2017 Ford F-250 6.7L PowerStroke: The Definitive Guide Specs, Towing & Reliability 2026

The launch of the 2017 Ford F-Series Super Duty represented one of the most significant pivots in the history of heavy-duty trucks. For the first time in the nameplate’s history, Ford completely severed ties with traditional steel body construction for its heavy-duty line, adopting the high-strength, military-grade aluminum-alloy body architecture first pioneered by the F-150 in 2015. This strategic shift was not merely cosmetic; it was a fundamental reengineering effort designed to solve the perennial conflict between weight and capability.

By shedding up to 350 pounds of body weight, Ford engineers were able to reinvest that mass into a significantly stronger frame, more robust axles, and heavier-duty suspension components, effectively creating a truck that was lighter on the scales but denser in capability.

For the automotive enthusiast and the heavy-duty consumer, the 2017 F-250 is more than just a model year update; it is the genesis of the “Alumi-Duty” era. This report provides an exhaustive, data-driven analysis of the 2017 Ford F-250 equipped with the 6.7L Power Stroke V8 Turbo Diesel. We will dissect the engineering behind the second-generation Scorpion engine, analyze the long-term reliability of the Bosch CP4.2 fuel system, evaluate the real-world implications of the aluminum body, and provide a granular assessment of its towing capabilities against its contemporary rivals, the Chevrolet Silverado 2500HD L5P and the Ram 2500 Cummins.

The Strategic Shift to Aluminum

The decision to move to aluminum was driven by the physics of payload and towing. In the Class 2 and Class 3 truck segments, Gross Vehicle Weight Rating (GVWR) is a fixed ceiling—often 10,000 lbs for the F-250 to keep it within specific registration classes. Every pound of curb weight is a pound subtracted from payload capacity. Steel bodies, while durable, are heavy. By utilizing heat-treated aluminum alloys, Ford reduced the body mass while increasing dent resistance. This weight savings allowed the 2017 F-250 to offer class-leading payload figures, a critical metric for owners hauling slide-in campers or heavy fifth-wheel pin weights.

However, this transition was not without controversy. Questions regarding collision repair costs, galvanic corrosion, and long-term durability in severe duty cycles were paramount in the minds of fleet managers and private owners alike. Years of data now suggest that while repair costs for aluminum bodies can be higher due to specialized tools and labor rates, the corrosion resistance benefits in “salt belt” states have significantly extended the service life of the body panels compared to previous steel generations.

Market Position in 2017

In 2017, the heavy-duty truck market was engaged in a fierce “arms race” for torque dominance. The 2017 F-250 entered the arena against a refreshed Chevrolet Silverado 2500HD featuring the new L5P Duramax engine and a Ram 2500 still relying on the proven, though aging, 6.7L Cummins ISB. The F-250’s 6.7L Power Stroke was updated to produce 925 lb-ft of torque, a figure explicitly targeted to surpass the Ram’s 800 lb-ft and the GM twins’ 910 lb-ft. This specific model year stands as a sweet spot in the used market today: it offers the modern aluminum body and high-output engine architecture without the added complexity of the 10-speed transmission introduced in 2020.

2017 FORD F-250

6.7L Power Stroke V8 Turbo Diesel

The definitive data-driven analysis of the first-generation “Alumi-Duty”. Specs, reliability, and market value optimized for semantic search.

The Aluminum Revolution

The 2017 model year marked a seismic shift for the Ford Super Duty lineup. Marking the transition to a high-strength, military-grade aluminum-alloy body, Ford cut nearly 350 lbs of weight while stiffening the frame by 24 times compared to the previous generation.

Under the hood lies the refined 2nd Generation 6.7L Power Stroke V8 Turbo Diesel. This wasn’t just a facelift; it was a declaration of war in the heavy-duty segment, pushing torque figures to near-four-digit territory. This guide breaks down the data to determine if the 2017 F-250 stands the test of time.

Max Conventional Towing

15,000 lbs

Max Payload

4,200 lbs

The Torque Wars: 2017 Competitive Landscape

In 2017, the heavy-duty truck segment was fiercely competitive. The chart below illustrates how the 6.7L Power Stroke stacked up against the Duramax L5P and the Cummins 6.7L. Ford aggressively tuned the 2017 model to lead in torque, essential for heavy towing acceleration.

