Diagram Timing Marks 2.3 Ford Ranger: Alignment Guide

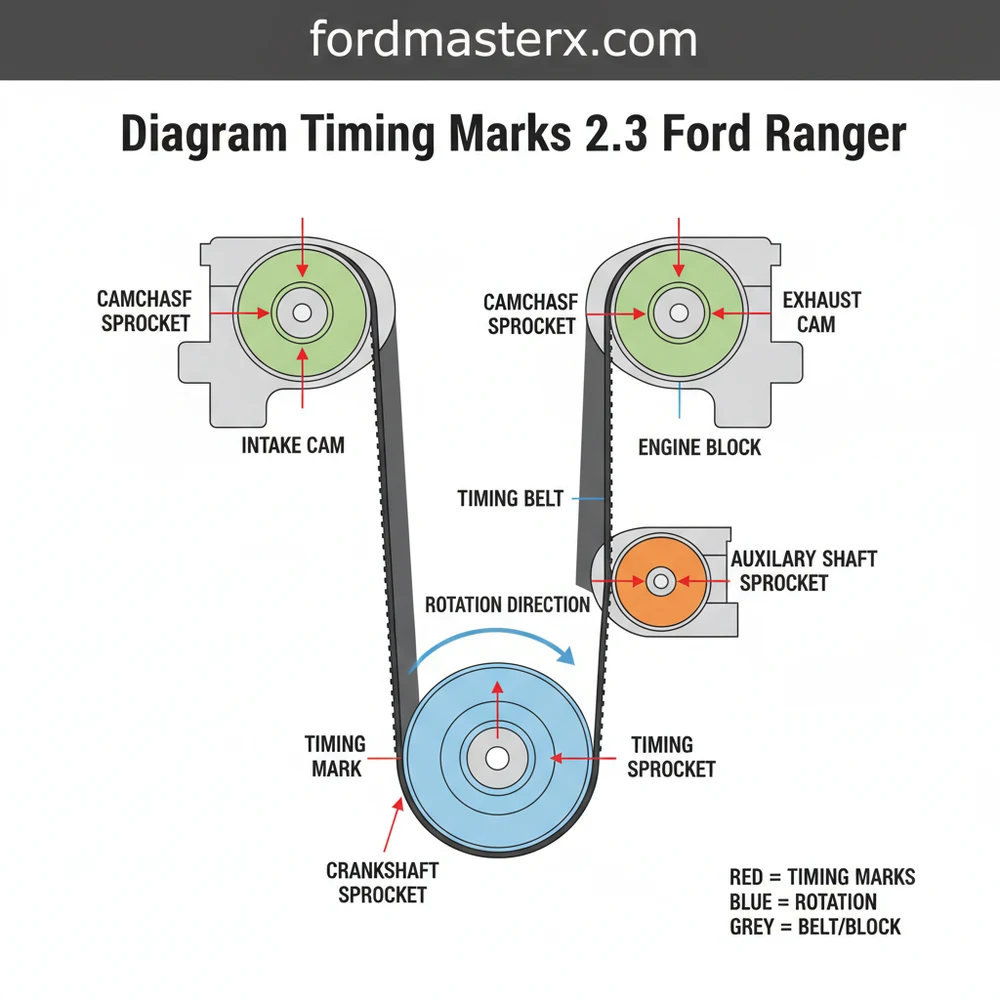

The diagram timing marks 2.3 Ford Ranger show the crankshaft keyway pointing at 12 o’clock, the camshaft sprocket triangle aligned with the notch on the rear cover, and the oil pump sprocket diamond aligned with its corresponding mark. This layout ensures the internal structure of the engine is synchronized for proper combustion.

📌 Key Takeaways

- Accurate alignment of the three main sprockets is vital for engine health

- Always use Top Dead Center (TDC) on cylinder one as your baseline

- Manual rotation of the engine is required to verify the configuration before starting

- Misalignment can lead to valve damage or severe engine failure

- Use this diagram whenever replacing the timing belt or water pump

When you are performing a timing belt replacement or engine rebuild, understanding the diagram timing marks 2.3 ford ranger is the difference between a smooth-running machine and a costly mechanical failure. The 2.3L engine, particularly the SOHC (Single Overhead Cam) “Lima” variant, is a staple of automotive reliability, but its internal synchronization depends entirely on the precise alignment of three specific rotating assemblies. This guide is designed to provide you with a comprehensive blueprint of the timing system, ensuring you can identify every component and configuration required to keep your engine in perfect harmony. Whether you are troubleshooting a rough idle or installing a fresh belt, having a clear schematic of these reference points is essential for any DIY enthusiast or professional mechanic.

