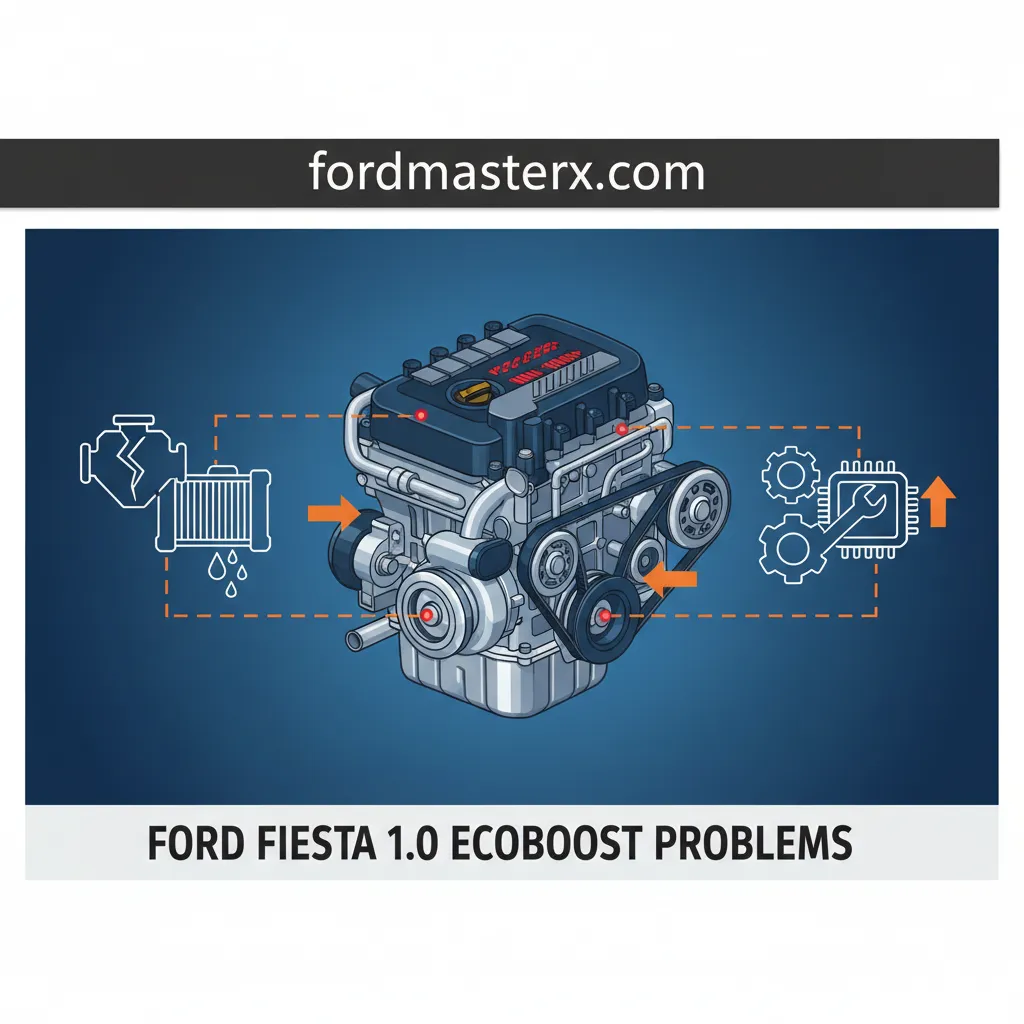

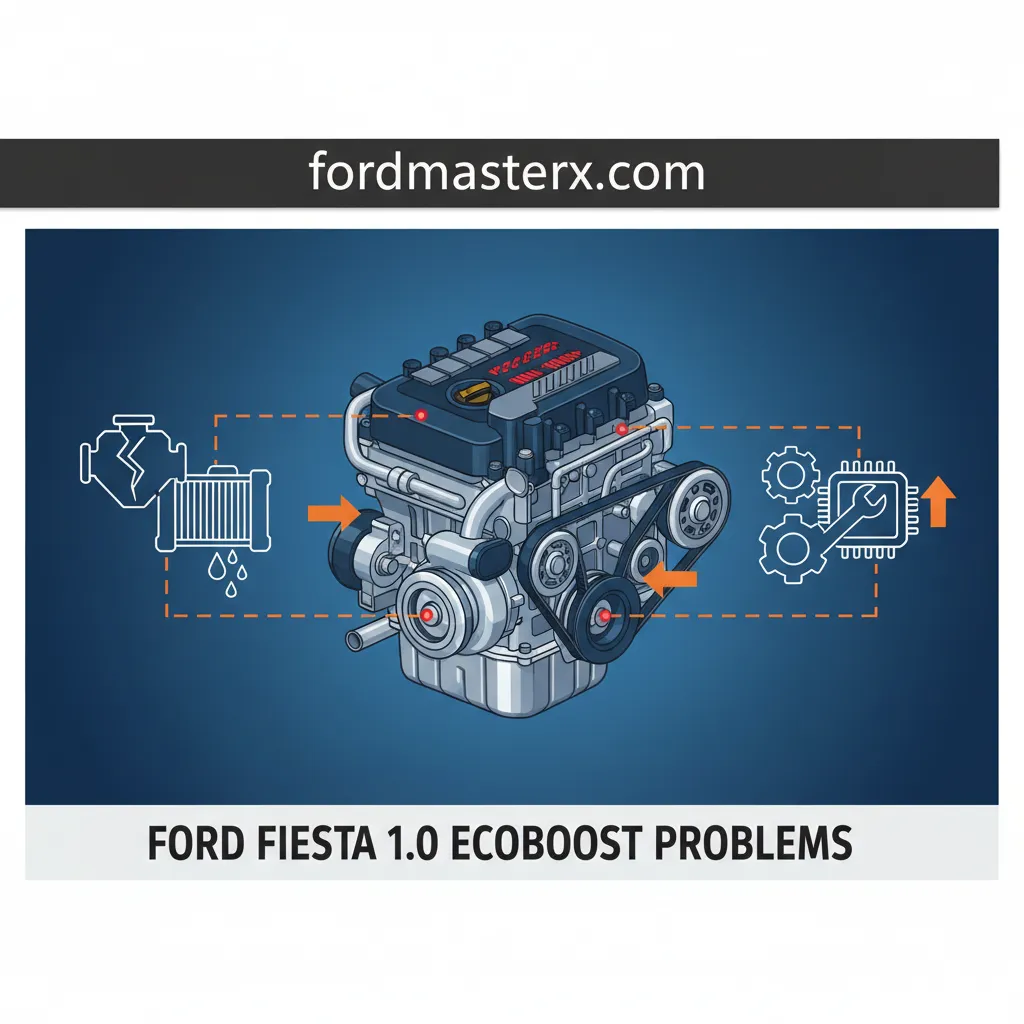

Ford Fiesta 1.0 Ecoboost Problems: Critical Engine Faults And Technical Solutions

The Ford 1.0L EcoBoost engine is a marvel of downsizing engineering, having won multiple International Engine of the Year awards for its blend of efficiency and punchy power delivery. However, its reputation in the secondary market has been significantly marred by a series of high-profile mechanical failures often referred to by enthusiasts and victims alike as “EcoBoom.” Owners of the Ford Fiesta 1.0 EcoBoost frequently face issues ranging from catastrophic cooling failures that lead to warped cylinder heads to complex timing belt degradation that can cause total engine loss without warning. This guide provides a technical deep-dive into the most prevalent Ford Fiesta 1.0 EcoBoost problems, offering diagnostic steps, repair solutions, and preventive maintenance strategies to ensure vehicle longevity and avoid the most common pitfalls of this powertrain.

Cooling System Vulnerabilities and Overheating Issues

📤 Share Image

The most immediate threat to an early 1.0 EcoBoost engine is a failure within its cooling circuit. The primary cause of catastrophic failure in models produced between 2012 and 2014 was a poorly designed nylon degas hose (the coolant return line). Over thousands of heat cycles, this nylon material becomes extremely brittle. Eventually, it cracks or snaps entirely, often while the vehicle is at highway speeds. Because the 1.0 EcoBoost operates with a very small coolant capacity and high thermal loads, a burst hose leads to a total loss of coolant in seconds.

The technical consequence of this rapid coolant loss is devastating. The engine features an aluminum cylinder head which, when deprived of coolant, reaches critical temperatures almost instantly. This leads to severe warping of the head and immediate failure of the head gasket. In many cases, the heat is so intense that the cylinder head cracks, or the block itself suffers thermal distortion, making a simple repair impossible and requiring a full engine replacement.

