal canister system and specially designed metering blocks to handle high under-hood temps.

- Electric Pumps: In the mid-1980s, Ford began moving to in-tank electric fuel pumps even on carbureted models to keep the fuel under pressure up to the engine, raising the boiling point and reducing vapor lock.

1979–1987 Specification Matrix

| Model Year | Horsepower (Net) | Torque (Net) | Compression | Induction | Notes |

| 1979 | 205-225 | 360-380 | 8.0:1 | 4-bbl | D9TE Block intro. Externally balanced. |

| 1980-1982 | 215 @ 4000 | 375 @ 2600 | 8.0:1 | 4-bbl | Steady output. |

| 1983-1985 | 225 @ 4000 | 380 @ 2400 | 8.5:1 | 4-bbl Holley | Power creeps up; "Hot Fuel" updates. |

| 1986 | 225 @ 4000 | 380 @ 2400 | 8.5:1 | 4-bbl Holley | Last full year of carb dominance. |

| 1987 | 225 @ 4000 | 380 @ 2400 | 8.5:1 | 4-bbl Holley | Transitional year. Some EFI prototypes. |

The EFI Renaissance: Electronic Fuel Injection (1988–1997)

The final chapter of the 460’s life was arguably its most efficient. In 1988, Ford introduced the EEC-IV electronic fuel injection system to the 7.5L, transforming its character. No longer reliant on fickle carburetors, the EFI 460 became a reliable, turn-key workhorse that powered nearly every U-Haul truck, ambulance, and Class A motorhome in America during the 1990s.

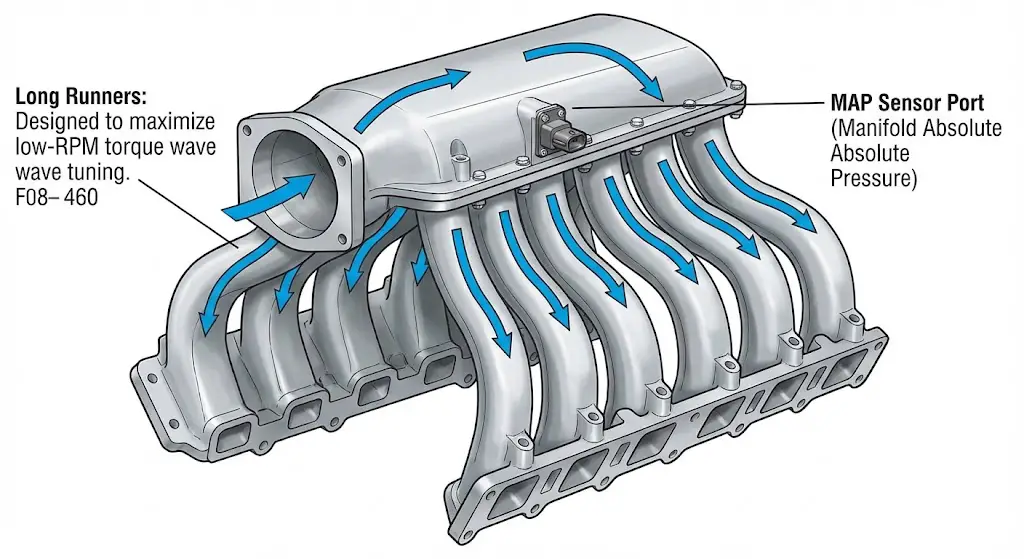

Speed Density Injection Mechanics

The EFI system used on the 460 was a Speed Density system, rather than the Mass Air Flow (MAF) system found on Mustangs.

- How it works: The Engine Control Unit (ECU) calculates air mass based on manifold pressure (MAP sensor), engine RPM, and intake air temperature. It consults a pre-programmed lookup table to determine fuel injector pulse width.

- The Pros: Extremely robust and reliable. It is immune to vacuum leaks affecting the reading as much as MAF systems and provides consistent fueling for towing.

