The Ultimate Technical Analysis of Ford Bolt Patterns: A Comprehensive Engineering and Fitment Guide

In the domain of automotive engineering, few specifications are as critical yet frequently misunderstood as the wheel bolt pattern, technically referred to as the Pitch Circle Diameter (PCD). For Ford Motor Company, a manufacturer with a lineage spanning over a century of mass production, the evolution of wheel fastening systems serves as a historical record of chassis development, payload capacity increases, and the globalization of automotive platforms.

This report serves as a definitive “pillar page” resource, synthesizing data from over seventy years of production to provide an exhaustive reference for technicians, wheel fitment specialists, and automotive enthusiasts.

The necessity for such a comprehensive guide arises from the sheer diversity of Ford’s lineup. Unlike manufacturers that may standardize a single pattern across their entire fleet for decades, Ford has engineered specific fastening solutions tailored to the unique dynamic loads of each platform.

From the legacy SAE (Society of Automotive Engineers) imperial measurements of the mid-20th century to the precise metric standards of the modern “One Ford” global architecture, understanding these patterns is not merely a matter of aesthetics—it is a matter of mechanical safety and structural integrity.

A bolt pattern is defined by two primary integers: the count of the lug nuts and the diameter of the imaginary circle that passes through the center of each lug hole. While this appears simple in theory, the practical application involves a complex interplay of measurement standards (SAE vs. Metric), hub-centric versus lug-centric designs, and model-specific nuances such as the 7-lug Heavy Duty Payload Packages or the orphan 5x135mm pattern of the tenth-generation F-Series.

This report will dissect these elements with granular precision, ensuring that whether a user is restoring a 1966 Bronco or upfitting a 2026 F-150 Lightning, the fitment data is accurate, verified, and contextually grounded in engineering reality.

The Ultimate Ford Bolt Pattern Guide

Fitment, Safety, and Performance. Decoded.

How to Measure Your Bolt Pattern

Getting this wrong means your new wheels won’t fit. The method changes depending on how many lugs you have. Ford primarily uses 4, 5, 6, and 8 lug configurations.

4-Lug Patterns

Common on: Fox Body Mustang, Focus, Escort

Measure from the center of one hole to the center of the opposite hole.

5-Lug Patterns

Common on: Modern Mustang, Ranger, Explorer

Measure from the back edge of one hole to the center of the opposite hole.

The “Big Three” Ford Patterns

While Ford has used dozens of bolt patterns over the last century, three configurations dominate the modern landscape. Understanding these covers 90% of Ford vehicles on the road today.

-

1

5×114.3mm (5×4.5″) The “Universal” Ford pattern. Used on Mustangs since 1994, Rangers, Explorers, and many sedans.

-

2

6x135mm The modern Truck standard. Introduced with the 2004 F-150 and used on Expeditions/Navigators.

-

3

5x135mm The “Transition” Truck pattern. Exclusively found on 1997-2003 F-150s and Expeditions.

Estimated distribution based on production volume of popular models 1990-2023.

The Evolution of the F-Series

As the F-150 grew in capability and payload, its bolt pattern evolved to handle the stress.

5 x 139.7mm (5 x 5.5″)

The classic “old school” truck pattern. Shared with Jeeps and older Dodges. Known for compatibility with a massive range of aftermarket off-road wheels.

5 x 135mm

The “Jellybean” Era. Ford introduced a unique metric pattern for the 10th Gen F-150. Finding wheels for this specific era can be difficult as it wasn’t used long.

6 x 135mm

The Modern Standard. With the 11th Gen F-150, Ford moved to a 6-lug design to support larger brake rotors and higher payload capacities. The HD Payload package occasionally used 7-lug (7x150mm).

Platform Comparison: Lug Count Analysis

Comparing standard lug counts across Ford’s most popular vehicle families over time.

Torque Matters

Incorrect torque is the #1 cause of warped rotors and sheared studs. The torque spec isn’t determined by the wheel, but by the stud size.

12mm Studs (Older Cars)

Common on older Mustangs/Rangers. DO NOT overtighten to modern truck specs.

14mm Studs (Modern F-150/Mustang)

Standard for S550 Mustangs and 2004+ F-150s. Requires significantly more torque.

Popular Model Quick Lookup

| Model Family | Years | Bolt Pattern (Metric) | Bolt Pattern (Inch) | Stud Size |

|---|---|---|---|---|

| Mustang | 1994 – Present | 5 x 114.3 | 5 x 4.5″ | 1/2″ (Old) / 14×1.5 (New) |

| Mustang (Fox) | 1979 – 1993 | 4 x 108 | 4 x 4.25″ | 1/2″ |

| F-150 | 2004 – Present | 6 x 135 | – | 14×2.0 / 14×1.5 |

| F-150 | 1997 – 2003 | 5 x 135 | – | 12mm / 14mm |

| Explorer | 1991 – 2010 | 5 x 114.3 | 5 x 4.5″ | 1/2″ |

| Explorer | 2011 – 2019 | 5 x 114.3 | 5 x 4.5″ | 1/2″ |

| Focus | 2012 – 2018 | 5 x 108 | 5 x 4.25″ | 12×1.5 |

| F-250 Super Duty | 1999 – Present | 8 x 170 | – | 14×1.5 |

* Always verify fitment with your specific VIN before purchasing wheels.