- Engine: 6.7L Power Stroke V8 Turbo Diesel

- Turbo: Single Sequential Turbocharger (SST)

- Trans: TorqShift 6-Speed SelectShift Automatic

Source: Manufacturer Specs (2017 Model Year)

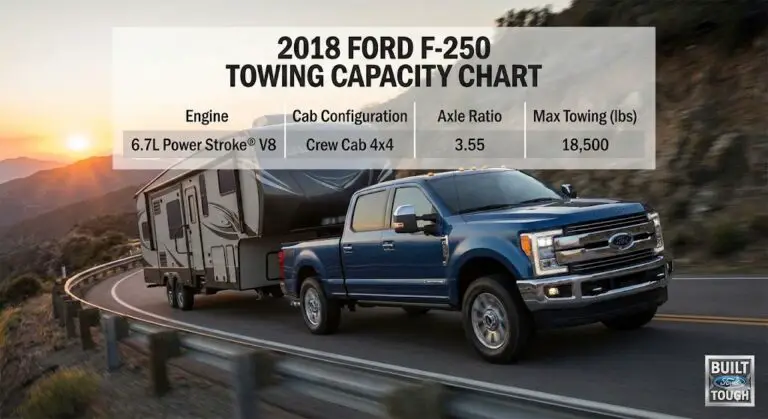

Towing & Capability Matrix

The primary driver for purchasing an F-250 is capability. The 2017 redesign brought a stiffer frame, allowing for higher weight ratings. Note that “Maximum” ratings often require specific configurations (e.g., 2WD, Regular Cab). The chart below averages the capabilities for the popular Crew Cab 4×4 configuration.

Capability Notes

Conventional Towing

Standard receiver hitch towing. The 2017 F-250 utilized a new 2.5″ or 3″ receiver depending on the package.

5th Wheel / Gooseneck

Requires the in-bed puck system. Offers significantly better stability for loads over 12,000 lbs.

Payload

Varies heavily by trim. A fully loaded Platinum trim will have less payload than an XL due to the weight of luxury features.

Reliability Profile: The “Watch List”

While the 6.7L Power Stroke is widely regarded as one of Ford’s best diesel engines, the 2017 model year is not without specific faults. Buyers should be aware of these common failure points during pre-purchase inspections.

Relative Frequency of Common Issues (0-10 Scale)

1. Upper Oil Pan Leak

Ford used a composite (plastic) upper oil pan sealed with RTV silicone. These are notorious for leaking. Fixing it properly often requires removing the transmission or lifting the engine, making it a labor-intensive repair ($1,500+).

2. CAC Tube Failure

The cold-side Charge Air Cooler (intercooler) tube is plastic and can burst under heavy boost/load. Enthusiasts often replace this with an aftermarket metal piping kit (~$300) to prevent roadside breakdowns.

3. DEF Heater Failure

The reductant heater assembly in the DEF tank can fail, triggering a Check Engine Light (P20BA). While not catastrophic to the engine, it must be fixed to pass emissions and clear dash warnings.

Real-World Economy & Value

Heavy-duty trucks are exempt from official EPA fuel economy ratings, making real-world user data critical. The 2017 F-250 6.7L typically sees improved efficiency over the 2011-2016 generation thanks to the lighter aluminum body and improved transmission logic.

Estimated Depreciation (2017-2024)

Average MPG Distribution

Powertrain Deep Dive: The 2nd Generation 6.7L Power Stroke

The heart of the 2017 F-250 is the second-generation 6.7L Power Stroke V8, internally code-named "Scorpion." First introduced in 2011 to replace the troubled 6.4L and 6.0L engines (which were manufactured by Navistar), the 6.7L was Ford’s first in-house heavy-duty diesel engine. The 2017 update brought significant refinements aimed at durability, thermal management, and output.

Engine Architecture and Block Design

The foundation of the 6.7L Power Stroke is a Compacted Graphite Iron (CGI) engine block. CGI is a material choice that bridges the gap between the weight of aluminum and the strength of grey cast iron. It offers approximately double the fatigue strength of standard iron, allowing for thinner cylinder walls and reduced overall weight without compromising the structural integrity needed to contain peak cylinder pressures exceeding 2,500 psi.

- Valvetrain: The engine utilizes a pushrod design (OHV) with four valves per cylinder, actuated by a single camshaft located in the block. This design keeps the engine’s physical height lower and reduces complexity compared to overhead cam designs.

- Cylinder Heads: Aluminum cylinder heads are used to save weight and improve heat dissipation. They feature a unique "reverse-flow" design.

