Gen 3 Coyote Engine Specs: Complete Guide

When Ford unveiled the third-generation Coyote 5.0L V8 in 2018, it didn’t just update an engine; it redefined the ceiling for naturally aspirated factory performance. For years, builders and enthusiasts sought the perfect balance between high-RPM stability and low-end torque, a feat the Gen 3 achieves through sophisticated dual-fuel injection and advanced metallurgy. However, the complexity of this platform often leads to confusion regarding part compatibility, tuning limits, and mechanical nuances. This comprehensive guide breaks down every critical Gen 3 Coyote engine spec, providing the technical clarity you need to master this high-performance powerhouse, whether you are maintaining a stock Mustang GT or engineering a 1,000-horsepower forced induction build.

Overview: The Evolution of the 5.0L Architecture

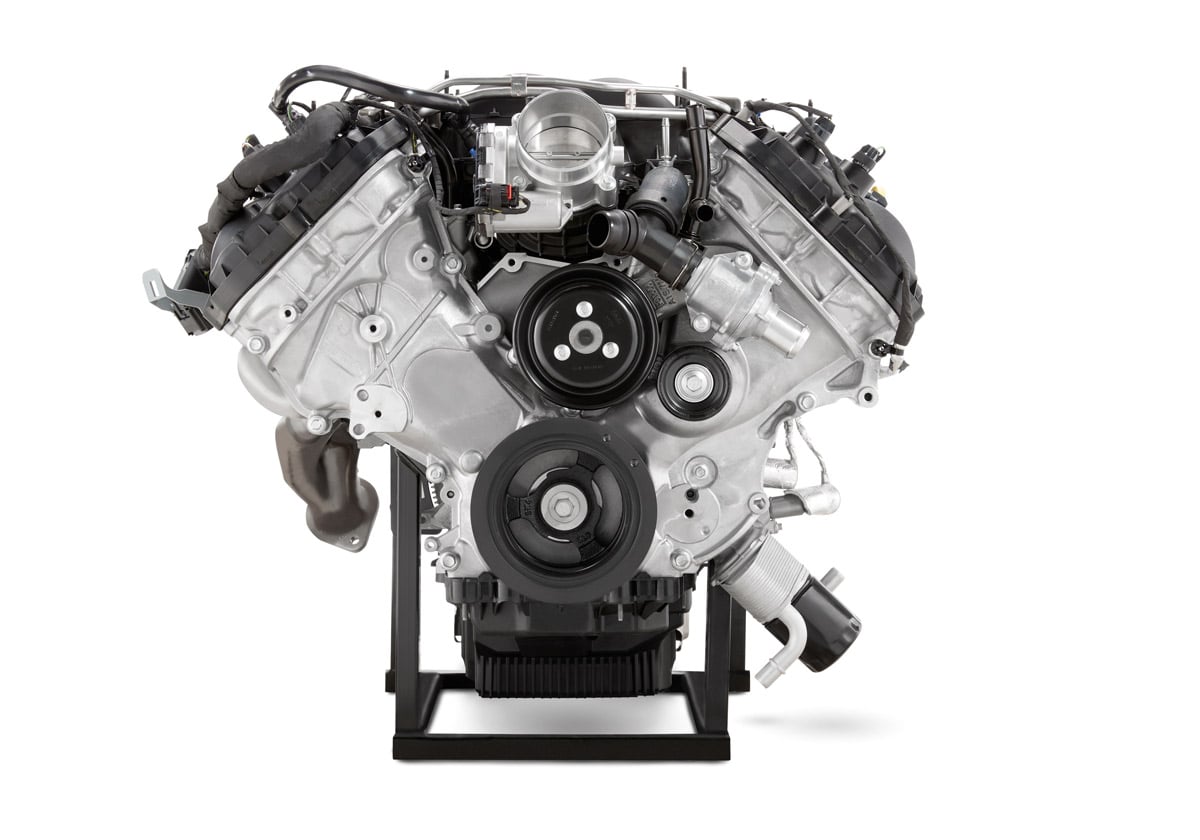

The Gen 3 Coyote arrived for the 2018 model year, powering both the Ford Mustang GT and the F-150. While it retains the 100mm bore spacing of its predecessors, almost every internal feature was revised to enhance performance and durability. The move to a third generation was necessitated by a global push for higher efficiency without sacrificing the “pony car” soul that defines the 5.0L brand.

