7.3 Powerstroke Sensor Location Diagram: Quick Guide

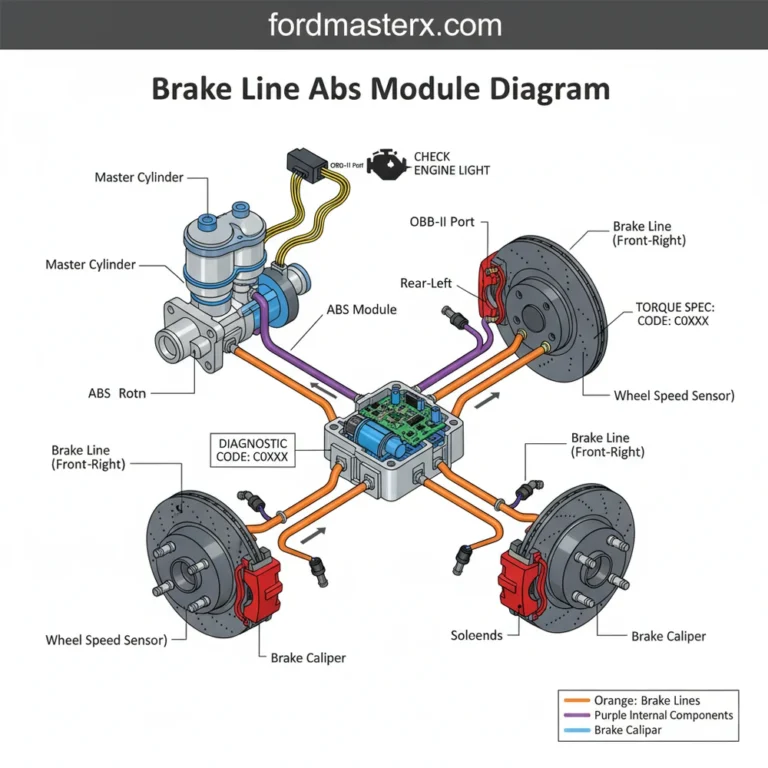

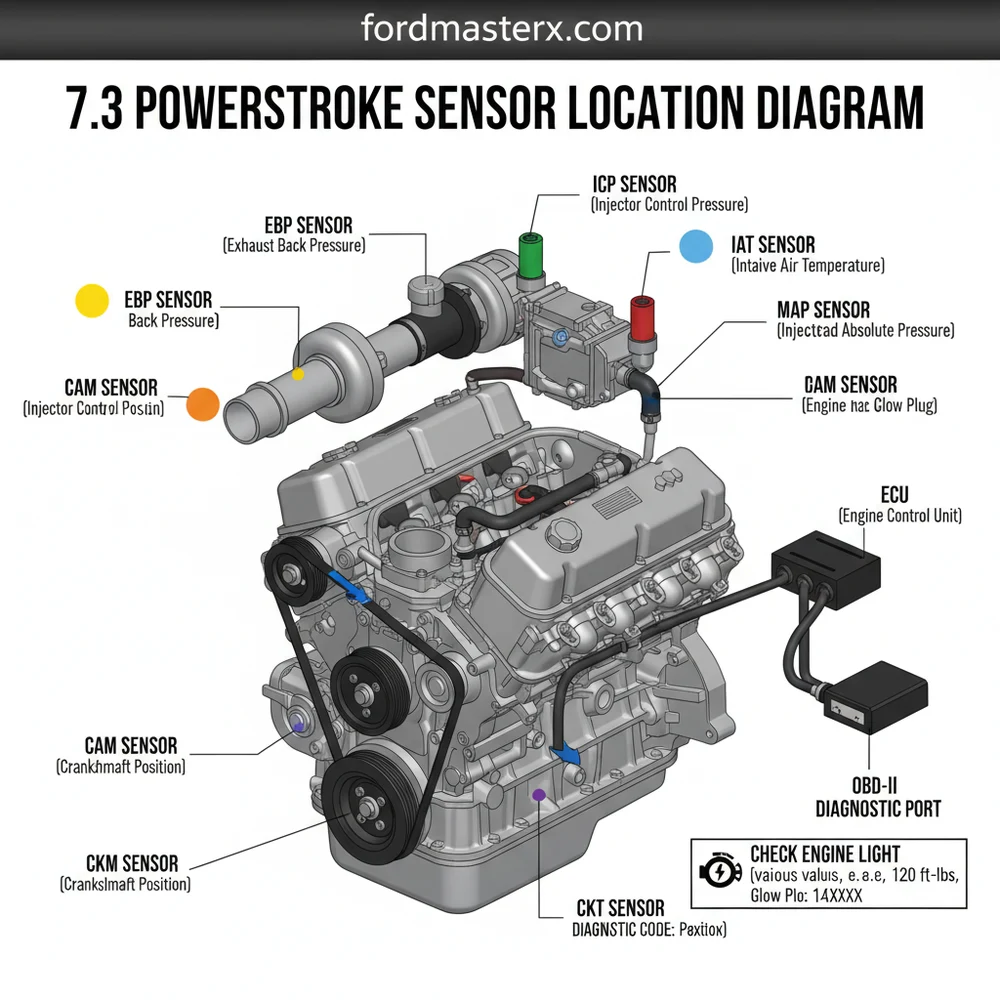

The 7.3 Powerstroke sensor location diagram identifies critical components like the ICP sensor on the driver side head, the IPR valve on the HPOP, and the CPS on the front cover. These sensors send data to the ECU to manage timing. Use an OBD-II scanner to pull a diagnostic code first.

