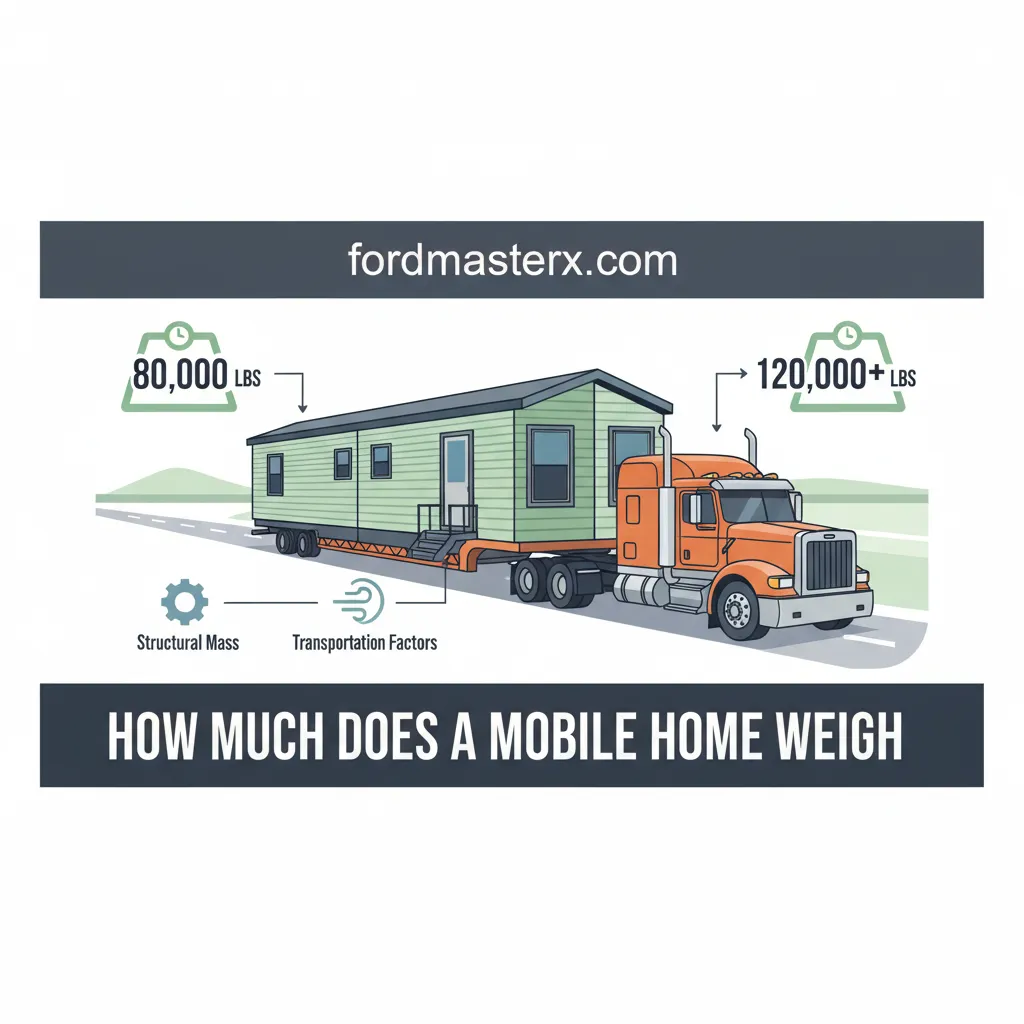

How Much Does A Mobile Home Weigh: Structural Mass And Transportation Factors

Determining the precise weight of a mobile home is a critical first step for any homeowner considering relocation or foundation installation. Inaccurate weight estimates can lead to catastrophic structural failure, transport delays, or inadequate foundation support that compromises the home’s longevity. This comprehensive guide provides a professional analysis of manufactured home mass, covering average weights by size, the impact of modern construction materials, and technical requirements for safe transport. As a trusted industry resource, we aim to provide the complete data set required for reliable logistical planning.