© 2026 FordMasterX Infographics. Data sourced from manufacturer owner manuals.

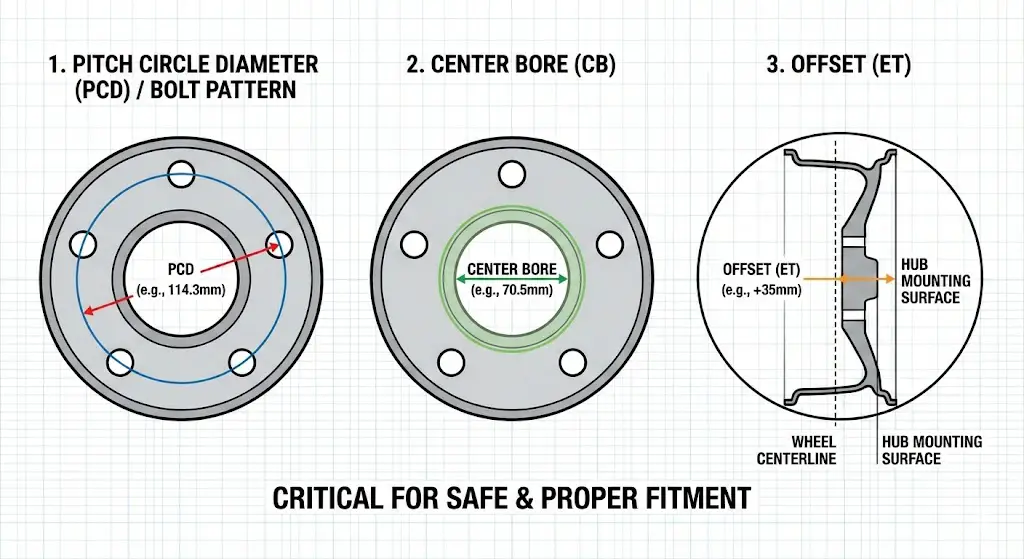

The Physics and Geometry of Wheel Fitment

Before delving into model-specific charts, it is imperative to establish a robust understanding of the geometric principles governing wheel fitment. The “bolt pattern” is only one variable in a multivariable equation that includes Center Bore (CB), Offset (ET), and Backspacing. Failure to account for any single variable can result in catastrophic wheel separation, suspension interference, or accelerated bearing failure.

Pitch Circle Diameter (PCD) Analysis

The Pitch Circle Diameter is the foundational metric of wheel compatibility. For Ford vehicles, this measurement has transitioned from Imperial inches to Metric millimeters, creating a bifurcation in the aftermarket.

The legacy standard, often referred to as “Small Ford,” is the 5×4.5 inch pattern. In modern engineering terms, this is mathematically equivalent to 5×114.3 mm.1 This equivalence is derived from the conversion factor where 1 inch equals 25.4 millimeters (4.5 x 25.4 = 114.3). Consequently, a wheel manufactured in the 1960s for a Mustang using imperial tooling is theoretically compatible with a 2024 Ford Explorer manufactured with metric tooling, provided the other variables (bore and offset) align.

Conversely, the “Big Ford” pattern, utilized on trucks and large SUVs, is 5×5.5 inches, which converts to 5×139.7 mm. This pattern was the industry standard for half-ton trucks for nearly half a century, shared with manufacturers like Dodge and Jeep, creating a massive ecosystem of interchangeable parts. However, the introduction of the metric system in the late 1990s brought about unique patterns like 5×135 mm and 6×135 mm, which have no imperial whole-number equivalents, deliberately segregating Ford fitments from competitors to ensure load-rating compliance.

The Hub-Centric Imperative

A critical distinction in Ford chassis design is the reliance on hub-centric wheel mounting. In a hub-centric system, the vehicle’s weight is supported by the wheel hub’s collar, which fits snugly into the wheel’s center bore. The lug nuts serve primarily to secure the wheel laterally against the rotor face, rather than bearing the vertical shear loads of the vehicle’s mass.

For example, the modern Ford F-150 utilizes a hub bore of 87.1 mm. If a technician attempts to install a wheel with a larger bore (e.g., a generic aftermarket wheel with a 106mm bore) without a hub-centric ring, the assembly becomes “lug-centric.” Under these conditions, the studs are subjected to cyclic shear stress with every rotation of the wheel. Over time, this leads to vibration, loosened lug nuts, and potential stud failure. This report emphasizes that matching the bolt pattern is insufficient; the center bore must either match the hub or be adapted via precision rings to maintain the integrity of the factory engineering.

Measuring Methodology: Precision Protocols

Accurate identification of a bolt pattern is the first line of defense against fitment errors. The methodology differs significantly based on the lug count.