📌 Key Takeaways

- Visualizing the layout of over ten critical engine sensors

- Identifying the CPS and ICP as primary failure points

- Inspecting electrical connectors for oil intrusion and corrosion

- Mapping OBD-II diagnostic codes to physical engine locations

- Essential reference for diagnosing no-start or rough idle conditions

Finding the correct 7.3 powerstroke sensor location diagram is the critical first step for any owner looking to maintain or repair this legendary diesel engine. Because the 7.3 engine relies heavily on an intricate network of sensors to manage high-pressure oil and fuel delivery, a single failed component can lead to a “crank but no start” condition or a frustrating check engine light. This guide provides a detailed visual and descriptive roadmap of the engine’s electronic nerve center. By understanding these locations, you will learn how to identify, test, and replace vital sensors, transforming complex diagnostic codes into manageable weekend projects.

Understanding the 7.3 Powerstroke Sensor Architecture

The 7.3 Powerstroke engine is a “HEUI” (Hydraulic Electronic Unit Injection) system, meaning it uses highly pressurized engine oil to fire the fuel injectors. Because of this, the 7.3 powerstroke sensor location diagram is more complex than a standard gasoline engine. The diagram is generally divided into three main zones: the upper valley, the front timing cover, and the external chassis/firewall components.

In the upper valley, the most prominent landmark is the High-Pressure Oil Pump (HPOP). Mounted directly to the back of the HPOP is the Injection Pressure Regulator (IPR) valve, while the Injection Control Pressure (ICP) sensor is typically found on the driver-side cylinder head. The Engine Oil Temperature (EOT) sensor is located on the rear of the HPOP reservoir. These three sensors work in tandem with the ECU to ensure the oil pressure is sufficient to atomize fuel.

Moving to the front of the block, the Camshaft Position Sensor (CPS) is located at the 10 o’clock position relative to the harmonic balancer. Unlike many modern engines that utilize a timing chain, the 7.3 uses a heavy-duty gear train; the CPS reads the rotation of these gears to tell the ECU when to fire the injectors. Near the top-front of the engine, you will also find the Exhaust Back Pressure (EBP) sensor, which sits on a pedestal and connects to the passenger-side exhaust manifold via a metal tube.

This diagram illustrates the top-down and front-facing views of the 7.3L engine, highlighting the CPS, ICP, IPR, EBP, MAP, and EOT sensor locations relative to the HPOP and cylinder heads.

On the passenger-side firewall, you will find the Manifold Absolute Pressure (MAP) sensor, which is connected to the intake manifold by a rubber hose. This sensor is vital for the ECU to calculate boost levels and adjust fueling accordingly. Finally, the Intake Air Temperature (IAT) sensor is usually located within the air intake assembly, monitoring the air density before it enters the turbocharger.

Step-by-Step Guide to Identifying and Accessing Sensors

Navigating a 7.3 powerstroke sensor location diagram requires a systematic approach. Follow these steps to locate and inspect your sensors correctly.

Before touching any sensors, always plug a scanner into the OBD-II port under the dashboard. A specific diagnostic code (like P1211 for ICP or P0340 for CPS) will tell you exactly which part of the diagram to focus on.

- Safety First and Battery Disconnection: Before accessing any sensors, especially those near the accessory belt or the high-voltage injector wires, disconnect both negative battery terminals. This prevents accidental shorts to the ECU.

- Locate the Camshaft Position Sensor (CPS): Crawl under the front of the truck. Look at the harmonic balancer (the large wheel at the bottom-center of the engine). At the 10 o’clock position, you will see a small sensor held in by a 10mm bolt. This is the CPS. It is tucked behind the accessory belt, so you may need a long extension to reach it.

- Find the Injection Control Pressure (ICP) Sensor: Open the hood and look at the driver-side cylinder head near the front. You will see a sensor sticking out of the top of the head with a three-wire connector. This is the ICP. Pull the connector; if you see oil inside the plug, the sensor has failed internally.

- Access the Injection Pressure Regulator (IPR) Valve: Look deep into the “valley” (the center area between the two cylinder heads). Behind the HPOP, you will see a solenoid with a large tin nut (the “tin nut”) holding a spacer in place. This is the IPR. You will need a specialized 1-1/8 inch deep socket to remove it.

- Identify the Exhaust Back Pressure (EBP) Sensor: Locate the thermostat housing at the front of the engine where the coolant flow exits the block. Just to the side of this, there is a bracket holding a sensor connected to a metal tube. This tube often clogs with soot, causing the EBP sensor to give false readings to the ECU.

