2018 Ford F-250 Towing Capacity Chart: The Ultimate Technical Guide & Performance Analysis

The 2018 Ford F-250 Super Duty represents a significant maturation point in the history of heavy-duty pickup trucks. Following the radical redesign of the 2017 model year—which introduced the high-strength, military-grade aluminum-alloy body to the Super Duty lineup—the 2018 model arrived with a focus on refining capability, durability, and technological integration. For the automotive engineer, fleet manager, or heavy-duty towing enthusiast, the 2018 F-250 is not merely a vehicle; it is a complex system of thermal dynamics, structural rigidity, and torque multiplication designed to move massive loads with high reliability.

The shift to aluminum was a calculated engineering gamble that paid dividends in the 2018 model. By shaving approximately 350 pounds from the body compared to previous steel generations, Ford engineers did not simply pocket the weight savings for fuel economy. Instead, this mass was reinvested into the components that matter most for towing: a fully boxed high-strength steel frame, significantly larger axles, and heavier suspension components.

This redistribution of mass created a vehicle with a lower center of gravity relative to its payload capability and a chassis stiffness that is 24 times greater than the previous generation, a critical factor when managing the torsional stresses applied by heavy trailers.

This report serves as an exhaustive technical resource. Unlike simplified brochures that present “maximum” numbers that apply to only a single, theoretical truck configuration, this document dissects the towing capabilities of the 2018 F-250 across every variable: engine selection, cab configuration, drive train, and the all-important axle ratio.

Furthermore, we analyse these numbers through the lens of SAE J2807 compliance, ensuring that the data presented reflects real-world performance standards rather than marketing hyperbole. We will also contextualize the F-250’s performance against its contemporary rivals and provide deep mechanical insights into the systems that enable these capacities.

FORDMASTERX | 2018 F-250 Guide

Built to Haul.

Ready to Work.

The 2018 Ford F-250 Super Duty redefined heavy-duty towing with its lightweight aluminum-alloy body and high-strength steel frame. Whether you’re hauling a contractor’s trailer or a massive camper, understanding your specific limits is crucial for safety and performance.

Max Diesel Towing

18,500 lbs

Max Gas Towing

15,000 lbs

The Heart of the Beast

Your towing capacity starts under the hood. The 2018 F-250 offered two distinct powerplants. While the 6.2L Gas V8 is a capable workhorse, the 6.7L Power Stroke® Turbo Diesel offers more than double the torque, making it the clear choice for heavy mountain towing.

Horsepower vs. Torque

Comparison of peak output.

6.2L SOHC V8 (Gas)

- 385 Horsepower @ 5,750 rpm

- 430 lb-ft Torque @ 3,800 rpm

- Max Conventional Tow: 15,000 lbs

- Best for: Daily driving, lighter loads.

6.7L Power Stroke® V8 (Diesel)

- 450 Horsepower @ 2,800 rpm

- 935 lb-ft Torque @ 1,800 rpm

- Max Conventional Tow: 18,000 lbs

- Best for: Heavy 5th wheels, heavy machinery.

Conventional Towing

“Conventional” refers to “bumper pull” towing. For the 2018 F-250, the maximum rating requires the High Capacity Trailer Tow Package. Without this package, diesel models are often capped to lower limits comparable to gas models.

Important Note:

Always check your specific door jamb sticker. Real-world capacity is often limited by payload (tongue weight) before you hit the max tow rating.

Max Conventional Towing by Configuration

Values in lbsThe Axle Ratio Factor

The axle ratio is the number of revolutions the driveshaft makes for every one revolution of the wheel. A higher number (e.g., 4.30) provides more torque multiplication, making it easier to get heavy loads moving, thus increasing tow rating.

-

1

3.31 Ratio

Standard on many diesels. Great for highway fuel economy, but lower max tow rating.

-

2

3.73 Ratio

The “Goldilocks” ratio. Good balance of towing power and daily drivability.

-

3

4.30 Ratio

Available on Gas engines. Maximizes towing capacity at the expense of fuel economy.

Effect of Axle Ratio on Max GCWR (Gas)

5th Wheel & Gooseneck

Connecting to a hitch in the truck bed places the weight directly over the rear axle, allowing for significantly heavier loads and better stability.

Crew Cab 4×4

The most popular configuration. Max Tow:

14,700 lbs

(Diesel, Std Axle)

Max Capacity Config

Regular Cab 4×2. Max Tow:

18,500 lbs

Pre-Tow Safety Checklist

Check Door Sticker

Locate the VIN sticker on the driver’s door jamb. Note the Payload capability and GVWR.

Calculate Payload

Add up passengers, cargo, and hitch weight. Subtract this from your sticker’s max payload.

