Where Is The Abs Module Located: Identification And Access Guide

The Anti-lock Braking System (ABS) represents the most critical safety barrier between a driver and a total loss of vehicular control during an emergency stop. By preventing wheel lock-up, this system maintains steering geometry and traction, even on slick surfaces. However, when the ABS warning light illuminates on the dashboard, it signals a disruption in this sophisticated safety loop. While most drivers recognize the fault, few possess the technical insight to locate the physical module required for a professional-grade inspection or replacement. This comprehensive guide serves as a reliable roadmap to identifying, accessing, and understanding the ABS control unit across a variety of vehicle architectures.

Section 1: Understanding the Anti-lock Braking System Architecture and Control Unit

📤 Share Image

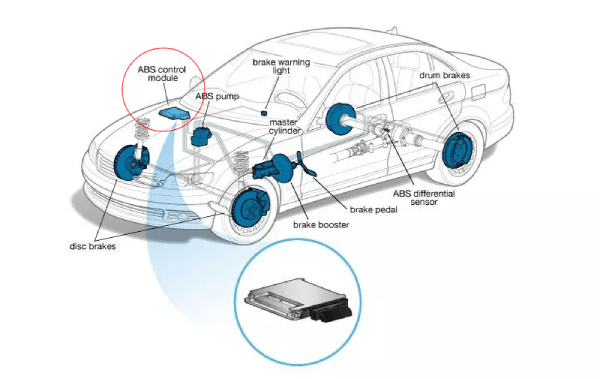

To find the ABS module, one must first understand what they are looking for. In modern automotive engineering, the ABS module is rarely a singular component; instead, it is an assembly comprising the Electronic Control Unit (ECU) and the Hydraulic Control Unit (HCU). The ECU acts as the “brain,” containing the microprocessor and circuitry, while the HCU serves as the “heart,” managing the physical flow of brake fluid through a series of internal valves.

Physically, the assembly appears as a compact, silver or black aluminum block. It is easily distinguished by the presence of multiple metal brake lines—usually four to six—protruding from its sides or top. These lines are the conduits that distribute modulated pressure to each individual wheel. A professional tip for identification is to look for the large, multi-pin wiring harness connector. This connector facilitates CAN bus communication, allowing the module to exchange data with the Engine Control Module (ECM) and Transmission Control Module (TCM).

Inside this unit, the microprocessor works at staggering speeds. The ABS module can process data from wheel speed sensors up to 100 times per second. When a potential lock-up is detected, the ECU triggers solenoid valves within the HCU to pulse the brake pressure, which prevents the tire from skidding. Because this unit is sensitive to both heat and vibration, it is typically mounted to a specialized rubber-isolated bracket and requires a solid electrical ground to function without interference.

Expert Example: The Bosch Standard

Consider the Bosch 8.0 or 9.0 series modules. These are the gold standard for many European and Domestic vehicles. They are characterized by a black plastic electronic housing mated to a polished aluminum hydraulic block. If you see this specific “two-tone” appearance with six lines snaking out of it, you have found the hub of your vehicle’s braking safety system.

By The Numbers

Data Processing Frequency

Maximum Hydraulic Lines

Section 2: Identifying Common Locations in the Engine Compartment

In the vast majority of front-wheel-drive sedans and crossovers, the engine bay is the primary home for the ABS module. This placement is not accidental; automotive engineers prioritize hydraulic efficiency. Placing the module near the master cylinder reduces the length of the high-pressure lines, minimizing “pedal mush” and increasing response time. In fact, approximately 75% of passenger cars house the module within 18 inches of the master cylinder.

When searching the engine compartment, your primary visual cue should be the brake fluid reservoir. Follow the steel lines emerging from the master cylinder downward. They will lead you directly to the ABS “spider,” so called because of the way the lines radiate from the block. Common hotspots include the driver’s side inner fender well or the area near the firewall where the steering column passes through to the cabin. In vehicles like the Toyota Camry or Honda Accord, the unit is usually visible and accessible just behind the strut tower.

📋

Accessing the Engine Bay Module

Locate the master cylinder and follow the two primary lines down to the aluminum HCU block.

Remove the air filter housing or battery tray if the module is tucked underneath for protection.

Be aware that some manufacturers protect these sensitive electronics with a dedicated heat shield, especially if they are located near the exhaust manifold. If you see a metallic shroud that seems out of place, there is a high probability the ABS module is hiding beneath it. Always inspect the harness for signs of heat damage or “greening” (corrosion) at the connector interface.

Section 3: Locating the ABS Module in Trucks and SUVs with Frame Mounts

If you are working on a full-size pickup or a body-on-frame SUV, looking in the engine bay may leave you empty-handed. In heavy-duty applications, such as the Ford F-150 or Chevrolet Silverado (1999–2014), the ABS module is frequently mounted directly to the driver’s side frame rail. This placement helps lower the vehicle’s center of gravity and frees up vital real estate in the engine bay for larger V8 powerplants and cooling systems.

To locate a frame-mounted module, you will likely need a professional-grade lift or a floor jack with secure stands. Look underneath the vehicle, specifically in the area directly beneath the driver’s seat. You will see the brake lines running along the frame rail, meeting at the Electronic Brake Control Module (EBCM). These units are often protected by a plastic or metal skid plate to shield them from road salt, moisture, and debris. Despite this protection, frame-mounted modules are 40% more likely to suffer from harness failure or corrosion compared to their engine-mounted counterparts due to their proximity to the road.

