What Happens If You Disconnect Throttle Position Sensor: Mechanical And Electronic Consequences

In the precision-engineered world of modern automotive electronics, a single disconnected sensor can transform a high-performance engine into an unpredictable and sluggish liability. Drivers often wonder if they can bypass a faulty throttle position sensor (TPS) by simply disconnecting it, perhaps to troubleshoot a rough idle or a “dead spot” in acceleration, unaware of the complex chain reaction this causes within the engine management system. This comprehensive guide provides an expert analysis of the mechanical, electronic, and safety consequences of disconnecting your throttle position sensor, detailing why it remains a reliable and critical component for vehicle performance and longevity.

The Critical Role of the TPS in Modern Fuel Management Systems

📤 Share Image

The Throttle Position Sensor (TPS) is effectively the “eyes” of the Engine Control Unit (ECU). Structurally, it functions as a potentiometer—a variable resistor—that monitors the exact angle of the throttle butterfly valve. As the driver presses the accelerator, the TPS transmits a fluctuating DC voltage signal, typically ranging from 0.5V at idle to approximately 4.5V at Wide Open Throttle (WOT). This signal provides the ECU with instantaneous data regarding driver intent and engine load requirements.

Potentiometer vs. Hall Effect Precision

In older or budget-conscious designs, the TPS relies on physical wiper arms moving across resistive tracks. However, professional-grade modern vehicles often utilize Hall Effect technology. This non-contact method uses magnets to determine position, eliminating the friction and wear associated with traditional resistive sensors. This ensures high-precision data transmission even in high-vibration environments, where a standard sensor might suffer from signal “noise” or dropouts.

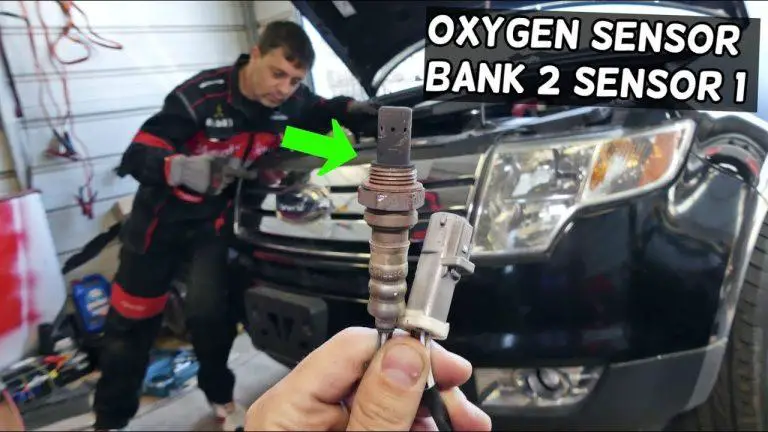

Mechanical Linkage vs. Drive-by-Wire (ETC)

In a traditional mechanical linkage system, the throttle cable physically opens the plate, and the TPS simply reports that movement to the ECU for fuel calculation. In contrast, Electronic Throttle Control (ETC), or “Drive-by-Wire” systems, rely on the TPS as a feedback loop. When you press the pedal, you are actually sending a request to the ECU; the ECU then moves the throttle motor and uses the TPS signal to verify that the plate has reached the commanded position. If you disconnect the TPS in an ETC system, the ECU loses its ability to verify throttle movement, often resulting in a complete throttle shutdown for safety reasons.

By The Numbers: Signal Logic

Typical Idle Voltage

Wide Open Throttle

ECU Reaction Time

Immediate Engine Performance Degradation and Driveability Issues

The moment the TPS is disconnected, the engine management system enters a reactive, rather than proactive, state. The most jarring symptom is a severe loss of “Tip-In” acceleration. Under normal conditions, when the ECU sees a rapid increase in TPS voltage, it preemptively adds an extra “squirt” of fuel (similar to an accelerator pump on a carburetor) to compensate for the sudden rush of air. Without this signal, the engine will experience a massive hesitation or “stumble” every time you touch the gas pedal.