Weigh Tongue

Ensure trailer tongue weight is 10-15% of total trailer weight (Conventional) or 15-25% (5th Wheel).

Inflate rear tires to the “Max Load” PSI specified on the sidewall or door sticker for stability.

The SAE J2807 Standard: Defining “Capacity”

To understand the towing charts presented in this report, one must first understand the methodology behind the numbers. The 2018 Ford F-250’s ratings are fully compliant with the Society of Automotive Engineers (SAE) J2807 standard, titled “Performance Requirements for Determining Tow-Vehicle Gross Combination Weight Rating and Trailer Weight Rating”.

Prior to the industry-wide adoption of this standard, manufacturers could calculate towing capacity using proprietary methods, often leading to inflated numbers that were difficult to reproduce in the real world.

The SAE J2807 standard imposes a rigorous gauntlet of tests that a truck must pass to claim a specific Gross Combined Weight Rating (GCWR). These include:

- The Davis Dam Test: The vehicle must tow its maximum rated load up a continuous 11.4-mile stretch of Highway 68 in Arizona (the Davis Dam grade) with an average grade of 5%, during ambient temperatures of at least 100°F (37.8°C), while maintaining a minimum speed of 40 mph and running the air conditioning at maximum. This tests the thermal efficiency of the engine, transmission, and cooling stack under extreme load.

- Acceleration: The truck and trailer combination must accelerate from 0 to 30 mph in under 12 seconds and from 0 to 60 mph in under 30 seconds.

- Launch Capability: The vehicle must be able to launch the load from a dead stop on a 12% grade, both in forward and reverse, repeatedly.

- Braking and Handling: The standard mandates specific performance metrics for understeer, trailer sway damping, and stopping distances.

When this report lists a towing capacity of 15,000 lbs for a specific 2018 F-250 configuration, it implies that the vehicle has structurally and thermally survived these torture tests at that weight. This provides a layer of assurance to the consumer that the limits are engineered, not estimated.

Powertrain Engineering: The Heart of Capability

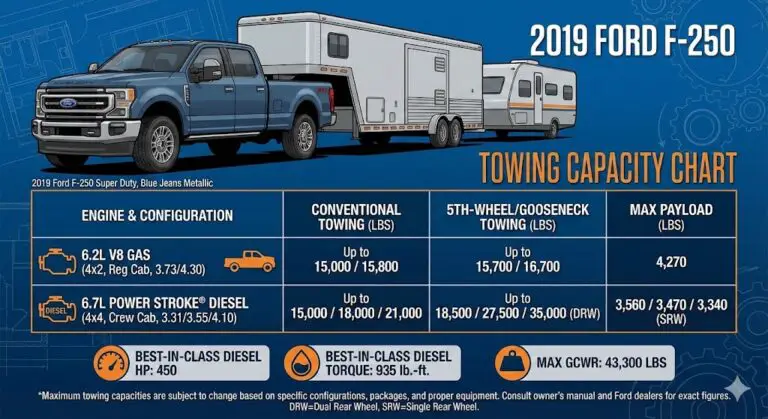

The towing capacity of the 2018 F-250 is inextricably linked to the prime mover under the hood. For this model year, Ford offered two distinct powertrain philosophies: the high-revving, naturally aspirated 6.2L gasoline V8 and the low-RPM, forced-induction 6.7L diesel V8. Understanding the mechanical architecture of these engines is essential for selecting the right tool for the job.

The 6.2L SOHC 2-Valve Flex Fuel V8 (Gasoline)

The standard powerplant for the 2018 F-250 is the 6.2L Boss V8. While the market often gravitates toward the torque figures of the diesel option, the 6.2L gas engine remains a critical option for commercial fleets and private owners who require high payload capacities without the added weight and maintenance complexity of a modern diesel emissions system.

Mechanical Architecture:

The 6.2L utilizes a cast-iron cylinder block with deep skirts for maximum rigidity, paired with aluminum cylinder heads. Unlike the smaller Coyote V8 found in the F-150, the 6.2L employs a Single Overhead Cam (SOHC) design with massive intake and exhaust valves controlled by roller-rocker shafts. This valvetrain design was chosen specifically for truck applications to optimize low-end airflow and durability.3 The engine features a large bore (102 mm) and a shorter stroke (95 mm), allowing it to breathe freely at high RPMs, which is necessary for generating horsepower in a naturally aspirated gas engine.

