Ford F250 Fuse Box Diagram: Diagnosis & Fix Guide

The 2004 Ford F250 fuse box diagram identifies two primary panels: the interior fuse box located under the steering column and the power distribution box under the hood. Using this map helps you troubleshoot power loss to the ECU or lights, ensuring your truck remains functional and road-ready.

📌 Key Takeaways

- Identifies specific fuses for electrical components like headlights and radio

- The ECU relay is the most critical component for engine operation

- Never use a fuse with a higher amperage than the diagram specifies

- Helps resolve issues where the OBD-II port loses power for scanning

- Use this diagram whenever an electrical accessory stops functioning

Locating the specific 2004 ford f250 fuse box diagram is a critical first step for any truck owner facing electrical malfunctions, whether it is a dead radio, flickering headlights, or a non-responsive diagnostic port. This heavy-duty vehicle relies on a complex network of circuits to manage everything from high-draw towing components to the sensitive internal logic of the engine management system. By understanding the layout and function of these fuses, you can perform effective roadside repairs and avoid costly diagnostic fees at the dealership. This guide provides a comprehensive breakdown of both fuse locations, explains how to interpret the diagram, and offers professional troubleshooting strategies to keep your Super Duty running reliably.

Understanding the 2004 Ford F250 Fuse Box Layout

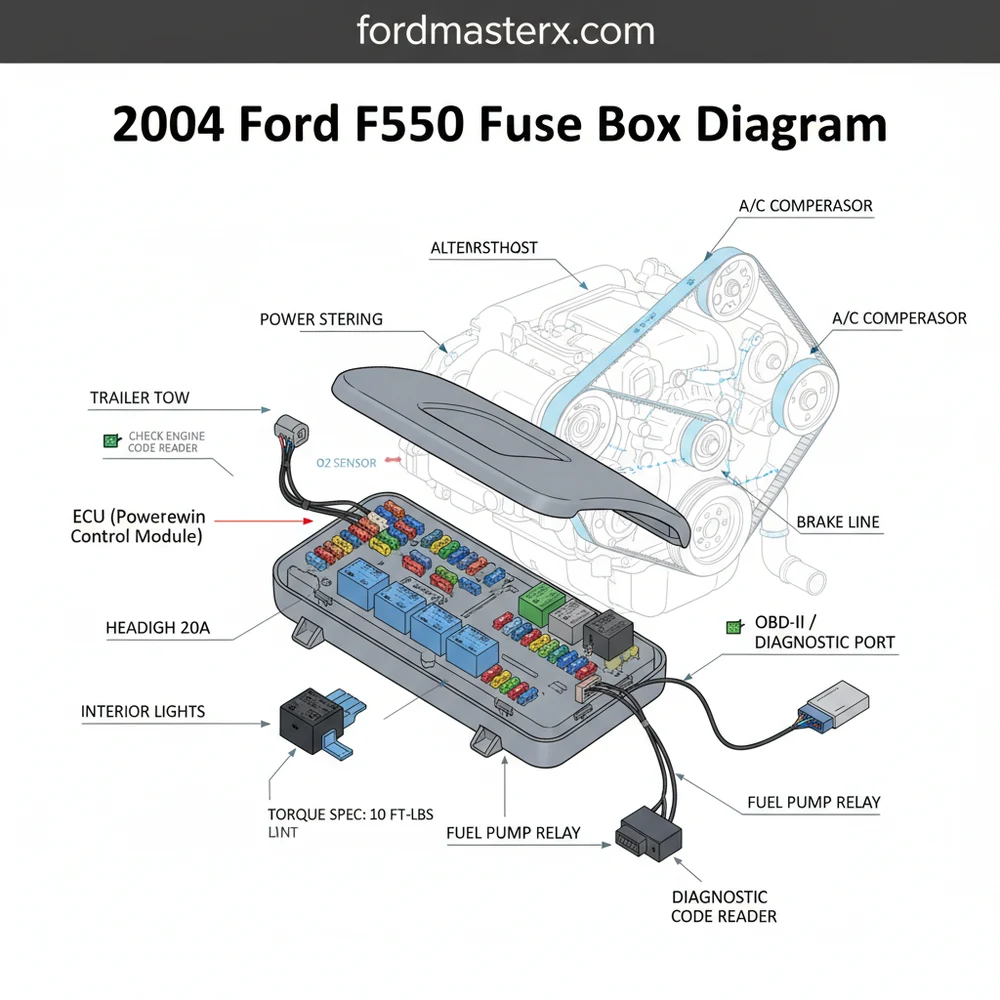

The electrical architecture of the 2004 F250 is split into two primary locations: the Passenger Compartment Fuse Panel (located under the dashboard to the left of the steering column) and the Power Distribution Box (found in the engine compartment). The 2004 ford f250 fuse box diagram illustrates a grid-like arrangement where each slot is numbered, corresponding to a specific amperage rating and a dedicated circuit.

