Camshaft Position Timing Over Advanced Bank 1: Diagnostic And Repair Procedures

A persistent Check Engine light accompanied by a rough idle often points to a complex synchronization error within your engine’s internal timing system. When the Engine Control Module (ECM) detects that the camshaft position timing is over advanced on Bank 1, typically signaled by Diagnostic Trouble Code (DTC) P0011, it indicates that the intake valves are opening earlier than the engineered optimal window. This mismatch disrupts the combustion cycle, potentially leading to immediate performance degradation and, if left unaddressed, significant internal engine damage. This expert guide provides a professional deep-dive into the causes, symptoms, and reliable repair strategies for resolving over-advanced timing issues with absolute precision.

Understanding the Mechanism of Camshaft Position Timing Over Advanced Bank 1

📤 Share Image

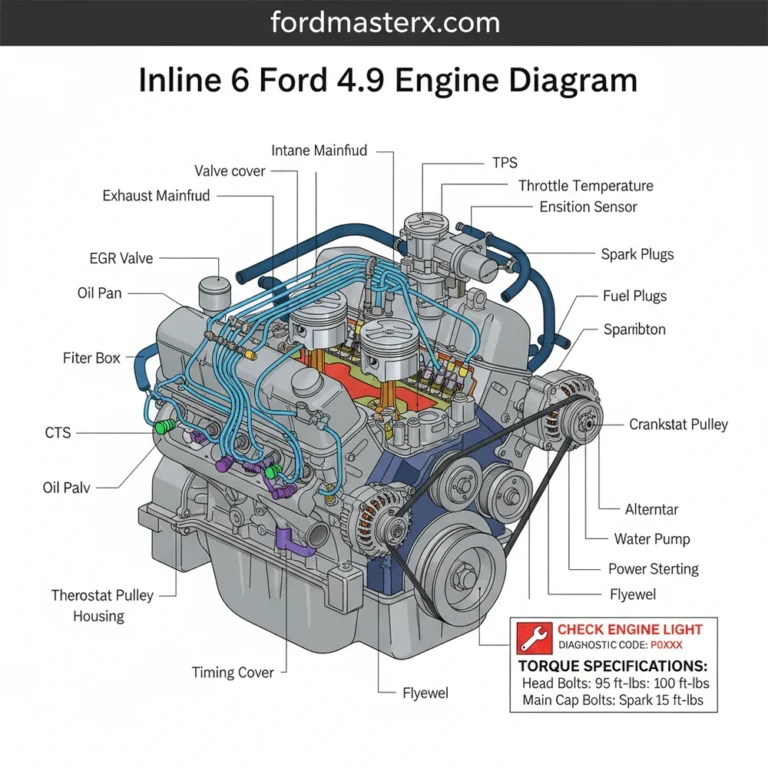

In modern internal combustion engines, the relationship between the crankshaft and the camshaft is no longer static. To maximize efficiency, manufacturers utilize Variable Valve Timing (VVT) systems. The ECM acts as the brain of this operation, constantly monitoring the Crankshaft Position Sensor and the Camshaft Position Sensor to ensure they are perfectly synchronized. By manipulating hydraulic oil pressure through an Oil Control Valve (OCV), the ECM can rotate the camshaft relative to its drive gear, advancing or retarding the timing based on engine load and RPM.

The term “Over-Advanced” specifically refers to a condition where the camshaft has moved ahead of its commanded position by a specific degree threshold—typically between 10 and 15 degrees. When this deviation is sustained for more than 5 seconds, the ECM concludes there is a mechanical or hydraulic failure and triggers a DTC. In V-configured engines, Bank 1 identifies the side of the engine block that contains cylinder number one. This distinction is critical for accurate diagnosis, as it prevents technicians from replacing components on the healthy side of the engine.

I have frequently encountered scenarios where a driver experiences a sudden, violent loss of power at high RPMs. This often occurs because the VVT phaser becomes mechanically “stuck” in the advanced position due to internal vane damage, preventing the engine from retarding the timing as the vehicle returns to idle.