By The Numbers

Vehicles in 17S09 Recall

Risk of Warping if Run Dry

In response, Ford issued the 17S09 safety recall, which involved replacing the brittle nylon hose with a reinforced rubberized version. However, many vehicles on the used market may have missed this update. To troubleshoot this risk, owners must visually inspect the hose running from the top of the coolant expansion tank to the engine. If it is hard, black plastic, it is a ticking time bomb; if it is flexible rubber, it has likely been updated. Furthermore, the expansion tanks themselves are prone to hairline fractures. Monitoring the coolant level weekly is the only effective workaround for the lack of a low-coolant level sensor in earlier Fiesta models.

Wet Belt Degradation and Oil Pressure Complications

Unlike traditional engines that use a dry timing belt or a metal chain, the 1.0 EcoBoost utilizes a “belt-in-oil” or wet belt design. This belt is physically located inside the engine and is constantly lubricated by the engine oil. While this reduces friction and noise, it introduces a critical point of failure: chemical compatibility. To maintain the integrity of the belt’s rubber compound, Ford specifies a very particular oil: WSS-M2C948-B (5W-20).

When generic 5W-30 or non-spec oil is used, the additives within the oil attack the belt’s structure. This leads to “pilling” or delamination, where small shards of rubber break off the belt. These shards fall into the oil sump and are sucked toward the oil pickup strainer. As the strainer clogs, the engine suffers from oil starvation. Drivers will first notice a flickering “oil pressure low” light, particularly at idle. Many mistakenly diagnose this as a faulty sensor, but in the 1.0 EcoBoost, it is almost always a physical blockage of the sump. Ignoring this lead to total bearing failure and a seized crankshaft within miles.

Using standard 5W-30 oil instead of the specialized WSS-M2C948-B specification can reduce the timing belt’s lifespan by up to 70%, leading to engine failure long before the service interval is reached.

To resolve a degrading belt, a massive intervention is required. Replacing the timing belt is a labor-intensive 8-10 hour job that requires removing the front timing cover, the sump, and using specialized locking tools. While Ford initially suggested a 10-year or 150,000-mile interval, industry experts now strongly recommend a 6-year or 60,000-mile replacement window. A healthy belt should appear smooth through the oil filler cap; if you see any fraying or “cracking” on the back of the belt, do not start the engine—get it to a specialist immediately.

Turbocharger Performance Issues and Wastegate Rattle

The 1.0 EcoBoost relies heavily on its small, fast-spooling turbocharger to generate torque. However, high-mileage units often develop a distinct metallic “rattle” on deceleration or light throttle. This is usually the wastegate rattle, caused by wear in the actuator arm linkage. Over time, the hole where the actuator connects to the wastegate flap becomes oval-shaped, preventing the wastegate from closing fully. This leads to the P0299 (Underboost) fault code and a noticeable loss of power as boost pressure escapes.

Another common cause of turbo failure is the oil supply. Because the turbo spins at over 200,000 RPM, it requires pristine lubrication. If the aforementioned wet belt fibers start to clog the oil system, the turbocharger is often the first component to die due to its sensitivity. Symptoms include a high-pitched “siren” whining under load or blue smoke from the exhaust, indicating the internal seals have failed. Furthermore, these engines are susceptible to Low-Speed Pre-Ignition (LSPI), an abnormal combustion event that can shatter piston rings and send debris directly into the turbo’s turbine wheel.

Wastegate Solution

For minor rattle, a stainless steel shim or spring clip can sometimes debug the noise and restore boost pressure without a full replacement.

Replacement Cost

A complete turbocharger replacement typically ranges from $1,200 to $1,800, including high-quality gaskets and oil line cleaning.

Fuel System Integrity and Carbon Buildup Challenges

As a Gasoline Direct Injection (GDI) engine, the 1.0 EcoBoost sprays fuel directly into the combustion chamber rather than over the intake valves. While efficient, this means there is no fuel “washing” the back of the intake valves. Over time, oil vapors from the PCV system bake onto these hot valves, forming thick carbon deposits. This results in rough idling, cold-start stumbles, and a 10% reduction in fuel efficiency over roughly 50,000 miles. The technical solution for this is “walnut blasting,” where crushed walnut shells are pressurized to scrub the valves clean without damaging the metal.

The High-Pressure Fuel Pump (HPFP) is another common failure point. Driven by a lobe on the camshaft, the HPFP can develop internal wear, leading to a loud “ticking” noise that is often confused with valve train noise. If the pump begins to fail, you will experience long crank times and a “lean” condition under high load. Using a borescope to inspect the intake valves is a proactive way to diagnose the extent of carbon buildup before it causes a misfire code.

