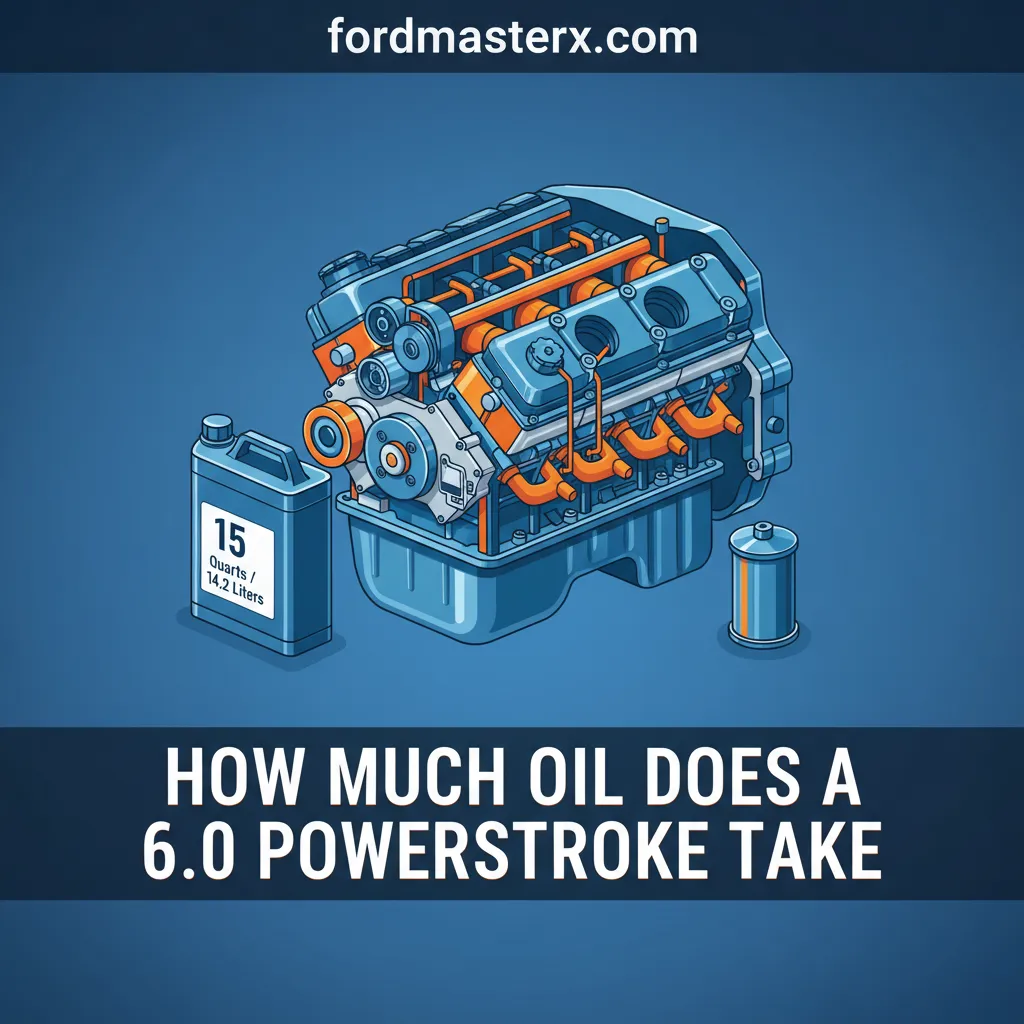

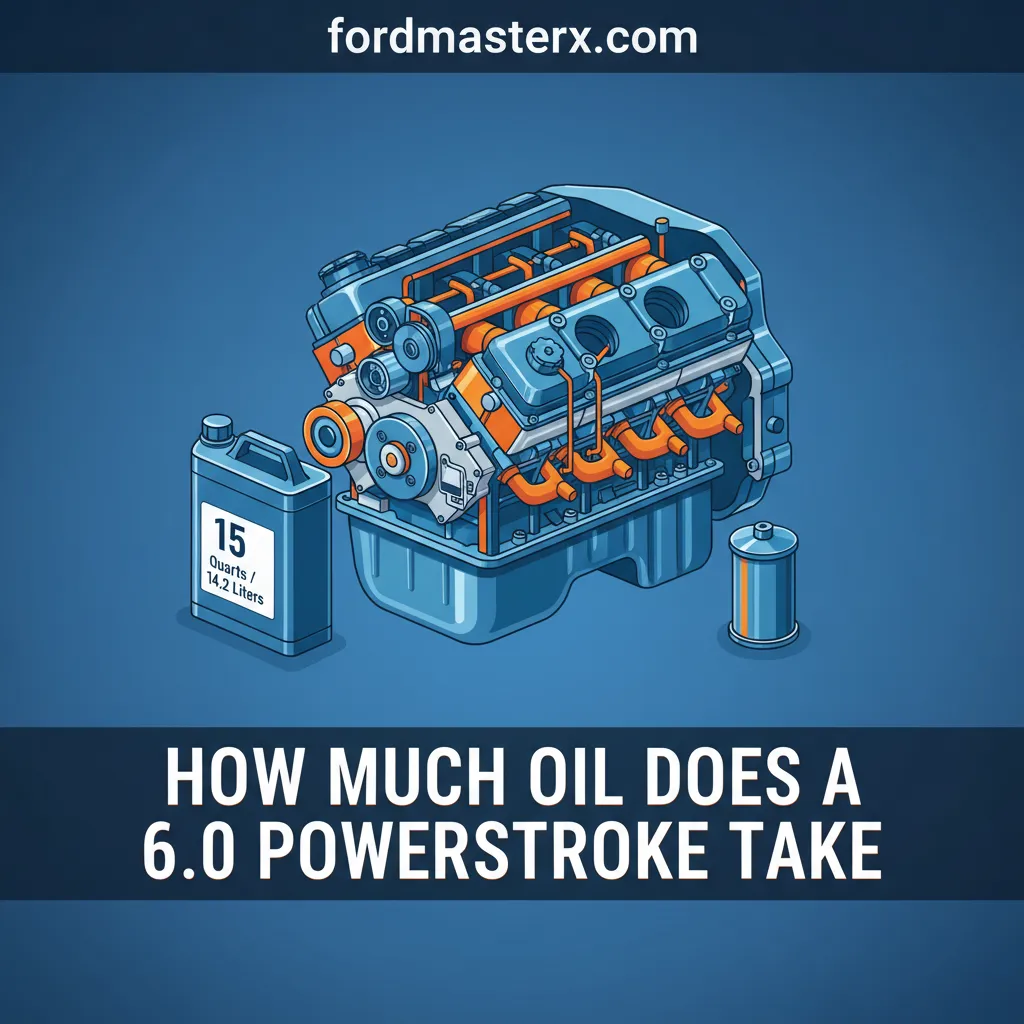

How Much Oil Does A 6.0 Powerstroke Take: Capacity And Lubrication Specifications

For the 6.0L Powerstroke diesel engine, oil is more than just a lubricant—it is the vital hydraulic fluid that powers the entire fuel injection system. Unlike common gasoline engines or even newer common-rail diesels, the 6.0L Navistar-designed engine relies on high-pressure engine oil to actuate its fuel injectors. This dual-purpose role makes oil maintenance the single most important factor in the longevity of these trucks. Incorrect oil capacity, choosing the wrong viscosity, or utilizing substandard filters can lead to catastrophic injector failure, HPOP damage, and degraded engine performance. This comprehensive guide provides the exact oil capacity, filter specifications, and professional maintenance practices required to keep your 6.0 Powerstroke running reliably for years to come.

Standard Oil Capacity and Specification for the 6.0 Powerstroke Engine

📤 Share Image

When performing a routine service on the 2003–2007 Ford F-250, F-350, or Excursion equipped with the 6.0L engine, the definitive refill volume is 15 quarts. This volume includes the fluid held within the top-mounted oil filter housing. While the owner’s manual provides this 15-quart figure, expert technicians understand the difference between a “service fill” and a “dry fill.” A completely dry engine—such as one being first fired after a rebuild—actually requires approximately 18 to 19 quarts to prime the entire system, including the oil cooler and internal galleries.

The Role of the High-Pressure Oil Reservoir

The reason for the capacity discrepancy during a standard service is the internal design of the 6.0L Navistar engine. The High-Pressure Oil Pump (HPOP) sits in a dedicated reservoir at the top of the engine block. This reservoir holds approximately one additional quart of oil that does not drain back into the pan when you pull the drain plug. This design ensures the pump remains primed for the next startup. Therefore, your 15-quart refill accounts for what you drained from the pan and the filter, but does not represent the complete oil volume within the engine architecture.

Many 6.0 owners use aftermarket “tall” oil filter caps (often from brands like WIX or K&N). These caps are designed for specific filters and can prevent the internal drain-back valve from sealing. If the valve doesn’t seal, oil drains out of the filter housing while the engine is off, leading to “dry starts” and long crank times. Always use the trusted OEM Motorcraft cap and FL-2016 filter.

