Ford 6.7 Secondary Cooling System Diagram: Complete Guide

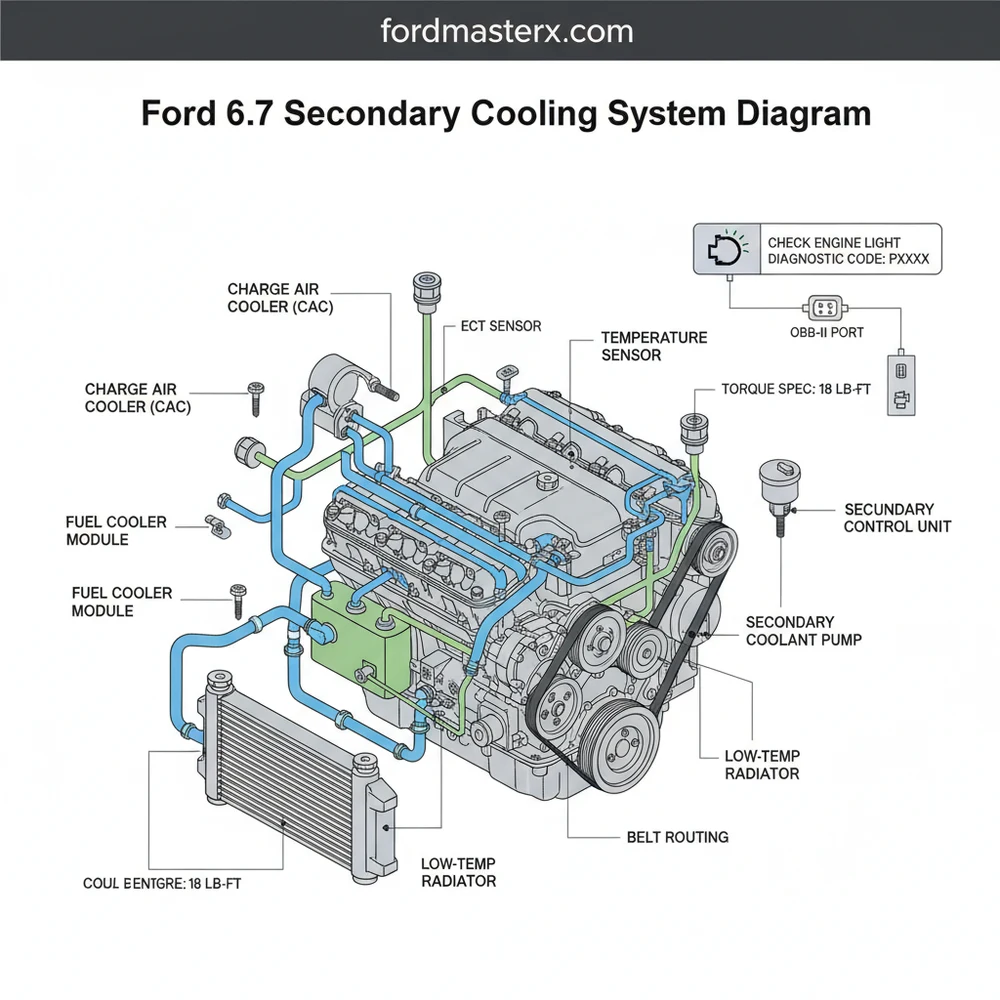

The Ford 6.7 secondary cooling system diagram illustrates the low-temperature loop responsible for cooling the charge air cooler, fuel cooler, and transmission oil cooler. Unlike the primary loop, this system operates at lower temperatures and utilizes its own dedicated radiator, water pump, and degas bottle to maintain optimal component temperatures and performance.

📌 Key Takeaways

- Visualizes the low-temperature cooling loop for the CAC and fuel system

- Identify the secondary radiator and belt-driven water pump

- Bleeding air from this system is critical to prevent component overheating

- Check for leaks at the quick-connect fittings and hose junctions

- Use this diagram when diagnosing high intake temps or cooling leaks

Understanding the ford 6.7 secondary cooling system diagram is essential for any truck owner or diesel technician looking to maintain the peak performance of the Power Stroke engine. Unlike traditional diesel engines that rely on a single cooling loop, the 6.7L utilizes a sophisticated dual-cooling architecture. The secondary system, often called the low-temperature loop, is a specialized circuit designed to regulate the temperature of the charge air cooler, fuel cooler, and transmission oil cooler. By studying the correct diagram, you can accurately identify components, trace coolant flow, and diagnose cooling inefficiencies that could otherwise lead to expensive repairs. This guide will provide a comprehensive breakdown of the system, from component identification to advanced troubleshooting techniques using modern diagnostic tools.