VVT systems are highly sophisticated, typically operating within a range of 0 to 60 degrees of crankshaft rotation. The OCV acts as the gatekeeper, directing oil into specific chambers within the camshaft actuator (phaser). If the oil is too thick, too thin, or contaminated with debris, the phaser cannot react quickly enough to the ECM’s commands, resulting in a timing error.

VVT Operational Standards

Rotation Range

DTC Trigger Window

Error Threshold

Identifying Critical Symptoms and Diagnostic Trouble Codes

When an engine is over-advanced on Bank 1, the symptoms are rarely subtle. Because the intake valves are opening too early in the combustion cycle, the engine suffers from excessive valve overlap. At low speeds or idle, this causes exhaust gases to flow back into the intake manifold, diluting the fresh air/fuel charge. This manifest as a rough, stumbling idle or frequent stalling at stoplights. Conversely, at higher speeds, the engine may feel sluggish or “choked” because the timing is not optimized for the current load.

Beyond the physical performance, the ECM will store specific codes. While P0011 is the primary indicator, it is rarely alone. You will often see secondary codes such as P0016 (Crankshaft/Camshaft Correlation) or P0300 (Random Misfire). These secondary codes are the result of the timing error causing combustion instability. Furthermore, a noticeable “rattling” or “clattering” noise from the front or top of the engine is common. This is often the VVT phaser’s internal locking pin failing to secure the unit, causing the internal vanes to slap against the housing during low oil pressure conditions, such as a cold start.

Performance Loss

A significant drop in throttle response and a decrease in fuel economy by as much as 15%.

Auditability

The vehicle will fail OBD-II emissions inspections due to the active Check Engine Light.

Professional diagnosis involves using a high-quality scan tool to observe ‘Desired vs. Actual’ camshaft angle data. In a healthy engine, these two numbers should mirror each other within 1-2 degrees during a test drive. If the ‘Actual’ value stays at 20 degrees while ‘Desired’ is at 0 degrees at idle, you have confirmed the over-advanced state. Statistics show that approximately 70% of P0011 cases involve neglected oil changes, where sludge has physically jammed the VVT components.

Primary Causes of Timing Deviation in Bank 1

To solve an over-advanced timing issue permanently, one must understand that VVT is a hydraulic system managed by electrical signals. Any failure in the fluid, the plumbing, or the actuator will result in a fault. The most common culprit is oil quality. VVT solenoids contain tiny ports protected by mesh screens that can be restricted by particles as small as 100 microns. When oil is not changed regularly, sludge forms, blocking these ports and trapping oil pressure inside the phaser, which keeps the timing advanced.

Mechanical and Electrical Failures

The VVT solenoid itself is a high-wear item. Over time, its internal return spring can fatigue, or the electrical coil can short-circuit. If the solenoid stays stuck in the “open” position, it will continue to feed oil to the advance chamber of the phaser even when the ECM wants it retarded. We also must consider timing chain stretch. Even a 2mm stretch in a high-mileage chain can create enough slack to confuse the synchronization sensors, though this more often triggers correlation codes (P0016) rather than P0011 alone.

Using the wrong oil weight is a leading cause of VVT errors. I have seen multiple cases where a “trusted” brand of 10W-30 was used in an engine requiring 0W-20. The higher viscosity creates delayed solenoid response times, triggering the P0011 code almost immediately after the engine reaches operating temperature.

The camshaft phaser, or actuator, can also fail internally. These units rely on a small “locking pin” that holds the phaser at 0 degrees (the retard position) during startup. If this pin shears or becomes stuck, the camshaft will float freely, often swinging to the advanced position under the engine’s natural rotational inertia, leading to the over-advanced state at idle.

Systematic Diagnostic Procedure for Professional Results

A systematic approach is required to avoid “parts-cannon” repairs. Before replacing any sensors or phasers, a technician must perform a visual inspection of the engine oil level and condition. Low oil level is a primary driver of VVT failure, as the system requires a minimum of 20 PSI at idle to operate the hydraulic actuators correctly.

📋

Professional Diagnostic Steps

Check oil level and look for signs of sludge on the dipstick or under the oil cap. A reliable fix often starts with a simple oil and filter change using the correct OEM-specified weight.

Use a digital multimeter to check the resistance across the VVT solenoid terminals. While specs vary, most professional-grade solenoids should read between 6.9 and 12 ohms.