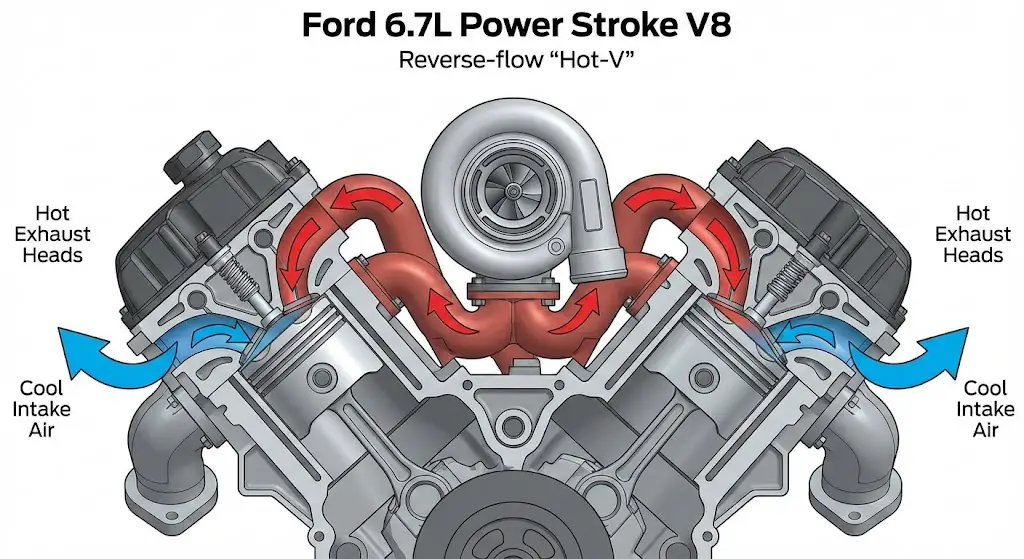

The "Hot-V" Configuration

One of the most distinct engineering features of the 6.7L Power Stroke is its reverse-flow layout. In a traditional V8, air enters from the valley (top) and exhaust exits out the sides. The 6.7L Power Stroke flips this: intake air enters through the cylinder heads from the outside of the engine, and exhaust gases exit into the engine valley.

Engineering Insight: This "Hot-V" configuration places the turbocharger directly in the center of the engine valley.

- Thermal Efficiency: By minimizing the distance exhaust gases travel from the exhaust ports to the turbine wheel, Ford engineers significantly reduced thermal loss and turbo lag. The heat energy is retained, spinning the turbine faster and sooner.

- Packaging: This layout simplifies the plumbing for the exhaust system and allows for a more compact overall engine envelope, facilitating better fitment in the engine bay and easier access to the turbocharger for service.

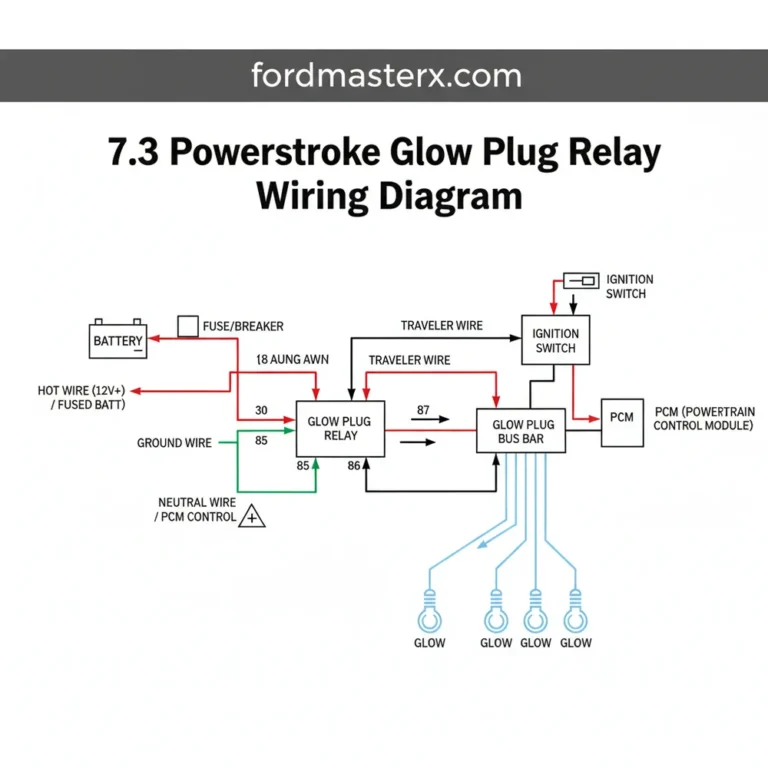

Turbocharging: The GT37 Single Sequential VGT

For 2017, Ford simplified the turbocharging strategy. The previous generation (2011–2014) utilized a dual-compressor "GT32" turbo that was prone to ceramic ball bearing failures. The 2015+ and specifically the 2017 model utilize a larger, single Garrett GT37 Variable Geometry Turbocharger (VGT).

