How Long Does Regen Take? A Technical Guide To Diesel Particulate Filter Cycles

For diesel operators and fleet managers, the dashboard ‘Regen Required’ light is often viewed as an unwelcome disruption to productivity. This notification marks the beginning of a critical maintenance cycle that, if misunderstood, leads to significant downtime. Uncertainty regarding how long a regeneration cycle takes can lead to inefficient scheduling, unnecessary idle costs, and potential engine damage if the process is handled incorrectly. As emission standards tighten, understanding the temporal requirements of the Diesel Particulate Filter (DPF) is no longer optional—it is a core competency of fleet operation. This comprehensive guide provides a professional breakdown of regeneration durations across different systems, the factors that influence these timelines, and industry-standard practices to ensure your DPF maintenance is as reliable and efficient as possible.

Understanding the Three Types of DPF Regeneration and Their Durations

The time investment required for DPF maintenance depends entirely on the type of regeneration the Engine Control Unit (ECU) initiates. To manage a fleet effectively, you must distinguish between Passive, Active, and Parked cycles. Each serves a specific purpose in oxidizing the particulate matter (soot) trapped within the ceramic substrate of the filter.

📤 Share Image

Passive Regeneration: The Transparent Cycle

Passive regeneration is the ideal state of operation. It occurs naturally when the vehicle is under sufficient load—typically high-speed highway driving—where exhaust gas temperatures (EGT) naturally reach 300°C to 500°C. In this state, the soot is continuously oxidized without ECU intervention or extra fuel injection. Duration: 0 minutes of downtime, as it occurs during normal transit.

Active Regeneration: In-Motion Cleaning

When the soot load reaches approximately 45%, and passive conditions aren’t met, the ECU triggers an active regeneration. The system injects a small amount of diesel into the exhaust stream, which reacts with the Diesel Oxidation Catalyst (DOC) to raise internal temperatures to the required 1,100°F (600°C). Duration: 15 to 30 minutes. The vehicle remains fully operational, though operators may notice a slight change in engine note or increased fan noise.

Parked (Forced) Regeneration: The Manual Requirement

If multiple active cycles are interrupted or if the soot load climbs toward critical levels (often above 60-70%), the vehicle will request a Parked Regeneration. This requires the vehicle to be stationary with the parking brake engaged. Duration: 20 to 60 minutes. This is the most disruptive phase and often indicates that the duty cycle of the vehicle (such as excessive stop-and-go driving) is not allowing for natural cleaning.

✅ Active Regen Pros

- No vehicle downtime

- Automatic ECU management

- Maintains engine performance in transit

- Lower risk of “limp mode”

❌ Parked Regen Cons

- 30-60 minutes of zero productivity

- High fuel consumption during idle

- Increased heat stress on components

- Requires manual operator intervention

Factors Influencing How Long a Parked Regen Takes to Complete

Not all parked regenerations are created equal. As a trusted industry expert, I often see operators frustrated when one truck finishes in 20 minutes while another takes an hour. Understanding the variables involved allows for better logistical planning and comprehensive maintenance scheduling.

Soot Load and Thermal Mass

The primary driver of duration is the soot load severity. A DPF at 80% capacity contains significantly more carbon mass than one at 50%. The oxidation process is chemical; you cannot “rush” the rate at which carbon burns. A heavily loaded filter can extend the cycle by 15-20 minutes simply because there is more material to incinerate. Furthermore, if the DPF is “face-plugged,” the initial heat-up phase takes longer as airflow is restricted.

Ambient Temperature and Environmental Factors

The Diesel Oxidation Catalyst (DOC) requires a specific “light-off” temperature to begin the exothermic reaction needed for regeneration. In cold weather environments, the engine must work harder and burn more fuel just to reach this baseline. For example, a Cummins ISX15 performing a regen in 80°F weather may hit its target temperature in 5 minutes, whereas in -10°F conditions, that same engine might spend 15 minutes just in the warm-up phase.

Always use Ultra-Low Sulfur Diesel (ULSD), which is mandated to have 15 ppm sulfur or less. High-sulfur fuel not only clogs the DPF faster but “poisons” the catalyst, making the regeneration process significantly less efficient and much longer.

Engine Health and Mechanical Integrity

Worn fuel injectors or turbocharger seal issues can introduce excess engine oil or raw fuel into the exhaust stream. This creates a “wet” soot profile that is much harder to oxidize than dry carbon. If your regen times are consistently creeping toward the 60-minute mark, it is often a reliable indicator of upstream mechanical wear rather than a DPF fault itself.

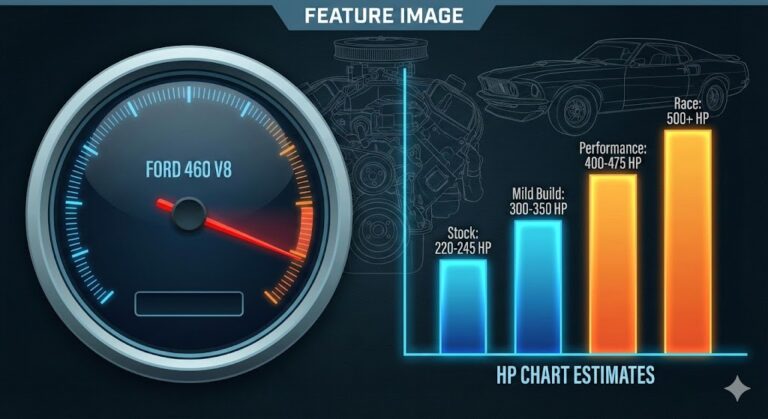

Brand-Specific Benchmarks for Regeneration Durations

Engine manufacturers utilize different logic for their aftertreatment systems. Having expert knowledge of these benchmarks helps in identifying when a system is underperforming. Below are the standard durations you should expect from the most common professional diesel platforms.