Measuring Even-Lug Patterns (4, 6, 8 Lugs):

For Ford vehicles with even lug counts—such as the Fiesta (4-lug), F-150 (6-lug), or Super Duty (8-lug)—measurement is linear and straightforward. The technician must measure from the precise center of one stud to the precise center of the stud directly opposite it.7 This straight-line distance is the PCD. For an F-250, measuring across the hub from stud to stud will yield 170mm.

Measuring 5-Lug Patterns (The Geometric Challenge):

The 5-lug pattern, ubiquitous on the Mustang, Explorer, and Ranger, presents a geometric challenge because no stud has a directly opposing counterpart. A common error involves measuring from center-to-center of adjacent studs, which yields a useless chord length rather than the diameter.

To accurately approximate the PCD on a 5-lug Ford hub, one must measure from the center of one stud to the outer edge of the third stud (the stud furthest away in the star pattern).7 While this method is an approximation, it is sufficiently accurate to distinguish between the two most common Ford 5-lug patterns:

- 5×108 mm (4.25 inches): Found on Focus, Fusion, Edge, Bronco Sport, Maverick.

- 5×114.3 mm (4.5 inches): Found on Mustang, Explorer, Ranger (pre-2011), Flex, Taurus.

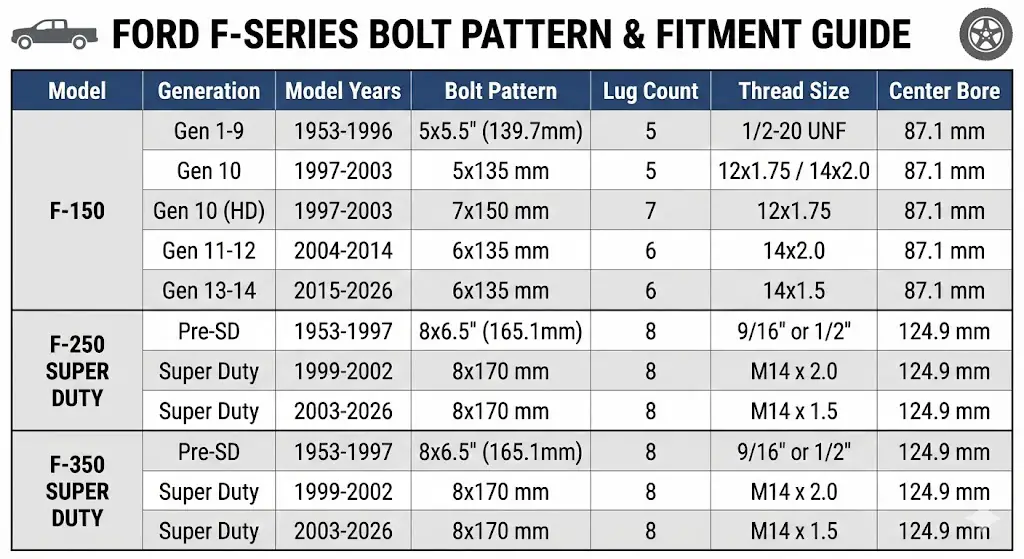

The F-Series Dynasty: Light Duty Evolution (F-100 / F-150)

The Ford F-Series has been the best-selling vehicle in the United States for decades. Its bolt pattern history is not random; it tracks the vehicle’s transition from a pure utility implement to a sophisticated, multi-purpose passenger vehicle.

The Classic Era (1953–1996): The 5×5.5 Standard

For over forty years, the Ford F-100 and F-150 utilized a unified standard that became legendary in the off-road community.

- Bolt Pattern: 5 x 5.5 inches (5 x 139.7 mm)

- Stud Size: 1/2-20 UNF

- Hub Bore: ~87.1 mm

This era encompasses the “Bump side,” “Dent side,” “Bullnose,” “Bricknose,” and “OBS” (Old Body Style) generations. The 5×5.5 pattern was robust, offering a wide bolt circle that distributed torque load effectively across the hub face, which was essential for the solid front axles and Twin I-Beam suspensions of the time. The interchangeability of this pattern with the Jeep CJ series and older Dodge Ram 1500s created a vast aftermarket of wheels, many of which are still in circulation today.

The Transitional “Aero” Era (1997–2003): The Metric Shift

The release of the tenth-generation F-150 (PN96 platform) in 1997 marked a radical departure in Ford’s truck engineering. Coinciding with the new aerodynamic body and modular overhead-cam engines, Ford switched to a purely metric chassis system.

- Bolt Pattern: 5 x 135 mm

- Stud Size: 12mm x 1.75 (1997-1999); 14mm x 2.0 (2000-2003)

- Engineering Context: This 5x135mm pattern is unique to this specific generation of F-150, the first-generation Expedition, and the Lincoln Navigator. It is effectively an “orphan” spec. It is not interchangeable with the earlier 5×5.5 pattern, nor the later 6-lug patterns. This creates a specific sourcing difficulty for owners of these trucks, as modern wheel manufacturers rarely produce new designs in 5x135mm due to the limited vehicle population remaining on the road.