Mechanism of Action:

The VGT system uses movable vanes surrounding the turbine wheel.

- Low RPM: The vanes close, restricting the exhaust path. This increases the velocity of the exhaust gas hitting the turbine wheel, allowing the turbo to spool up quickly even at low engine speeds. This mimics the behavior of a small turbocharger.

- High RPM: The vanes open, allowing maximum exhaust flow to bypass the restriction. This prevents excessive backpressure and allows the turbo to act like a large unit, supporting high-horsepower operation.

- Exhaust Braking: In Tow/Haul mode, the vanes can close electronically when the driver lifts off the throttle. This creates significant exhaust backpressure, effectively turning the engine into an air compressor to slow the vehicle down. This "smart exhaust brake" is integrated seamlessly with the transmission’s shift strategy.

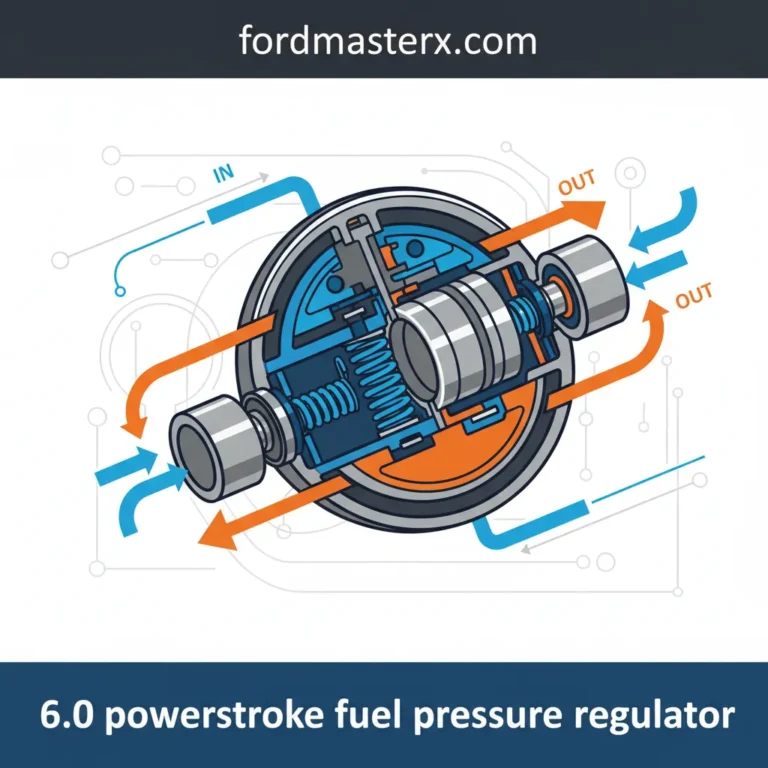

Fuel Injection System: The Bosch CP4.2

The fuel system is the most critical—and controversial—subsystem of the 2017 Power Stroke. It utilizes a high-pressure common rail design driven by a Bosch CP4.2 injection pump. This pump is capable of generating fuel pressures up to 30,000 psi (2,000 bar), which is necessary to atomize the fuel into microscopic droplets for cleaner, more powerful combustion.

The CP4.2 Vulnerability:

The Bosch CP4.2 pump was designed primarily for the European market, where diesel fuel adheres to the EN590 standard, requiring a high lubricity rating. In North America, Ultra-Low Sulfur Diesel (ULSD) meets the ASTM D975 standard, which has a lower lubricity requirement.

- Failure Mode: The CP4 pump relies on the diesel fuel itself to lubricate its internal cam and roller assembly. If the fuel lubricity is insufficient, or if water contaminates the fuel (even in minute amounts), the cam can scour the roller. This metal-on-metal friction generates fine metallic debris.

- Systemic Contamination: Because the pump feeds the high-pressure rails directly, this metallic debris is blasted into the fuel rails and injectors. The debris clogs the piezo injectors, causing them to stick open or fail. The return fuel lines then carry the debris back to the tank, contaminating the entire low-pressure side as well.