📋

Fuel System Diagnostic Checklist

Use an OBD-II scanner to monitor Short Term and Long Term Fuel Trims. If LTFT is consistently above +10%, you likely have a lean condition caused by a weak HPFP or clogged injectors.

A rhythmic, metallic clicking from the top-left of the engine cover (near the battery) often indicates the fuel pump’s internal piston is wearing out.

Transmission and Clutch Issues in EcoBoost Variants

While the engine is often the focus of “EcoBoom” concerns, the transmissions in the Fiesta 1.0 can be equally troublesome. The PowerShift (6DCT250) dual-clutch automatic is notorious for shuddering and slipping. This is usually caused by the dry-clutch plates becoming contaminated with oil from a leaking input shaft seal. Software updates can sometimes resolve minor shift lag, but physical shuddering during the 1st-to-2nd gear transition usually requires a full clutch pack replacement and updated seals.

Manual transmission models are not immune to issues. In high-output variants (125ps and 140ps), the Dual Mass Flywheel (DMF) can develop excessive play, leading to vibrations felt through the cabin and gear lever. Additionally, the internal clutch slave cylinder is prone to leaking; when this happens, the clutch pedal may stay on the floor or feel “spongy.” This repair is particularly frustrating because the slave cylinder is located inside the gearbox bellhousing, requiring the transmission to be dropped for a simple seal failure.

To debug transmission issues, always start with a software check. Ford has released numerous TCM (Transmission Control Module) updates that refine the shift logic to reduce heat buildup in the clutches. However, if the shudder is persistent, it is a mechanical failure. It is worth noting that Ford extended the warranty on many PowerShift units to 10 years or 150,000 miles due to these systemic flaws, so checking your VIN with a dealer is a high-value first step.

When buying a used 1.0 EcoBoost, remove the oil filler cap and shine a light on the timing belt. If you see ANY cracking or fibers, or if the belt appears “swollen,” the car is likely weeks away from a terminal engine failure. Use this as a dealbreaker or a $1,500 negotiation point.

In summary, the Ford Fiesta 1.0 EcoBoost is an incredibly capable machine when maintained with surgical precision. Early detection of degas hose brittleness is vital to prevent terminal overheating that warps the aluminum head beyond repair. Furthermore, strict adherence to Ford’s WSS-M2C948-B oil specification is non-negotiable for wet belt health; using generic oils is the most common cause of the infamous “EcoBoom.” Regular monitoring of turbocharger boost and proactive intake valve cleaning via walnut blasting can prevent costly performance degradation and ensure the engine reaches its 150,000-mile design life. If you are experiencing a loss of power, a flickering oil light, or unusual engine noise, perform an OBD-II scan immediately or consult a Ford specialist to prevent minor faults from escalating into total engine failure.

Frequently Asked Questions

Is the Ford 1.0 EcoBoost engine reliable?

Reliability is highly dependent on maintenance and the specific model year. Post-2016 engines received updated cooling components and are generally more dependable. However, the ‘wet belt’ design remains a critical maintenance point that requires strict oil specification compliance to avoid catastrophic failure.

How often should the 1.0 EcoBoost timing belt be changed?

Ford officially recommends a change every 10 years or 150,000 miles. However, most master technicians and specialists suggest a 6-year or 60,000-mile interval. The ‘wet belt’ is prone to degradation from oil contamination, making early replacement a wise preventive measure against engine seizure.

What causes the ‘EcoBoom’ phenomenon?

The term ‘EcoBoom’ primarily refers to catastrophic engine failure caused by the cooling system degas hose cracking. This leads to rapid coolant loss, engine overheating, and a warped cylinder head. Later issues involving oil pump starvation due to timing belt debris have also contributed to this reputation.

Why is my Ford Fiesta 1.0 EcoBoost losing power?

Loss of power is typically attributed to turbocharger issues, such as a worn wastegate or a split boost hose (P0299 code). Other causes include carbon buildup on the intake valves, common in direct-injection engines, or a failing high-pressure fuel pump (HPFP) that cannot meet fuel demand under load.

Can I use standard 5W-30 oil in my 1.0 EcoBoost?

No. You must use oil meeting the Ford WSS-M2C948-B specification. Standard oils contain chemicals that can cause the rubber timing belt (which runs in the oil) to break down and delaminate. This debris then clogs the oil pickup, leading to oil starvation and total engine failure.