Bottle Jack vs. Floor Jack: The Ultimate Ford Owner’s Guide (2026)

In the expansive ecosystem of automotive maintenance, few decisions are as foundational, yet frequently overlooked, as the selection of hydraulic lifting equipment. For the Ford owner—a demographic that spans the utilitarian ruggedness of the F-Series Super Duty to the track-bred precision of the Mustang Dark Horse—the choice between a bottle jack and a floor jack is not merely a matter of tool storage or purchase price.

It is a complex determination involving chassis engineering, suspension geometry, hydraulic fluid dynamics, and operational safety standards governed by rigorous bodies such as OSHA and ASME.

The debate is often reductively framed as a choice between portability and convenience. However, a deeper analysis reveals that this dichotomy is false. The selection of a hydraulic jack is a life-safety decision. According to safety data, a significant percentage of automotive repair injuries stem from the improper pairing of lifting equipment with vehicle architecture.

A jack designed to lift the solid axle of a 1978 Bronco may cause catastrophic damage to the unibody pinch welds of a 2024 Maverick. Conversely, a floor jack optimized for a garage floor may become a lethal instability hazard when deployed on the soft shoulder of a trail during an overland recovery.

This report serves as an exhaustive technical manual for the readership of fordmasterx.com. It synthesizes data from manufacturing specifications, regulatory safety standards (ASME PASE-2019), and field-tested recovery protocols. We will dissect the internal mechanical architecture of vertical-piston versus bell-crank hydraulics, analyze the specific lift-point requirements of the modern Ford lineup (including the high-voltage complications of the F-150 Lightning and Mustang Mach-E),

and provide a strategic buying guide based on 2025/26 market data. By the conclusion of this document, the reader will possess a nuanced, expert-level understanding of hydraulic lifting physics, enabling them to make informed decisions that protect both their vehicle and their life.

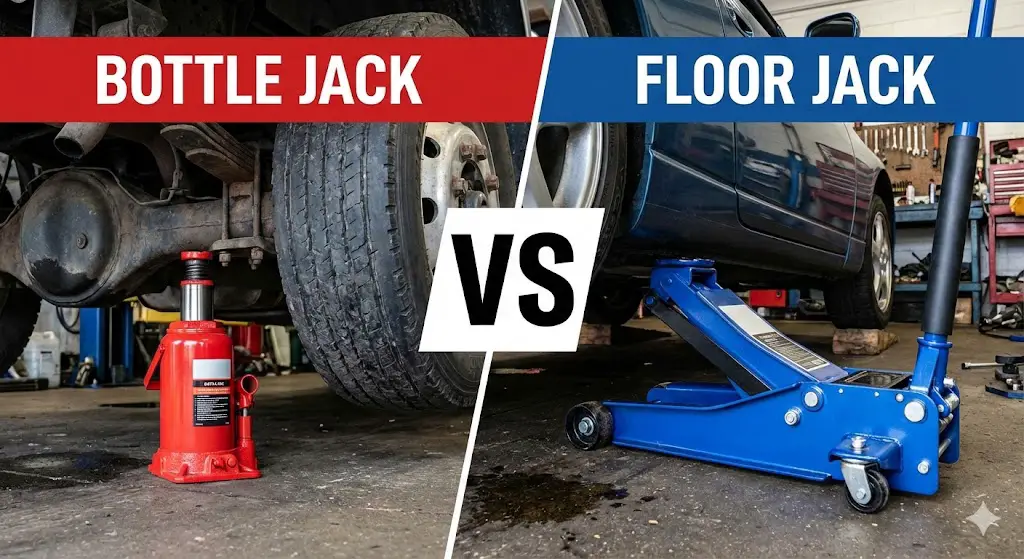

Bottle Jack VS Floor Jack

The ultimate showdown between the portable powerhouse and the garage king. Which one belongs in your trunk, and which belongs in your shop?

The Floor Jack

A trolley-style hydraulic jack mounted on wheels. It slides under the vehicle and uses a long pump handle to lift. Known for speed, stability, and ease of use on flat concrete surfaces.