- Locate the Manifold Absolute Pressure (MAP) Sensor: Move to the passenger-side firewall. You will see a small plastic sensor mounted to a bracket with a vacuum line running down to the intake manifold. Ensure the hose is not cracked or brittle, as this is a common cause of low power.

- Find the Engine Oil Temperature (EOT) Sensor: On the back side of the HPOP reservoir (the rectangular aluminum box at the top front of the engine), you will find the EOT sensor. This sensor tells the ECU how thin the oil is, which affects how long the injectors stay open.

Always follow the correct torque spec when reinstalling sensors. For example, the CPS bolt requires only 18 lb-ft. Over-tightening can crack the sensor housing or strip the threads in the front cover.

Common Issues and Troubleshooting with Sensors

When the check engine light illuminates on a 7.3 Powerstroke, the sensors are the most likely culprits. The most frequent issue is a failing CPS, which causes the engine to die unexpectedly or fail to start. If your tachometer does not move while cranking the engine, the CPS is almost certainly the problem.

Another common failure point is the ICP sensor. When this sensor fails, it may send erratic pressure data to the ECU, resulting in a rough idle or surging. Troubleshooting involves unplugging the ICP; if the engine suddenly runs better, the ECU has defaulted to a “base map,” confirming the sensor is bad.

The IPR valve is also prone to “sticking” due to dirty oil. If the IPR cannot build enough pressure (at least 500 PSI is required for the engine to fire), the truck will not start. Utilizing the 7.3 powerstroke sensor location diagram allows you to quickly locate these components to perform an “unplug test” or a voltage check to see if the hardware or the wiring harness is at fault.

Maintenance Tips and Best Practices

To keep your 7.3 Powerstroke running for hundreds of thousands of miles, follow these professional maintenance recommendations:

- ✓ Use OEM Sensors Only: The 7.3 is notoriously picky about sensors. Aftermarket sensors from local parts stores often have incorrect resistance levels. Always buy Motorcraft or International brand sensors for the CPS, ICP, and IPR.

- ✓ Inspect Wiring Pigtails: Because these sensors sit in a high-heat environment, the plastic connectors (pigtails) often become brittle and crumbly. Whenever you replace a sensor, inspect the wiring for exposed copper or melted insulation.

- ✓ Clean the EBP Tube: Every 50,000 miles, remove the metal tube connecting the EBP sensor to the exhaust manifold. Use a piece of speedometer cable or a stiff wire to poke out the carbon buildup. This ensures the sensor can properly read the pressure.

- ✓ Dielectric Grease: Use a small amount of dielectric grease on the weather seals of your sensor connectors to prevent moisture intrusion and corrosion.

Experienced 7.3 owners always keep a spare Camshaft Position Sensor and a 10mm wrench in the glove box. Since the CPS can fail without warning and leave you stranded, being able to swap it on the side of the road is a life-saving skill.

In conclusion, mastering the 7.3 powerstroke sensor location diagram is the best way to ensure the longevity of your vehicle. By knowing exactly where each component sits—from the CPS behind the accessory belt to the MAP sensor on the firewall—you can diagnose issues faster and avoid costly mechanic bills. Remember to always check your diagnostic codes via the OBD-II port first, use high-quality parts, and respect the torque specs to keep your Powerstroke huming for years to come.

Frequently Asked Questions

Where is the ICP sensor located?

The Injection Control Pressure (ICP) sensor is located on the front of the driver side cylinder head. It is easily visible near the lift bracket. If you see oil in the connector, the sensor has failed and may trigger a check engine light or cause poor idling and stalling issues.

What does the 7.3 powerstroke sensor location diagram show?

This diagram illustrates the physical placement of electronic components like the Camshaft Position Sensor, Injection Pressure Regulator, and EBP sensor. It helps technicians correlate a specific diagnostic code from an OBD-II scanner to the correct engine component, ensuring efficient repairs and accurate part replacement on the 7.3 diesel engine.

How many wires does the IPR valve have?

The Injection Pressure Regulator (IPR) valve features a two-wire electrical connector and is held in place by a small tin nut. It is located at the back of the High-Pressure Oil Pump (HPOP). When reinstalling, ensure you meet the specific torque spec to prevent the nut from vibrating loose.

What are the symptoms of a bad CPS?

A failing Camshaft Position Sensor (CPS) typically causes sudden engine stalling, a no-start condition, or intermittent stumbling while driving. Because the ECU relies on this signal for timing and fuel delivery, a total failure will prevent the engine from firing. It is a legendary 7.3 Powerstroke failure point.

Can I replace these sensors myself?

Yes, most sensors on the 7.3 Powerstroke are accessible with basic hand tools. Components like the ICP and EBP sensors are straightforward, though the CPS requires reaching near the crank pulley. Always disconnect the batteries before working on electronic components to protect the vehicle’s ECU from electrical shorts.

What tools do I need for sensor replacement?

You will need a standard socket set, deep-well sockets for the ICP, and a scan tool to clear the check engine light. A torque wrench is vital to ensure every sensor meets the manufacturer’s torque spec, preventing oil leaks or damage to the engine’s cast iron and aluminum threads.