Using a bi-directional scan tool, command the solenoid “ON” at idle. If the solenoid is working, the engine should immediately stumble or stall, confirming hydraulic flow.

If the solenoid fails the active test, remove it and inspect the filter screens. Many technicians miss the screen located inside the cylinder head itself, which can be clogged even if the solenoid is new. Finally, check the wiring harness for continuity and ground. A frayed wire near the connector can mimic a failed solenoid by preventing the ECM’s pulse-width modulated (PWM) signal from reaching the actuator.

Proven Repair Solutions and Maintenance Strategies

Once the diagnosis is complete, the repair must be thorough to prevent recurrence. If the VVT solenoid is faulty, replace it with an OEM or high-quality professional-grade part. I strongly advise against ultra-cheap aftermarket solenoids, as their internal tolerances often fail to meet the high-speed switching requirements of the ECM. In cases where sludge is present, a professional engine flush is recommended. However, use caution; if an engine is heavily sludged, a flush may dislodge large chunks of carbon that can clog the oil pump pickup screen.

If the physical timing components—the chains, guides, and phasers—show signs of wear or excessive slack, a full timing set replacement is the only reliable solution. This is labor-intensive but prevents catastrophic engine failure should the chain jump a tooth. Additionally, always check for Technical Service Bulletins (TSBs). Some manufacturers, such as Toyota and GM, have released ECM software updates that widen the acceptable timing window to prevent “nuisance” codes on older engines with minor, non-critical wear.

To prevent future Bank 1 timing issues, establish a maintenance schedule using full synthetic oils that meet American Petroleum Institute (API) standards. Synthetic oils offer superior resistance to thermal breakdown and sludge formation, ensuring the VVT passages remain clear for the life of the vehicle. A “keep-clean” oil service every 5,000 miles is the most cost-effective insurance policy against VVT failure.

In summary, over-advanced timing is primarily driven by oil pressure inconsistencies or mechanical failure of the VVT solenoid and phaser. Accurate diagnosis requires a combination of scan tool data, electrical testing, and a physical inspection of oil quality to ensure a complete and trusted repair. Preventative maintenance through regular oil changes remains the most reliable method to ensure the longevity of your engine’s complex timing system. If you are currently experiencing P0011 symptoms, begin with a professional oil change and solenoid inspection before moving to more costly mechanical repairs.

Frequently Asked Questions

Can I drive with a camshaft position timing over advanced code?

While the vehicle may still be drivable, it is not recommended for long distances. An over-advanced camshaft can cause poor combustion, excessive heat, and decreased fuel efficiency. Continued operation may lead to internal engine damage or failure of the catalytic converter due to unburnt fuel entering the exhaust stream. Seek professional inspection promptly.

How does engine oil quality affect camshaft timing?

Variable Valve Timing (VVT) systems are highly sensitive to oil pressure and cleanliness. The VVT solenoid uses engine oil as hydraulic fluid to move the camshaft. If the oil is dirty, of the wrong viscosity, or depleted of additives, it can clog the narrow passages or screens, causing the camshaft to stick in the advanced position.

Is a P0011 code always caused by a faulty sensor?

No, in most expert diagnostic cases, the sensor itself is functioning correctly and is accurately reporting a mechanical timing error. The actual cause is usually a stuck Oil Control Valve, a failed camshaft phaser, or restricted oil flow. Replacing the sensor without diagnosing the hydraulic and mechanical components often fails to resolve the issue.

What is the difference between Bank 1 and Bank 2?

Bank 1 refers to the side of the engine that contains the number one cylinder. On inline engines, there is only Bank 1. On V6 or V8 engines, you must identify which side houses the first cylinder in the firing order. ‘Over advanced Bank 1’ specifically isolates the problem to the VVT components on that side of the block.

How much does it cost to fix an over-advanced camshaft timing issue?

The cost varies significantly based on the root cause. A simple VVT solenoid replacement may cost between $200 and $400 including labor. However, if the issue is a failed camshaft phaser or a stretched timing chain, professional repairs can range from $1,500 to $2,500 depending on the vehicle’s make and model and the labor hours required.