- Best for: Oil changes, Tire rotations

- Environment: Flat, paved garages

- Mechanism: Horizontal cylinder

The Bottle Jack

A compact, vertical piston jack that resembles a milk bottle. It operates directly under the lift point. Known for immense lifting power in a tiny footprint, often found in trucks and 4x4s.

- Best for: Emergency roadside, Truck lifting

- Environment: Uneven terrain (with board)

- Mechanism: Vertical cylinder

Performance Polygon

We rated both jack types on five critical metrics. While the Floor Jack dominates in stability and low-clearance access (essential for sports cars), the Bottle Jack wins purely on portability and raw weight capacity per dollar.

The Clearance & Lift Gap

One of the most critical factors is Minimum Height. If the jack doesn’t fit under your car, it’s useless. Floor jacks are designed to slide under low profiles. Bottle jacks require significantly more starting clearance.

Floor Jack Advantage

Can slide under sports cars with as little as 3 inches of ground clearance.

Bottle Jack Limitation

Requires 9-11 inches of clearance. Not suitable for lowered vehicles without ramps.

By The Numbers

The Price of Power

If you need to lift a house (or a heavy duty truck), the Bottle Jack is the undisputed king of value. You can buy a 20-ton bottle jack for the price of a standard 2-ton floor jack.

However, with a Floor Jack, you are paying for engineering, stability, and the complex trolley mechanism that makes lifting safer and easier.

Which One Should You Buy?

The DIY Mechanic

You do oil changes, brake jobs, and tire rotations in your home garage or driveway.

The Truck Owner

You drive a lifted F-150 or Jeep. You need a jack for roadside emergencies.

The Pro Setup

You have a diverse fleet and want to be prepared for suspension work and heavy lifting.

The Physics of Hydraulic Lifting: Fundamental Architectures

To truly understand the operational divergence between bottle jacks and floor jacks, one must first appreciate the shared physical principles that drive them and the mechanical implementations that distinguish them. Both tools rely on Pascal’s Law, which states that a change in pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and to the walls of its container.

Theoretical Basis: Pascal’s Law and Mechanical Advantage

In a hydraulic jack system, a small force applied to a small area (the pump plunger) creates a pressure that is transferred to a larger area (the lifting ram), resulting in a multiplied force. This is the definition of mechanical advantage.

$$P = \frac{F_1}{A_1} = \frac{F_2}{A_2}$$

Where:

- $P$ is pressure (Pascal or PSI)

- $F_1$ is the input force on the pump piston

- $A_1$ is the area of the pump piston

- $F_2$ is the lifting force of the ram

- $A_2$ is the area of the ram

The Bottle Jack: Direct Vertical Linearity

The bottle jack, often referred to as a piston jack, represents the purest application of hydraulic theory. Its design consists of a vertical cylinder mounted directly to a static baseplate. The hydraulic ram extends vertically along the Z-axis, pushing straight up against the load.

This linear architecture provides distinct engineering characteristics. Because the force vector is perfectly vertical (assuming level ground), there are minimal shear forces applied to the internal seals during a static lift. The lack of complex linkage mechanisms means that nearly 100% of the hydraulic force is translated into lift, making bottle jacks exceptionally efficient in terms of size-to-power ratio. A unit no larger than a quart of oil can lift 12 tons (24,000 lbs) because the structural path of the force is a straight column of steel and oil.

However, this verticality is also its Achilles’ heel. As the ram extends, the center of gravity (CG) of the jack-load system rises significantly. Mechanics dictate that stability is a function of the height of the CG relative to the width of the base. The bottle jack has a notoriously narrow base—often only 4 to 5 inches square. As the jack extends to its maximum height of 18 inches, the stability pyramid becomes dangerously inverted. If the vehicle shifts laterally—a common occurrence as suspension droops or tires leave the ground—the resultant vector can easily fall outside the jack’s base footprint, causing the unit to topple.