- Horsepower: 385 hp @ 5,750 rpm

- Torque: 430 lb-ft @ 3,800 rpm

- Compression Ratio: 9.8:1

- Fuel System: Sequential Multi-Port Electronic Fuel Injection

Transmission Pairing: The TorqShift® G:

For the 2018 F-250 specifically, the 6.2L engine is mated to the TorqShift-G 6-speed automatic transmission (Ford 6R100). This transmission was a new development for the Super Duty line in 2017, designed specifically for the torque curve of the gas engine. It features lower first-gear ratios to help get heavy loads moving and optimized step ratios to keep the engine in its power band (typically 3,500–5,500 RPM) during towing. It is lighter than the diesel transmission, contributing to the gas model’s superior payload rating.

The 6.7L Power Stroke® V8 Turbo Diesel

The optional 6.7L Power Stroke V8 represents the pinnacle of Ford’s heavy-duty engineering for the 2018 model year. Designed in-house by Ford (moving away from the previous Navistar partnership), this engine—codenamed “Scorpion”—was engineered to solve the thermal and packaging inefficiencies of traditional V8 diesels.

Mechanical Architecture:

The defining feature of the 6.7L Power Stroke is its Compact Graphite Iron (CGI) block, which is significantly stronger and lighter than traditional gray cast iron. This material strength allows for higher cylinder pressures, which translates directly to torque. The engine utilizes a “reverse-flow” layout where the exhaust ports are located in the valley of the V8 (inboard) and the intake ports are on the outside. This shortens the path from the exhaust valves to the turbocharger, drastically reducing thermal loss and turbo lag.

- Horsepower: 450 hp @ 2,800 rpm

- Torque: 935 lb-ft @ 1,800 rpm

- Induction: Single-Sequential Turbocharger (SST)

- Fuel System: Bosch CP4.2 High-Pressure Common Rail (29,000 psi)

Turbocharger Geometry:

The 2018 model benefits from updates to the turbocharger system. It uses a single variable-geometry turbocharger (GT37) that functions like a twin-turbo setup. At low RPMs, the vanes constrict to accelerate exhaust gas velocity, providing immediate boost response. At high RPMs, the vanes open to allow maximum flow. This system is crucial for towing, as it provides the “table-top” torque curve where peak torque is available almost instantly off idle (1,800 rpm).

Transmission Pairing: The TorqShift® 6R140:

The diesel engine produces torque forces that would shred a standard transmission. Therefore, it is paired with the heavy-duty TorqShift 6R140 6-speed automatic. This unit features massive clutch packs, a robust torque converter with a lock-up clutch capable of handling 935 lb-ft of torque, and a dedicated power take-off (PTO) provision. Critically, it integrates with the engine’s exhaust brake, using the transmission’s gear selection to mechanically hold the truck back on steep descents, reducing reliance on the friction brakes.

Powertrain Comparison Matrix

The following table summarizes the key engineering differences that influence towing performance.

| Feature | 6.2L V8 Gas (Boss) | 6.7L V8 Diesel (Power Stroke) | Towing Implication |

| Peak Torque | 430 lb-ft @ 3,800 RPM | 935 lb-ft @ 1,800 RPM | Diesel offers over double the torque at less than half the engine speed, enabling superior grade climbing without downshifting. |

| Horsepower | 385 hp | 450 hp | Diesel provides better high-speed passing capability while towing. |

| Block Material | Cast Iron | Compact Graphite Iron (CGI) | CGI handles higher combustion pressures required for heavy towing efficiency. |

| Transmission | TorqShift-G (6R100) | TorqShift (6R140) | Diesel transmission is physically larger and heavier to absorb torque spikes. |

| Engine Weight | ~580 lbs | ~1,100 lbs | The lighter gas engine results in higher payload capacity for pin weights. |

| Exhaust Braking | No | Yes | Diesel provides superior safety and control on downhill grades. |

| Turbocharging | None (Naturally Aspirated) | Single Sequential Variable Geometry | Diesel maintains power at high altitudes where gas engines lose ~3% power per 1,000 ft of elevation. |

2018 Ford F-250 Conventional Towing Capacity Analysis

Conventional towing—utilizing a ball hitch attached to the rear bumper receiver—is the most common form of towing for travel trailers, utility trailers, and boats. The 2018 F-250 is equipped with a frame-mounted hitch receiver that is integrated into the chassis design for maximum strength.

Receiver Classes:

Most 2018 F-250 models come standard with a 2.5-inch (Class V) hitch receiver. However, specific configurations, particularly diesels with the High-Capacity Trailer Tow Package, may feature a 3-inch receiver to accommodate the sheer shear strength required for 18,000-lb loads. Ford provides reducer sleeves (to 2.5″ or 2″) with the truck, but owners should be aware that using sleeves introduces additional play in the hitch connection.

Weight Distribution:

It is critical to note that for conventional trailers exceeding 5,000 lbs, Ford recommends (and J2807 standards assume) the use of a Weight Distributing Hitch (WDH). This device leverages leverage mechanics to transfer a portion of the tongue weight from the truck’s rear axle to the truck’s front axle and the trailer’s axles, ensuring that the front steering geometry remains planted and effective.