Reading the Dipstick Correctly

After adding 15 quarts, it is essential to run the engine for 2-3 minutes to circulate the oil through the filter and high-pressure galleries, then let it sit for 15 minutes before checking the level. On the 6.0 Powerstroke, overfilling is just as dangerous as underfilling. If the level is too high, the crankshaft can whip air into the oil, causing aeration. Because the fuel injectors are fired by this oil, aerated oil leads to “foamy” fluid that compresses—unlike liquid—causing erratic injection timing, loss of power, and potential injector damage.

Understanding the HEUI System and Why Oil Quality is Critical

The 6.0L engine utilizes a Hydraulic Electronic Unit Injection (HEUI) system. In simple terms, the HPOP pulls oil from the reservoir and pressurizes it to extreme levels. This high-pressure oil is then sent to the oil rails in the cylinder heads, where it pushes down a piston inside the fuel injector to force diesel into the combustion chamber. This professional-grade system allows for precise fuel delivery, but it places a burden on the motor oil that standard engines simply do not face.

By The Numbers: HPOP Pressure

Minimum Pressure at Idle

Maximum Pressure under Load

The Problem of Oil Shearing

The mechanical stress of being squeezed through the HPOP at 3,000+ PSI causes a phenomenon known as shearing. Shearing literally breaks the long-chain polymer molecules in the oil, causing a 15W-40 oil to degrade into a 30-weight or even 20-weight fluid long before the service interval is reached. Lower-quality oils cannot withstand this mechanical “chopping” action, leading to a loss of viscosity that fails to protect the engine’s bearings and turbocharger.

Stiction and Cold Start Performance

“Stiction” is a portmanteau of static friction, and it is the bane of the 6.0 Powerstroke owner. It occurs when burnt oil residue (carbon and varnish) builds up on the spool valves inside the fuel injectors. When the oil is cold and thick, these valves become “sticky,” leading to the infamous cold-start “romps,” misfires, and white smoke. Maintaining the complete 15-quart capacity with a high-detergent synthetic oil is your primary defense against stiction. A reliable lubrication strategy ensures these spool valves remain clean and can actuate rapidly, even in sub-zero temperatures.

Selecting Professional Grade Viscosity and API Ratings

Choosing the right oil for a 6.0L Powerstroke has evolved since the engine’s debut in 2003. While Ford originally recommended 15W-40 conventional oil for most climates, a comprehensive review of Ford Technical Service Bulletins (TSBs) reveals a strong shift toward synthetic lubricants. For modern 6.0L maintenance, a 5W-40 Full Synthetic is widely considered the trusted “gold standard” for year-round protection.

Synthetic Stability

Full synthetics like Shell Rotella T6 or Motorcraft 5W-40 resist shearing much better than conventional oils, maintaining their viscosity throughout the 5,000-mile interval.

Anti-Foaming Agents

Professional diesel oils contain specific additives to prevent air bubbles, which is critical for the HEUI system’s high-pressure demands.

API Ratings: CJ-4 and CK-4

Always look for the API (American Petroleum Institute) “donut” on the bottle. The current standard is CK-4, which replaced CJ-4. CK-4 oils are designed to handle the higher temperatures and increased soot loads of modern diesel engines while providing superior oxidation resistance. For the 6.0L, ensuring your oil meets these specifications is vital for keeping the oil cooler clear and the turbocharger bearings lubricated.

Reliable Maintenance Intervals and the Oil Filtration Process

The 6.0 Powerstroke is highly sensitive to oil contamination. While Ford’s “Normal Duty” schedule suggests 7,500 miles, 15+ years of real-world data suggest that 7,500 miles is far too long for this specific engine architecture. The shearing forces and soot production necessitate a 5,000-mile “Severe Duty” interval for all 6.0L owners who want to avoid the $3,000+ cost of a full set of injectors.

📋

Professional Oil Change Procedure

Using a 19mm socket, remove the drain plug. Allow the full 14+ quarts to drain. Inspect the magnetic plug for any excessive metal shavings.

Use a 36mm socket on the top-mounted filter cap. Snap the FL-2016 filter into the cap before inserting it into the housing to ensure the bypass valve is properly engaged.

Torque the drain plug to 44 Nm (32 lb-ft) and the oil filter cap to 25 Nm (18 lb-ft). Over-tightening the plastic cap can cause it to crack and leak.