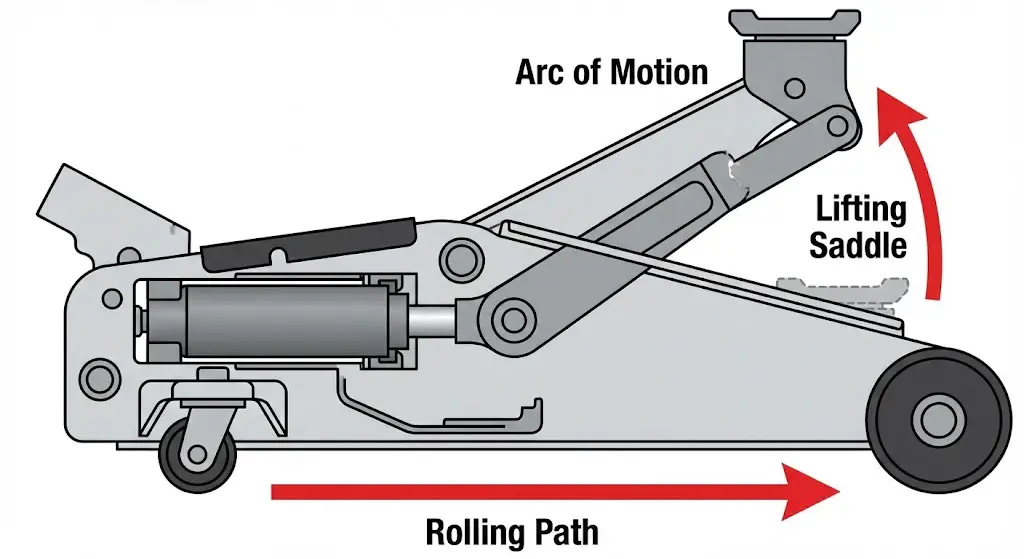

The Floor Jack: Bell Crank Geometry and Vector Translation

The floor jack, or trolley jack, introduces a complex mechanical linkage to the hydraulic equation. The hydraulic cylinder is mounted horizontally or at a low angle. The linear force of the piston pushes against a bell crank or a lifting arm, which converts the horizontal motion into vertical lift.

This conversion comes with a kinematic consequence: the lifting pad (saddle) does not travel in a straight vertical line. Instead, it travels in an arc relative to the pivot point of the lift arm. As the arm rises, the horizontal distance between the pivot and the saddle changes. To maintain a vertical relationship with the vehicle’s lift point, the entire jack must move. This is why floor jacks are mounted on casters. As the jack lifts, it must roll forward under the load to compensate for the arc of the arm.

This “arc of motion” is the critical operational constraint of the floor jack. If the jack is placed on a surface where the wheels cannot roll—such as gravel, dirt, or cracked asphalt—the jack cannot center itself. Instead, the lateral component of the lifting arc will pull the vehicle sideways. This lateral stress can bend the jack’s frame, damage the vehicle’s pinch welds, or cause the saddle to slip off the lift point entirely. Conversely, on a smooth concrete floor, this rolling action allows for precise positioning and stability, as the wide track width and long wheelbase of the floor jack create a robust stability triangle that resists tipping.

Structural Materiality: Metallurgy and Design

The choice of materials further defines these tools. Bottle jacks are typically constructed from cast iron bases with steel cylinders. This heavy, rigid construction is ideal for sustaining the immense compressive loads of 20+ tons. The critical failure point in cheap bottle jacks is often the weld quality between the cylinder and the base, or the porosity of the cast iron.

Floor jacks, by contrast, utilize stamped steel or aluminum plates bolted together. “Racing” jacks favor aluminum for its high strength-to-weight ratio, reducing the tool’s weight to under 50 lbs for portability. However, aluminum has a finite fatigue life compared to steel. Professional heavy-duty floor jacks (like the Daytona Super Duty) use heavy-gauge steel side plates to resist the twisting forces (torque) that occur when lifting a vehicle on slightly uneven ground.

The Floor Jack: Anatomy, Evolution, and Garage Dominance

For the home mechanic servicing a mixed fleet—perhaps a Mustang for the weekend and an Explorer for the family—the floor jack is the indisputable primary tool. Its evolution from the heavy iron “trolley jacks” of the early 20th century to the rapid-pump, low-profile tools of 2025/26 reflects an adaptation to modern vehicle design.

The Low-Profile Revolution and Rapid Pump Technology

In the past two decades, vehicle ride heights have generally decreased for aerodynamics and fuel economy (with the exception of trucks), while curb weights have increased due to safety equipment and electrification. This necessitates a jack that can slide under a 4-inch side skirt yet lift 6,000 lbs.