6.2L Gasoline Engine Conventional Towing Charts

The data below reveals the profound impact of the rear axle ratio on the gas engine’s capability. The 4.30 axle ratio acts as a torque multiplier, allowing the engine to spin faster for a given wheel speed, effectively placing the engine in its optimal power band for towing.

Regular Cab | 6.2L V8 Gas

| Drive Type | Axle Ratio | GCWR (lbs) | Max Towing Capacity (lbs) |

| 4×2 | 3.73 | 19,500 | 13,300 |

| 4×2 | 4.30 | 22,000 | 15,000 |

| 4×4 | 3.73 | 19,500 | 12,900 |

| 4×4 | 4.30 | 22,000 | 15,000 |

SuperCab | 6.2L V8 Gas

| Drive Type | Axle Ratio | GCWR (lbs) | Max Towing Capacity (lbs) |

| 4×2 | 3.73 | 19,500 | 13,000 |

| 4×2 | 4.30 | 22,000 | 15,000 |

| 4×4 | 3.73 | 19,500 | 12,600 |

| 4×4 | 4.30 | 22,000 | 14,800 |

Crew Cab | 6.2L V8 Gas

| Drive Type | Axle Ratio | GCWR (lbs) | Max Towing Capacity (lbs) |

| 4×2 | 3.73 | 19,500 | 12,900 |

| 4×2 | 4.30 | 22,000 | 15,000 |

| 4×4 | 3.73 | 19,500 | 12,500 |

| 4×4 | 4.30 | 22,000 | 15,000 |

Analysis of Gas Performance:

The variance between the 3.73 and 4.30 axle ratios is substantial—often a difference of 2,100 to 2,500 lbs in capacity. For the prospective buyer looking at a gas F-250, verifying the axle ratio is the single most important step. A 3.73 truck will struggle on grades with a 12,000 lb load, constantly downshifting to 2nd or 3rd gear to maintain RPMs. The 4.30 truck, while consuming more fuel when empty due to higher highway RPMs, will hold gears longer and pull with significantly more authority.

6.7L Diesel Engine Conventional Towing Charts

The diesel engine’s massive torque output changes the equation. Here, the limitation is less about the engine’s ability to pull and more about the chassis’s ability to handle the dynamic forces. Consequently, the standard towing capacity is capped at 15,000 lbs across the board unless the High-Capacity Trailer Tow Package is equipped.

Regular Cab | 6.7L Diesel

| Drive Type | Axle Ratio | GCWR (lbs) | Max Towing Capacity (lbs) |

| 4×2 | 3.31 / 3.55 | 23,500 | 15,000 |

| 4×4 | 3.31 / 3.55 | 23,500 | 15,000 |

SuperCab | 6.7L Diesel

| Drive Type | Axle Ratio | GCWR (lbs) | Max Towing Capacity (lbs) |

| 4×2 | 3.31 / 3.55 | 23,500 | 15,000 |

| 4×4 | 3.31 / 3.55 | 23,500 | 15,000 |

Crew Cab | 6.7L Diesel

| Drive Type | Axle Ratio | GCWR (lbs) | Max Towing Capacity (lbs) |

| 4×2 | 3.31 / 3.55 | 23,500 | 15,000 |

| 4×2 (High Cap) | 3.31 / 3.55 | 25,700 | 18,000 |

| 4×4 | 3.31 / 3.55 | 23,500 | 15,000 |

| 4×4 (High Cap) | 3.31 / 3.55 | 25,700 | 17,500 |

Analysis of Diesel Performance:

The data shows a “plateau” effect for the standard diesel configuration. Whether you choose the 3.31 or 3.55 axle ratio, the conventional tow rating remains static at 15,000 lbs. This indicates that the limitation is the Class V hitch receiver or the rear suspension springs, not the powertrain. To unlock the full 18,000 lb potential, the High-Capacity Trailer Tow Package is mandatory.

This package adds a modified rear axle (often the Dana M275 in place of the Sterling 10.5 on earlier builds, though 2018s largely standardized on robust axles) and often includes a 3-inch receiver hitch.

5th-Wheel and Gooseneck Towing Analysis

For loads exceeding 15,000 lbs, or for enhanced stability with any heavy trailer, the 5th-wheel (recreational/RV) or Gooseneck (commercial/agricultural) hitch is superior. These hitches mount in the bed of the truck, directly over or slightly forward of the rear axle centerline. This geometry eliminates the lever-arm effect of a bumper pull, drastically reducing sway and improving maneuverability.

