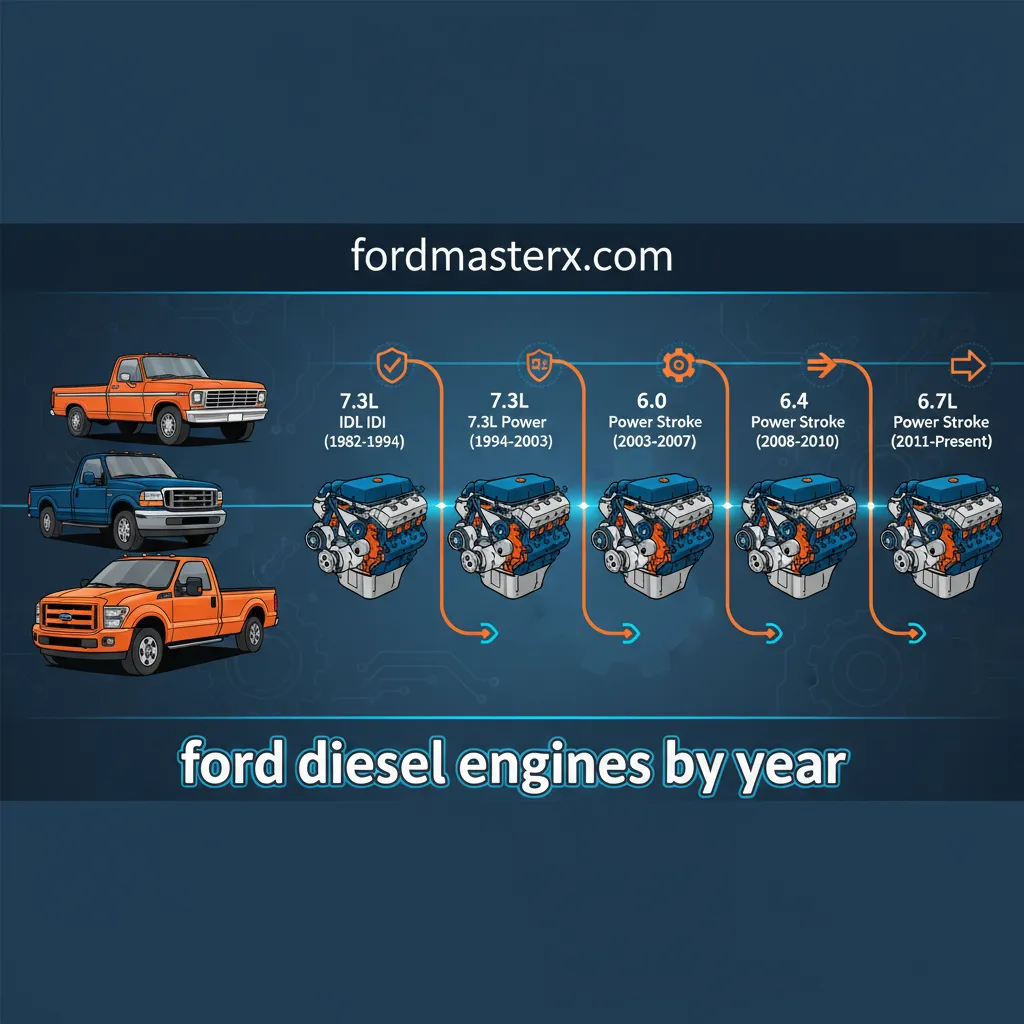

Ford Diesel Engines By Year: A Technical Guide To Generations, Reliability, And Specifications

For over four decades, Ford’s diesel powertrain lineup has been the backbone of the American work truck, evolving from simple mechanical workhorses to complex, high-output marvels. Choosing the right truck requires navigating a maze of engine displacements, reliability reputations, and changing emissions technologies across forty years of production. Whether you are a fleet manager seeking longevity or an enthusiast hunting for the legendary 7.3L, understanding the technical nuances of each generation is critical to making a sound investment. This article provides a professional, year-by-year breakdown of every Ford diesel engine, identifying which models offer the best reliability, the highest towing capacity, and the most trusted engineering.

The Foundation of Ford Diesel: 6.9L and 7.3L IDI Engines (1983–1994)