- Repair Scope: A CP4 failure is catastrophic. It typically requires the replacement of the pump, all eight injectors, the fuel rails, the fuel lines, and the fuel tank cleaning. Costs at a dealership often exceed $10,000 to $12,000.

Mitigation Strategies:

Owners of 2017 F-250s are strongly advised to use fuel additives that improve lubricity (such as Stanadyne or Hot Shot’s Secret) and to install a "Disaster Prevention Kit" (discussed in Section 9).

Cooling Systems: The Dual-Loop Strategy

To manage the immense heat generated by 925 lb-ft of torque and the emissions equipment, the 2017 F-250 employs a complex dual-loop cooling system.

- High-Temperature Loop (Primary): This loop circulates coolant through the engine block, cylinder heads, oil cooler, and the exhaust gas recirculation (EGR) cooler. It operates at standard engine temperatures (190°F - 210°F).

- Low-Temperature Loop (Secondary): This separate system cools the Charge Air Cooler (intercooler), the fuel cooler, and the transmission fluid cooler. It operates at a lower temperature (~120°F - 140°F) to maximize the density of the intake air and keep transmission temps in check during heavy towing.

Visualizing Cooling Capacities:

| System | Fluid Type | Capacity (Quarts) |

| Primary Engine Cooling | Motorcraft Orange (VC-3-B) | ~33.2 - 35.1 |

| Secondary Cooling | Motorcraft Orange (VC-3-B) | ~14.3 - 15.1 |

| Engine Oil | 10W-30 / 5W-40 Diesel Oil | 13.0 |

Transmission and Drivetrain

While the engine garners the headlines, the transmission is the unsung hero of the Super Duty’s capability. In 2017, Ford relied on the TorqShift 6R140, a heavy-duty 6-speed automatic transmission designed and built by Ford.

The TorqShift 6R140 Automatic

The 6R140 is a massive unit, weighing nearly 350 pounds. It was engineered specifically to handle the torque of the 6.7L diesel. Unlike the 68RFE found in the Ram 2500, which has a reputation for fragility under high torque, the 6R140 is widely considered "bulletproof" in stock applications.

- Gear Ratios: The transmission features a deep first gear (3.97:1) to get heavy loads moving and a double overdrive (0.85:1 in 5th, 0.67:1 in 6th) to keep engine RPMs low at highway speeds.

- SelectShift: This feature allows the driver to manually lock out upper gears or select a specific gear range, which is critical for controlling descent speed on steep grades when towing.

- Torque Converter: The torque converter in the 2017 model is robust, with a lock-up clutch capable of handling the engine's full torque output without slipping. This lock-up capability is utilized aggressively in Tow/Haul mode to provide direct mechanical coupling between the engine and wheels for engine braking.

Driveline and 4WD Systems

The F-250’s transfer case is a part-time, 2-speed unit (BorgWarner 44-series).

- Electronic Shift-on-the-Fly (ESOF): Most Lariat and higher trims feature a rotary dial to engage 4WD High and Low. This system uses vacuum-operated hub locks.

- Manual Locking Hubs: A distinct advantage of the Ford Super Duty is that even with ESOF, the front hubs have a "Manual" override position. If the vacuum system fails (a common issue with aging lines), the driver can physically turn the dial on the hub to "LOCK" to ensure 4WD engagement. This redundancy is highly valued in off-road and fleet communities.

Rear Axle: The 2017 F-250 typically utilizes the Sterling 10.5-inch rear axle. This is a full-floating axle, meaning the weight of the truck is carried by the axle housing, not the axle shafts themselves. The shafts only transmit torque. Electronic Locking Rear Differentials (E-Locker) are a common option, allowing the driver to lock both rear wheels together for maximum traction at low speeds.

Chassis, Suspension, and Body

The "Alumi-Duty" moniker refers to the body, but the frame underneath tells an equally important story of strength and rigidity.

High-Strength Steel Frame

The 2017 frame is composed of 95% high-strength steel. It is fully boxed from front to rear. Previous generations utilized C-channel rails in the rear sections to allow for easier upfitting and flex. The move to a fully boxed frame increased torsional rigidity by 24 times compared to the 2016 model. This stiffness provides a stable platform for towing heavy loads but places a greater demand on the suspension to absorb road irregularities.

Military-Grade Aluminum Alloy Body

The switch to aluminum shaved approximately 350 pounds from the vehicle's mass.

- Benefits:

- Payload: The weight savings translate directly to payload capacity. An F-250 Crew Cab 4x4 Diesel, which historically struggled with payload due to the heavy engine, gained significant headroom.