Detailed Breakdown of the Secondary Cooling System Diagram

The secondary cooling system in a Ford 6.7L Power Stroke is an independent loop that operates at a lower temperature and lower pressure than the primary engine cooling system. When viewing a ford 6.7 secondary cooling system diagram, the first thing you will notice is the placement of the secondary radiator. It is typically positioned in front of the primary radiator to ensure it receives the coolest ambient air first. This positioning is vital because the secondary loop must maintain significantly lower temperatures to effectively cool the intake air after it has been compressed by the turbocharger.

The diagram illustrates a closed-loop path that begins at the secondary water pump. This pump is driven by the accessory belt and is responsible for circulating coolant through several heat exchangers. The key components you will find on the diagram include:

- ✓ Secondary Radiator: The primary heat dissipation point for the low-temp loop.

- ✓ Secondary Water Pump: A belt-driven pump located on the front of the engine.

- ✓ Charge Air Cooler (CAC): A liquid-to-air heat exchanger that cools intake air for better combustion density.

- ✓ Fuel Cooler: Protects the fuel system by lowering the temperature of the return fuel.

- ✓ Transmission Oil Cooler: A dedicated heat exchanger to keep transmission fluid within safe operating ranges.

While the primary system handles the engine block and heads, the secondary system is the “workhorse” for auxiliary components. Always ensure you are looking at the secondary diagram, as the primary and secondary hoses are often located near each other but are NOT interchangeable.

In most diagrams, the coolant flow is color-coded to show the transition from “cool” liquid leaving the radiator to “warm” liquid returning from the components. It is important to note that variations exist between different model years regarding hose routing and the specific design of the degas bottle (coolant reservoir). Early versions of the 6.7 Power Stroke may have slightly different mounting brackets for the secondary pump compared to later iterations, though the fundamental flow logic remains consistent.

[DIAGRAM_PLACEHOLDER – A visual map showing the secondary radiator connected via blue and red lines to the secondary water pump, CAC, and fuel cooler, illustrating the independent nature of the low-temperature loop.]

Step-by-Step Guide to Interpreting and Servicing the System

Reading a ford 6.7 secondary cooling system diagram requires a systematic approach. If you are performing a flush or replacing a component like the CAC, follow these steps to ensure the job is done correctly. Proper interpretation of the diagram will help you avoid mixing up the two independent cooling circuits found on this engine.

1. Identify the Dual Reservoirs

The 6.7 Power Stroke uses a split degas bottle or two separate reservoirs depending on the specific model. Use your diagram to locate the secondary reservoir. It is usually the smaller of the two or the specific chamber designated for the low-temp loop. Never add coolant to one reservoir expecting it to fill the other; they are separate systems.

2. Inspect the Accessory Belt and Pump

The secondary water pump is driven by the main accessory belt. Locate the pump on your diagram and then find it physically on the front of the engine. Check for signs of leaking around the pump weep hole or a glazed belt. Unlike some older engines that might use a timing chain to drive water pumps internally, the 6.7 keeps this pump accessible on the exterior for easier service.

3. Trace the Coolant Flow

Following the lines on the diagram, trace the path from the pump to the Charge Air Cooler. This is the most critical part of the secondary system. If the flow is restricted, the ECU will detect high intake air temperatures and may pull timing or reduce power to protect the engine.

4. Gather Required Tools

To work on this system effectively, you will need several specific tools:

- ✓ OBD-II Scanner: To monitor real-time temperatures and clear codes.

- ✓ Vacuum Refill Kit: Essential for removing air pockets from the secondary loop.

- ✓ Torque Wrench: To ensure bolts meet the specific torque spec for the pump and housings.

- ✓ Coolant Pressure Tester: To verify system integrity after repairs.

The secondary cooling system can still be under significant pressure even if the engine feels cool to the touch. Always allow the vehicle to sit for at least an hour before opening any caps or disconnecting hoses shown on the diagram.

5. Pressure Test and Refill

Once you have identified the components and performed any necessary repairs, use a vacuum fill tool. The secondary system is notorious for trapping air in the Charge Air Cooler. A vacuum fill ensures that coolant flow is immediate upon startup, preventing localized hotspots. Refer to the diagram to ensure you have reconnected all vent lines, as these are crucial for air evacuation.

