7.3 Powerstroke Fuel Pressure Regulator Diagram Guide

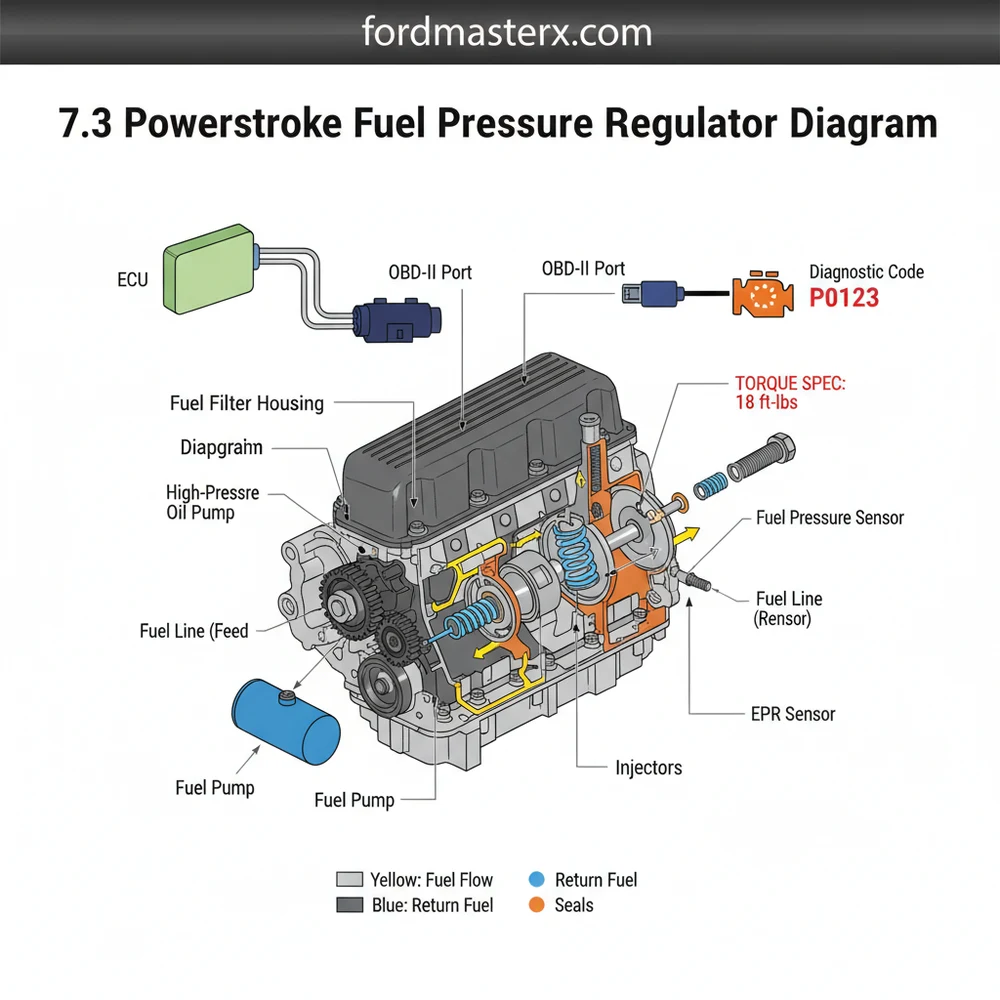

The 7.3 Powerstroke fuel pressure regulator diagram illustrates the mechanical relief valve assembly located on the side of the fuel filter bowl. It details the spring, poppet, and O-ring arrangement critical for maintaining 55-65 psi. This visual guide is vital when diagnosing a check engine light or specific diagnostic code.

📌 Key Takeaways

- Visualizes the fuel bowl assembly and the return-to-tank relief path.

- Identifying the poppet valve and spring assembly is crucial for pressure regulation.

- Always relieve fuel system pressure before attempting any disassembly.

- Use the diagram to inspect for torn O-rings causing external fuel leaks.

- Consult this diagram when diagnosing rough idle or low-power conditions.

If you are looking to maintain the longevity and performance of your Ford diesel engine, understanding the 7.3 powerstroke fuel pressure regulator diagram is an essential first step. This guide is designed to provide you with a comprehensive visual and technical breakdown of the fuel pressure regulator (FPR) assembly, located on the fuel filter bowl. By the end of this article, you will be able to identify every component within the regulator housing, understand how it interacts with the rest of the fuel system, and learn the specific steps required to rebuild or adjust the unit for optimal fuel delivery. Whether you are dealing with a rough idle or preparing for a performance upgrade, having the correct diagram and technical context ensures your repairs are accurate and safe.