- Corrosion: Aluminum does not rust like steel. For trucks operating in the "Rust Belt" or coastal areas, this eliminates the common wheel-arch and rocker panel rot that plagued previous generations.

- Drawbacks:

- Repair Costs: Repairing aluminum requires a "clean room" environment to prevent cross-contamination with steel dust (which causes galvanic corrosion) and specialized welding equipment. This has led to higher insurance premiums and collision repair estimates.

Suspension Geometry: The Solid Front Axle

The F-250 is unique in the modern ¾-ton segment for retaining a Solid Front Axle (SFA) on 4x4 models, specifically the Dana Super 60. GM’s Silverado 2500HD uses Independent Front Suspension (IFS).

- SFA Pros: Extreme durability, simpler to lift, consistent ground clearance, and better articulation off-road.

- SFA Cons: Higher unsprung weight and susceptibility to "Death Wobble."

The front suspension utilizes coil springs and radius arms, a setup introduced in 2005. The radius arms locate the axle fore and aft, while a track bar centers the axle laterally.

The "Death Wobble" Phenomenon

"Death Wobble" is a violent, resonant oscillation of the front wheels that occurs after hitting a bump at highway speeds (usually 45-65 mph). It is a known issue on the 2017–2019 Super Duty.

- Physics: It is essentially a harmonic vibration. When an external force (a bump) excites the wheels, worn components fail to dampen the oscillation, leading to a feedback loop where the wheels shake violently left and right.

- Causes: The root cause is often a combination of insufficient caster angle, a worn track bar ball joint, or a weak steering damper. The 2017 model has been particularly prone to this due to factory caster settings that were optimized for fuel economy (lower rolling resistance) rather than stability.

- Ford’s Response: Ford issued a warranty extension (CSP 20N04) covering the steering damper for 7 years/100,000 miles. However, replacing the damper often masks the symptom rather than curing the disease. A permanent fix usually requires an aftermarket adjustable track bar and caster shims.

Towing and Payload Capabilities

The raison d'être of the F-250 is towing. However, understanding exactly what a specific 2017 F-250 can tow requires navigating a complex matrix of ratings.

Understanding the Numbers: GVWR, GCWR, and Payload

- GVWR (Gross Vehicle Weight Rating): The maximum allowable weight of the truck itself, including fuel, passengers, and cargo (tongue weight). For the F-250, this is typically capped at 10,000 lbs (Class 2B).

- GCWR (Gross Combined Weight Rating): The maximum weight of the truck plus the trailer. For the 2017 F-250 6.7L, this ranges up to 28,700 lbs depending on axle ratio.

- Payload: Calculated as GVWR minus Curb Weight.

- Example: A highly optioned F-250 Platinum 4x4 Diesel has a curb weight of approx. 7,500 - 7,800 lbs.

- Payload Calculation: 10,000 lbs (GVWR) - 7,800 lbs (Curb) = 2,200 lbs Payload.

- Insight: This payload limit is the "glass ceiling" for the F-250. A 15,000 lb 5th wheel typically has a pin weight of 3,000 lbs (20%). Therefore, a diesel F-250 Platinum often cannot legally tow a 15,000 lb 5th wheel, despite the engine having the power to pull it. The F-350 SRW, with a GVWR of 11,500 lbs, is the solution for heavy 5th wheels.

Towing Capacities Matrix (6.7L Diesel SRW)

| Hitch Type | Configuration | Axle Ratio | Max Trailer Weight (lbs) |

| Conventional | Crew Cab 4x4 | 3.31 / 3.55 | 15,000 (Standard) |

| Conventional | Crew Cab 4x4 | 3.55 (High Cap Tow Pkg) | 18,000 |

| 5th Wheel | Crew Cab 4x4 | 3.31 / 3.55 | 14,700 |

| Gooseneck | Regular Cab 4x2 | 3.31 / 3.55 | 16,300 |

Real-World Towing Performance

- Power: With 925 lb-ft of torque available at 1,800 RPM, the 2017 F-250 accelerates confidently with 10,000+ lbs attached. It does not "hunt" for gears on slight grades.

- Stability: The stiffer frame and longer wheelbase (especially on Crew Cab Long Bed models) provide exceptional tracking stability.

- Adaptive Steering: This optional feature changes the steering ratio based on speed. At low speeds (parking a trailer), fewer turns of the wheel are needed. At highway speeds, the steering becomes less sensitive, reducing driver fatigue.

