Ford 300 Inline 6 Performance Parts For Maximizing Torque And Horsepower

The Ford 300 inline-six is a legendary workhorse known for reaching 300,000 miles with ease, yet it often remains an untapped reservoir of performance potential. Despite its “bulletproof” reputation, the factory 4.9L suffers from restrictive breathing and an antiquated valvetrain that chokes output to less than 150 horsepower in many configurations. This comprehensive guide leverages 15+ years of engine building experience to show you how to unlock that hidden power. By selecting the right combination of high-quality intake, exhaust, and internal performance parts, you can transform this reliable industrial engine into a high-torque powerhouse capable of rivaling small-block V8s while maintaining its signature reliability.

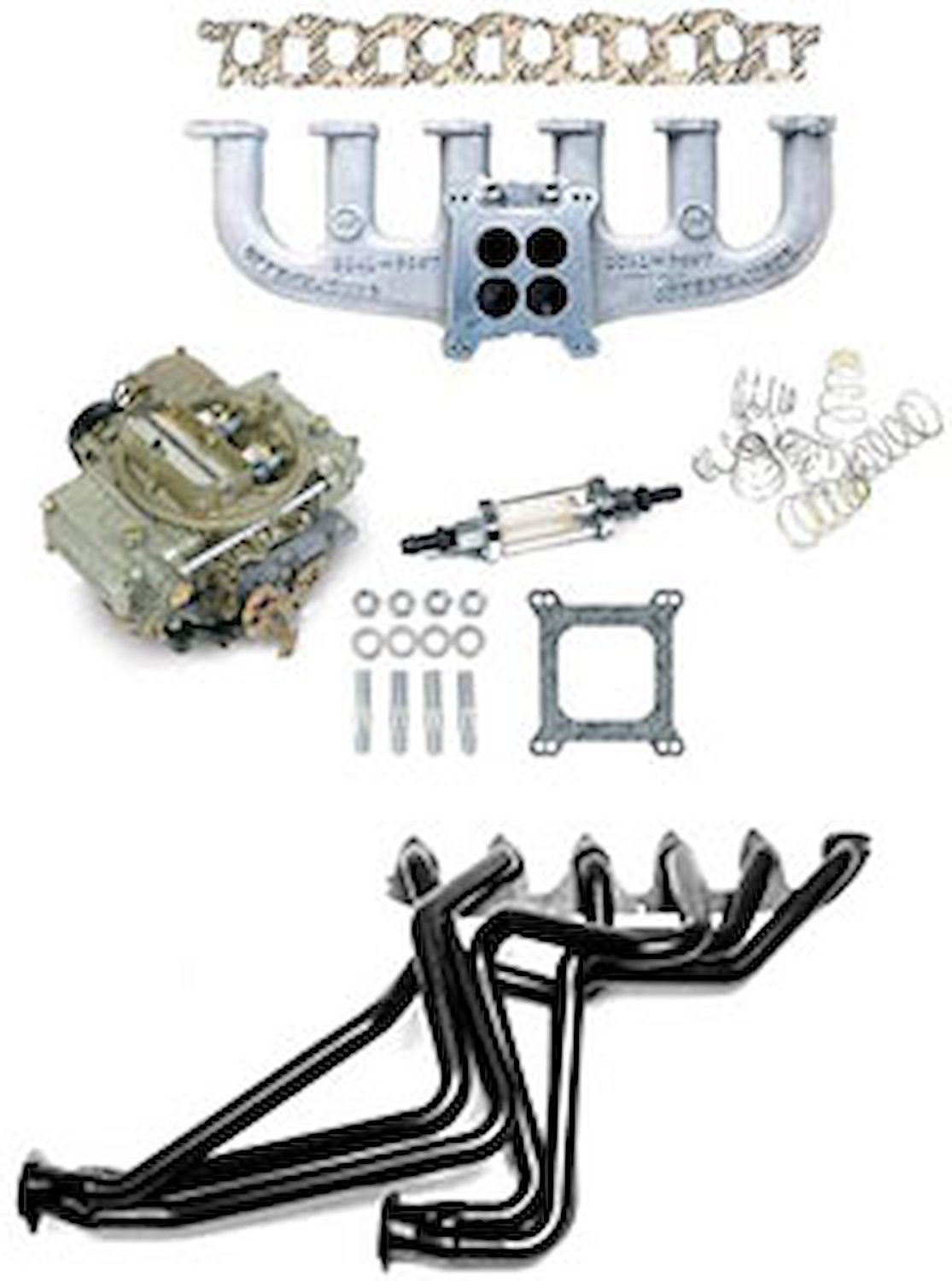

Optimizing Airflow with High-Quality Intake Manifolds and Carburetion

The factory 4.9L intake manifold is a “log” design that prioritizes low-speed industrial torque over volumetric efficiency. In its stock form, the single-barrel carburetor and its associated manifold restrict the engine to a ceiling of approximately 120-140 horsepower. To break through this barrier, professional builders look to trusted brands like Offenhauser and Clifford Performance.