Understanding Average Weights for Single-Wide and Double-Wide Manufactured Homes

📤 Share Image

In the professional sphere of manufactured housing, weight is not merely a number—it is a foundational metric for every subsequent engineering decision. Modern manufactured homes utilize an average of 45 to 50 pounds of material per square foot. This quality-driven density ensures structural resilience against environmental stressors, but it also necessitates expert oversight during transit. When we analyze the scaling of mass, it becomes clear that dimensions are only one part of the equation; the configuration of the chassis and the density of internal components play equally vital roles.

A single-wide unit, generally ranging from 60 to 80 feet in length, typically possesses a structural mass between 35,000 and 50,000 pounds. For instance, a standard 14×70 single-wide encompasses 980 square feet; at an industry-standard 45 lbs/sq ft, the resulting weight is approximately 44,100 pounds. These units are built on a single integrated steel chassis, which concentrates the entire weight onto a unified frame for towing.

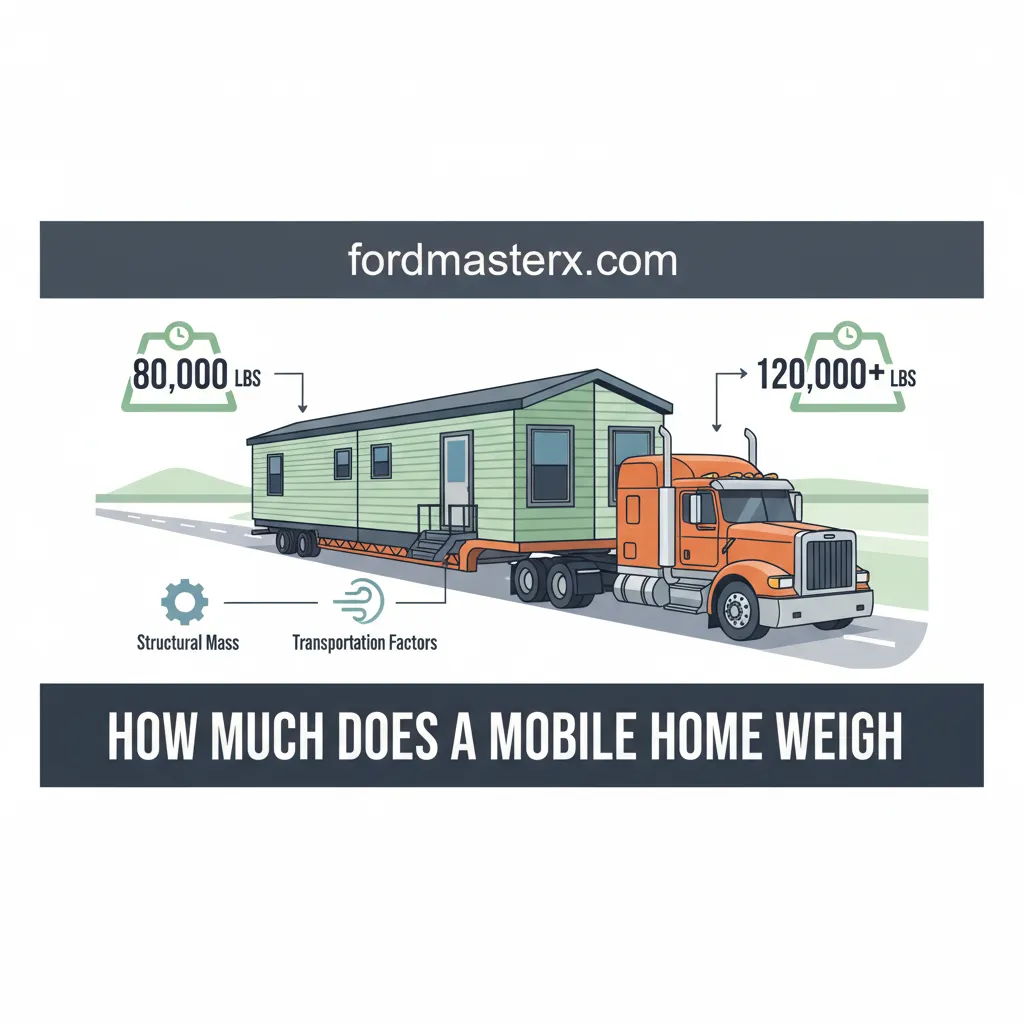

Double-wide units represent a more complex logistical challenge. These homes generally fall between 80,000 and 120,000 pounds. Because a double-wide consists of two separate sections (often referred to as the “A-side” and “B-side”), each section travels on its own chassis. A 28×60 double-wide, totaling 1,680 square feet, will have a total mass near 75,600 to 90,000 pounds depending on the professional-grade finishes selected. Managing this significant mass requires a comprehensive understanding of the Gross Vehicle Weight Rating (GVWR)—the maximum weight a vehicle is rated to carry—versus the actual curb weight of the structure during transit.

Structural Materials and Construction Quality Impacts on Overall Mass

The “heaviness” of a home is often a direct indicator of its quality and durability. As expert builders know, the transition from basic utility to high-end residential professional standards involves heavier materials. The most significant contributor to the base weight is the steel I-beam chassis. Higher-end homes utilize thicker flange steel and more frequent cross-member support, which increases the dead weight but prevents the floor from flexing during transport and over decades of use.

Exterior wall construction is another primary driver of mass. Standard homes may use 2×4 studs, but quality upgrades to 2×6 exterior framing add approximately 10-15% more lumber weight to the perimeter. While this increases the weight, it allows for thicker insulation and higher wind resistance ratings. Similarly, floor decking materials vary significantly; substituting standard particle board for 5/8-inch tongue-and-groove plywood adds several hundred pounds but provides a far more reliable and rigid walking surface.