📤 Share Image

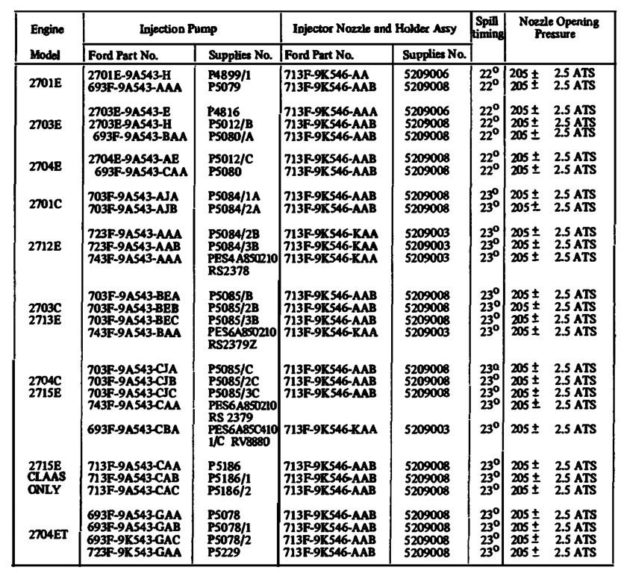

Ford’s foray into the diesel market began in 1983 through a strategic partnership with International Harvester (later Navistar). This collaboration was a direct response to the fuel crises of the 1970s and the rising competition from GM’s Detroit Diesel-powered trucks. The result was the 6.9L Indirect Injection (IDI) engine. Unlike modern common-rail systems, the IDI utilized a mechanical fuel injection system that prioritized extreme simplicity. It featured a Stanadyne rotary pump and relied on high compression ratios to ignite fuel within a pre-chamber rather than directly in the cylinder.

In 1988, the engine evolved into the 7.3L IDI. This update wasn’t just about displacement; it involved increasing the bore size to improve low-end torque. While these engines were never performance leaders—producing 170 hp in the 6.9L and up to 180 hp in the 7.3L—their lack of electronic sensors and complex emissions equipment earned them a trusted, bombproof reputation. The only significant technical hurdle was cavitation (pitting of the cylinder walls), which required the use of Supplemental Coolant Additives (SCA) to maintain block integrity.

The 1993-1994 Factory Turbocharged IDI

As the market demanded more power for towing, Ford introduced a factory-turbocharged 7.3L IDI in 1993. This served as a critical bridge between the purely mechanical era and the electronic Power Stroke era. While it only produced 190 hp and 388 lb-ft of torque, the inclusion of a turbocharger significantly improved performance at higher altitudes and laid the groundwork for the forced induction dominance that would follow.

IDI Performance Stats

6.9L HP

7.3L Turbo Torque

The 7.3L Power Stroke Era: The Benchmark for Professional Reliability (1994–2003)

The introduction of the 7.3L Power Stroke in mid-1994 changed the diesel landscape forever. While it shared the same displacement as its predecessor, it was a completely different design. The primary innovation was the HEUI (Hydraulic Electronic Unit Injection) system. This system used high-pressure engine oil to fire the fuel injectors, allowing for precise electronic control over fuel delivery. This resulted in vastly improved cold-start performance, reduced smoke, and a massive jump in torque.

In 1999, Ford launched the “Super Duty” platform, which brought further refinements to the 7.3L Power Stroke. These models introduced an air-to-air intercooler and a wastegated turbocharger, allowing the engine to produce more sustained power under heavy loads without overheating. However, buyers should note the subtle differences between “Early 99” models and late-production variants. Early 99s featured a smaller turbocharger and different intake plumbing, making them slightly less desirable for those looking to maximize aftermarket tuning.

Hardware Evolution and the “PMR” Shift

One of the most debated technical shifts occurred in 2001 when Ford transitioned from forged steel connecting rods to powdered metal rods (PMR). While PMRs are perfectly reliable for stock and moderate towing applications, high-performance enthusiasts often seek out pre-2001 blocks because the forged rods can handle significantly higher cylinder pressures during extreme tuning.

Simplicity

Lacks complex DPF/SCR systems, reducing potential failure points and maintenance costs.

Proven Durability

Frequently reaches 400,000+ miles with routine oil changes and basic sensor maintenance.

Navigating Emissions Challenges: The 6.0L and 6.4L Power Stroke Years (2003–2010)

The mid-2000s represented a turbulent era for Ford diesel as federal emissions mandates tightened. The 6.0L Power Stroke (introduced in 2003.5) was a high-tech marvel, featuring a Variable Geometry Turbocharger (VGT) that virtually eliminated turbo lag. However, its reputation was marred by several “critical failure points.” The engine utilized a smaller number of head bolts compared to the 7.3L, which often led to head gasket failure under high boost. Furthermore, the EGR (Exhaust Gas Recirculation) cooler was prone to clogging, which would eventually rupture and allow coolant into the intake.

In 2008, Ford replaced the 6.0L with the 6.4L Power Stroke. This engine introduced compound (twin) turbocharging and switched to a Siemens common-rail piezo injection system. While the 6.4L was a powerhouse—producing 350 hp—it was the first to include a Diesel Particulate Filter (DPF). The active regeneration cycles required to clean the DPF significantly reduced fuel economy and led to internal fuel dilution of the engine oil, making frequent oil analysis a necessity for professional owners.

The 6.0L and 6.4L engines require proactive maintenance to avoid catastrophic failure. If purchasing one today, ensure it has been “bulletproofed” with high-quality aftermarket head studs, a heavy-duty oil cooler, and a monitored cooling system.

📋

Professional Bulletproofing Steps

Replace factory head bolts with ARP head studs to prevent cylinder head lifting under pressure.

Install a high-efficiency external or relocated oil cooler to prevent delamination and clogging.