📤 Share Image

Choosing Your Plenum: C-Series vs. Dual Port

Offenhauser offers two primary designs for the 300 straight six. The C-Series is an open-plenum design that excels in the mid-to-high RPM range (2,500–5,500 RPM). It is the preferred choice for lighter vehicles or street-strip applications where peak horsepower is the goal. Conversely, the Dual Port manifold utilizes separate primary and secondary runners. This design maintains high intake velocity at low RPM, maximizing the low-end torque that the 300 is famous for, making it ideal for heavy trucks and towing.

Carburetor Sizing: The “Sweet Spot”

A common pitfall is “over-carbing” the inline six. Because the 300 does not rev like a V8, a 600 or 750 CFM carburetor will often result in sluggish throttle response and poor fuel atomization. For a street-driven 4.9L, the 390 CFM to 500 CFM range is the expert recommendation. A Holley 4160 390CFM offers crisp response, while an Edelbrock 500CFM AVS2 provides excellent tunability and cold-start performance on an Offenhauser C-Series manifold.

Unlike V8s, the Ford 300 intake and exhaust hang off the same side of the head. When switching to an aftermarket intake, you lose the factory exhaust-gas heating. Always use a heated intake spacer or plumb coolant to the bottom of the manifold to prevent fuel dropout and “icing” during cold weather.

By The Numbers: Intake Gains

HP Gain (Manifold + Carb)

Ideal CFM for Street

Cylinder Head Modifications and Valvetrain Enhancements

Even with a massive carburetor, the 300’s output is limited by a cylinder head that flows poorly from the factory. The exhaust side is particularly egregious, typically flowing only 60-65% of the intake air. Professional porting and valvetrain upgrades are required to turn the 4.9L into a high-revving or high-output engine.

Strategic Porting: Removing the “Hump”

The primary restriction in the Ford 300 head is a massive casting “hump” in the exhaust port, designed for thermactor (smog) emissions. Removing this hump and smoothing the transition in the bowls can significantly improve flow. For the intake ports, a mild clean-up is often sufficient; the goal is to maintain high velocity rather than just increasing volume.

The “Big Valve” Conversion

A well-known expert secret for the Ford 300 is adapting Chevrolet valves. The stock Ford valves are small, but a machinist can install Chevy 1.94-inch intake and 1.60-inch exhaust valves. This upgrade, combined with professional porting, can result in a 25% increase in CFM flow on a SuperFlow bench, providing the head with the capacity to support 250+ horsepower.

Reducing Friction and Improving Lift

Installing high-quality roller rockers (specifically the 1.7 ratio intended for Big Block Fords) is a reliable way to increase total valve lift without opening the engine to swap the camshaft. This reduces internal friction and heat while improving the “effective” duration of the cam, allowing the engine to rev past the factory 4,000 RPM redline without valve float, provided you also install heavy-duty valve springs.

Performance Camshaft Selection for Reliable Power Delivery

The camshaft is the “brain” of your engine build. Selecting the wrong profile can ruin driveability, while the right choice can shift the power band to exactly where you need it. For the 300 inline six, dual-pattern camshafts are almost mandatory to compensate for the restrictive exhaust ports.

✅ Top Cam Choices

- Comp Cams 268H: Best all-around for street performance and mid-range passing power.

- Crower 284H: Ideal for “hot” builds with higher compression and 4-barrel carbs.

- Isky Mile-A-Mor: Designed for max torque and fuel economy in towing rigs.

❌ Common Pitfalls

- Choosing a “race” cam with too much duration (kills low-end torque).

- Neglecting to match the cam to the rear-end gear ratio.

- Skipping the critical break-in process for flat-tappet designs.

RV Profiles vs. Performance Grinds

The “RV Cam” is the most popular choice for the 4.9L. These profiles feature short duration and high lift, keeping the peak torque curve between 1,500 and 3,500 RPM. However, if your 300 is in a lighter truck (like a short-bed F-150), a more aggressive grind like the Comp Cams High Energy 268H will shift the peak torque curve up by 500-800 RPM, providing significantly better highway performance and a distinct “lopey” idle.

Retro-fit Hydraulic Roller Cams

For those with a higher budget, a retro-fit hydraulic roller setup offers the ultimate in reliable performance. Roller cams eliminate the risk of wiped lobes—a common issue with modern low-zinc oils—and allow for more aggressive ramp rates. This results in more “area under the curve,” meaning more torque across the entire operating range.