- Trailer Reverse Guidance: Utilizing cameras in the side mirrors and tailgate, this system provides visual cues and steering guidance for backing up trailers—a game-changer for solo drivers.

Interior, Trims, and Technology

The 2017 redesign brought the F-150’s cab architecture to the Super Duty, resulting in a significantly more spacious and tech-focused interior.

Trim Levels: From Work Truck to Luxury Liner

- XL: Vinyl floors, manual seats, basic AM/FM radio. Built for fleets.

- XLT: Cloth seats, carpet, SYNC basic screen, chrome bumpers. The volume seller.

- Lariat: Leather seating, 8-inch touchscreen, digital productivity screen in dash. This is the entry point for "luxury" features.

- King Ranch: Western-themed premium leather, unique saddle-brown interior, standard navigation and premium audio.

- Platinum: The top-tier (until Limited arrived later). Multi-contour massaging seats, power running boards, satin chrome exterior accents, and every safety feature standard.

Infotainment and Connectivity

The 2017 model runs Ford’s SYNC 3 system on an 8-inch capacitive touchscreen (Lariat and up).

- Features: Apple CarPlay and Android Auto support (requires USB hub upgrade on early 2017 builds), voice recognition, and integrated navigation.

- Ultimate Trailer Tow Camera System: This system stitches together views from four cameras (grille, tailgate, and side mirrors) to create a 360-degree bird’s-eye view of the truck. It also includes a "Center High-Mounted Stop Lamp" (CHMSL) camera for viewing the 5th wheel/gooseneck hitch in the bed.

Driver Assist and Safety Systems

The 2017 F-250 was the smartest Super Duty to date, incorporating:

- Adaptive Cruise Control: Capable of braking the truck and trailer to maintain distance.

- Blind Spot Information System (BLIS): Uniquely optimized for towing, this system can be programmed with the trailer's length (up to 33 feet) to extend the blind spot monitoring zone to cover the trailer.

- Lane Keeping Alert: Vibrates the steering wheel if the truck drifts out of its lane.

Reliability, Maintenance, and Common Issues

Owning a modern diesel requires adherence to a strict maintenance regimen. Neglect can lead to five-figure repair bills.

The Maintenance Schedule

The 6.7L Power Stroke uses an Intelligent Oil Life Monitor (IOLM), but reliance on it is debated. Most experts recommend the "Severe Duty" schedule for any truck that tows, idles, or drives in stop-and-go traffic.

| Service Item | Interval (Normal) | Interval (Severe/Towing) | Part/Fluid Spec |

| Engine Oil | 7,500 - 10,000 miles | 5,000 - 7,500 miles | 10W-30 or 5W-40 (CK-4) |

| Fuel Filters | Every 3rd Oil Change (22.5k) | Every 2nd Oil Change (15k) | Motorcraft FD-4625 |

| Air Filter | Inspect every oil change | Replace at 45,000 miles | Motorcraft FA-1927 |

| Transmission | 150,000 miles | 60,000 miles | Mercon LV |

| Coolant | 105,000 miles / 6 years | Check acidity annually | Motorcraft Orange (VC-3-B) |

| Front Hubs | N/A | Grease via Zerk fitting annually | High Temp Grease |

Critical Procedure: Fuel Filter Change

The 2017 F-250 has two fuel filters: one on the frame rail (Primary) and one on the engine (Secondary).

- Water Separator: The primary filter has a water drain. This must be drained monthly. Water is the enemy of the CP4 pump.

- Priming: After changing filters, the fuel system must be primed. Cycle the ignition key to "Run" (do not start) for 30 seconds, repeat 6-10 times. This purges air. Starting the engine with air in the lines can damage the CP4 pump instantly.

Common Failures and TSBs

Beyond the CP4 and Death Wobble, owners should be aware of:

- Upper Oil Pan Leak (TSB 22-2201): The glued-on composite upper oil pan leaks oil at the rear of the engine. The repair involves dropping the transmission and replacing the pan/sealant.

- Frozen Door Latches (TSB 19-2373): Moisture can enter the door latch cables and freeze in cold weather, causing the door to either not open or not latch shut. Ford released a shield kit to prevent water ingress.

- Tailgate Opening (Recall 19S48): On some models, water shorted the electric tailgate switch, causing the tailgate to drop open while driving. Ford modified the wiring harness to fix this.

- Particulate Matter Sensor (TSB 18-2225): The sensor measuring soot in the exhaust can fail, triggering a Check Engine Light and preventing regeneration.