- The Cons: It does not tolerate modifications well. Changes to the camshaft (specifically lobe separation angle) that alter engine vacuum will confuse the computer, causing surging or stalling. Modifications generally require "computer-compatible" camshafts or a conversion to a MAF system.

The E7TE and F3TE Cylinder Heads

The EFI era brought two distinct cylinder head castings:

- E7TE (1987–1992): These heads were essentially revised D3VE castings designed to accept the EFI intake manifold bolt pattern. The combustion chambers remained similar, and flow characteristics were comparable to the smog-era heads.

- F3TE (1993–1997): In 1993, Ford updated the heads one last time. The F3TE castings featured revised intake ports designed to induce "swirl" into the air charge, improving combustion efficiency and slightly bumping compression. These are considered the best of the production EFI heads, but they have a unique intake manifold bolt pattern that is not backward compatible with older intakes without modification.

Performance peak: 1993–1997

With the F3TE heads and refined ECU mapping, the 460 reached its net horsepower peak in the mid-90s. Rated at 245 horsepower and 400-410 lb-ft of torque, these engines delivered massive low-end grunt. The torque curve was nearly flat from 1,800 RPM to 3,000 RPM, making it functionally feel much more powerful than the horsepower number suggested.

1988–1997 Specification Matrix

| Model Year | Horsepower (Net) | Torque (Net) | Induction | Head Casting | Key Changes |

| 1988 | 230 @ 3600 | 390 @ 2200 | EFI (Speed Density) | E7TE | First year of EFI. Big torque jump. |

| 1989-1992 | 230 @ 3600 | 390 @ 2200 | EFI (Speed Density) | E7TE | Stable production. |

| 1993 | 240 @ 4000 | 395 @ 2400 | EFI (Speed Density) | F3TE | New Swirl-Port Heads. |

| 1994 | 245 @ 4000 | 400 @ 2200 | EFI (Speed Density) | F3TE | Peak Output. |

| 1995-1997 | 245 @ 4000 | 410 @ 2200 | EFI (Speed Density) | F3TE | Final years. Highest Net Torque. |

Beyond the Road: Marine and Industrial Applications

The sheer mass and durability of the 460 made it a favorite for applications outside of automotive transportation. In these environments, where emissions regulations were often lax or non-existent, the 460 showed its true potential.

The Jet Boat Kings: Hardin, Commander, Indmar

In the 1970s and 80s, the "Jet Boat" craze swept the western United States. These boats required engines that could turn a jet pump impeller at constant high RPMs (4,000+) against massive resistance—a task that destroys lesser engines. The 460 became the standard.

- Power Ratings: Freed from mufflers and smog pumps, marine 460s were rated significantly higher. A typical Hardin Marine or Commander 460 with a single 4-barrel carburetor was rated between 320 hp and 340 hp.

- The "Packjet": Companies like Berkley and Indmar sold complete "Packjet" units—engine and pump assembled together—ready to drop into a hull.

- Marine Specifics: These engines utilized unique components:

- Brass Freeze Plugs: To prevent corrosion from lake/sea water cooling systems.

- Marine Camshafts: Designed with less valve overlap to prevent "water reversion"—the sucking of water from the exhaust back into the cylinders at idle.

- Water-Cooled Manifolds: Massive aluminum or iron exhaust logs (like the Hardin "Snail" headers) that jacketed the exhaust in water to keep engine bay temperatures safe.

The Industrial LSG-875

In the industrial sector, the 460 was labeled the LSG-875 (Lima, Gas, 8-cylinder, 7.5 Liter).

- Applications: These engines powered 60kW standby generators, large-scale irrigation pumps, and wood chippers.

- Governor Spec: Unlike truck engines that varied RPM, industrial 460s were often governed to run at a specific speed—typically 1,800 RPM (for 4-pole generators) or 3,600 RPM (for 2-pole).

- Output: At a constant 1,800 RPM, an LSG-875 on natural gas might be rated for 80-100 continuous horsepower, but with massive torque reserve to handle sudden electrical load spikes.

- Differences: Industrial blocks often featured reinforced webbing, and the water pumps had different impellers to prevent cavitation at static RPMs.