If using a hydraulic flat-tappet cam, you MUST use high-zinc (ZDDP) break-in oil and run the engine at 2,000–2,500 RPM for the first 20 minutes. Failure to do so will result in immediate camshaft failure.

Exhaust Headers and System Scavenging Dynamics

Removing backpressure is just as important as increasing intake flow. The original heavy cast-iron log manifold is designed for durability, not performance. Aftermarket headers can reduce exhaust backpressure by up to 40%, allowing the cylinder head to “scavenge” spent gases more effectively.

Long-Tube Headers

Maximize torque scavenging at lower RPMs. Brands like Clifford and Hedman offer dual-outlet designs that allow for a true dual exhaust setup.

The “EFI Manifold” Trick

Factory manifolds from 1987–1996 models are a split, “dual” design. They flow nearly as well as shorty headers but are more reliable and less prone to leaks.

Exhaust Sizing and Materials

For a modified 300 inline six, the ideal piping diameter is a single 3-inch system or dual 2.25-inch pipes. Larger diameters will decrease exhaust velocity, killing low-end torque. When selecting headers, ceramic coating is highly recommended over raw stainless steel; it keeps heat inside the tubes (improving flow) and protects the intake manifold from heat soak, which is a major concern on this engine layout.

Ignition System Upgrades and Fuel Management

To capitalize on increased airflow and better camshaft profiles, you need a spark capable of burning the denser air-fuel mixture. The factory TFI or Duraspark systems are adequate for stock engines, but performance builds require more professional ignition solutions.

📋

Step-by-Step Tuning Guide

Switch to a High Energy Ignition (HEI) one-wire distributor, such as those from Davis Unified Ignition (DUI). This simplifies the wiring and provides a much hotter spark.

With a high-voltage coil, you can widen the spark plug gap to 0.050–0.055 inches. This creates a larger flame front for more complete combustion.

Use a wideband sensor to dial in your carburetor. Aim for an Air-Fuel Ratio (AFR) of 14.7 for cruise and 12.5–13.0 for wide-open throttle (WOT) to maximize power without detonation.

Fuel Delivery Consistency

As you move toward the 200 HP mark, the factory mechanical fuel pump may struggle to keep the carburetor bowls full during sustained high-load situations. Transitioning to a low-pressure (5–7 PSI) electric fuel pump ensures consistent delivery. Expert builders also recommend adjustable vacuum advance canisters to fine-tune the timing curve for better part-throttle driveability and improved fuel economy.

In summary, upgrading the intake and exhaust manifolds is the primary step to unlocking the Ford 300’s airflow potential. Precision valvetrain components and camshaft selection allow the engine to breathe and rev safely beyond factory limits, while modern ignition and fuel calibration ensure that these hardware upgrades translate into smooth, reliable street performance. Evaluate your performance goals—whether for towing, off-roading, or street cruising—and begin your build by addressing the intake and exhaust restrictions first for the most noticeable gains.

Frequently Asked Questions

How much horsepower can I realistically expect from Ford 300 performance parts?

With a trusted combination of a four-barrel intake, a mild camshaft, and free-flowing headers, a Ford 300 can easily produce 200-225 horsepower and over 300 lb-ft of torque. While higher numbers are possible with forced induction or extensive head work, these figures represent a reliable, street-legal build that maintains the engine’s signature longevity.

Can I install performance parts on a fuel-injected (EFI) 4.9L engine?

Yes, though the approach differs. For EFI models, focus on high-quality headers, a free-flowing exhaust, and professional porting of the factory intake plenum. For significant gains, many enthusiasts choose to swap the restrictive factory EFI for an Offenhauser intake and a modern aftermarket EFI system like the Holley Sniper, which offers better tunability for performance camshafts.

Is the Ford 300 inline 6 a good candidate for turbocharging?

The Ford 300 is an exceptional candidate for turbocharging due to its seven main bearing design and robust bottom end. Professional builders often use the 4.9L for boost because it handles cylinder pressure remarkably well. To do this safely, you must prioritize high-quality forged pistons and a reliable fuel management system to prevent detonation under load.

Will performance upgrades ruin my gas mileage?

Not necessarily. When using professional-grade components like a properly sized 4-barrel carburetor and a high-energy ignition, many owners report a slight increase in fuel efficiency. This occurs because the engine no longer has to ‘fight’ to breathe at highway speeds, allowing it to operate more efficiently within its power band.

What are the most essential supporting mods for a performance 300 build?

Beyond the engine itself, you should invest in a high-quality cooling system (3-row radiator) and an upgraded clutch or torque converter. The increased torque of a modified 300 can stress factory driveline components, so ensuring your transmission and cooling are up to the task is vital for a reliable, expert-level build.