Idle Instability and Surging

The ECU also uses TPS data to confirm “Closed Throttle” status. Without this confirmation, the Idle Air Control (IAC) logic becomes confused. Drivers will often notice a fluctuating or high idle speed, as the ECU attempts to “guess” whether the engine should be idling or if the driver is attempting to maintain a steady speed. This lack of precision often leads to stalling at intersections—especially when additional loads, such as the air conditioning compressor or power steering pump, engage.

The Fail-Safe “Rich” Mixture

In the absence of trusted data, the ECU defaults to a “Rich” fuel map. This is a safety measure designed to prevent a lean condition that could melt pistons, but it comes at a high cost. Fuel economy can drop by as much as 25-30% almost immediately. You may notice black smoke from the exhaust and a pungent smell of unburned gasoline, indicating that the engine is dumping far more fuel into the cylinders than it can efficiently burn.

Imagine making a left-hand turn across oncoming traffic. As you turn the wheel, the power steering pump places a heavy load on the engine. Normally, the TPS and ECU would coordinate to maintain RPM. Without the TPS, the engine may stumble or stall mid-turn, leaving you stranded in the path of oncoming vehicles with no power steering or brakes.

Transmission Shift Patterns and Limp Home Mode Activation

For vehicles equipped with automatic transmissions, the TPS is just as vital to the Transmission Control Module (TCM) as it is to the ECU. The TCM uses throttle angle data to determine “Shift Schedules” and “Shift Feel.” Without a complete data set from the TPS, the transmission cannot determine how much torque the engine is producing, leading to harsh, jarring gear changes or “hunting” between gears.

Loss of Torque Converter Lock-up

One of the most significant professional concerns with a disconnected TPS is the loss of torque converter lock-up. The TCM will usually disable the lock-up clutch as a fail-safe. This results in the torque converter constantly slipping at highway speeds, which generates massive amounts of internal heat. Transmission fluid temperatures can rise by 20-40 degrees Fahrenheit, significantly accelerating the degradation of the fluid and internal friction plates.

Limp Home Mode Restrictions

Most modern vehicles will trigger a “Limp Home” or “Reduced Power” mode upon TPS disconnection. This typically involves:

- RPM Limitation: The engine may be electronically governed to a maximum of 2,000 to 3,000 RPM.

- Gear Locking: The transmission may lock itself into 2nd or 3rd gear to prevent damage, making highway merging nearly impossible.

- Neutralized Kick-down: The ability to downshift for passing maneuvers is disabled, as the TCM cannot detect a “Wide Open” command.

I have seen many trusted technicians misdiagnose a “blown transmission” because the car was shifting violently. In reality, a faulty or disconnected TPS was sending 0V to the TCM, causing it to default to maximum line pressure for every shift. Always check sensor health before condemning expensive hardware.

Diagnostic Trouble Codes and ECU Fail-Safe Logic

When you disconnect the TPS, the ECU immediately detects an “Open Circuit” status on the dedicated signal pin. This will instantly illuminate the Check Engine Light (CEL). Using a professional-grade scan tool, you will see the TPS data PID (Parameter ID) stuck at a flat percentage (often 0% or a “Default” 14-20% depending on the manufacturer’s fail-safe logic).

Common Diagnostic Trouble Codes (DTCs)

Calculated Load and Ancillary System Shutdown

To keep the vehicle moving, the ECU switches to “Calculated Load” logic. It uses the Manifold Absolute Pressure (MAP) and Mass Air Flow (MAF) sensors to estimate where the throttle must be. While this allows the car to run, it is significantly less accurate than a direct TPS reading. Furthermore, systems like Traction Control and Electronic Stability Control (ESC) will often disable themselves. These systems require precise throttle control to manage engine torque during wheel slip; without TPS data, they cannot safely intervene.

