Diesel Care And Performance Reviews: Complete Guide

The modern diesel engine is a marvel of high-pressure engineering, capable of generating massive torque while maintaining thermal efficiency that puts gasoline counterparts to shame. However, the margin for error in maintenance has shrunk as injection pressures have soared to 30,000+ PSI and emissions systems have become incredibly sensitive. For owners of Powerstroke, Cummins, or Duramax platforms, the difference between a 500,000-mile workhorse and a $15,000 repair bill often comes down to the quality of their maintenance regimen. This comprehensive guide distills 15 years of industry experience into an actionable framework for professional diesel care and performance optimization, ensuring your rig remains reliable and trusted under any load.

Comprehensive Overview: The Evolution of Diesel Maintenance

📤 Share Image

Diesel engines have transitioned from mechanical “rattle-boxes” to sophisticated, computer-controlled power plants. In the expert community, we view diesel care through two distinct lenses: preventative maintenance and performance enhancement. The two are inextricably linked; you cannot have a high-performing engine that is neglected mechanically. Professional technicians understand that modern Ultra-Low Sulfur Diesel (ULSD) lacks the natural lubricity of older fuels, which places an immense burden on fuel system components.

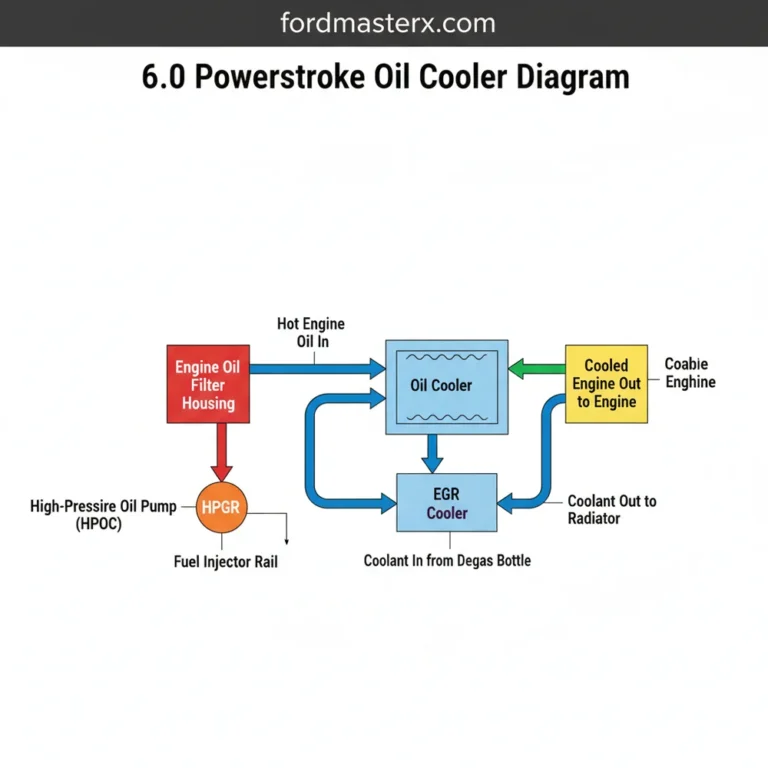

A complete diesel care strategy involves monitoring four primary systems: the fuel delivery system, the lubrication circuit, the cooling system, and the air management system (including the turbocharger and EGR). Ignoring any one of these leads to a “cascading failure” where a minor issue, such as a clogged fuel filter, causes the high-pressure pump to cavitate, eventually sending metal shards through the entire common-rail system.

By The Numbers

Common Rail PSI

Target Mileage

Torque Increase Potential

The Role of Performance Reviews

When searching for reliable performance reviews, it is vital to distinguish between subjective “butt-dyno” claims and objective data-logging. Trusted industry reviews focus on Exhaust Gas Temperatures (EGTs), shift points, and fuel trim stability. We have seen thousands of engines fail because an owner installed a generic tuner that simply “dumped fuel” to create smoke, which is nothing more than wasted energy and excessive heat that cracks pistons and heat-checks turbo housings.

Key Benefits of a Rigorous Diesel Care Program

The investment in quality parts and regular maintenance yields dividends that far outweigh the initial costs. In my years of expert consulting for fleet managers, the data consistently shows that a proactive approach reduces the Total Cost of Ownership (TCO) by up to 25% over the life of the vehicle.

Unmatched Longevity

By using high-efficiency oil filters (2-micron bypass systems) and quality synthetic lubricants, you can virtually eliminate frictional wear, allowing the engine to reach 500,000 miles without a major overhaul.

Optimized Fuel Economy

Proper care includes keeping the air induction system clean and the injectors calibrated. A well-maintained diesel engine can see a 10-15% improvement in MPG compared to a neglected one.

