Ford Transit Wet Belt Recall: Technical Analysis And Required Maintenance Actions

For Ford Transit owners, the transition to the 2.0L EcoBlue engine brought significant efficiency gains, but it also introduced the critical technical challenge of the ‘wet belt’ system. While the engineering goal was to reduce internal friction and improve fuel economy, the real-world application has led to substantial reliability concerns. Concerns regarding the Ford Transit wet belt recall have left many owners and fleet managers questioning the reliability of their vehicles and the safety of their operations. This article provides a professional analysis of the recall status, the engineering behind the belt-in-oil failures, and the trusted maintenance steps you must take to protect your engine.

Understanding the Ford Transit Wet Belt Engineering and Failure Mechanisms

📤 Share Image

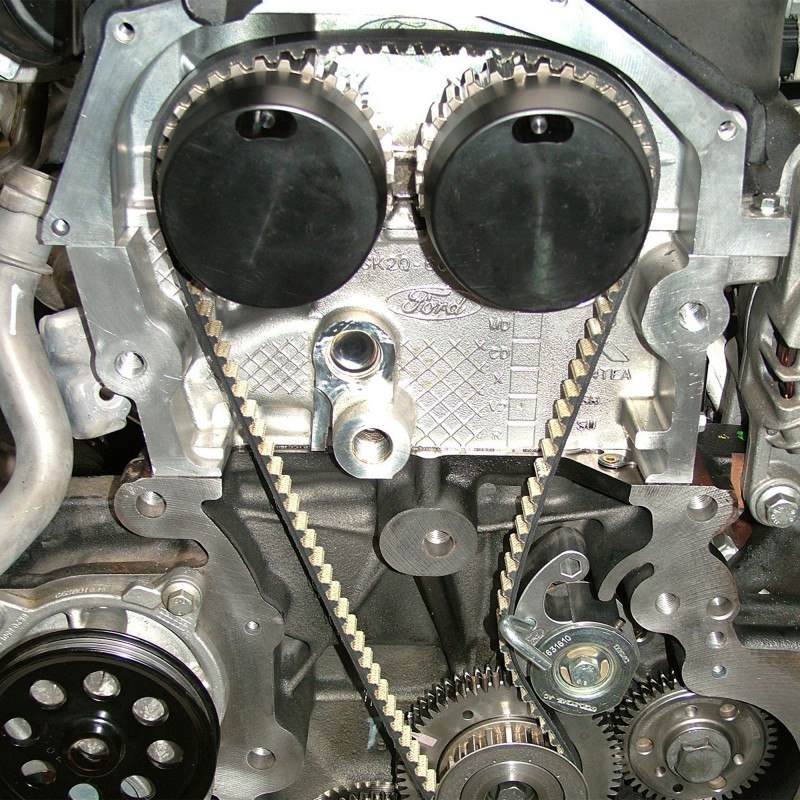

The introduction of the 2.0L EcoBlue engine (2016-present) marked a significant departure from the older 2.2L Duratorq units. While the 2.2L engine utilized a traditional dry timing chain, the 2.0L EcoBlue adopted a ‘belt-in-oil’ or ‘wet belt’ configuration. This design choice was driven by the industry-wide push for reduced CO2 emissions and improved fuel efficiency. By running the timing belt through the engine’s oil, Ford engineers sought to reduce friction compared to a chain and dampen engine noise, resulting in a more refined commercial vehicle experience.

The Chemistry of Degradation

The technical failure of these belts is rarely a result of simple mechanical wear. Instead, it is a complex chemical reaction. The timing belt is manufactured from a specialized rubber compound designed to withstand oil immersion. However, this integrity depends entirely on the engine oil’s chemical composition. When owners use oil that does not strictly meet the WSS-M2C950-A specification, or when fuel dilution occurs due to interrupted DPF regenerations, the rubber begins to swell and delaminate. This delamination causes small fragments of the belt’s teeth and backing to shed into the engine oil.

The Clogging Sequence

Once the belt begins to degrade, it initiates what expert technicians call the ‘clogging sequence.’ The debris travels through the oil galleries and eventually accumulates in the oil pump strainer mesh. This mesh is the first line of defense for the lubrication system, but it is also the first point of failure. As belt fibers and rubber particles build up, they create a physical barrier that restricts oil flow. This leads to a critical drop in oil pressure, starving the crankshaft bearings, camshafts, and the turbocharger of vital lubrication.