Technical Deep Dive: Components and Interchanges

For the restorer or builder, understanding the granular differences between years is critical.

Camshaft Evolution

- 1968-1971: The "High Power" cam. Duration was approximately 200/210 degrees at.050 lift, with lift values around.440/.480.

- 1972-1987: The "Retarded" cam. While the grind profile was similar to the earlier cams, the installation angle (via the timing set) retarded the intake centerline by ~4-8 degrees. This killed low-end response.

- 1988-1997 (EFI): The "Towing" cam. These cams had very short duration (sub-200 degrees at.050) to build maximum cylinder pressure at low RPM. The Lobe Separation Angle (LSA) was wide (112-114 degrees) to maintain a smooth idle and high vacuum for the MAP sensor.

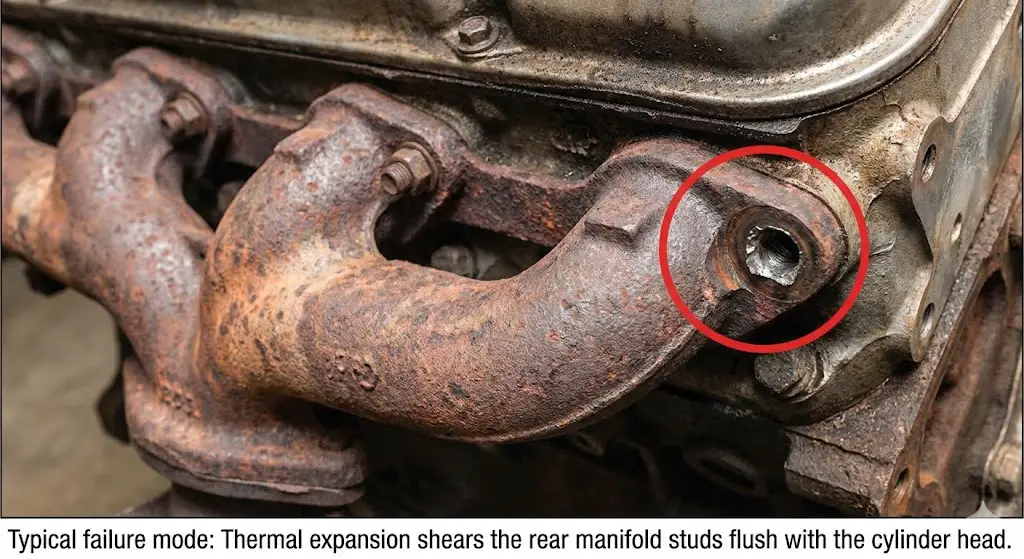

Exhaust Manifold Issues

The stock exhaust manifolds on the 460 are a known weak point, particularly the passenger side on F-Series trucks and F53 motorhomes.

- The Restriction: The "log" style manifolds force exhaust gases to make sharp 90-degree turns and collide with each other, creating massive backpressure.

- The Stud Failure: Due to the extreme heat retained by the cast iron manifolds, the thermal expansion cycles fatigue the steel studs that hold them to the head. It is extremely common for the rear studs on the passenger side to shear off flush with the head.

- Repair: This is a nightmare scenario for owners. Fixing it often requires removing the cylinder head or using specialized drilling jigs to extract the hardened steel stud from the iron head while working through the wheel well.

Performance Potential and Modifications

The 460 is widely considered one of the most "mod-friendly" engines in history because it was so severely detuned from the factory in its later years. Unlocking its potential is often just a matter of removing factory restrictions.

The "Free" Upgrade: Timing Chain

As detailed in Section 3.2, replacing the stock post-1972 timing set with a pre-1971 specification double-roller timing set restores the cam timing to 0 degrees "straight up."

- Cost: ~$50-100 for parts.

- Gain: 20-30 hp, improved throttle response, and cooler exhaust temperatures.

The "Stroker" Advantage

The 460 block is physically massive and capable of swallowing enormous crankshafts.

- Common Kits: It is trivial to stroke a 460 to 514, 521, or even 557 cubic inches using aftermarket cranks.