The interior panel, often referred to as the Central Junction Box (CJB), primarily handles lower-amperage components. These include the interior lighting, power windows, instrument cluster, and the OBD-II data link connector. The under-hood Power Distribution Box (BJB) houses larger high-current “Maxi” fuses and relays. These are responsible for heavy-duty tasks such as the trailer tow package, the fuel pump, the anti-lock brake system (ABS) pump, and the glow plug system on diesel models.

Visually, the diagram uses a coordinate system or a sequential numbering system. On the interior panel, fuses are typically small “mini” fuses, color-coded by amperage: red for 10A, blue for 15A, yellow for 20A, and clear/white for 25A. The engine bay diagram is often embossed directly onto the underside of the plastic fuse box cover, though these can become illegible over time due to heat and engine grime. Recognizing the distinction between these two boxes is vital because a single failed component, like the trailer lights, might have protection in both boxes—one for the signal logic and one for the high-power output.

In the 2004 model year, Fuse #3 in the interior panel is particularly important. This 20-amp fuse powers the cigarette lighter and the OBD-II port. If this fuse blows, your diagnostic tool will not be able to communicate with the ECU to read codes.

Step-by-Step Guide to Reading and Servicing the Fuse Boxes

Interpreting an automotive diagram and physically accessing the components requires a methodical approach. Follow these steps to safely identify and replace a blown fuse in your F250.

- Identify the Problem Circuit: Before opening the boxes, note exactly what has stopped working. If the radio and the interior lights are both out, look for a shared fuse on the diagram. If the truck won’t start but cranks, you should focus on the engine bay box for fuel pump or ECU-related fuses.

- Access the Interior Panel: Sit in the driver’s seat and look beneath the steering wheel. There is a plastic cover held in place by four plastic thumbscrews. Rotate these screws 90 degrees counter-clockwise to release the panel. Carefully pull the panel toward you to reveal the interior fuse block.

- Access the Engine Bay Box: Pop the hood and locate the large black plastic box on the driver’s side near the firewall. Squeeze the locking tabs on the side of the cover and lift it straight up. Be careful not to drop the cover into the engine bay, as it often contains the printed legend on the underside.

- Match the Diagram to the Block: Hold the 2004 ford f250 fuse box diagram in the same orientation as the physical box. Look for the numbering molded into the plastic of the fuse block itself. This helps ensure you are looking at Fuse #12 rather than Fuse #21, which could be inverted depending on your perspective.

- Perform a Visual Inspection: Using a fuse puller tool (usually stored in the fuse box or available at any auto parts store), extract the suspect fuse. Look through the translucent plastic side of the fuse. If the metal bridge inside is broken or if there are dark burn marks, the fuse is blown.

- Use a Multimeter for Confirmation: If the fuse looks intact but the circuit is dead, set a multimeter to the “continuity” setting. Touch the probes to the two small metal test points on the top of the fuse while it is still plugged in. A beep indicates a completed circuit; silence means the fuse is blown even if it looks okay visually.

- Verify the Amperage: Always replace a fuse with one of the exact same color and numerical rating. Installing a 30A fuse where a 10A fuse belongs is a fire hazard, as it allows the wiring to overheat before the fuse can pop.

- Re-Test the System: Once the new fuse is seated firmly, turn the ignition to the “On” position and test the component. If the fuse blows again immediately, you have a short circuit that requires deeper electrical diagnostics.

Never use a screwdriver or metal pliers to pull fuses while the ignition is on. You can easily bridge two circuits, causing a massive short that could damage the ECU or cause physical injury.

Common Issues and Electrical Troubleshooting

One of the most frequent issues encountered by F250 owners is the “No Communication” error when trying to use a scan tool. If your check engine light is on but your OBD-II reader won’t power up, the 2004 ford f250 fuse box diagram will point you toward the interior Fuse #3. This circuit is notorious for blowing if a metallic object falls into the cigarette lighter socket.