However, moving the connection point to the bed introduces the Payload Constraint. A 5th-wheel trailer typically transfers 15% to 25% of its total weight to the truck’s bed (pin weight). A Gooseneck is typically 15-20%. This pin weight counts directly against the truck’s Gross Vehicle Weight Rating (GVWR).

The Payload Paradox: Gas vs. Diesel

A counter-intuitive finding in the 2018 F-250 data is that the Gasoline models often have higher payload capacities than their Diesel counterparts, which can sometimes make them legally superior for carrying heavy pin weights, even if they have less pulling power.

- Diesel Penalty: The 6.7L engine and 6R140 transmission add approximately 800 to 900 lbs to the front of the truck compared to the gas powertrain.

- GVWR Cap: The F-250 is a Class 2b truck, meaning its GVWR is legally capped at 10,000 lbs (or slightly less) to avoid Class 3 commercial regulations in some jurisdictions.

- Calculation:

Payload = GVWR - Curb Weight. Since the Diesel truck is heavier (higher curb weight) but has the same 10,000 lb GVWR ceiling, it has less available payload for tongue weight.

5th-Wheel/Gooseneck Towing Charts

6.2L V8 Gas | 5th-Wheel/Gooseneck

| Cab Configuration | Drive | Axle Ratio | Max Towing Capacity (lbs) |

| Regular Cab | 4×2 | 3.73 | 13,300 |

| 4×2 | 4.30 | 15,800 | |

| 4×4 | 3.73 | 12,900 | |

| 4×4 | 4.30 | 15,400 | |

| SuperCab | 4×2 | 3.73 | 13,000 |

| 4×2 | 4.30 | 15,500 | |

| 4×4 | 3.73 | 12,600 | |

| 4×4 | 4.30 | 15,100 | |

| Crew Cab | 4×2 | 3.73 | 12,900 |

| 4×2 | 4.30 | 15,400 | |

| 4×4 | 3.73 | 12,500 | |

| 4×4 | 4.30 | 15,000 |

Insight: The 4.30 axle continues to be the dominator here, pushing the gas engine to a respectable 15,800 lb maximum. This is sufficient for most mid-profile fifth-wheel RVs.

6.7L Diesel | 5th-Wheel/Gooseneck

| Cab Configuration | Drive | Axle Ratio | Max Towing Capacity (lbs) |

| Regular Cab | 4×2 | 3.31/3.55 | 16,400 |

| 4×4 | 3.31/3.55 | 16,000 | |

| SuperCab | 4×2 | 3.31/3.55 | 16,300 |

| 4×4 | 3.31/3.55 | 14,800 | |

| Crew Cab | 4×2 | 3.31/3.55 | 16,200 |

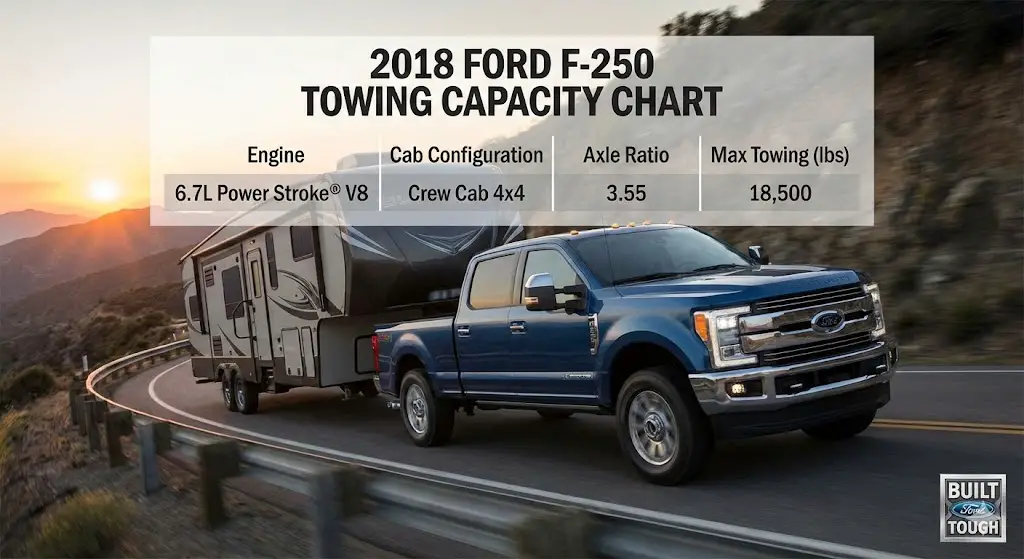

| Crew Cab (High Cap) | 4×2 | 3.31/3.55 | 18,500 |

| Crew Cab | 4×4 | 3.31/3.55 | 14,700 |

| Crew Cab (High Cap) | 4×4 | 3.31/3.55 | 17,500 |

Critical Observation: Notice the Crew Cab 4×4 standard rating of only 14,700 lbs. This is lower than the gas 4×2 model! Why? Because the heavy Crew Cab 4×4 Diesel configuration eats up so much payload that the pin weight of a heavier trailer would cause the truck to exceed its GVWR. The High-Capacity package rectifies this not just by stiffening the rear, but by technically allowing for higher GCWR, though the GVWR sticker on the door often remains the limiting legal factor.