Resale Value Retention

A vehicle with comprehensive maintenance records and quality performance upgrades (documented by professional reviews) commands a premium in the used market.

How It Works: The Mechanics of Performance

To master diesel care, one must understand that a diesel engine is essentially a massive air pump. The more cool, dense air you can force into the cylinders and the more precisely you can inject fuel, the more power you produce. However, this process creates immense heat and pressure. Expert performance tuning works by re-mapping the Engine Control Unit (ECU) to optimize these variables without exceeding the mechanical limits of the hardware.

The Critical Triangle: Air, Fuel, and Heat

Every reliable performance review will analyze how a modification affects these three pillars:

- • Fuel Quality & Atomization: Modern injectors use piezoelectric crystals to fire up to five times per combustion stroke. Any contamination or lack of lubricity causes wear on the pintle, leading to “injector stick” and potential engine runaway or melt-down.

- • Air Density: Aftermarket intake systems and larger intercoolers reduce Intake Air Temperatures (IATs). Cooler air is denser, containing more oxygen molecules per cubic inch, allowing for more complete combustion.

- • Exhaust Flow & EGTs: The primary enemy of a diesel engine is heat. High Exhaust Gas Temperatures (EGTs) can melt turbo vanes and crack cylinder heads. Quality performance reviews always include EGT testing under load.

After a heavy tow or high-speed run, never shut the engine off immediately. Allow it to idle for at least two minutes. This keeps oil flowing through the turbocharger, preventing “oil coking” on the bearings, which is a leading cause of premature turbo failure.

Analyzing Performance Upgrades: A Comparative Guide

Choosing the right upgrades requires a nuanced understanding of your vehicle’s specific needs. A daily driver has different requirements than a dedicated sled-puller or a heavy-haul hotshot rig. Below is a complete comparison of standard vs. optimized performance paths based on years of professional feedback.

If you own a diesel equipped with the Bosch CP4 high-pressure pump (common in 2011-2016 Duramax and Powerstroke models), fuel lubricity is your biggest threat. A single tank of poor-quality fuel can “grenade” the pump, sending debris through the entire $10,000 fuel system. Always use a trusted fuel additive to increase lubricity.

Getting Started: Your Phased Implementation Plan

Don’t make the mistake of buying every shiny part in the catalog at once. A professional approach to diesel care is methodical. Start by establishing a baseline of health before adding stress to the system with performance modifications.

📋

Step-by-Step Guide to Professional Diesel Care

Before changing your oil, send a sample to a lab (like Blackstone Labs). This provides an expert look at the internal health of your engine, detecting coolant leaks or bearing wear before they become catastrophic.

Install a reliable lift pump system (such as FASS or AirDog). These systems remove air and water from the fuel more effectively than factory filters and provide a steady supply of fuel to the high-pressure pump.

Select a trusted tuner that allows for digital monitoring. Use an Edge Insight or similar device to keep an eye on EGTs, boost levels, and soot loading in the DPF in real-time.

Choosing Quality Parts: The Expert’s Verdict

The market is flooded with “knock-off” parts that look identical to the originals but fail under the intense heat cycles of a diesel engine. When reviewing performance components, always verify the source. Quality manufacturers invest in rigorous R&D and offer warranties that back their claims. In our professional experience, spending 20% more on a reliable turbo or injector set saves you thousands in labor costs when the cheap alternative inevitably fails after 10,000 miles.

✅ Pros of Proper Care

- Significantly lower long-term repair costs

- Increased engine “up-time” and reliability

- Better towing performance and torque

- Enhanced fuel economy and range

❌ Cons of Neglect

- High risk of catastrophic fuel system failure

- Frequent DPF/emissions system plugging

- Reduced resale value and buyer trust

- Poor efficiency and increased soot buildup

Conclusion: The Path to Diesel Excellence

Achieving peak diesel performance is not a one-time event but a continuous commitment to quality and professional maintenance. By understanding the mechanical sensitivities of your platform and following the comprehensive guidelines outlined here, you can enjoy the massive power and efficiency of your diesel engine for decades. Remember, the most expensive performance mod you can buy is the one that causes your engine to fail. Focus on reliability first, use trusted data for your reviews, and your rig will reward you with reliable service for hundreds of thousands of miles.

Summary Points:

- • Filtration is King: 2-micron fuel and oil filtration are the best insurance policies for your engine.

- • Data-Driven Decisions: Use oil analysis and EGT monitoring to guide your maintenance and tuning.

- • Quality Matters: Never compromise on critical fuel system or turbocharger components.

Ready to take your diesel performance to the next level? Start by scheduling a complete fluid analysis today and build your performance roadmap on a foundation of mechanical health.