The 7-Lug Anomaly (Heavy Duty Payload Package):

Within this era, Ford produced a specific variant known as the F-250 Light Duty (later rebadged as the F-150 7700). These vehicles utilized a 7 x 150 mm bolt pattern.12 This 7-lug configuration was an engineering bridge, offering higher clamping force than the 5-lug setup but without the weight penalty of the 8-lug Super Duty axle. These wheels are exceptionally rare and represent a significant hurdle for restoration or modification.

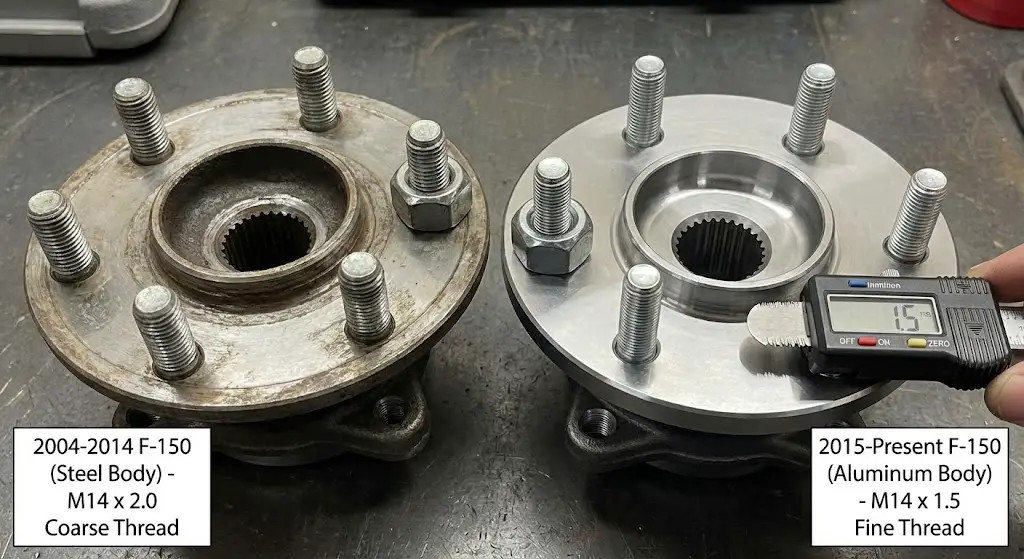

The Modern Standard (2004–2026): The 6-Lug Revolution

With the eleventh-generation F-150 (P221) introduced in 2004, Ford implemented a fully boxed hydroformed frame and significantly increased towing capacities. To accommodate the higher gross vehicle weight ratings (GVWR), the hub assembly was redesigned to a 6-lug configuration.

- Bolt Pattern: 6 x 135 mm

- Hub Bore: 87.1 mm

This 6x135mm pattern has remained the standard for over two decades, covering the steel-body trucks (2004-2014) and the aluminum-body trucks (2015-Present). However, a critical nuance exists regarding the wheel studs.

- 2004–2014: Used M14 x 2.0 lug nuts.

- 2015–Present: Switched to M14 x 1.5 lug nuts.10While the bolt pattern and center bore remained constant, the thread pitch change means that lug nuts are not interchangeable between the steel and aluminum generations. A technician using 2014 lug nuts on a 2016 truck would strip the threads, leading to potential wheel failure.

The F-150 Lightning (2022–Present): EV Specifics

The electrification of the F-Series with the F-150 Lightning introduced immense battery weight and instant torque, necessitating a re-evaluation of wheel load ratings.

- Bolt Pattern: 6 x 135 mm

- Load Requirements: Although the Lightning shares the 6×135 bolt pattern with the internal combustion F-150, standard F-150 wheels may not possess the structural integrity to support the Lightning’s curb weight, which can exceed 6,500 lbs.

- Insight: Aftermarket wheels for the Lightning must be explicitly rated for “Heavy Duty” or EV applications. Brands like Fuel and Method have released specific variants with reinforced spoke structures to handle the torque output while maintaining the 6×135 geometry.

Table 3.1: Ford F-150 Bolt Pattern & Fitment Matrix

| Generation | Model Years | Chassis Code | Bolt Pattern | Lug Count | Thread Size | Center Bore |

| Gen 1-9 | 1953–1996 | Various | 5 x 5.5″ (139.7mm) | 5 | 1/2-20 UNF | 87.1 mm |

| Gen 10 | 1997–2003 | PN96 | 5 x 135 mm | 5 | 12×1.75 / 14×2.0 | 87.1 mm |

| Gen 10 (HD) | 1997–2003 | PN96 (7700) | 7 x 150 mm | 7 | 12×1.75 | 87.1 mm |

| Gen 11 | 2004–2008 | P221 | 6 x 135 mm | 6 | 14×2.0 | 87.1 mm |

| Gen 12 | 2009–2014 | P415 | 6 x 135 mm | 6 | 14×2.0 | 87.1 mm |

| Gen 13 | 2015–2020 | P552 | 6 x 135 mm | 6 | 14×1.5 | 87.1 mm |

| Gen 14 | 2021–2026 | P702 | 6 x 135 mm | 6 | 14×1.5 | 87.1 mm |

| Lightning | 2022–2026 | P702 (EV) | 6 x 135 mm | 6 | 14×1.5 | 87.1 mm |

The Heavy Haulers: Super Duty (F-250 / F-350 / F-450)

The Ford Super Duty line represents the commercial backbone of the brand. The bolt pattern selection here is driven entirely by clamping force and axle weight ratings (GAWR). The divergence of the F-250 from the F-150 in 1999 created a separate lineage of fitment that remains distinct to this day.