The CP4 Disaster Prevention Strategy

Given the cost of a fuel system failure ($10k+), proactive owners often install a Disaster Prevention Kit.

- Concept: The kit (e.g., from S&S Diesel) modifies the fuel routing. It separates the lubricating fuel from the fuel being fed to the injectors.

- Mechanism: If the pump fails and generates metal, the kit routes that debris-laden fuel back to the tank (where it is caught by filters) rather than into the high-pressure injectors.

- Result: The truck will still die (pump failure), but you only replace the pump, not the injectors and rails, saving roughly $8,000 in repairs.

Market Comparison: Ford vs. GM vs. Ram

In 2017, the choice between the Big Three HD trucks was distinct.

The Horsepower and Torque Wars

- Ford F-250 (6.7L V8): 440 hp / 925 lb-ft.

- Chevy Silverado 2500HD (6.6L L5P V8): 445 hp / 910 lb-ft.

- Ram 2500 (6.7L I6): 370 hp / 800 lb-ft (with 68RFE).

Analysis: The Ford won on torque, while Chevy took the horsepower crown. The Ram 2500 was significantly detuned compared to the 3500 (which got the Aisin trans and 900 lb-ft). The Ford 6.7L’s torque curve peak at 1,800 RPM gave it a "snappier" feel off the line compared to the Ram’s more gradual delivery.

Towing and Hauling Face-Off

- Ford: Best-in-class payload (due to aluminum body) and strong conventional towing ratings. Solid front axle allows for tighter turning radius than expected.

- Chevy: The Independent Front Suspension (IFS) offers superior high-speed stability and steering precision but has lower ground clearance. The chassis was older (dating back to 2011) compared to Ford’s all-new 2017 frame.

- Ram: The rear coil suspension gave the Ram the best unladen ride quality. However, the 68RFE transmission was the clear weak link for heavy towing, with gear ratios that were less optimal than Ford’s 6R140.

Daily Driving and Comfort

The 2017 Ford interior was a generational leap ahead of the Ram and Chevy. The flat floor in the rear crew cab (thanks to a fold-away storage bin) provided the best cargo utility. The panoramic sunroof ("Twin Panel Moonroof") was a Ford exclusive that opened up the cabin, making it feel less like a dungeon than the Ram’s Mega Cab.

Modifications and Aftermarket Support

The 6.7L Power Stroke has massive aftermarket support.

Reliability Upgrades

- Intercooler Pipe Upgrade: Replacing the factory plastic cold-side pipe with a metal one is the #1 recommended mod. It prevents a guaranteed roadside breakdown.

- CCV Reroute: The Crankcase Ventilation system vents oily vapors into the intake, gumming up the turbo and valves. A reroute kit vents this to the atmosphere or a catch can, keeping the intake clean.

- Fuel Additives: Regular use of additives like Archoil AR9100 or Hot Shot’s Secret EDT is considered mandatory by many to protect the CP4 pump and injectors from stiction.

Performance Tuning and Suspension

- Tuning: "Delete" tuning (removing DPF/EGR) is illegal federally. However, "emissions-intact" tuning (e.g., Banks Derringer) can add 50-80 hp safely by optimizing boost and fuel rail pressure without removing emissions equipment.

- Leveling Kits: A 2.5-inch leveling kit is popular to fit 35-inch tires. When doing this, it is critical to add an adjustable track bar to recenter the axle and caster shims to prevent Death Wobble.

Conclusion

The 2017 Ford F-250 6.7L Power Stroke stands as a landmark vehicle in the evolution of the heavy-duty pickup. By combining the rust-resistant "Alumi-Duty" body with a high-torque, second-generation diesel powertrain, Ford created a truck that balanced luxury, capability, and efficiency in a way that set the bar for the industry.

While it is not without faults—specifically the fragile CP4 fuel pump and the susceptibility to steering oscillation—these issues are well-documented and manageable with proactive maintenance and specific aftermarket upgrades. For the buyer looking for a tow rig that can pull 15,000 lbs comfortably while offering a modern, tech-rich cabin, the 2017 F-250 remains a premier choice in the secondary market. Its engineering foundation—the boxed frame, the 6R140 transmission, and the Scorpion diesel—has proven to be a durable platform capable of clocking hundreds of thousands of miles when treated with respect.

Final Recommendation:

Purchase a 2017 F-250 6.7L if you prioritize towing power and interior space. Budget immediately for a cold-side intercooler pipe replacement and a CP4 disaster prevention kit. With those safeguards in place, you possess one of the most capable ¾-ton trucks ever built.