Modern professional-grade floor jacks address this with “dual parallel pump” technology. In a traditional single-piston jack, raising the saddle to the contact point might take 8-10 strokes. The “Rapid Pump” design utilizes two unequal diameter pistons. The larger piston moves a high volume of fluid at low pressure to raise the arm quickly when unloaded (often in 3-4 strokes). Once the saddle contacts the frame and resistance is met, the system bypasses the high-volume piston and engages the smaller, high-pressure piston to perform the heavy lifting. This significantly reduces operator fatigue.

Stability Dynamics on Hard Surfaces

The paramount advantage of the floor jack is stability. The footprint of a standard 3-ton floor jack is approximately 15 inches wide by 28 inches long. This creates a support area of over 400 square inches, compared to the ~25 square inches of a bottle jack. This wide stance provides a massive margin of error. If a mechanic is torquing a suspension bolt and inadvertently shakes the vehicle, the floor jack absorbs this energy. A bottle jack would likely tip.

Furthermore, the saddle of a floor jack is typically a large, cupped steel disc, 4 to 5 inches in diameter. This distributes the compressive load over a larger area of the vehicle’s frame or unibody rail. In contrast, the quarter-sized head of a bottle jack creates extreme point-loading (high PSI), which can dent frame rails or crush unibody seams if not used with an adapter.

Limitations: The Garage Queen

Despite its superiority in stability and speed, the floor jack is tethered to the garage.

- Weight and Bulk: A high-quality 3-ton steel jack weighs between 80 and 100 lbs. It is unwieldy to load into a trunk and occupies significant cargo space. Even aluminum “racing” jacks are bulky due to their long handles.

- Surface Dependency: As previously noted, the floor jack must roll to lift safely. On asphalt in the summer, the small steel casters can sink, preventing the jack from rolling. On gravel or dirt, the casters dig in, turning the jack into a dangerous anchor that pulls the vehicle off balance. This renders the floor jack largely useless for trail recovery scenarios unless a large plywood platform is carried.

The Bottle Jack: Concentrated Power and Field Utility

If the floor jack is the scalpel of the garage, precise and effective, the bottle jack is the hammer of the field—blunt, powerful, and essential for heavy lifting.

Hydraulic Density and Tonnage Economics

The most striking feature of the bottle jack is its power density. A cylinder no larger than a thermos can lift 20 tons. For owners of Ford Super Duty trucks (F-250, F-350, F-450) or those towing heavy fifth-wheel trailers, the bottle jack is the only portable solution capable of lifting the Gross Vehicle Weight Rating (GVWR).

Economically, the bottle jack dominates the “cost per ton” metric. A 2025/26 market analysis shows that a reliable 12-ton bottle jack retails for approximately $40-$60. A floor jack rated for 12 tons is industrial equipment costing upwards of $1,500. For the consumer, the bottle jack is the democratizing force of heavy lifting.

The “Axle Lift” Advantage

For solid-axle vehicles like the rear of the F-150 and the Bronco, the bottle jack offers a geometric advantage. When lifting by the frame (as one typically does with a floor jack), the suspension must fully extend (“droop”) before the tire leaves the ground. On a long-travel vehicle like a Bronco Raptor, this might require lifting the frame 10-14 inches just to take up the slack, requiring a jack with massive vertical travel.

A bottle jack, however, is small enough to be placed directly under the axle tube or the leaf spring U-bolt plate. By lifting the unsprung weight directly, the suspension remains compressed, and the tire lifts immediately. This efficiency makes the bottle jack the preferred tool for changing tires on lifted trucks.

Extension Mechanics and Limitations

Most bottle jacks feature a telescoping screw extension inside the hydraulic ram. This allows the user to manually adjust the starting height of the jack to meet the chassis, ensuring that the limited hydraulic stroke (typically only 4-6 inches) is used entirely for lifting, not just reaching.