The In-House Revolution: The 6.7L Power Stroke ‘Scorpion’ (2011–Present)

In 2011, Ford ended its partnership with Navistar and brought diesel engine design entirely in-house. The resulting 6.7L Power Stroke, codenamed “Scorpion,” was a radical departure from traditional V8 diesel architecture. Its most striking feature is the reverse-flow cylinder head design, where the exhaust manifolds are located in the engine’s “valley,” while the intake manifolds are on the outer sides of the heads. This configuration allows for much shorter exhaust plumbing to the turbocharger, resulting in instantaneous throttle response and better thermal efficiency.

The engine block is cast from Compacted Graphite Iron (CGI), a material that is significantly stronger and lighter than traditional grey iron. This allows the 6.7L to handle the extreme cylinder pressures required to produce its massive torque figures. Over the years, Ford has refined this platform through several generations:

- Gen 1 (2011–2014): Featured the GT32 Single Sequential Turbo. While innovative, the ceramic bearings were a known failure point.

- Gen 2 (2015–2016): Switched to the larger GT37 turbo with traditional ball bearings, solving the reliability issues and increasing high-altitude towing capability.

- Gen 3 (2020+): Introduced steel pistons to replace aluminum, allowing for higher combustion temperatures and increased longevity. It also upgraded to the CP4.2 fuel pump with improved internals.

The 2023 High Output (HO) Variant

The current pinnacle of Ford diesel engineering is the 2023 6.7L High Output Power Stroke. It produces a class-leading 500 hp and 1,200 lb-ft of torque. To manage this power, Ford integrated water-cooled turbo housings and stainless steel exhaust manifolds. This engine is designed specifically for professionals who regularly tow 30,000+ pounds and require a powertrain that can handle the thermal stress of heavy commercial use.

For 2011–2019 models using the Bosch CP4.2 high-pressure fuel pump, consider installing a disaster prevention kit (bypass kit). This prevents metal debris from entering the fuel injectors and rails if the pump fails, potentially saving you $10,000 in repair costs.

Ford Diesel Options in Light-Duty and Commercial Applications

While the Super Duty dominates the conversation, Ford has also offered specialized diesel engines for smaller applications. The 3.0L Power Stroke V6 (2018–2021) was designed specifically for the F-150. Based on the Lion V6 architecture used by Land Rover, it achieved a best-in-class EPA-estimated 30 mpg on the highway. It provided a quiet, refined driving experience with 440 lb-ft of torque, making it an excellent choice for light-duty towing where fuel efficiency was the primary concern.

In the commercial sector, the 3.2L I-5 Power Stroke (Duratorq) served as the workhorse for the Ford Transit. This inline-five engine is renowned globally for its serviceability. Unlike the high-performance V8s, the 3.2L was tuned for stop-and-go urban delivery duty. Its simple common-rail injection system and robust cooling design make it one of the most reliable engines in Ford’s European and commercial fleets.

In summary, Ford’s diesel history is a journey of constant engineering evolution. The 7.3L Power Stroke remains the benchmark for long-term mechanical quality, while the 6.0L and 6.4L eras require specific maintenance and aftermarket upgrades to ensure professional-grade reliability. The modern 6.7L Power Stroke represents the pinnacle of Ford’s in-house engineering, offering a level of towing performance that was unimaginable a decade ago. Whether you are purchasing a used Super Duty or a new High Output 6.7L, always verify the service history and ensure all recalls for that specific engine year have been addressed by a certified technician to protect your investment.

Frequently Asked Questions

What is the most reliable Ford diesel engine by year?

The 7.3L Power Stroke, produced between 1994 and 2003, is widely considered the most reliable. Its combination of a simple HEUI injection system, low-stress turbocharging, and heavy-duty internal components allows it to frequently surpass 400,000 miles with basic maintenance. It avoids the complex EGR and DPF systems that complicated later generations.

Which years of the Ford 6.0L diesel should I avoid?

The early 6.0L Power Stroke models (2003–2005) generally had the highest failure rates regarding fuel injection control modules (FICM) and head gaskets. While 2006–2007 models saw improvements, any 6.0L purchase should be contingent on ‘bulletproofing,’ which involves upgrading the oil cooler, EGR cooler, and installing head studs to ensure expert-level reliability.

Is the 6.7L Power Stroke better than the 7.3L?

From a performance and technology standpoint, yes. The 6.7L offers significantly more horsepower and triple the torque of the 7.3L, along with better refinement. However, the 7.3L is simpler and cheaper to repair. Professionals seeking maximum towing power choose the 6.7L, while those prioritizing mechanical simplicity often prefer the 7.3L.

When did Ford start making its own diesel engines?

Ford began manufacturing its own diesel engines in-house with the release of the 6.7L Power Stroke in 2011. Prior to this, all Ford diesel engines were produced in partnership with International Harvester (Navistar). This transition allowed Ford to control the entire design process, resulting in the highly successful ‘Scorpion’ engine platform.

What is the ‘High Output’ 6.7L Power Stroke?

Introduced in 2023, the High Output (HO) version of the 6.7L Power Stroke features a water-cooled turbocharger and upgraded exhaust manifolds. These enhancements allow the engine to produce a class-leading 500 horsepower and 1,200 lb-ft of torque, specifically designed for heavy-duty commercial towing and extreme duty cycles.