On older trucks, you might only find a RWAL module. This is typically located near the rear proportioning valve on the frame rail, specifically designed to prevent rear-end swing-out during heavy braking.

Section 4: Variation by Vehicle Make: Domestic vs. Import Placements

A comprehensive search for the ABS module requires an understanding of manufacturer-specific design philosophies. European manufacturers, for instance, favor the engine bay for 90% of their modular brake designs. This is done to facilitate high-speed CAN bus communication, as shorter wiring runs result in less signal degradation. However, they are notorious for “tucking” the module away. For example, a BMW E39 may have the module mounted dangerously close to the exhaust manifold, leading to premature circuit failure, while a Mercedes-Benz might hide it under a plastic cover near the windshield cowl.

In contrast, Japanese manufacturers like Subaru often mount the module high up in the engine bay near the passenger-side firewall. This protects the unit from moisture ingress during heavy rain or snow. Newer electric vehicles (EVs) present a unique challenge; they often use “Integrated Power Brake” systems. In these designs, the ABS module, master cylinder, and brake booster are combined into one single, massive unit, often located directly behind the brake pedal assembly in the “frunk” or engine compartment.

Section 5: The Importance of Quality Diagnostics and Professional Removal

Once you have identified the module, the temptation to immediately unbolt it is strong. However, expert protocol dictates a rigorous diagnostic phase first. Always use a professional-grade OBD-II scanner with ABS/SRS capabilities. A standard $20 scanner will not communicate with the brake network. You must confirm the fault code (e.g., C0020 for a pump motor circuit) before disturbing the hydraulic system.

✅ Why Use Remanufacturing?

- Eliminates VIN-locking issues

- Keeps original vehicle coding

- Upgraded components vs OEM

- Significant cost savings

❌ Risks of Used Units

- Odometer “tamper” flags

- Internal seal degradation

- Mismatching software versions

- Potential VIN mismatch start-lock

The most significant pitfall in ABS module replacement is the “bleeding” process. Modern modules contain internal chambers that remain closed unless activated. Improper bleeding can leave up to 15% of air trapped in these secondary valves, resulting in a dangerously “spongy” brake pedal. To do this correctly, a bi-directional scan tool is required to cycle the solenoids and “burp” the air out of the module during the fluid flush.

The electronic portion of the module is highly sensitive. Handling the multi-pin connector without proper grounding can cause a static discharge that destroys the expert-level circuitry, rendering a new module useless before it is even installed.

Finally, remember that many modules are “VIN-locked.” If you install a module from a different vehicle, the EBCM may refuse to communicate with the rest of the car, sometimes preventing the engine from starting or causing a “limp mode” scenario. This is why trusted remanufacturing services are often superior to used parts—they rebuild your specific unit, preserving the original programming and vehicle identity.

Conclusion

Locating the ABS module is the first step toward restoring your vehicle’s safety profile. Whether tucked behind the firewall of a sedan or mounted to the rugged frame of a pickup, this complete guide has outlined the physical markers and common locations needed for successful identification. Remember that tracing the brake lines from the master cylinder remains the most reliable method for visual confirmation. Given the complexity of modern CAN bus communication and hydraulic requirements, professional diagnostics and high-quality replacement parts are non-negotiable for maintaining system integrity. If your ABS light is on, perform a scan with a professional tool today or consult a trusted technician to ensure your braking system remains a shield in an emergency.

Frequently Asked Questions

Can I drive my car if the ABS module is removed?

While the mechanical portion of your brakes will technically function, you will lack anti-lock protection and electronic brakeforce distribution. This creates a high risk of wheel lock-up in wet conditions. Additionally, most modern vehicles will enter a ‘limp mode’ or disable traction control and stability systems, making the vehicle significantly less safe and potentially illegal to operate on public roads.

Why is my ABS module located under the car where it gets wet?

Engineers often place the module on the frame rail in trucks and SUVs to save space in the engine compartment and to keep the hydraulic lines shorter for the rear wheels. These units are designed with automotive-grade weather sealing and heavy-duty connectors to withstand moisture, though long-term exposure to road salt can eventually lead to terminal corrosion or housing failure.

Do I need to program a new ABS module once I find and replace it?

Yes, in almost all vehicles manufactured after 2005, the ABS module is a networked component that must be programmed with the vehicle’s VIN. This ensures the module correctly communicates with the PCM and TCM. Failure to perform this ‘initialization’ with a professional scan tool will usually result in a persistent warning light and system deactivation.

What does a failing ABS module sound like?

A failing module may cause the ABS pump to run continuously, even when the ignition is off, resulting in a low buzzing or humming sound from the engine bay. This often leads to a dead battery. Internally, failing solenoid valves may also cause a ‘clicking’ noise or a mechanical grinding sensation through the brake pedal during normal, non-emergency braking maneuvers.

Is it better to repair or replace a located ABS module?

Professional remanufacturing of your existing module is often superior to buying a used unit. It avoids the need for VIN reprogramming and typically involves upgrading the internal components to fix known factory defects. However, if the hydraulic block itself is leaking or the internal valves are seized, a full replacement with a quality, trusted new unit is the only reliable solution.