Understanding the Timing System Configuration and Layout

The 2.3 Ford Ranger engine utilizes a belt-driven system that synchronizes the crankshaft, the camshaft, and an auxiliary shaft. To read the diagram correctly, you must first understand the structural layout of these components. The schematic typically displays a triangular configuration. At the bottom, you have the crankshaft sprocket, which is the primary driver of the system. Above it and to the left (exhaust side) is the auxiliary shaft sprocket, responsible for driving the oil pump and, on older models, the distributor. At the top of the engine is the camshaft sprocket, which regulates the opening and closing of the valves.

Each of these sprockets features a specific timing mark—usually a notch, a triangle, or a diamond—that must align with a corresponding pointer or mark on the engine block or the inner timing cover. This system overview is vital because if the auxiliary shaft is out of sync, your oil pressure or ignition timing may fail, even if the cam and crank are aligned. The blueprint of this engine also accounts for the timing belt tensioner, which is located between the camshaft and crankshaft sprockets to maintain the appropriate “wrap” and pressure on the belt.

The 2.3L Lima engine is generally a non-interference engine, meaning that if the timing belt breaks, the pistons and valves typically do not collide. However, the later 2.3L DOHC Duratec engines are interference engines and require even greater precision during alignment.

Step-by-Step Guide to Interpreting the Timing Marks

To properly apply the diagram timing marks 2.3 ford ranger to your vehicle, you must follow a methodical approach to ensure Top Dead Center (TDC) is achieved. Interpreting the schematic requires patience and the right tools, such as a 19mm socket for the crankshaft bolt and a torque wrench for final assembly.

- ✓ Step 1: Preparation and Access — Begin by disconnecting the battery and removing the cooling fan, fan shroud, and the serpentine belt. You will then need to remove the plastic outer timing cover to expose the sprockets and the belt.

- ✓ Step 2: Rotating to Top Dead Center (TDC) — Using a socket on the crankshaft pulley bolt, rotate the engine clockwise. Look for the “0” or “TDC” mark on the harmonic balancer. It must align perfectly with the pointer on the engine block. This ensures the number one piston is at the peak of its compression stroke.

- ✓ Step 3: Aligning the Crankshaft Sprocket — Once the balancer is removed, verify that the keyway on the crankshaft is pointing at the 12 o’clock position. The small notch on the sprocket should align with the vertical rib or pointer cast into the engine block.

- ✓ Step 4: Aligning the Camshaft Sprocket — Look at the camshaft sprocket at the top of the engine. There is a small triangle or notch on the sprocket teeth. This mark must align with the pointer on the inner timing cover, which is usually positioned at roughly the 4 o’clock or 5 o’clock position, depending on the specific engine casting.

- ✓ Step 5: Synchronizing the Auxiliary Shaft — The auxiliary shaft sprocket also has a notch. This must align with a pointer on the engine block, typically at the 12 o’clock position. While this doesn’t affect valve timing, it is critical for oil pump operation and ignition synchronization in older electronic distributor systems.

- ✓ Step 6: Installing the New Belt — Route the belt starting from the crankshaft, then around the auxiliary shaft, and finally over the camshaft sprocket. Ensure the “slack” side of the belt is on the side with the tensioner.

- ✓ Step 7: Releasing the Tensioner — Loosen the tensioner adjustment bolt to allow the spring to apply pressure to the belt. Once the belt is tight, tighten the tensioner bolt.

- ✓ Step 8: Final Verification — Rotate the crankshaft by hand for two full revolutions. Re-check all three timing marks. If they still align with their respective pointers, the engine is properly timed.

Never use an impact wrench to rotate the engine when checking timing marks. Forceful rotation can cause the belt to skip teeth or damage the internal keyways of the sprockets, leading to an inaccurate reading of the schematic.