Pre-Super Duty Era (1953–1997): The SAE Standard

Before 1999, the F-250 and F-350 shared the same cab as the F-150 but utilized the industry-standard 8-lug pattern found on heavy trucks from GM and Dodge.

- Bolt Pattern: 8 x 6.5 inches (8 x 165.1 mm)

- Stud Configuration: 9/16″ or 1/2″ studs depending on GVWR.

- Interchangeability: This era offered high cross-compatibility. A wheel from a 1980 Chevy K20 could often fit a 1985 Ford F-250, provided the center bore (which was largest on the Ford at ~124.9mm) cleared the hub. This 8×6.5 pattern is legendary for its ubiquity and is still used by Dodge (Ram) today, but Ford abandoned it over 25 years ago.

The Metric Super Duty (1999–2026): 8x170mm

With the launch of the dedicated PHN131 Super Duty platform in early 1998 (as a 1999 model), Ford revolutionized the heavy truck market. Engineering analysis necessitated a switch to a metric, hub-centric interface to improve wheel centering and reduce the incidence of wheel-off events under heavy towing loads.

- Bolt Pattern: 8 x 170 mm

- Center Bore: 124.9 mm

- Stud Size: M14 x 2.0 (1999-2002); M14 x 1.5 (2003-Present)

The move to 170mm (approx 6.69 inches) meant that old 8×6.5 wheels would physically not fit over the studs of the new trucks. This was a deliberate engineering firewall to prevent the use of older, lower-load-rated wheels on the more capable Super Duty chassis.

The Offset Migration (2005 Update):

While the bolt pattern remained 8x170mm, the offset requirements changed drastically in 2005.

- 1999–2004: Utilized leaf spring front suspension (4WD). Wheels had lower offsets (approx -6mm to +10mm) because the axles were narrower.

- 2005–Present: Ford switched to a Radius Arm coil spring front suspension. The axles were widened to improve turning radius. Consequently, wheels required high positive offsets (+40mm to +55mm) to keep the tires under the fenders.

- Fitment Warning: Installing 1999-spec wheels on a 2010 Super Duty will cause the tires to stick out approximately 2 inches past the fenders, wreaking havoc on wheel bearings and scrubbing the fender arches during turns.

The Behemoths: F-450 and Wide Track

For the F-450 and F-550, the 8x170mm pattern is insufficient for the extreme Gross Combined Weight Ratings (GCWR), which can exceed 40,000 lbs.

- F-450 Pickup (2011–Present): Utilizes an 8 x 200 mm bolt pattern. This massive circle allows for significantly larger wheel studs and hub structures.

- F-450/F-550 Chassis Cab: Older models and current heavy chassis cabs often utilize a 10 x 225 mm pattern. This is a commercial vehicle standard, often requiring pneumatic torque multipliers for service.

Table 4.1: Ford Super Duty Bolt Pattern & Fitment Matrix

| Model | Year Range | Bolt Pattern | Lug Count | Offset Profile | Center Bore |

| F-250/350 (OBS) | 1953–1997 | 8 x 6.5″ (165.1mm) | 8 | Low / Zero | 124.9 mm |

| Super Duty (Leaf) | 1999–2004 | 8 x 170 mm | 8 | Low (+10mm) | 124.9 mm |

| Super Duty (Coil) | 2005–2026 | 8 x 170 mm | 8 | High (+40mm) | 124.9 mm |

| F-450 Pickup | 2011–2026 | 8 x 200 mm | 8 | Dually (Front/Rear distinct) | 142.0 mm |

| F-450/550 Cab | Various | 10 x 225 mm | 10 | Commercial | varies |

The Ranger Evolution: From Compact to Global Mid-Size

The Ford Ranger’s bolt pattern history offers a fascinating case study in platform globalization. The shift from a US-designed compact truck to an Australian-designed global mid-size truck necessitated a complete change in wheel fitment specifications.

The Compact Ranger (1983–2011)

The Ranger that defined the segment in the 1990s was built on a dedicated North American platform. It shared significant suspension components with the Ford Explorer (1st/2nd Gen) and the Bronco II.

- Bolt Pattern: 5 x 114.3 mm (5 x 4.5 inches)

- Center Bore: 70.3 mm

- Context: This is arguably the most common 5-lug pattern in automotive history. Ranger owners could easily swap wheels with Jeep Wranglers (YJ/TJ), Ford Mustangs, and older Toyota pickups (5-lug variants). This interchangeability fueled a massive budget off-road culture.