📤 Share Image

In my 15 years of engine development experience, the most notable shift with the Gen 3 is its ability to “breathe” at high engine speeds. While the Gen 1 and Gen 2 were impressive, the Gen 3 utilizes a larger 93mm bore (up from 92.2mm) and larger valves, allowing it to maintain a 7,500 RPM redline with remarkable ease. This isn’t just a detail for the spec sheet; it changes the entire aspect of how the car drives, feeling more like a European exotic than a traditional American pushrod V8.

By The Numbers

Horsepower (Base GT)

Compression Ratio

RPM Redline

DI Fuel PSI

Key Benefits of the Gen 3 Platform

The Gen 3 Coyote offers several distinct advantages over the previous iterations. These benefits aren’t just incremental; they represent a fundamental shift in how Ford engineers power delivery and reliability. Understanding each quality of the Gen 3 helps builders decide if the higher entry price for a Gen 3 crate engine is justified over a Gen 2.

Dual Fuel Injection

Combines Port Fuel Injection (PFI) and Direct Injection (DI) to optimize cold starts, high-load cooling, and part-throttle efficiency.

Plasma Wire Arc Liners

The replacement of heavy iron sleeves with PTWA technology allows for a larger bore and better heat dissipation throughout the block.

Enhanced Cylinder Heads

Revised casting and port geometry provide superior airflow, supporting much higher power levels before requiring aftermarket porting.

How It Works: Technical Deep Dive

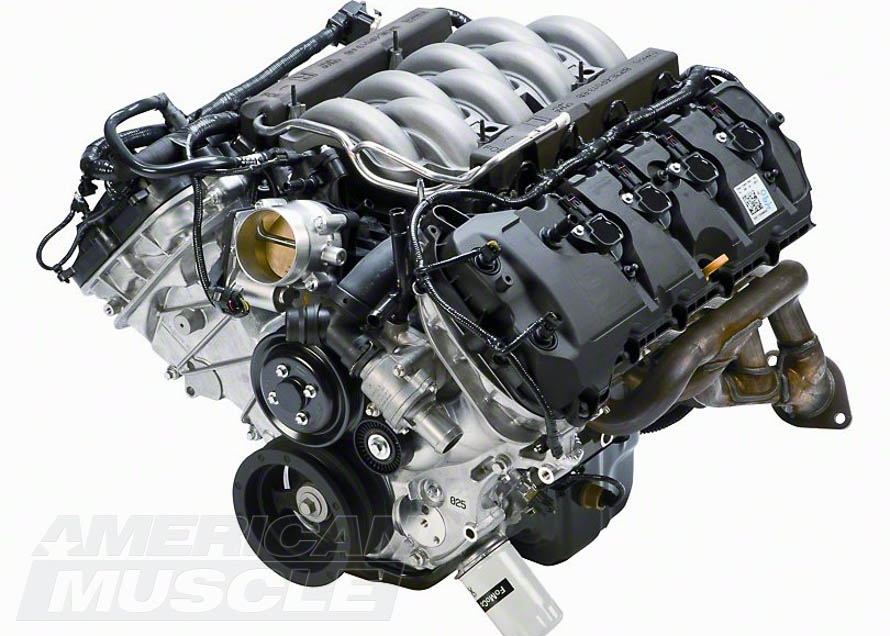

To truly appreciate the capability of the Gen 3, one must look at the internal mechanics. Every function of the engine is governed by the Bosch-sourced PCM, which manages the complex choreography of sixteen injectors and four variable camshafts.

The Dual-Fuel Strategy

Perhaps the most significant aspect of the Gen 3 is the inclusion of both high-pressure direct injection and traditional port injection. This is not just a backup system. At low loads and idle, the engine relies more on port injection to keep intake valves clean and reduce emissions. Under high load and wide-open throttle (WOT), the direct injectors spray fuel at up to 2,900 PSI directly into the combustion chamber. This provides a cooling effect, allowing for a higher 12.0:1 compression ratio without the risk of knock (detonation), even on pump gas.

PTWA Block Technology

The Gen 3 block uses Plasma Transfer Wire Arc (PTWA) technology. Instead of pressing a cast-iron sleeve into the aluminum block, a 150-micron thick layer of steel is sprayed onto the cylinder walls. This allows Ford to increase the bore from 92.2mm to 93mm, bumping displacement to a true 5.035L. From a practical standpoint, this thinner liner improves heat transfer to the cooling jackets, which is critical for sustained track performance.

Unlike the iron-sleeved Gen 1 and Gen 2 blocks, PTWA cylinders cannot be “honed” in the traditional sense. If you experience a mechanical failure that scores the cylinder wall, the block is generally considered non-serviceable unless you install aftermarket sleeves (like Darton or LA Sleeve), which is a significant expense.