Common Issues and Troubleshooting the Timing System

Even with a detailed diagram timing marks 2.3 ford ranger, you may encounter obstacles. One of the most common issues is “belt stretch,” where the rubber teeth no longer sit perfectly within the sprocket grooves, causing the marks to appear slightly off-center. If you notice that your camshaft mark is half a tooth off, it is likely that the belt has stretched or the tensioner has lost its integrity.

Another frequent problem is a slipped harmonic balancer. The balancer consists of two metal rings joined by a rubber dampener. Over time, the rubber can fail, causing the outer ring (with the TDC mark) to rotate independently of the inner ring. This makes the timing marks on the balancer completely unreliable. In this scenario, you must use a “piston stop” tool or visual inspection through the spark plug hole to verify true TDC.

Signs that your timing is incorrect include a “no-start” condition, backfiring through the intake, or a significant loss of low-end torque. If the auxiliary shaft is misaligned on older models, you may experience “phantom” ignition issues where the spark occurs at the wrong time despite the computer showing correct data. Using the diagram to verify these three points of contact is the first step in diagnosing any performance-related engine trouble.

Tips and Best Practices for Long-Term Maintenance

When you are deep enough into the engine to see the timing marks, it is wise to perform “preventative maintenance” to save time and money in the future. Quality components are the backbone of a reliable 2.3L engine. Always opt for a high-quality, reinforced timing belt from a reputable manufacturer.

Always replace the water pump and the front crankshaft seal while the timing belt is off. These components are easily accessible during a timing job, and failing to replace them now could result in having to take the entire system apart again in six months if a leak develops.

Maintain a clean environment while working. Oil or coolant on the timing belt can cause the rubber to degrade rapidly, leading to premature failure. Use a degreaser to clean the sprocket teeth and ensure no debris is trapped between the belt and the gear. Additionally, replace the timing belt tensioner pulley and spring. The spring can lose its tension over hundreds of thousands of miles, leading to belt “slap” or vibration at high RPMs.

Finally, document your work. Note the mileage and date of the belt replacement. For the Ford Ranger 2.3L SOHC engine, the recommended interval for a timing belt change is typically every 60,000 to 100,000 miles, depending on driving conditions. By following the diagram timing marks 2.3 ford ranger precisely and adhering to these best practices, you ensure your truck remains a dependable workhorse for years to come. Proper synchronization of the crankshaft, camshaft, and auxiliary shaft is not just a maintenance task; it is the fundamental requirement for the longevity and efficiency of your Ford engine.

Frequently Asked Questions

Where are the timing marks located on a 2.3 Ford Ranger?

On the 2.3L engine, the marks are located on the crankshaft sprocket, the camshaft sprocket, and the oil pump (auxiliary) sprocket. The crankshaft mark is typically at the 12 o’clock position, while the camshaft and oil pump marks align with specific notches or arrows on the rear timing cover.

What does the 2.3 Ford Ranger timing diagram show?

The diagram illustrates the exact configuration of the timing belt and how each component must be positioned relative to the others. It shows the spatial layout required to synchronize the pistons and valves, preventing mechanical interference and ensuring the engine system runs smoothly and efficiently.

How many alignment points does the 2.3 engine have?

This specific system features three primary alignment points: the crankshaft, the camshaft, and the auxiliary/oil pump shaft. Each sprocket has a distinct mark—typically a triangle or diamond—that must point to a specific reference mark on the engine block or the inner timing belt cover structure.

What are the symptoms of bad timing on a 2.3 Ford Ranger?

Common symptoms include a rough idle, engine misfires, lack of power, or a ‘no start’ condition. If the timing is off by even one tooth, you may hear backfiring or notice a significant drop in fuel economy. Severe misalignment can cause internal mechanical failure in this engine type.

Can I adjust the timing marks myself?

Yes, a confident DIYer can set the timing marks, but it requires patience and the correct tools. Following the diagram timing marks 2.3 Ford Ranger layout is essential to avoid errors. If you aren’t comfortable with mechanical engine work, professional assistance is recommended for this critical task.

What tools do I need for setting the timing?

You will need a basic socket set, a torque wrench, a harmonic balancer puller, and potentially a camshaft holding tool. A reliable light source is also helpful to clearly see the small alignment notches on the sprockets and the engine’s internal structure during the synchronization process.