However, the limited total stroke is a major drawback. If a vehicle is high-centered in mud, the 6 inches of lift provided by a standard bottle jack may not be enough to stack traction boards under the tires. Telescoping (dual-ram) bottle jacks exist to solve this, but they are more expensive and complex. Furthermore, the high minimum height (often 9 inches) makes bottle jacks impossible to use on flat tires where the axle has dropped close to the ground, unless the user drives onto blocks first.

Regulatory Framework: Safety Standards and Compliance

Before analyzing vehicle-specific applications, we must establish the regulatory baseline. In the United States, the design and use of jacks are governed by the American Society of Mechanical Engineers (ASME) and the Occupational Safety and Health Administration (OSHA).

ASME PASE-2019: The Design Standard

The governing standard for “Portable Automotive Service Equipment” is ASME PASE-2019 (a revision of the 2014 standard). This document dictates the safety factors manufacturers must engineer into their products.

- Overload Protection: PASE-compliant jacks must feature an internal bypass valve. This prevents the user from pumping the jack beyond its rated capacity. If a user attempts to lift a loaded F-450 with a 2-ton jack, the valve will open, and the handle will simply go limp, preventing structural failure.

- Load Sustaining: The standard requires that the jack be able to sustain its load without “leak down” for a set period. However, it explicitly states that jacks are lifting devices, not holding devices.

- Off-Center Loading: The 2024 update to ASME B30.1 emphasizes the “Center of Gravity Rule,” requiring the load’s CG to remain within the central 60% of the saddle. This regulation highlights the inherent risk of bottle jacks, whose small saddles offer a tiny margin for error.

OSHA 1926.305: The “Fatal Collapse” Regulation

For professional environments, OSHA standard 1926.305 dictates strict protocols that should be adopted by every DIY enthusiast.

- The Blocking Rule: The standard mandates that “the load shall be immediately blocked” (i.e., jack stands placed) after lifting. Working under a vehicle supported only by hydraulic pressure is a federal violation and a statistical driver of fatalities.

- Blocking Base: Jack stands must be placed on a firm, level foundation. On asphalt, this often requires plywood sheets to prevent the stands from sinking and tipping.

- Inspection: Jacks must be inspected every 6 months. Visual inspection for leaking oil is insufficient; the inspection must verify that the saddle has not deformed and that the release valve operates smoothly.

Vehicle-Specific Application: The Ford Ecosystem

The general “bottle vs. floor” debate is useless without context. We must analyze the specific chassis architectures of the Ford lineup to determine the correct tool for each.

Ford F-150 (Gen 13/14) and Super Duty

The F-Series utilizes a high-strength steel fully boxed ladder frame. This provides numerous safe lifting points but demands high tonnage.

- The Garage Scenario (Maintenance):

- Primary Tool: 3-Ton or 4-Ton Floor Jack.

- Application: Front-end maintenance (oil changes, brake jobs) on the F-150 requires lifting the independent front suspension (IFS). The safest lift points are the frame rails behind the front wheels or the heavy crossmember. A floor jack is essential here because lifting from the frame requires significant vertical reach (to overcome suspension droop) and stability. A bottle jack on a front frame rail is dangerously unstable due to the height required.

- The Roadside Scenario (Emergency):

- Primary Tool: 12-Ton Bottle Jack.

- Application: Changing a rear tire. The rear axle of the F-150 is a robust steel tube. A bottle jack placed directly under the axle (between the U-bolts and the shock mount) is the safest and most efficient method. It lifts the tire instantly.

- Warning: The factory scissor jack supplied with 2009-2014 F-150s has a reputation for instability. Replacing it with a high-quality aftermarket bottle jack is a critical safety upgrade for owners.

Ford Bronco (Gen 6)

The Bronco is a purpose-built off-roader, presenting unique challenges due to its suspension articulation and ground clearance.

- The Articulation Challenge: The Bronco (especially Sasquatch and Raptor trims) has massive suspension travel. Lifting by the frame with a standard floor jack is often futile; the jack hits its max height of 18 inches, and the tire is still touching the ground.

- The Solution: The bottle jack is the superior tool for the Bronco, provided it is used on the axle or lower control arms.

- Safe Jack Extensions: Because the Bronco sits high, a standard bottle jack may be too short. Products like “Safe Jack” extensions or simple 6×6 lumber cribbing are necessary to bridge the gap to the frame or axle safely.