Drivetrain Deep Dive: Axles and Transfer Cases

The 2018 F-250’s towing prowess is supported by a robust driveline.

Rear Axles: Sterling vs. Dana

Ford has historically used the Sterling 10.5-inch rear axle for the F-250. This is a full-floating axle, meaning the weight of the truck rests on the axle housing, not the axle shafts themselves. The shafts only transmit torque.

However, for the 2017+ redesign (including 2018), F-250s equipped with the High-Capacity Tow Package or the heavy-duty diesel options often received the Dana M275 rear axle. The Dana M275 features a larger 10.8-inch ring gear and higher fluid capacity, providing better heat dissipation during heavy towing.3

Axle Ratios Explained

The axle ratio (or final drive ratio) is the number of times the driveshaft must rotate to turn the wheels once.

- 3.31 (Diesel Only): Lowest numerical ratio. Best for fuel economy. The engine turns fewer RPMs at highway speeds. Can feel sluggish when starting a heavy load on a hill.

- 3.55 (Diesel Standard): The “Goldilocks” ratio for the diesel. Good mix of economy and pulling power.

- 3.73 (Gas Standard): Standard for the 6.2L. Acceptable for light duties, but suboptimal for max towing.

- 4.30 (Gas Optional): Highest numerical ratio. The engine spins faster (higher RPM) for any given speed. This maximizes the mechanical leverage of the engine. For a gas engine that makes torque at high RPMs, this is the essential “Towing Gear.”

Identification:

To determine which axle your 2018 F-250 has, check the Safety Compliance Certification Label on the driver’s door jamb under the code “AXLE”:

- 3E: 3.73 Electronic Locking

- 3J: 3.55 Electronic Locking

- 3H: 3.31 Electronic Locking

- 4M: 4.30 Electronic Locking

Transfer Case (4×4 Models)

The 2018 F-250 4×4 models use a heavy-duty transfer case.

- Electronic Shift-on-the-Fly (ESOF): Standard on XLT and above. Allows shifting between 2WD and 4WD High at speed.

- Manual Shift: Standard on XL (base) models. Requires stopping and physically pulling a lever on the floor. Preferred by some commercial operators for its mechanical simplicity.

- 4WD Low: Provides a gear reduction (usually 2.64:1 or similar) for extreme low-speed torque. Crucial for pulling a heavy boat up a slippery ramp.

Suspension and Chassis Dynamics

The suspension engineering of the 2018 F-250 is a study in compromise between load-carrying capacity and ride quality.

The “Mono-Beam” Front Axle

Unlike the Chevrolet Silverado 2500HD, which uses an Independent Front Suspension (IFS), the 2018 Ford F-250 4×4 utilizes a solid “Mono-Beam” front axle with coil springs.

- Advantage: Extreme durability. The alignment is fixed and does not change as the suspension cycles. This prevents tire wear when the truck is loaded heavy and the nose lifts slightly.

- Disadvantage: Susceptibility to “Death Wobble” (Steering Oscillation).

The Death Wobble Phenomenon:

Detailed in reports 10, some 2018 F-250 owners experience violent steering wheel oscillation after hitting a bump at speeds over 45 mph. This is caused by resonance in the solid axle setup, typically exacerbated by worn track bar bushings or a weak steering damper.

- Impact on Towing: Experiencing this event with a 10,000 lb trailer attached is extremely dangerous, as the trailer’s inertia can amplify the sway.

- Solution: Ford issued a customer satisfaction program to replace the steering linkage damper. For serious towers, installing a high-quality dual steering stabilizer kit (aftermarket) is a highly recommended preventative measure.

Rear Suspension

The rear uses traditional leaf springs. However, the 2018 model features longer leaf springs than previous generations.

Comparative Market Analysis: F-250 vs. Ram & Chevy

To fully value the 2018 F-250, we must benchmark it against its fierce rivals from the same model year.

vs. 2018 Ram 2500

Engine: 6.7L Cummins I6 (Turbo Diesel) vs. 6.4L Hemi V8 (Gas).

- Rear Suspension: The Ram 2500 is unique in using a 5-link Coil Spring rear suspension. This provides a significantly smoother ride than the Ford’s leaf springs but can feel less stable (“squirmy”) under maximum side-wind loads with a heavy trailer.