The T6 Global Ranger (2019–2023)

When Ford reintroduced the Ranger to North America in 2019, it did not resurrect the old platform. Instead, it imported the T6 platform, which had been engineered by Ford Australia and sold globally since 2011.

- Bolt Pattern: 6 x 139.7 mm (6 x 5.5 inches)

- Center Bore: 93.1 mm

- Stud Thread: M12 x 1.5

- Offset: High Positive (+55mm)

The 6-Lug Shift: The move to 6-lugs aligned the Ranger with the global standard for mid-size trucks. The Toyota Tacoma, Chevy Colorado, and Nissan Frontier all utilize the 6×139.7 pattern. However, the Ranger requires a uniquely high offset (+55mm). Installing a standard Chevy wheel (typically +30mm) on a Ranger pushes the wheel outward by 25mm (1 inch), which is often desirable for stance but can cause rubbing on the crash bars located in the front wheel wells.

The Next-Gen Ranger (P703) (2024–2026)

The newest iteration of the Ranger continues the T6 lineage but with a wider track and updated suspension geometry.

- Bolt Pattern: 6 x 139.7 mm

- Center Bore: 93.1 mm

- Ranger Raptor: Like the Bronco Raptor, the Ranger Raptor is a specialized high-performance machine. However, unlike the Bronco Raptor (which switches to F-150’s 6×135), the global Ranger Raptor generally maintains the 6×139.7 pattern to ensure compatibility with the extensive overland aftermarket developed in Australia, although exact fitment for US-spec Raptors should always be verified against the specific VIN due to regional variations. Note: Always check the specific US-market build sheet, as Ford Performance sometimes mixes parts bins.

The Bronco Ecosystem: A Tale of Two Platforms

One of the most frequent sources of confusion for consumers in the 2020s is the distinction between the “Bronco” and the “Bronco Sport.” Despite sharing a brand name and styling cues, these vehicles share zero mechanical DNA regarding wheels.

6.1 Ford Bronco (2021–2026): The Off-Road Icon

The full-size Bronco is a body-on-frame truck derived from the Ranger’s T6 chassis. As such, it inherits the truck-grade wheel specifications.

- Bolt Pattern: 6 x 139.7 mm (6 x 5.5 inches)

- Center Bore: 93.1 mm

- Lug Nut Thread: M12 x 1.5

- Fitment Interchange: There is direct interchangeability between the 2019+ Ranger and the 2021+ Bronco. Ranger owners frequently purchase “take-off” wheels from Bronco owners who are upgrading to aftermarket beadlocks. The Bronco wheels (often 17×7.5 or 17×8) fit the Ranger perfectly, filling out the wheel wells slightly better due to the aggressive tire compounds used on Bronco trims like the Badlands.

The Bronco Raptor Exception:

The Bronco Raptor is engineered by Ford Performance and utilizes suspension components derived from the F-150 Raptor to withstand high-speed desert running.

- Bolt Pattern: 6 x 135 mm

- Why? This prevents standard Bronco owners from installing Raptor wheels without adapters, but more importantly, it allows the Bronco Raptor to share the heavy-duty hub assemblies of the F-150, which are designed for the extreme leverage forces generated by 37-inch tires and wide-track suspension arms.

Ford Bronco Sport (2021–2026): The Crossover

The Bronco Sport is built on the C2 unibody platform, shared with the Ford Escape and Ford Maverick. It is mechanically a car, not a truck.

- Bolt Pattern: 5 x 108 mm

- Center Bore: 63.4 mm

- Implication: A consumer who buys a set of rugged 6-lug wheels intended for a “Bronco” will find they are physically incompatible with their Bronco Sport. Bronco Sport owners must shop for wheels compatible with the Ford Escape, Ford Focus ST, or Ford Maverick.

The Mustang Lineage: Performance and Heritage

The Ford Mustang has carried the banner for American performance since 1964. Its bolt pattern has remained remarkably consistent, with only a few deviations for specific eras.

The Fox Body Anomaly (1979–1993)

The Fox platform Mustangs are legendary for their customizability, but their stock wheel hubs are a known weak point for performance builds.

- Bolt Pattern: 4 x 108 mm (4 x 4.25 inches)

- Limitations: The 4-lug pattern limits the clamping force available for high-horsepower launches and severely restricts wheel choice.

- The 5-Lug Swap: A rite of passage for Fox Body owners is the “5-Lug Swap,” which involves installing rotors and drums/axles from the Lincoln Mark VII (for the front) and Ford Ranger (for the rear) to convert the car to the 5×114.3 standard. This opens up the vast catalog of SN95 and S197 Mustang wheels to the older chassis.

The Modern Era (1994–2026): The 5×114.3 Standard

From the SN95 generation through the current S650, the Mustang has adhered to the classic Ford pattern.