- Trail Recovery: In sand or mud, a floor jack is dead weight. A bottle jack mounted to a specialized base plate (like the AEV jack base or a DIY plywood board) is the industry standard for changing tires on the trail.

Ford Mustang (S550/S650)

The Mustang is a unibody monocoque with low ground clearance. It is the antithesis of the F-150.

- The Clearance Constraint: A standard bottle jack requires ~9 inches of clearance. A stock Mustang GT often has less than 6 inches at the side rails. A bottle jack simply will not fit.

- The Pinch Weld Problem: The lifting points on a Mustang are the “pinch welds”—vertical seams of metal running under the rocker panels.

- The Danger: The head of a bottle jack is a small, serrated steel circle. If pressed against a pinch weld, it will concentrate tons of force on a few millimeters of metal, crushing the weld, cracking the paint, and introducing rust. It can also slip off easily.

- The Requirement: A low-profile floor jack is the only safe option. It must be paired with a “pinch weld puck”—a rubber adapter with a slot cut in it to support the chassis on either side of the weld without crushing the seam itself.

- Track Days: For track enthusiasts, lightweight aluminum floor jacks (1.5 – 2 ton) are preferred for their portability in the paddock, despite their higher cost.

Ford Maverick and Bronco Sport

These vehicles are “unibody trucks.” They look like rugged off-roaders but share the chassis architecture of the Ford Escape/Focus.

- Mistaken Identity: Owners often assume the Maverick has a frame rail like the F-150. It does not. Lifting a Maverick requires the same care as a Mustang—using pinch welds or specific subframe hardpoints.

- Jack Selection: A 3-ton floor jack is the recommendation. While a bottle jack can be used on the rear control arm pivots (if careful), the risk of slipping on the unibody structure is high. A floor jack with a pinch weld adapter is the safest protocol.

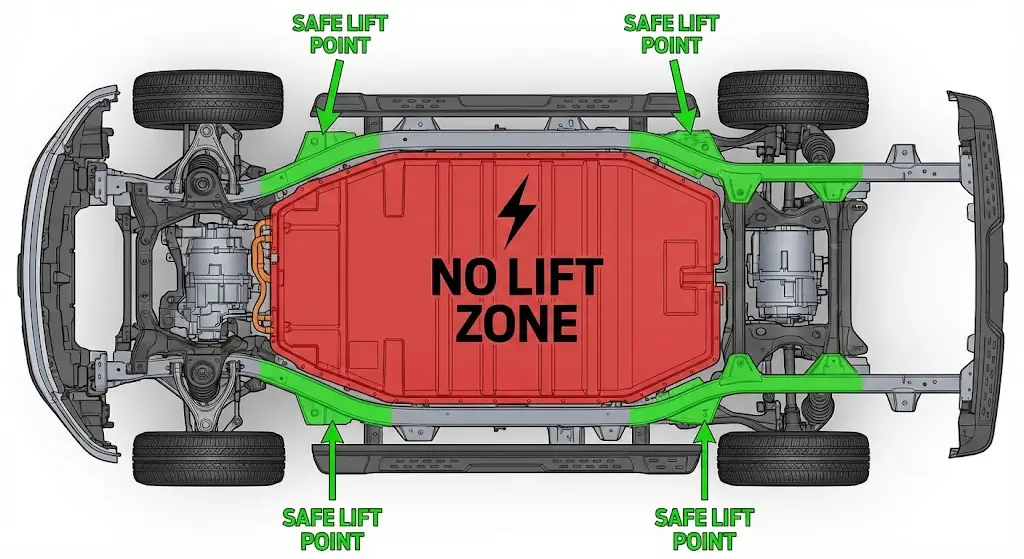

F-150 Lightning and Mustang Mach-E (EV Considerations)

The electrification of the Ford lineup introduces a new, critical variable: the High-Voltage (HV) Battery.

- The “No-Lift” Zone: The battery pack spans the entire floor between the axles. The casing is structural but vulnerable to point-loading. Placing a jack head—especially the sharp head of a bottle jack—anywhere on the battery armor can dent the casing. A dented battery pack is considered a total loss by insurance and Ford service protocols due to the risk of internal cell shorting and thermal runaway (fire).