- Torque: The Cummins in the 2500 was rated at ~800 lb-ft, significantly lower than the Ford’s 935 lb-ft. The Ram transmission (68RFE) was also considered the weak link compared to the Ford TorqShift.

- Verdict: Ram wins on ride comfort; Ford wins on raw towing stability and torque.

vs. 2018 Chevrolet Silverado 2500HD

Engine: 6.6L Duramax L5P V8 (Diesel) vs. 6.0L Vortec V8 (Gas).

- Front Suspension: Chevy uses Independent Front Suspension (IFS). This offers superior handling and steering feel (car-like) but has less ground clearance and is more complex to lift or modify than Ford’s solid axle.

- Diesel Performance: The L5P Duramax (445 hp / 910 lb-ft) is a very close match to the Power Stroke. It is a potent engine.

- Gas Performance: The 6.0L Vortec was an ancient design by 2018, producing only 360 hp and 380 lb-ft. It is significantly outclassed by Ford’s 6.2L Boss engine (385 hp / 430 lb-ft).

- Verdict: Chevy offers a great diesel powertrain but falls short on chassis stiffness (older frame design in 2018) and gas engine performance.

Comparison Data Matrix

| Metric | 2018 Ford F-250 | 2018 Ram 2500 | 2018 Chevy 2500HD |

| Diesel Torque | 935 lb-ft | 800 lb-ft | 910 lb-ft |

| Gas Torque | 430 lb-ft | 429 lb-ft | 380 lb-ft |

| Max Diesel Towing | 18,500 lbs | 17,980 lbs | 18,100 lbs |

| Rear Suspension | Leaf Spring | Coil Spring | Leaf Spring |

| Front Suspension | Solid Axle | Solid Axle | IFS |

Real-World Ownership: Maintenance & Reliability

Towing heavy loads accelerates wear. Understanding the weak points of the 2018 F-250 is vital for long-term ownership.

The CP4.2 Fuel Pump Issue (Diesel)

The 2018 6.7L engine uses the Bosch CP4.2 high-pressure fuel pump. This pump relies on diesel fuel for lubrication.

- The Risk: American diesel fuel has lower lubricity than European diesel (for which the pump was designed). If the fuel contains water or is of poor quality, the internal cam of the pump can scour, sending metal shavings through the injectors and fuel rails.

- The Cost: This is a catastrophic failure often requiring the replacement of the entire high-pressure fuel system ($8,000 – $10,000 repair).

- Prevention: Use high-quality fuel from high-volume stations. Use diesel fuel additives that add lubricity (e.g., Stanadyne, Hot Shot’s Secret). Drain the water separator monthly.

DEF and Emissions Systems

The 2018 F-250 uses Diesel Exhaust Fluid (DEF) to reduce NOx emissions.

- Towing Consumption: While towing heavy loads, DEF consumption increases dramatically. The 7.5-gallon tank may need refilling every 1,500–2,000 miles when towing, compared to 5,000+ miles empty.

- Reliability: The heater in the DEF tank is a common failure point, triggering a “Speed Limited to 50mph” warning.

6.2L Gas Reliability

The gas engine is widely regarded as “bulletproof.”

- Spark Plugs: It has 16 spark plugs (2 per cylinder). Changing them is a labor-intensive job usually due at 100,000 miles.

- Exhaust Manifolds: Studs can break, leading to ticking noises on cold starts.

- Comparison: While it consumes more fuel, the maintenance cost is roughly 50% lower than the diesel over 100,000 miles due to cheaper oil changes, no fuel filters, and no DEF.

Maintenance Schedule for Towing

If you tow more than 50% of the time, you fall under “Severe Duty” maintenance.

- Oil Changes: Every 5,000 miles (Gas) or 200-300 engine hours (Diesel).

- Transmission Fluid: Inspect every 30,000 miles; replace at 60,000 miles (TorqShift gets hot!).

- Differential Fluid: Rear axle fluid should be changed every 30,000–50,000 miles if towing heavy, as the gears shear the fluid viscosity.

Safety and Technology Features

The 2018 F-250 introduced several technologies specifically designed to reduce the stress of towing.

BLIS® with Trailer Coverage

The Blind Spot Information System (BLIS) on the 2018 F-250 is unique because it can be programmed to include the length of the trailer.

- Function: Radar sensors in the tail lights monitor the lane next to you. You input the trailer length (up to 33 feet) into the dashboard computer. The system then extends the blind spot warning zone to cover the trailer.

- Limitation: Does not work with 5th-wheel trailers generally, primarily designed for conventional trailers.

Adaptive Steering

Available on higher trims (Platinum/Limited), this system changes the steering ratio based on speed.