The fuel pressure regulator on a 7.3L Powerstroke is a mechanical assembly found on the driver’s side of the fuel filter housing. A comprehensive 7.3 powerstroke fuel pressure regulator diagram typically illustrates a small, vertical housing held in place by two T-20 Torx screws. Inside this housing, the diagram reveals a specific stack of components: a compression spring, a brass plunger with a rubber seat, and a small plastic spacer or guide. On the exterior, the diagram points to the return line that sends excess fuel back to the fuel tank and a Schrader valve, which is the primary port for testing fuel pressure.

Most diagrams will also indicate the placement of a Viton O-ring, which is critical for preventing external leaks. It is important to note that while the core design remained consistent throughout the production run, there are slight variations in fuel bowl positioning between early models and those produced later in the cycle. Specifically, the proximity to the accessory belt and the coolant flow lines may vary slightly, making it necessary to consult a diagram that matches your specific engine layout. The diagram effectively serves as a map for the “return-to-tank” system, ensuring that fuel pressure remains consistently between 50 and 65 PSI.

The 7.3 Powerstroke uses a mechanical fuel pressure regulator. Unlike modern common-rail systems where the ECU manages pressure via electronic solenoids, this system relies on the physical tension of a spring to maintain the correct pressure for the injectors.

[DIAGRAM_PLACEHOLDER: A detailed technical illustration showing the 7.3 Powerstroke fuel filter bowl. The diagram features an exploded view of the Fuel Pressure Regulator (FPR) on the side of the bowl. Labels include: 1. Regulator Housing, 2. Compression Spring, 3. Brass Plunger, 4. Viton O-ring, 5. Fuel Return Line, 6. T-20 Torx Bolts, 7. Schrader Test Port. Arrows indicate fuel entering from the filter and excess fuel exiting through the return line to the tank.]

To properly use the 7.3 powerstroke fuel pressure regulator diagram during a repair or inspection, follow these detailed steps. This process will help you interpret the diagram in a real-world application while ensuring your engine remains in peak condition.

- ✓ 10mm socket and ratchet for engine cover removal

- ✓ T-20 Torx bit for the regulator housing

- ✓ Fuel pressure gauge (0-100 PSI range)

- ✓ Replacement O-rings and FPR spring kit

- ✓ Clean rags and shop towels

1. Safety and Preparation: Before beginning, ensure the engine is cool. Disconnect the batteries to prevent any electrical mishaps. Locate the fuel filter bowl in the valley of the engine. You may need to move the plastic decorative cover and inspect the area near the accessory belt to ensure you have enough clearance for your tools.

2. Relieve System Pressure: Even with the engine off, the fuel system may hold residual pressure. Use a rag to cover the Schrader valve on the regulator and carefully depress the center pin to bleed off pressure. This prevents fuel from spraying onto the engine block or into your eyes.

3. Identify Components: Compare your 7.3 powerstroke fuel pressure regulator diagram to the actual unit on your truck. Note the orientation of the fuel return line attached to the bottom of the regulator housing.

4. Disassemble the Housing: Using the T-20 Torx bit, remove the two screws holding the regulator cover. Hold the cover firmly as you loosen the screws, as the internal spring is under tension and may cause the components to pop out unexpectedly.

5. Inspect the Internal Parts: Remove the spring and the brass plunger. Refer to the diagram to ensure no parts are missing. Look for debris or pitting on the brass plunger seat. This is also the time to inspect the rubber O-ring for cracks or flat spots.

6. Clean and Reassemble: Clean the housing and the plunger with a lint-free cloth. Lubricate the new O-ring with a small amount of clean diesel fuel or clean engine oil. Reinsert the plunger, then the spring, and finally the cover.

7. Tighten to Specification: Reinstall the Torx screws. The torque spec for these small fasteners is very low, typically around 25-30 inch-pounds. Over-tightening can easily strip the aluminum threads in the fuel bowl.

8. Test for Leaks: Cycle the key to the “On” position to prime the fuel pump. Check for any leaks around the housing. Start the engine and verify that the fuel pressure matches the specifications identified in your diagnostic guide.

Diesel fuel is highly flammable. Avoid performing this work near an open flame or while the engine is hot. Ensure that the coolant flow lines nearby are not damaged during the removal process, as pressurized coolant can cause severe burns.

Even with a high-quality 7.3 powerstroke fuel pressure regulator diagram, troubleshooting can be tricky. One of the most common issues is a “low fuel pressure” condition, which often results in a rough idle, white smoke upon startup, or a lack of power under load. If your pressure drops below 45 PSI, the injectors may not fill completely, leading to poor atomization.