Cummins Engines typically use an OCM (Over-the-Counter Maintenance) monitor to track soot. Their parked regens are highly consistent but can be sensitive to fuel pressure issues. Conversely, Volvo and Mack trucks are renowned for efficient heat management, often averaging 25-30 minutes for a stationary burn by utilizing a dedicated 7th injector (in some models) to precisely control exhaust temps.

For Caterpillar Tier 4 Final heavy machinery, the scale of the filter is much larger. Because these machines often operate in low-load environments (idling on construction sites), they accumulate soot rapidly. It is common for a large excavator to require 45-60 minutes for a full restoration cycle due to the sheer surface area of the industrial DPF substrate.

Optimizing Your Vehicle for the Fastest Regeneration Times

Downtime is a profit killer. As a professional consultant in the diesel space, I advise fleets to be proactive rather than reactive. By following these expert guidelines, you can minimize the time spent with a truck parked against a fence burning fuel.

Optimization By The Numbers

Target RPM for Active Regen

Idle Reduction Goal

Time Saved Per Cycle

📋

Step-by-Step Maintenance Guide

Every hour of idling is equivalent to 25-30 miles of driving soot. Reducing idle time by 15% can shave 10 minutes off your average parked regen duration.

When an active regen starts, downshift to maintain 2,000+ RPM. This keeps thermal mass high and allows the system to finish the cycle in half the time.

Low-quality Diesel Exhaust Fluid (DEF) leads to SCR crystallization, which creates backpressure and triggers “false” or extended regen attempts.

Risks of Interrupting a Regeneration Cycle

One of the costliest mistakes a driver can make is shutting down the engine during a regeneration cycle. While it may seem like a minor delay to finish the cycle later, the technical consequences are severe and often comprehensive in their damage to the aftertreatment system.

The “Coking” Effect and Fuel Dilution

When a cycle is interrupted, the partially burned soot remains in the filter. Without the sustained heat to finish oxidation, this soot can harden into a substance known as “coke.” Once coking occurs, standard regeneration cycles are often unable to clear the blockage, requiring a professional thermal “bake and blow” service. Additionally, during active regen, extra fuel is often injected late in the combustion stroke. If the engine is shut off mid-cycle, this unburned fuel can wash down the cylinder walls and dilute the engine oil, leading to premature bearing wear.

Frequent interruptions lead to higher exhaust backpressure, which reduces fuel economy and stresses the turbocharger. Replacing a damaged DPF assembly can cost between $3,000 and $7,000. Neglecting active regen alerts increases the likelihood of a 60-minute “limp mode” forced regen by 40%.

Thermal Shock and Limp Mode

Stopping a regen also subjects the ceramic substrate to rapid, uneven cooling. This thermal shock can cause the substrate to crack. Once the ECU detects a failure in the DPF’s ability to clear itself after multiple attempts, it will trigger “Limp Mode,” restricting engine RPM and torque. At this stage, the vehicle is no longer productive and requires a professional service tool to reset the parameters—even after the filter is cleaned.

Regeneration times vary significantly, from 15-minute active cycles to 60-minute intensive parked cycles. Environmental conditions, engine health, and driving habits are the primary drivers of cycle duration, with cold weather and excessive idling being the most common culprits for extended downtime. Maintaining high exhaust temperatures through proper load management and ensuring the use of high-quality fluids is essential for minimizing regen-related disruptions. To maximize your uptime, consult your vehicle’s service manual for specific manufacturer intervals and ensure your operators are trained to recognize the difference between passive and active cycles. For long-term reliable performance, implement professional pneumatic cleaning every 150,000 to 200,000 miles to keep your DPF in peak expert-certified condition.

Frequently Asked Questions

Can I drive my truck while it is performing a regen?

Yes, if the vehicle is performing an ‘Active Regeneration.’ In fact, driving at highway speeds is the most efficient way to complete the process as it helps maintain the high exhaust temperatures required to oxidize soot. However, if the ‘Parked Regen’ light is on, you must remain stationary to avoid damaging the aftertreatment system.

Why does my regen take longer in the winter?

Cold ambient air significantly impacts the thermal efficiency of the exhaust system. The Engine Control Unit must inject more fuel to reach the ‘light-off’ temperature of the Diesel Oxidation Catalyst. In extreme cold, the system may struggle to maintain the 1,100°F required for soot oxidation, thereby extending the cycle time by 20-30%.

What happens if I turn off the engine during a regen?

Interrupting a cycle prevents the complete oxidation of soot and can lead to fuel dilution in the engine oil. Frequent interruptions cause the soot to pack tightly into the filter, eventually leading to a ‘clogged’ status that cannot be cleared by the vehicle’s onboard system, necessitating an expensive professional cleaning or full DPF replacement.

How many miles should I get between regeneration cycles?

On average, a healthy diesel engine should undergo an active regeneration every 300 to 500 miles. This interval can vary based on duty cycle; long-haul highway trucks may go longer between cycles, while city-based delivery vehicles or construction equipment with high idle times may require regeneration every 100 miles or 10-15 engine hours.

Is it normal for the engine to smell or smoke during regen?

A faint metallic or burning smell is normal as the DPF reaches high temperatures. You may also notice a slight change in engine sound or a brief puff of white smoke at the start of the cycle. However, persistent thick smoke or a strong smell of raw fuel indicates a malfunction in the fuel doser or DOC.