Common Issues and Troubleshooting Tips

When the secondary cooling system fails, the symptoms can sometimes be subtle. One of the first signs is often a check engine light triggered by the ECU. Because the secondary system handles the intake air cooling, a failure will result in higher-than-normal “Intake Air Temperature 2” (IAT2) readings. If you connect an OBD-II scanner, you may find a diagnostic code such as P026A (Charge Air Cooler Efficiency Below Threshold).

Common failure points include the secondary radiator developing pinhole leaks due to road debris or the secondary water pump failing at the bearing. By referencing your ford 6.7 secondary cooling system diagram, you can perform a visual inspection of the “cold side” and “hot side” hoses. If you notice the hoses going to the CAC are both extremely hot, it indicates a lack of flow, likely caused by a failed pump or a massive air lock. If you see a diagnostic code related to transmission temperature, the diagram will help you locate the specific lines running to the transmission oil cooler for further inspection.

If you are chasing a mystery coolant loss but see no puddles, check the Charge Air Cooler internally. Using the diagram to locate the CAC, you can occasionally find that it is leaking internally, allowing coolant to be consumed by the engine through the intake tract.

Maintenance Tips and Best Practices

Longevity for the 6.7 Power Stroke comes down to rigorous maintenance of both cooling systems. Always use the Ford-approved OAT (Organic Acid Technology) coolant specified in your owner’s manual. Mixing different types of coolant can lead to “slugging,” which will clog the small passages in the secondary radiator and fuel cooler shown on your diagram. Periodically check the accessory belt for cracks or wear, as a snapped belt will immediately stop the secondary pump, leading to an instant spike in intake temperatures.

When replacing any component, always adhere to the manufacturer’s torque spec. For example, the secondary water pump bolts require precise tightening to prevent housing distortion and future leaks. Furthermore, we recommend a “coolant test” every 15,000 miles to check the nitrite levels and pH balance. Maintaining the chemical integrity of the fluid protects the aluminum components identified in your ford 6.7 secondary cooling system diagram from electrolysis and corrosion.

Finally, consider installing an aftermarket monitor that plugs into your OBD-II port. This allows you to watch the temperature delta between the primary and secondary systems in real-time. If you see the secondary system temperatures creeping up while the primary stays stable, you know exactly where to start your investigation. Investing in high-quality OEM or reputable aftermarket heat exchangers is always preferred over cheap alternatives, as the cooling efficiency of the secondary loop is vital for the turbocharger’s health and overall engine longevity.

By following these guidelines and keeping a copy of the ford 6.7 secondary cooling system diagram handy, you ensure that your truck remains reliable under heavy loads and extreme temperatures. Whether you are a weekend warrior or a professional mechanic, understanding this dual-loop system is the key to mastering the 6.7 Power Stroke platform.

Frequently Asked Questions

Where is the secondary radiator located?

In a 6.7 Powerstroke, the secondary radiator is positioned directly in front of the primary radiator. It is smaller and part of the low-temperature circuit designed to handle the cooling requirements for the charge air cooler and the fuel cooler, independent of the engine block’s primary cooling loop.

What does the ford 6.7 secondary cooling system diagram show?

This diagram details the flow of coolant through the low-temperature loop, including the secondary radiator, the secondary water pump, and the charge air cooler. It highlights how coolant travels to regulate temperatures for the fuel system and transmission, ensuring these parts stay within safe operational limits.

How many cooling systems does the Ford 6.7 have?

The Ford 6.7 Powerstroke features two separate cooling systems: the primary high-temperature system for the engine block and heads, and the secondary low-temperature system. The secondary system specifically manages the charge air cooler, transmission cooler, and fuel cooler to optimize efficiency and prevent damage.

What are the symptoms of a bad secondary cooling pump?

A failing secondary pump often triggers a check engine light and sets a specific diagnostic code. You may notice high intake air temperatures via OBD-II monitoring or reduced engine power as the ECU pulls timing to protect the engine from overheating components in the low-temp loop.

Can I flush the secondary cooling system myself?

Yes, you can flush the secondary system, but it requires specific procedures to remove trapped air. You must refill it with the correct Motorcraft coolant and use a vacuum tool if possible. Always ensure every bolt meets the factory torque spec to prevent future leaks or vibrations.

What tools do I need for secondary cooling repairs?

You will need a standard socket set, pliers for hose clamps, and a diagnostic tool to read any diagnostic code from the ECU. A vacuum cooling system filler is highly recommended for the Ford 6.7 to ensure no air pockets remain in the complex secondary lines.