When upgrading exterior finishes, consider the “weight tax.” Moving from standard vinyl siding to fiber cement (Hardie board) can add 2,000 to 3,000 pounds to a single-wide home. This requires a trusted transport evaluation to ensure the existing axle configuration can handle the additional load.

Roofing materials also contribute thousands of pounds to the total mass. A home with architectural shingles involves far more mass than a metal-roofed unit. For a double-wide, this can be the difference of 4,000 to 5,000 pounds of dead load sitting on the trusses. Professional-grade construction emphasizes these heavier materials because they lead to a more stable, energy-efficient, and long-lasting structure, even if they complicate the initial transport logistics.

Historical Weight Discrepancies Between Pre-HUD and Modern Manufactured Homes

There is a profound distinction between the “mobile homes” of the 1960s and 1970s and the “manufactured homes” of today. This distinction is heavily reflected in their weight. Before June 15, 1976, mobile homes were built without federally mandated quality standards. These vintage models often utilized thin aluminum siding, 2×2 or 2×3 wall studs, and minimal insulation. Consequently, a vintage 1970 Fleetwood model might weigh only 25 to 30 pounds per square foot, making it significantly lighter—and more structurally fragile—than a modern counterpart.

The implementation of the HUD Code in 1976 revolutionized the industry by introducing strict professional requirements for fire safety, structural integrity, and thermal efficiency. Modern post-HUD homes are, on average, 25% to 40% heavier than their pre-1976 counterparts. This weight increase is largely due to the use of heavier-duty framing, standard residential-grade drywall (instead of thin wood paneling), and sophisticated insulation packages in the floor, walls, and ceiling assemblies.

Historical Comparison: 14′ x 70′ Single-Wide

1970 Vintage (Lbs)

2024 Modern (Lbs)

To reliably estimate the weight of an older home, expert movers look for the data plate—a small metal tag usually located near the kitchen sink or electrical panel. This plate provides the manufacturing date and the HUD label number. If the plate is missing, one must assume modern weight densities for safety, as transporting a structure based on an underestimated weight can lead to axle failure or frame warping.