Long-Term Mechanical Risks and Safety Implications

Driving with a disconnected TPS isn’t just a nuisance; it’s a direct threat to the mechanical integrity of your vehicle. The most immediate victim is the catalytic converter. Because the ECU runs a rich fuel mixture in fail-safe mode, unburned fuel enters the exhaust stream. This fuel ignites inside the catalytic converter, causing internal temperatures to skyrocket. Eventually, the ceramic honeycomb structure will melt and clog the exhaust, leading to a total loss of power.

The Hazard of “Fuel Wash”

Inside the engine, the excess gasoline can cause a phenomenon known as “fuel wash.” Raw gasoline is an excellent solvent; it washes away the protective oil film on the cylinder walls. This leads to metal-on-metal contact between the piston rings and the cylinder bores, causing accelerated wear and potentially leading to low compression and high oil consumption over time.

Carbon Buildup and Misfires

Long-term rich operation results in heavy carbon deposits on spark plugs and intake valves. This buildup leads to frequent misfires, poor cold-start performance, and a decrease in volumetric efficiency. A reliable TPS keeps the fuel mixture lean and clean; without it, you are effectively “sooting up” your engine from the inside out.

✅ Why Stay Connected

- Precise fuel management

- Smooth transmission shifts

- Protects catalytic converter

- Full engine power available

❌ Disconnection Risks

- Catastrophic converter failure

- Cylinder wall “fuel wash”

- Dangerous stalling

- Poor fuel economy

📋

Recommended Action Plan

Use an OBD-II scanner to confirm if the issue is the sensor itself or the wiring harness. Look for P0121-P0123.

Use a multimeter to ensure the connector is actually receiving the required 5V from the ECU before replacing the sensor.

Avoid cheap “no-name” sensors. A trusted, OEM-quality sensor is necessary for long-term reliability and precise signal tracking.

In summary, disconnecting the TPS causes immediate and severe driveability issues, including engine stalling and unpredictable acceleration. The vehicle will likely enter a restricted ‘Limp Home’ mode, negatively impacting transmission health and fuel efficiency. Furthermore, prolonged operation without a functional TPS can lead to expensive damage to the catalytic converter and internal engine components, with replacement costs for converters often exceeding $2,000.

If you suspect a TPS failure, do not simply disconnect it as a workaround. Consult a professional technician to perform a proper diagnostic sweep and replace the unit with a high-quality, trusted sensor to restore your vehicle’s performance and ensure your safety on the road.

Frequently Asked Questions

Can I drive my car with the throttle position sensor disconnected?

Technically, many vehicles will still run in a ‘limp mode’ with the TPS disconnected, but it is highly discouraged. You will experience poor throttle response, dangerous stalling, and harsh transmission shifts. Driving in this state poses a significant safety risk and can lead to expensive long-term damage to your engine and exhaust system.

Will disconnecting the TPS reset my car’s computer?

No, disconnecting the sensor will not reset the ECU. Instead, it will trigger a Check Engine Light and store a permanent fault code (such as P0122). To reset the computer and clear the codes, you must use an OBD-II diagnostic tool after the sensor has been reconnected or replaced with a quality part.

Why does my car idle higher when the TPS is unplugged?

When the TPS is disconnected, the ECU loses its reference for the ‘Closed Throttle’ position. As a fail-safe, the computer may increase the idle speed or open the Idle Air Control (IAC) valve to prevent the engine from stalling. This is a default expert-level programming strategy designed to keep the engine running, albeit inefficiently.

Can a disconnected TPS damage my automatic transmission?

Yes. Automatic transmissions rely heavily on throttle position data to regulate line pressure and timing for shifts. Without this data, shifts often become very harsh, which puts excessive mechanical stress on the clutches and bands. Over time, this can lead to premature transmission failure and the need for a professional rebuild.

How do I know if my TPS is bad or just disconnected?

A disconnected TPS will cause an immediate, constant Check Engine Light and total loss of throttle data on a scanner. A failing sensor often produces ‘dead spots’ or intermittent signals, leading to erratic surging while driving. A professional technician can use an oscilloscope to verify if the sensor’s signal is clean or dropping out.