- Bolt Pattern: 5 x 114.3 mm

- Center Bore: 70.5 mm

- Stud Thread:

- 1994–2014: 1/2-20 UNF

- 2015–Present (S550/S650): M14 x 1.5

Brake Clearance Nuance:

While a 2005 Mustang wheel has the same bolt pattern as a 2024 Mustang GT wheel, fitment is not guaranteed. The S550 (2015+) and S650 Performance Pack models feature massive 6-piston Brembo brake calipers. Wheels for these cars require specific “high-disc” or “concave” spoke designs to clear the caliper face. A flat-spoke wheel from an older model will lock up against the caliper, rendering the car immovable.

Mustang Mach-E: The EV Divergence

The Mach-E controversy extends to its wheels. Despite the Mustang badge, it does not share the Mustang platform.

- Bolt Pattern: 5 x 108 mm

- Center Bore: 63.4 mm

- Reasoning: Built on the GE1 (Global Electrified 1) platform, derived from the C2 architecture, the Mach-E shares its running gear with the Edge and Escape. This allows Ford to streamline supply chains for the EV SUV but frustrates enthusiasts hoping to put classic Mustang wheels on their electric crossover.

The SUV Landscape: Explorer, Expedition, Edge, Escape

Ford’s SUV lineup requires careful navigation, as models have shifted between truck-based and car-based platforms multiple times.

Ford Explorer

- Gen 1-4 (1991–2010): Body-on-frame (Truck). Used 5 x 114.3 mm.

- Gen 5 (2011–2019): Unibody (D4 Platform). Remained 5 x 114.3 mm. This is notable because its platform mate, the Taurus, used 5×108. The Explorer kept the larger pattern for load handling.

- Gen 6 (2020–2026): RWD Unibody (CD6). 5 x 114.3 mm. Hub bore increased to 70.5 mm (same as Mustang) to allow for shared wheel designs between the RWD performance vehicles.

Ford Expedition

- Gen 1 (1997–2002): 5 x 135 mm (Shared with F-150 PN96).

- Gen 2-4 (2003–2026): 6 x 135 mm (Shared with modern F-150).

- Fitment Note: Expedition wheels are generally interchangeable with F-150 wheels of the corresponding generation, making F-150 take-offs a prime source for Expedition upgrades.

Ford Edge & Escape

These crossovers are the backbone of the 5×108 mm ecosystem.

- Ford Edge (2015+): 5 x 108 mm. Note that the 2007-2014 Edge used 5×114.3 mm.

- Ford Escape (2013+): 5 x 108 mm.

- Bolt Pattern: 5 x 108 mm is often referred to as “5×4.25” in older literature. It is shared with modern Volvos (XC90, XC60) due to Ford’s ownership of Volvo during the platform’s development phase. This opens a unique “Euro-style” wheel market for Ford crossover owners.

The Maverick: The New Compact Truck Standard

The Ford Maverick has disrupted the truck market by offering utility on a unibody chassis. Because it is built on the C2 platform alongside the Bronco Sport and Escape, it adheres to passenger car specs.

- Bolt Pattern: 5 x 108 mm

- Center Bore: 63.4 mm

- Lug Torque: 150 Nm (110 ft-lbs)

- Aftermarket Strategy: Maverick owners seeking aggressive wheels often struggle with the lack of “truck” wheels in 5×108 pattern. The best solution is often found in the Focus RS and Focus ST aftermarket. Rally-inspired wheels from brands like Sparco or OZ Racing, designed for the Focus, fit the Maverick perfectly and complement its compact proportions.

Technical Reference: Lug Nut Types and Torque

Selecting the correct wheel is futile if it is not fastened correctly. Ford has used various lug nut seats and thread pitches.

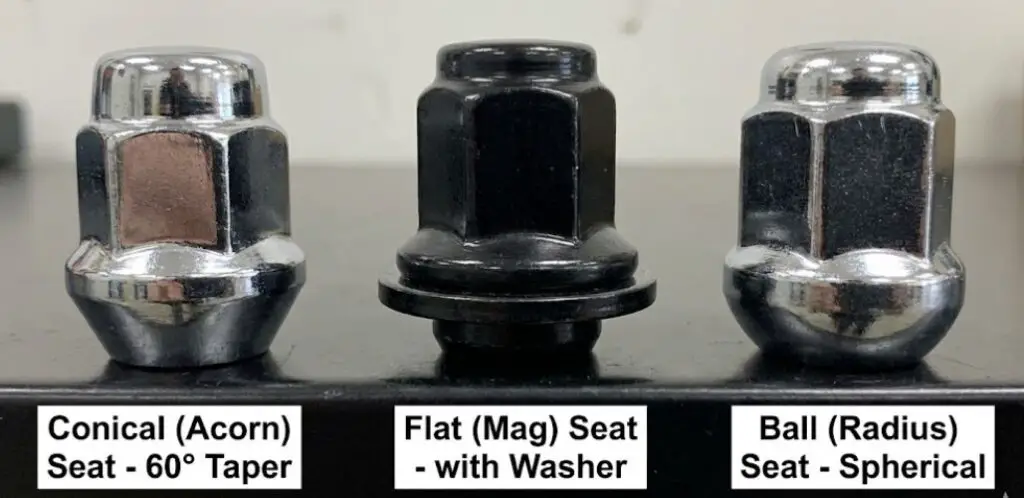

Lug Nut Seat Types

- Conical (Acorn) Seat (60 degrees): The industry standard for Ford aluminum wheels. The nut tapers to a point.