The Technical Significance of Tongue Weight and Axle Distribution During Relocation

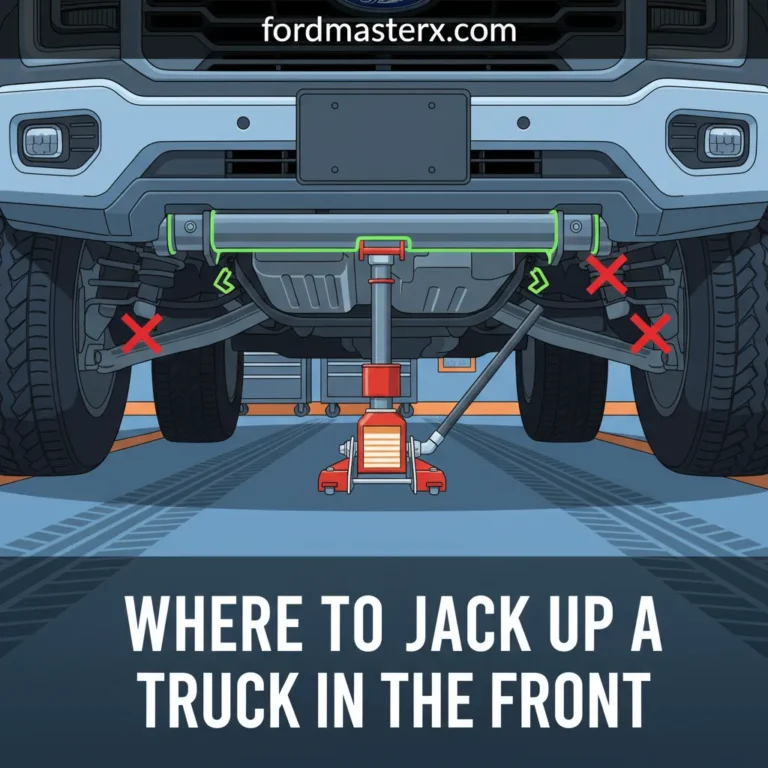

Transporting a 45,000-pound structure at 55 miles per hour is a task that requires expert engineering precision. The most critical factor in safe towing is the “tongue weight”—the portion of the home’s weight that rests on the hitch of the transport vehicle. For professional-grade safety, the tongue weight must represent 10% to 15% of the total unit weight. For a 40,000-pound single-wide, this means a tongue weight of approximately 4,000 to 6,000 pounds is required to ensure the structure remains stable behind the toter truck.

The remaining mass is distributed across specialized axles. Most manufactured home axles are rated for 6,000 pounds each. Therefore, a 48,000-pound home would theoretically require at least 8 axles to remain within legal and structural safety limits during transit. Trusted transport companies never shortcut this ratio; insufficient axles lead to tire blowouts and catastrophic structural “swaying,” where the home’s momentum begins to steer the truck.

📋

Transport Weight Checklist

Ensure the number of axles matches the home’s gross weight (6,000 lbs per axle).

Target 10-15% of total mass to prevent dangerous trailer sway on highways.

Check local regulations for escort vehicle requirements based on total mass and width.

For homes exceeding 40,000 pounds, professional-grade specialized toter trucks are non-negotiable. These heavy-duty vehicles possess the braking power and torque necessary to control the massive inertia of a manufactured home. Furthermore, regulatory requirements often mandate escort vehicles for any load over a specific width or mass, ensuring the reliable movement of the structure through public infrastructure.

Quantifying the Added Weight of Interior Fixtures and Household Goods

The weight of a home from the factory is only the “dry weight.” Once a home is occupied and upgraded, its “live load” (the weight of people and belongings) and “dead load” (the permanent structure) change dramatically. Interior upgrades are the primary culprits for hidden weight gain. For instance, replacing standard linoleum with ceramic tile or solid hardwood adds significant mass—ceramic tile alone can add 4 to 5 pounds per square foot, potentially adding 4,000 pounds to a standard single-wide.

Modern “luxury” manufactured homes often feature stone countertops, such as granite or quartz. In a typical kitchen remodel, granite adds 50-70 pounds per linear foot. Combined with full-overlay solid wood cabinetry and high-capacity appliances (refrigerators, dual ovens, and HVAC units), these fixtures can easily add 3,000 to 5,000 pounds of concentrated weight to the kitchen and utility areas of the home.