Another frequent problem is a leaking FPR housing, usually caused by a degraded O-ring. While the ECU does not directly monitor fuel pressure on this specific engine, low pressure can cause a generic check engine light or a diagnostic code related to injection control pressure (ICP). If you use an OBD-II scanner and see a P1211 code, it indicates that the injection pressure is not meeting the desired setpoint, which can sometimes be traced back to insufficient fuel supply from the regulator. Unlike engines that use a timing chain to drive the pump, the 7.3 relies on a gear-driven high-pressure oil pump, but both systems must work in harmony for the engine to run correctly.

If you are experiencing low pressure, many enthusiasts perform the “BB Mod,” which involves placing a small stainless steel BB behind the spring to increase tension. However, a better long-term solution is to install a dedicated high-performance spring kit designed for 60-65 PSI.

Maintaining your fuel pressure regulator is vital for the long-term health of your 7.3 Powerstroke. One of the best practices for this engine is to regularly check the fuel pressure at the Schrader valve during your routine oil changes. This allows you to catch a weakening spring before it causes injector damage. Furthermore, always use high-quality Viton seals when rebuilding the regulator. Standard rubber O-rings will deteriorate quickly when exposed to modern ultra-low sulfur diesel and biodiesel blends.

When working in the engine valley, take the opportunity to inspect the surrounding area. Check the accessory belt for fraying and ensure that the wiring harnesses going to the ECU and various sensors are not rubbing against the fuel lines. While the 7.3 is famous for its “million-mile” gear-driven timing system rather than a fragile timing chain, the fuel system components are the parts most likely to require attention over time.

By following the 7.3 powerstroke fuel pressure regulator diagram and maintaining a clean fuel system, you can ensure your truck remains reliable for years to come. If you encounter persistent issues after a rebuild, such as a recurring check engine light or complex diagnostic code, it may be time to inspect the electric fuel pump located on the frame rail, as the regulator can only manage the pressure it receives. Investing in a permanent fuel pressure gauge inside the cab is a popular upgrade that allows for real-time monitoring, giving you peace of mind during heavy towing or long road trips.

Step-by-Step Guide to Understanding the 7.3 Powerstroke Fuel Pressure Regulator Diagram Guide

Identify components using the 7.3 Powerstroke fuel pressure regulator diagram to ensure all seals are present.

Locate the regulator housing attached to the driver-side exterior of the fuel filter bowl.

Understand how the internal spring and poppet manage excess fuel return to maintain system pressure.

Apply the correct torque spec when reattaching the housing to prevent fuel leaks or stripped threads.

Verify that the OBD-II scanner shows no related diagnostic code and the engine idles smoothly.

Complete the process by checking for external leaks while the engine is running at operating temperature.

Frequently Asked Questions

Where is the fuel pressure regulator located?

On the 7.3 Powerstroke, the fuel pressure regulator is located on the driver’s side of the fuel filter housing (fuel bowl) in the engine valley. It is a small rectangular or oval-shaped housing held in place by two Torx screws, sitting just above the fuel return line connection.

What does this fuel pressure regulator diagram show?

The diagram displays the internal stack-up of the regulator assembly. It identifies the housing cover, the tension spring, the brass or plastic poppet valve, and the specific O-rings required to seal the unit. It also shows how fuel bypasses the poppet to return to the fuel tank.

How many connections does the regulator have?

The mechanical regulator itself has no electrical connections or wires. However, it interfaces with the fuel bowl and the return fuel line. It works alongside sensors monitored by the ECU; if pressure drops too low, the OBD-II system may trigger a diagnostic code related to injection control pressure.

What are the symptoms of a bad regulator?

Symptoms include a rough idle, blue smoke, hard starting, and a significant loss of power. If the internal spring weakens or the poppet fails to seat, fuel pressure will drop. This often triggers a check engine light and can be verified using a mechanical pressure gauge.

Can I replace the regulator components myself?

Yes, rebuilding or replacing the 7.3 fuel pressure regulator is a common DIY task. The process involves removing two screws and swapping the internal spring and seals. It requires basic tools and about 30 minutes of time, making it a very feasible project for most truck owners.

What tools do I need for this task?

You will primarily need a T20 or T25 Torx bit (depending on your specific year), a small flathead screwdriver or pick to remove old O-rings, and a clean rag. For diagnosis, an OBD-II scanner and a fuel pressure gauge are recommended to ensure the system reaches the proper PSI.