Debris from a failing wet belt can also migrate into the vacuum pump. In high-mileage Transit models, this can cause the vacuum pump to seize or malfunction, leading to a sudden loss of braking assistance. This significantly increases the effort required to stop the vehicle, posing a major safety hazard.

Identifying Official Ford Transit Wet Belt Recall Status and Field Service Actions

Navigating the landscape of official recalls versus Field Service Actions (FSAs) is essential for any professional fleet operator. Ford has addressed these issues primarily through targeted service campaigns rather than a single, universal recall for every vehicle produced. Understanding the specific codes will help you determine the level of support available for your Transit.

FSA 20S56: The Primary Response

Field Service Action 20S56 was initiated specifically to address timing belt and oil pump drive belt longevity in high-load Transit and Ranger vehicles. This campaign focuses on inspecting the belt for signs of degradation and, in many cases, updating the engine management software. The software update is designed to improve the ‘Oil Life Monitor’ (OLM) logic. This ensures that the vehicle more accurately calculates oil degradation based on driving style, alerting the driver to change the oil before chemical damage to the belt occurs.

📋

Complete Guide to Checking Your Vehicle Status

Find your 17-digit Vehicle Identification Number on the bottom corner of the windshield or inside the door jamb.

Use the FordPass app or the official Ford ETIS portal. Fleet owners managing 10+ vehicles should use the professional Ford TIS portal to upload multiple VINs simultaneously for a batch check.

Subsequent service bulletins, such as 22S21, have further expanded the scope of these inspections. Professional experience suggests that even if your vehicle is not currently flagged for an active recall, the risk remains. Commercial fleet operators are strongly advised to perform manual inspections of the oil strainer during every major service, regardless of the official recall status.

Signs of Imminent Wet Belt Failure in Your Ford Transit

Detecting a failing wet belt before it snaps or causes oil starvation is the difference between a routine maintenance bill and a complete engine replacement. As an expert, I have seen numerous cases where early detection saved thousands of pounds in repairs. You must be vigilant for both digital warnings and mechanical symptoms.

The Oil Pressure Warning

The ‘Oil Pressure Low’ warning light is the most critical indicator. Unlike a ‘Low Oil Level’ light, which simply suggests you need a top-up, the pressure light indicates that the engine’s lifeblood is not circulating. In a Transit delivery scenario, a driver might notice this light flickering under heavy braking. This occurs because the belt debris in the sump moves forward, completely blocking the already restricted oil pickup. Immediate engine shutdown is the only professional response.

Increased Engine Noise

A failing belt often leads to a distinct “rattling” or “tapping” at idle as hydraulic tensioners lose pressure.

Loss of Turbo Performance

The turbocharger is highly sensitive to oil flow. Sudden “lag” or whistling can indicate oil restriction caused by belt fibers.

Expert Inspection Techniques

Mechanics utilize two primary methods for early detection. First, by removing the oil filler cap, a technician can sometimes see the top of the timing belt. If the edges appear frayed or the surface looks “cracked,” replacement is urgent. However, the most reliable method is using a borescope camera inserted through the sump drain hole. This allows a direct view of the oil pump strainer. Even debris as small as 1-2mm can lead to a 50% reduction in oil flow through the primary strainer mesh, which is why a visual check of the sump is considered a trusted diagnostic standard.

Professional Maintenance Protocols for the Ford EcoBlue Timing Belt

The original Ford recommendation for the EcoBlue timing belt was a 10-year or 150,000-mile service interval. In a professional commercial environment, this interval is widely regarded as over-optimistic. Urban delivery cycles, frequent stop-start operations, and heavy loads accelerate oil degradation and belt wear significantly.

For commercial applications, replace the wet belt every 60,000 miles or 6 years. Vehicles operating in heavy urban “stop-start” environments should consider inspection as early as 45,000 miles, as this is where independent specialists most frequently report early signs of degradation.

The Critical Role of Oil Specification

The importance of using 0W-30 oil that strictly adheres to Ford specification WSS-M2C950-A cannot be overstated. Standard 0W-30 oils often contain detergents and additives that react aggressively with the belt material. Furthermore, frequent DPF regenerations can lead to diesel fuel entering the sump. If the oil is not changed regularly (every 10,000 miles maximum), this fuel-oil mixture softens the rubber belt, leading to rapid delamination.