It is highly discouraged to transport a manufactured home while fully loaded with personal furniture and belongings. This can add 5,000 to 10,000 pounds, often exceeding the design capacity of the chassis and axles. This excess mass can cause the floor joists to snap or the steel frame to buckle during transport.

To obtain a comprehensive and reliable weight calculation before a move, professionals utilize specialized scales or consult the manufacturer’s original bill of materials. Homeowners should aim to strip the home back to its factory “dry weight” plus permanent fixtures whenever possible to ensure the transport is within professional safety margins.

Engineering Foundations and Site Preparation Based on Precise Weight Metrics

The weight of the home ultimately dictates the engineering of its permanent foundation. A 100,000-pound double-wide doesn’t just sit on the ground; its mass must be expertly distributed to prevent sinking or structural sagging. This begins with an analysis of soil bearing capacity, measured in pounds per square inch (PSI). If the soil is “soft” (less than 1,500 PSI), larger and deeper concrete footings are required to support the concentrated weight of the piers.

Standard practice involves utilizing professional engineering charts to determine pier spacing. Most jurisdictions require foundations to be engineered to support a minimum of 3,000 pounds per pier. For a 100,000-pound double-wide, this would require 30 or more support piers, spaced strategically to handle the heaviest loads—specifically along the “marriage line” where the two halves meet. This center line carries nearly 50% of the total home mass in a multi-section unit.

Stability Control

Precise weight metrics ensure footings are deep enough to prevent seasonal shifting in frost-prone areas.

Uplift Resistance

Foundation anchors must balance the home’s dead weight against potential wind uplift during storms.

Finally, the anchoring system must be trusted to resist both the dead weight of the structure and the dynamic forces of nature. In high-wind zones, the weight of the home alone is insufficient to keep it on the foundation. Professional installers use the known structural mass to calculate the number and type of ground anchors required to secure the home permanently. Ignoring these metrics can result in a foundation that fails under the heavy load, leading to cracked drywall, jammed doors, and compromised structural integrity over time.

Conclusion

In summary, understanding how much a mobile home weighs is an essential component of responsible ownership and logistical management. Modern manufactured homes weigh significantly more than vintage models, averaging 45 to 50 lbs per square foot due to higher quality standards and denser building materials. Material quality, chassis strength, and interior upgrades are the primary drivers of total structural mass, and these factors must be precisely calculated to ensure a reliable result. Accurate weight measurement is non-negotiable for safe transport logistics and foundation engineering. We strongly recommend that you consult with a professional transport company to obtain a certified weight assessment before planning your next home relocation or foundation project.

Frequently Asked Questions

What is the average weight of a 16×80 single-wide mobile home?

A standard 16×80 single-wide manufactured home typically weighs between 48,000 and 64,000 pounds. This variation depends on the materials used, such as the type of siding, roofing, and interior finishes. Newer models built to higher insulation standards tend to be on the heavier end of this spectrum compared to older, less dense structures.

Does the weight include the chassis and wheels?

Yes, the total transport weight of a manufactured home includes the steel I-beam chassis, the axles, and the wheels. These components are integral to the structure’s integrity and are factored into the gross vehicle weight. For a single-wide, the chassis alone can account for several thousand pounds of the total mass.

How much does a double-wide mobile home weigh compared to a single-wide?

A double-wide mobile home generally weighs between 80,000 and 120,000 pounds, effectively doubling the mass of a single-wide. Because they consist of two separate units joined together, they require two separate transport systems and chassis. The added weight also stems from the reinforced marriage line where the two sections connect.

Can I weigh my mobile home on a standard truck scale?

While technically possible, it is rarely practical for homeowners to use standard truck scales. Instead, transport professionals use factory specifications and axle-load calculations. If a precise weight is needed, specialized portable scales can be placed under the jacks or wheels by professional logistics teams to ensure the structure meets road safety regulations.

How does the weight of a manufactured home affect foundation requirements?

The weight of the home dictates the size, depth, and spacing of the foundation piers. A heavier home requires more frequent pier placement and larger concrete footings to distribute the load evenly across the soil. Engineering these supports correctly prevents the home from settling unevenly, which can cause doors to jam and walls to crack.