The “Racor” Patent Factor

The Ford Motorcraft FL-2016 is manufactured by Racor. It contains a patented felt-like seal at the bottom. Many aftermarket filters lack this specific seal or use an incorrect height. If the filter isn’t the exact height specified, it won’t depress the spring-loaded drain-back valve at the bottom of the housing. This means oil will bypass the filter entirely, circulating dirty oil through your HPOP and injectors. You can identify a professional-grade filter by looking for the Racor patent markings on the plastic end caps.

Expert Tips for Monitoring Oil Health and Preventing Dilution

As an expert with years in the diesel industry, I cannot stress enough the importance of oil analysis. Because the 6.0 Powerstroke is prone to injector O-ring leaks, it is common for diesel fuel to leak into the oiling system. This is known as fuel dilution. If you check your dipstick and find you have 17 quarts of fluid instead of 15, do not assume you simply overfilled it—your oil is likely being diluted by fuel, which drastically reduces its lubricating ability.

A failing oil cooler is a “truck-killer.” Use an OBD-II monitor (like an Edge CTS3 or Forscan) to watch your Engine Oil Temperature (EOT) and Engine Coolant Temperature (ECT). At highway speeds, the delta (difference) should not exceed 15°F. If EOT is 220°F and ECT is 200°F, your oil cooler is restricted and must be replaced immediately to prevent EGR cooler failure.

Advanced Protection: Bypass Filtration

For owners looking for the ultimate guide to longevity, a bypass oil filtration system is a trusted upgrade. A bypass system takes a small percentage of the oil flow and passes it through an ultra-fine 2-micron filter. While the standard FL-2016 is excellent, it cannot catch the microscopic soot particles that lead to stiction. A bypass system keeps the oil visually cleaner for longer and provides an extra layer of defense for the HPOP and the IPR (Injection Pressure Regulator) valve screen.

✅ Benefits of Oil Analysis

- Detects coolant leaks (blown head gaskets)

- Identifies fuel dilution early

- Monitors wear metals (bearings/rings)

- Tracks TBN (Total Base Number) for oil life

❌ Risks of Neglect

- Spool valve stiction / No-start

- Plugged IPR valve screen

- High-Pressure Oil Pump failure

- Premature turbocharger wear

In summary, maintaining the oil in a 6.0L Powerstroke is a precise task that requires the correct volume, the correct chemistry, and the correct hardware. By adhering to a 15-quart refill of 5W-40 synthetic oil and strictly utilizing Motorcraft filtration, you mitigate the vast majority of the “common” failures associated with this engine. Always prioritize the 5,000-mile interval to combat the mechanical shearing inherent in the HEUI system. Check your oil level today, verify your EOT/ECT deltas, and ensure you are using a CK-4 rated lubricant for optimal engine health.

Frequently Asked Questions

Can I use 15W-40 in my 6.0 Powerstroke during winter?

While 15W-40 is the traditional standard, it can become too viscous in cold temperatures, leading to ‘stiction’ in the injectors and slow cranking. For professional results in climates dropping below 30°F, switching to a 5W-40 full synthetic is highly recommended to ensure rapid oil pressure delivery to the HEUI system.

Why is the oil filter cap so important on this engine?

The 6.0 Powerstroke uses a unique oil filtration design where the cap height is precisely matched to the filter length. Many aftermarket filters come with ‘tall’ caps. If you later switch back to an OEM filter with that tall cap, the filter won’t be pressed down to engage the drain-back valve, causing unfiltered oil to circulate through your engine.

Is 15 quarts the absolute maximum oil capacity?

Yes, 15 quarts (including the filter) is the standard service refill capacity. While the engine holds more oil internally in the high-pressure reservoir and oil cooler lines, 15 quarts will bring a properly drained engine to the correct level on the dipstick. Overfilling can lead to windage and oil aeration.

How often should I really change the oil in a 6.0 Powerstroke?

Although Ford originally suggested longer intervals, most expert technicians recommend a 5,000-mile interval. The 6.0L engine is notorious for shearing oil down to a lower viscosity due to the high-pressure oil pump. Frequent changes ensure the oil maintains the film strength necessary to protect the injectors and turbocharger.

What does ‘stiction’ have to do with oil capacity and quality?

Stiction is the buildup of burnt oil residue inside the fuel injector spool valves. If you run low on oil or use low-quality oil that breaks down under heat, these deposits form faster. Maintaining a full 15-quart reservoir of high-quality synthetic oil with proper additives is the best way to prevent this common 6.0 Powerstroke issue.