- Power Potential: A simple 521 stroker with aluminum heads and a mild cam can easily produce 600 hp and 650 lb-ft of torque on pump gas, making it a popular choice for drag racers and pulling trucks.

Cylinder Head Swaps

- Budget: Porting D0VE or D3VE iron heads can yield 500 hp capabilities, but it requires significant labor (grinding the massive thermactor bumps in the exhaust ports).

- Aftermarket: Aluminum heads from Edelbrock (Performer RPM), Trick Flow (PowerPort), or Ford Performance (Super Cobra Jet) save nearly 50-70 lbs off the front of the vehicle and offer modern combustion chamber designs that resist detonation, allowing for higher compression ratios (10:1+) on pump gas.

Common Failures and Troubleshooting (The F53 Motorhome Context)

A significant portion of 460s still on the road today are in 1990s Class A motorhomes (F53 chassis). These owners face unique challenges.

Fuel Pump Heat Soak / Vapor Lock

Many F53 owners report the engine dying after 2-3 hours of highway driving in hot weather.

- Cause: The in-tank fuel pump turbine overheats, or the fuel rail (which sits directly on top of the hot intake manifold) boils the fuel.

- Symptoms: Loss of power, bucking, and eventual stall. The engine restarts after cooling down for 45 minutes.

- Fixes: Installing a lower-temp thermostat (180F), adding heat wrap to fuel lines, or installing a high-volume aftermarket fuel pump.

Exhaust Manifold Leaks

(See section 7.2). The "ticking" sound under load is almost always a broken manifold stud or a cracked manifold. Ignoring it can lead to burnt valves due to cold air reversion.

Conclusion: The Last Dinosaur

The Ford 460’s retirement in 1997 marked the end of an era. It was replaced by the 6.8L V10 Triton, a modular overhead-cam engine that, while efficient, lacked the simple, brute-force character of the big-block pushrod V8.

The legacy of the 460 is one of uncompromised capability. It survived the death of the muscle car, the birth of the EPA, and the oil crisis, evolving from a high-compression luxury powerplant into the backbone of American heavy transport. Today, whether it’s powering a restored Lincoln Mark III, screaming down a river in a jet boat, or chugging along in a 30-foot motorhome, the 460 remains a testament to the old adage: there is no replacement for displacement.

Appendix: Quick Reference Data Tables

11.1 Cylinder Head Casting Quick Reference

| Casting ID | Years | Type | Combustion Chamber | Valve Sizes | Best For |

| C8VE / C9VE | 1968-69 | Closed | ~75cc | 2.08/1.65 | High Comp Performance |

| D0VE-C | 1970-71 | Closed | ~75cc | 2.08/1.65 | Max Factory Performance |

| D2VE-AA | 1972 | Open | ~100cc | 2.08/1.65 | Doorstops / Anchors (Avoid) |

| D3VE-A2A | 1973-86 | Closed | ~95cc | 2.08/1.65 | Street/Towing Builds |

| E7TE | 1987-92 | Closed | ~95cc | 2.08/1.65 | EFI Replacements |

| F3TE | 1993-97 | Closed | ~92cc | 2.08/1.65 | Late Model EFI Performance |

11.2 Torque Specification Guide

| Fastener | Torque Spec (ft-lbs) | Notes |

| Main Cap Bolts | 95-105 | Oil threads lightly |

| Connecting Rod Bolts | 40-45 | Critical for high RPM |

| Cylinder Head Bolts | 140 | Massive torque; use proper sequence |

| Intake Manifold | 25-30 | Do not overtighten (ears crack) |

| Harmonic Damper | 70-90 | Requires puller/installer tool |

11.3 Fluid Capacities (Stock Truck Oil Pan)

| Fluid | Capacity | Notes |

| Engine Oil | 6 Quarts | Includes filter change |

| Coolant | ~4-5 Gallons | varies by radiator size |

| Firing Order | 1-5-4-2-6-3-7-8 | Counter-clockwise distributor rotation |