- Flat (Mag) Seat: Used on some older heavy-duty steel wheels and hub-centric dual-wheel applications.

- Ball (Radius) Seat: Rare on Fords (common on Honda/VW), but sometimes found on specific steel spare wheels.

- Warning: Mismatching seats (e.g., using a conical nut on a flat-seat wheel) will cause the nut to loosen and the wheel to detach.

Thread Pitch Evolution

The most dangerous trap for Ford technicians is the F-150 thread pitch change.

- M14 x 2.0: Coarse thread. Used on F-150 (2004-2014), Expedition (2003-2014), F-250 (1999-2002).

- M14 x 1.5: Fine thread. Used on F-150 (2015+), Expedition (2015+), F-250 (2003+), Mustang (2015+), Bronco, Ranger (2019+).

- Visual ID: Fine thread studs have threads that appear closer together. Never force a lug nut; if it offers resistance by hand, stop immediately.

Torque Specifications

Modern Ford specifications have increased torque values to ensure clamping force on metric studs.

- Maverick / Escape / Focus: 100-110 lb-ft.

- Ranger / Bronco: 100 lb-ft.

- Mustang (S550/S650): 150 lb-ft. (Note: This is very high for a passenger car).

- F-150 (2015+): 150 lb-ft.

- Super Duty (F-250/350): 165 lb-ft.

Advanced Fitment: Adapters and Conversion

When the desired wheel does not exist in the vehicle’s bolt pattern, enthusiasts turn to adapters.

The 6×135 to 6×139.7 Conversion

This is the most common adapter request. F-150 owners (6×135) want to run the vast array of 6×139. wheels available for Chevy/Toyota/Bronco.

- Feasibility: Highly feasible.

- Requirement: The adapter must be hub-centric to vehicle (87.1mm) and hub-centric to wheel (usually 106mm or 78.1mm).

- Thickness: Adapters are typically 1.25″ to 1.5″ thick. This lowers the effective offset of the wheel. If the new wheel has a +0mm offset, adding a 1.5″ adapter makes the final offset approx -38mm, which is an extremely aggressive “stance” setup that will likely require fender cutting.

The “Spacer” vs. “Adapter” Danger

- Slip-on Spacer: A thin metal disc (3mm-5mm) placed between hub and wheel. Generally safe if lug nuts still have 7+ full turns of engagement.

- Bolt-on Adapter: A billet block with its own studs. Safe if torque specs are followed.

- Danger Zone: Using a slip-on spacer thicker than 5mm without extended studs. This leaves insufficient thread engagement, leading to wheel separation.

Conclusion: The Roadmap to Safe Fitment

The landscape of Ford bolt patterns is a map of the company’s engineering priorities over the last century. From the enduring utility of the 5×5.5 pattern to the specialized load-bearing capacity of the 8×170 Super Duty interface, every number represents a design decision focused on safety and performance.

For the modern Ford owner, the key takeaways are verified data and precise measurement. The bifurcation of the lineup into “Truck/Off-Road” (6×139.7), “Heavy Duty” (8×170), “Light Duty” (6×135), and “Crossover/Car” (5×108) provides a predictable framework. However, the nuances of thread pitch (M14x2.0 vs 1.5) and hub bore (63.4 vs 70.5) remain the details that separate a perfect fitment from a mechanical failure.

As Ford transitions to the TE1 (Truck Electric) and GE2 (Global Electrified) platforms, we may see further consolidation or new heavy-duty standards emerging to cope with the mass of solid-state batteries. Until then, adhering to the generation-specific charts provided in this report is the only way to ensure the safety and longevity of your Ford vehicle’s rolling stock.

Frequently Asked Questions

Q: Can I use F-150 wheels on my 2024 Ford Ranger?

A: No. The modern F-150 uses a 6×135 mm pattern, while the 2019-2026 Ranger uses a 6×139.7 mm pattern. They are not compatible without adapters.

Q: Do Bronco Sport wheels fit the Maverick?

A: Yes. Both vehicles share the C2 platform with a 5×108 mm bolt pattern and 63.4 mm center bore. They are directly interchangeable.

Q: Why did Ford change the F-150 lug nuts in 2015?

A: The switch from M14x2.0 to M14x1.5 (fine thread) provides higher clamping force for the same torque application, which was part of the engineering revision for the aluminum-body trucks to ensure wheel retention under higher payloads.

Q: Can I put older 8×6.5 wheels on my 2010 F-250?

A: No. The 2010 F-250 uses an 8×170 mm pattern. The older wheels will not physically fit over the studs.

Q: What is the bolt pattern for the 2025 Mustang Mach-E?

A: The Mach-E continues to use the 5×108 mm pattern, consistent with the Ford Escape and Edge, rather than the traditional Mustang 5×114.3 pattern.