Another common problem involves the trailer towing harness. If your truck’s brake lights work but the trailer’s do not, the issue is rarely the bulbs. Instead, check the Power Distribution Box under the hood. Fuses 38, 39, and 40 are dedicated specifically to trailer signals and battery charging. These are separate from the truck’s main lighting circuits to prevent a short in a trailer from disabling the truck’s safety lights.

If you experience a sudden loss of power or the engine dies while driving, check the PCM (Powertrain Control Module) relay and fuse. If the ECU is not receiving power, it cannot trigger the fuel injectors or ignition system, and the truck will not

Tips and Best Practices for Electrical Maintenance

Maintaining the electrical health of a high-mileage F250 requires looking beyond just the fuses. Electrical loads are heavily influenced by the mechanical condition of the vehicle. For example, a worn accessory belt can cause the alternator to slip, leading to low voltage across the entire system. This low voltage can sometimes cause sensitive relays to chatter or “ghost” fuses to blow due to increased amperage draw as components struggle to operate on insufficient power.

Keep a printed copy of the 2004 ford f250 fuse box diagram in your glove box. Smartphone screens can be hard to read in bright sunlight or rain, and having a physical reference makes roadside troubleshooting much faster.

- ✓ Check Grounds: Ensure the main ground strap near the battery is tight. Loose grounds are a primary cause of intermittent electrical issues.

- ✓ Inspect the Accessory Belt: A glazed or cracked belt reduces alternator efficiency, stressing the electrical system.

- ✓ Dielectric Grease: Use a small amount of dielectric grease on the prongs of engine bay fuses to prevent corrosion from moisture and road salt.

- ✓ Monitor Coolant Flow: While seemingly unrelated, a failing water pump or poor coolant flow can cause engine temperatures to rise, which increases resistance in wiring harnesses near the block, potentially leading to premature fuse failure.

When replacing heavy-duty components like the starter or alternator, always adhere to the manufacturer’s torque spec for the mounting bolts and electrical terminals. Over-tightening can crack the plastic housings of the power distribution box, while under-tightening creates resistance and heat. Furthermore, while the timing chain on the V8 and V10 engines is a mechanical component, the sensors that monitor it (like the Crankshaft Position Sensor) are protected by fuses in the main box. If you have timing-related codes, always verify the sensor’s fuse is intact before assuming a mechanical failure.

In summary, mastering the 2004 ford f250 fuse box diagram is about more than just swapping out bits of plastic. It is about understanding how power flows through your truck, from the ECU to the tailpipe. By keeping your fuses organized, your connections clean, and your belt system maintained, you ensure that your Ford F250 remains a dependable workhorse for years to come. If a fuse continues to blow after multiple replacements, it is a clear sign of a deeper wiring fault that should be inspected by a professional technician to prevent the risk of an electrical fire.

Frequently Asked Questions

Where is the 2004 Ford F250 fuse box located?

The 2004 Ford F250 features two main locations. The passenger compartment fuse panel is positioned beneath the steering wheel behind a plastic cover. The high-current power distribution box is located in the engine compartment, typically mounted on the driver’s side fender well near the firewall.

What does this fuse box diagram show?

This diagram provides a visual layout of every fuse, relay, and circuit breaker in your truck. It labels each slot with a number corresponding to its function, such as the fuel pump, trailer lights, or the ECU, allowing for rapid identification of electrical faults.

How many connections does the F250 fuse panel have?

The interior panel typically manages over 40 individual fuse connections, while the under-hood box handles high-amperage relays. Each fuse slot utilizes a two-pin connection, while relays may use four to five pins to facilitate switching larger electrical loads throughout the vehicle’s wiring harness.

What are the symptoms of a bad fuse or relay?

Common symptoms include sudden component failure, a persistent check engine light, or the inability of a scanner to read a diagnostic code because the OBD-II port lacks power. If a relay fails, you might experience a ‘crank but no start’ condition or intermittent accessory power.

Can I replace a fuse or relay myself?

Yes, replacing a fuse is one of the simplest DIY automotive tasks. Simply match the blown fuse’s location on the diagram and swap it with a new one of identical amperage. Relays are also plug-and-play, making this an accessible fix for most Ford truck owners.

What tools do I need for fuse box maintenance?

You generally only need a fuse puller tool, which is often found inside the fuse box cover. For deeper troubleshooting, a multimeter or test light is essential. If you need to remove the panel, a basic socket set may be required to meet the factory torque spec.