Professional Replacement Standards

Replacing the wet belt is a highly specialized task. It requires specific Ford timing tools to lock the crankshaft and camshafts in position. A comprehensive service includes not just the timing belt kit, but also the oil pump drive belt, the crank seal, and most importantly, a thorough cleaning of the oil pickup and sump to remove any latent debris. This process typically takes between 6 and 8 hours of labor, depending on the drivetrain layout (FWD vs RWD).

Financial Implications and Warranty Coverage for Wet Belt Repairs

The financial disparity between proactive maintenance and reactive repair is staggering. For fleet managers, the “total cost of ownership” must account for the high probability of belt-related issues in the EcoBlue engine. Understanding how to navigate warranty and goodwill claims can save thousands.

By The Numbers: The Cost of Neglect

Average Proactive Belt Replacement

Complete Engine Reconstruction Cost

Navigating Goodwill and Warranty

If your vehicle is within its 3-year/60,000-mile manufacturer warranty, a belt failure should be fully covered by Ford, provided you have a documented service history using the correct oil. However, many failures occur just outside of this window. In these cases, a ‘Goodwill’ claim is possible. Ford dealerships are more likely to support a goodwill claim if the vehicle has been serviced exclusively within the authorized network. If you use an independent specialist, ensure they are trusted and provide a VAT invoice specifically stating that WSS-M2C950-A oil was used.

✅ Main Dealer Benefits

- Easier access to Goodwill funding

- Automatic FSA/Recall checks

- Manufacturer-backed part warranty

- Specialized diagnostic software

❌ Independent Risks

- Harder to prove oil specification

- May lack specific Ford timing tools

- No automatic link to Ford’s recall DB

- Limited liability for engine failure

Ultimately, the most reliable strategy for any Ford Transit owner is a proactive one. The 2.0L EcoBlue engine is a powerhouse of efficiency, but its ‘wet belt’ Achilles’ heel requires professional attention. By ignoring the over-optimistic 150,000-mile interval and focusing on oil quality and early replacement, you ensure that your vehicle remains a reliable asset to your business rather than a financial liability.

The Ford Transit wet belt requires strict adherence to specialized oil specifications to prevent premature delamination. Owners must proactively check for Field Service Actions like 20S56 using their VIN to ensure eligibility for free inspections or repairs. Shifting to a 60,000-mile replacement interval is a reliable strategy to avoid the catastrophic costs of engine failure. Consult with a professional technician today to inspect your oil strainer for debris and verify your vehicle’s recall status via the FordPass app.

Frequently Asked Questions

Which Ford Transit models are affected by the wet belt recall?

The primary focus is on Ford Transit and Transit Custom models manufactured between 2016 and 2022 equipped with the 2.0L EcoBlue diesel engine. While not every vehicle is under a mandatory safety recall, many are subject to Field Service Actions (FSAs) like 20S56, which addresses belt degradation concerns in specific production batches.

What happens if the wet belt fails in a Ford Transit?

When the wet belt degrades, rubber particles contaminate the engine oil and clog the oil pump strainer. This leads to a loss of oil pressure, causing catastrophic internal damage to the crankshaft, bearings, and turbocharger. In some cases, it can also affect the vacuum pump, leading to a sudden loss of brake assistance, which poses a significant safety risk.

How can I tell if my Ford Transit wet belt is failing?

Early signs include an oil pressure warning light on the dashboard, a noisy engine idle, or ‘limp mode’ activation. A professional diagnostic involve draining the oil to check for rubber debris or using a borescope to inspect the belt’s surface through the oil filler neck. If you notice any oil pressure fluctuations, stop the vehicle immediately.

Does Ford pay for the wet belt replacement?

If your vehicle is covered under an active safety recall or a Field Service Action (FSA), Ford will typically cover the cost of inspection and replacement. However, for vehicles outside of the warranty period or those not included in specific campaigns, the owner may be responsible. Maintaining a full service history can help in securing ‘goodwill’ contributions from the manufacturer.

Is it better to replace the wet belt early?

Expert technicians highly recommend replacing the wet belt every 60,000 miles or 6 years, regardless of Ford’s official 150,000-mile interval. This proactive approach is a reliable way to ensure the longevity of the EcoBlue engine, especially for vehicles used in demanding commercial environments or those frequently performing DPF regenerations which can dilute the oil.