- Weight: The F-150 Lightning weighs approximately 6,500 lbs—about 1,500 lbs more than a gas F-150. This pushes the limits of “standard” 2-ton or 2.5-ton jacks.

- Protocol: Owners must use equipment rated for at least 3 tons (6,000 lbs) to maintain the ASME-recommended 20-30% safety margin. A 4-ton floor jack is preferred for the Lightning to ensure stability and sufficient hydraulic reserve.

Strategic Buying Guide: 2025-26 Market Landscape

Navigating the market requires understanding the “Tier” system of jack manufacturing.

Tier 1: Professional/Industrial (US/European Origin)

- Brands: Hein-Werner, Weaver, AC Hydraulic.

- Characteristics: Rebuildable US-made pumps, cast iron wheels, 50-year service life.

- Cost: $600 – $1,500.

- Verdict: Overkill for the DIYer, but essential for commercial shops servicing Super Duty fleets.

Tier 2: Pro-Sumer (Global Import)

- Brands: Harbor Freight “Daytona” (Super Duty), Arcan, Sunex.

- Characteristics: The “Daytona Super Duty” 3-ton jack has disrupted the market. Analysis suggests it is manufactured in the same facility as Snap-on’s FJ200, offering near-identical performance (rapid pump, robust seals) for 25% of the price ($289 vs $900).

- Verdict: The “Daytona 3-Ton Super Duty” is currently the undisputed value leader for Ford owners. It offers the reach for an F-150 and the low profile for a Mustang.

Tier 3: Economy/Emergency

- Brands: Pittsburgh (Harbor Freight), Torin Big Red, Husky.

- Characteristics: Functional but basic. Torin bottle jacks are the industry standard for budget hydraulics ($30-$50). They are reliable enough for emergency use but lack the refinement of Tier 1 tools.

- Verdict: Excellent for the “truck kit” bottle jack, but avoid economy floor jacks for regular use as they often lack rapid-pump features and have shorter lifespans.

Maintenance: The Hydraulics of Longevity

A hydraulic jack is a machine that requires maintenance. Neglect leads to the “spongy pedal” effect or failure to hold a load.

Hydraulic Fluid Dynamics

The lifeblood of the jack is its oil.

- Viscosity Matters:

- ISO VG 32: The standard for most automotive jacks. It is relatively thin (low viscosity), allowing it to flow well in cold temperatures. This is the correct choice for unheated garages in North America.

- ISO VG 46/68: Thicker oils used in industrial machinery. Using these in a consumer jack in winter will cause “cavitation”—the pump will suck air instead of oil because the fluid is too thick to flow into the chamber, resulting in a jack that won’t lift.

- Contamination: Oil is hygroscopic (absorbs moisture). Over time, water enters the reservoir, causing internal rust on the polished cylinder walls. This rust destroys the seals. Fluid should be changed every 3 years.

Air Bleeding Procedure

The most common “failure” of a jack is actually just trapped air. Air is compressible; oil is not. If air enters the high-pressure chamber, the handle feels spongy, and the jack won’t reach full height.

- The Purge Protocol:

- Open the release valve (turn handle counter-clockwise).

- Rapidly pump the handle 10-20 times. This cycles the fluid and forces air bubbles out of the plunger circuit and back into the reservoir.

- Close the release valve.

- Pump the jack to max height.

- Check the oil fill plug (with jack lowered) to ensure the level is correct.

Conclusion

The question “Bottle Jack vs. Floor Jack” is ultimately a question of Environment and Vehicle Architecture.

- The Floor Jack is the Workshop Sovereign. For the garage environment, it is safer, faster, and more versatile. It is the only tool for the Mustang, Maverick, and F-150 Lightning (due to stability/EV requirements). Every Ford owner who performs maintenance at home should own a high-quality 3-ton floor jack (preferably a Daytona Super Duty or Arcan).

- The Bottle Jack is the Field Commander. For the F-150, Super Duty, and Bronco, it is the essential mobile companion. Its ability to lift heavy axles directly and its compact form factor make it the superior choice for roadside tire changes and off-road recovery.