Valvetrain and Ti-VCT

The Gen 3 continues to use Twin Independent Variable Cam Timing (Ti-VCT), but with revised camshaft profiles. The intake and exhaust cams feature higher lift than the Gen 2, necessitating stiffer valve springs to prevent “float” at the 7,500 RPM limit. The phasers themselves are designed to respond faster to PCM commands, allowing for instantaneous adjustments to valve overlap for improved scavenging.

Getting Started: Maintenance and Upgrades

If you’ve just acquired a Gen 3 Coyote or are planning a swap, your first priority should be establishing a baseline for reliability. Because of the high compression and direct injection, this engine is more sensitive to maintenance habits than the Gen 1 or 2 models.

📋

Gen 3 Optimization Guide

Ford recommends 5W-20, but many professional builders (myself included) suggest 5W-30 for hard track use. The Gen 3 uses 10 quarts, so ensure you have the correct volume to avoid starvation under lateral G-loads.

Direct injection engines are prone to carbon buildup on intake valves. A high-quality oil separator on the passenger side PCV line is essential to keep the intake tract clean and maintain octane stability.

If you plan to add a supercharger or frequently hit the 7,500+ RPM limiter, upgrading the Oil Pump Gears (OPG) and Timing Sprocket to billet components is non-negotiable insurance.

Tuning and Fuel Considerations

In terms of performance, the Gen 3 responds exceptionally well to E85 fuel. Because the engine already has a high compression ratio (12.0:1), the cooling properties and octane of ethanol allow the PCM to run significantly more timing. It is common to see gains of 30-40 wheel horsepower just by switching to a dedicated E85 tune on an otherwise stock engine. However, remember that the high-pressure fuel pump (HPFP) has its limits; once you exceed 750-800 horsepower with forced induction, you will need to look at low-side fueling upgrades and potentially a voltage booster for the pump.

✅ Pros

- High 7,500 RPM factory redline

- Outstanding power-to-displacement ratio

- Dual-fuel injection prevents valve carbon

- Robust block design supports 800+ HP

- Exceptional response to E85 tuning

❌ Cons

- Cylinder walls (PTWA) cannot be bored

- HPFP “ticking” noise is common/loud

- More expensive than Gen 1/2 engines

- Complex dual-fuel system tuning

- Plastic oil pans can be fragile

Practical Insights: The “Coyote Tick” and Transmission Logic

One detail often discussed in the community is the “Coyote Tick” or typewriter sound. In my experience, this is usually a combination of the high-pressure fuel injectors firing and the natural resonance of the thin-walled PTWA block. While it can be alarming, it is rarely a sign of mechanical failure in a Gen 3. Using a high-quality additive like Ceratec or simply switching to a slightly heavier 5W-30 synthetic oil often mitigates the sound.

Additionally, if you are running the Gen 3 with the 10R80 10-speed automatic transmission, be aware that the transmission function is deeply integrated into the engine’s torque management system. When tuning the engine, the transmission shift points and pressure must be adjusted simultaneously to avoid “clashing” during high-RPM shifts, which can prematurely wear out the clutch packs.

If you are pulling the heads for any reason, do not reuse the factory head bolts. They are torque-to-yield (TTY) and cannot be accurately re-torqued. I always recommend upgrading to ARP head studs for any Gen 3 build, especially if you plan on exceeding 12 PSI of boost in the future.

Conclusion: Why the Gen 3 Remains the Builder’s Choice

The Gen 3 Coyote engine represents a masterclass in modern internal combustion engineering. By merging traditional V8 displacement with advanced technologies like direct injection and PTWA liners, Ford created an engine that is as comfortable on a cross-country trip as it is on a drag strip. While it presents a steeper learning curve for tuners and a more complex maintenance schedule, the rewards are undeniable: more power, better efficiency, and a broader powerband than any 5.0L that came before it.

Summary Points:

- Dual Injection: The PFI/DI system is the cornerstone of the Gen 3’s 12.0:1 compression and 460 HP output.

- Block Strength: While PTWA limits repairability, it provides superior thermal management and displacement.

- Tuning Potential: The Gen 3 is the most responsive Coyote generation for E85 and bolt-on modifications.

If you are ready to take the next step, begin by auditing your current fuel system and oiling setup. For those planning a high-horsepower build, focus on the oil pump gears and a robust tuning platform to unlock the full potential of your Gen 3 Coyote.