- Low Speed: Fewer turns of the wheel are needed to maneuver the truck, making backing up a trailer easier.

- High Speed: The steering becomes less sensitive, reducing the “twitchiness” that can induce trailer sway on the highway.

Ultimate Trailer Tow Camera System

This package includes 7 cameras.

- 360-Degree View: crucial for parking a large dually.

- CHMSL Camera: (Center High-Mounted Stop Lamp) camera looks into the bed, allowing the driver to line up a 5th-wheel hitch without a spotter.

- Trailer Reverse Guidance: Uses cameras to track the trailer angle and provides visual cues on the screen to tell you which way to turn the wheel to back up straight.

Legal and Licensing Considerations

Understanding the towing charts is one thing; understanding the law is another.

CDL Requirements

Does driving a 2018 F-250 require a Commercial Driver’s License (CDL)?

- General Rule: If the GCWR (Truck GVWR + Trailer GVWR) is 26,001 lbs or more, AND the trailer is 10,001 lbs or more, a Class A CDL is required for commercial use.

- F-250 Context: An F-250 (10,000 GVWR) + a 16,000 lb trailer = 26,000 lbs GCWR. This is just under the CDL limit in many interpretations, keeping it in a “sweet spot” for hotshot truckers. However, upgrading the truck to a 14,000 GVWR F-350 would push this combination into CDL territory.

Non-Commercial Class A

Some states (e.g., Texas, California, Maryland) require a “Non-Commercial Class A” license for RVers pulling trailers over a certain weight (usually 10,000 or 15,000 lbs), regardless of whether it is for business or pleasure. Owners should check the DMV regulations in their home state.

Conclusion: Summary and Recommendations

The 2018 Ford F-250 Super Duty remains a benchmark in the heavy-duty truck segment. Its combination of a lightweight, corrosion-resistant aluminum body and a high-strength steel chassis allows for impressive capabilities that hold up even against newer competitors.

Recommendations:

- For the Weekend Warrior: The 6.2L Gas V8 with 3.73 gears is sufficient for boats and travel trailers under 10,000 lbs. It is cheaper to buy and maintain.

- For the Heavy Hauler: If you tow over 12,000 lbs or tow in mountainous terrain, the 6.7L Diesel is non-negotiable. The exhaust brake and turbo torque provide a safety margin that the gas engine cannot match.

- The Hidden Gem: The 6.2L Gas V8 with 4.30 gears is the “secret weapon.” It provides near-diesel pulling confidence for loads up to 15,000 lbs without the diesel price tag or maintenance headaches.

- Inspection: If buying used, check the door jamb for the Axle Code and inspect the front steering components for signs of “Death Wobble” play.

Frequently Asked Questions (FAQ)

Q: Can a 2018 F-250 tow 20,000 lbs?

A: No. The maximum rated towing capacity for a 2018 F-250 is 18,500 lbs (5th wheel) and 18,000 lbs (conventional), and this requires the 6.7L Diesel and specific High-Capacity Tow packages. To tow 20,000 lbs safely and legally, you would need an F-350 DRW or F-450.

Q: What is the difference between the “Trailer Tow Package” and “High-Capacity Trailer Tow Package”?

A: The Standard Trailer Tow Package includes the hitch receiver and wiring. The High-Capacity Trailer Tow Package (Option Code 535) adds an upgraded rear axle (often Dana M275), increased GCWR, and often stiffened suspension components. It is required to unlock the max towing figures on the Diesel F-250.19

Q: How do I know which axle ratio my 2018 F-250 has?

A: Check the Safety Compliance Certification Label on the driver’s door jamb. Look for the “AXLE” code. A code of “3E” indicates a 3.73 Electronic Locking axle, while “4M” indicates a 4.30 Electronic Locking axle.

Q: What is the fuel economy of the 6.2L Gas F-250 while towing?

A: Expect 8-10 MPG when towing moderate loads (8,000 lbs). Heavy loads (12,000+ lbs) or steep grades can drop this to 6-7 MPG.20 The 6.7L Diesel typically achieves 11-14 MPG under similar conditions.

Q: Does the 2018 F-250 have an exhaust brake?

A: Only the 6.7L Power Stroke Diesel models are equipped with an integrated engine exhaust brake. The 6.2L Gas engine relies on transmission downshifting (Tow/Haul mode) but does not have a true exhaust brake.

Q: Is the “Death Wobble” a dealbreaker for the 2018 F-250?

A: It is a known issue but not necessarily a dealbreaker. It is caused by worn suspension parts on the solid front axle. Installing a quality dual steering stabilizer and maintaining the track bar bushings usually resolves or prevents the issue. Ford also offers extended warranty coverage for the steering damper on many 2018 models.