9 Blade Turbo 7.3 Powerstroke: Complete Guide

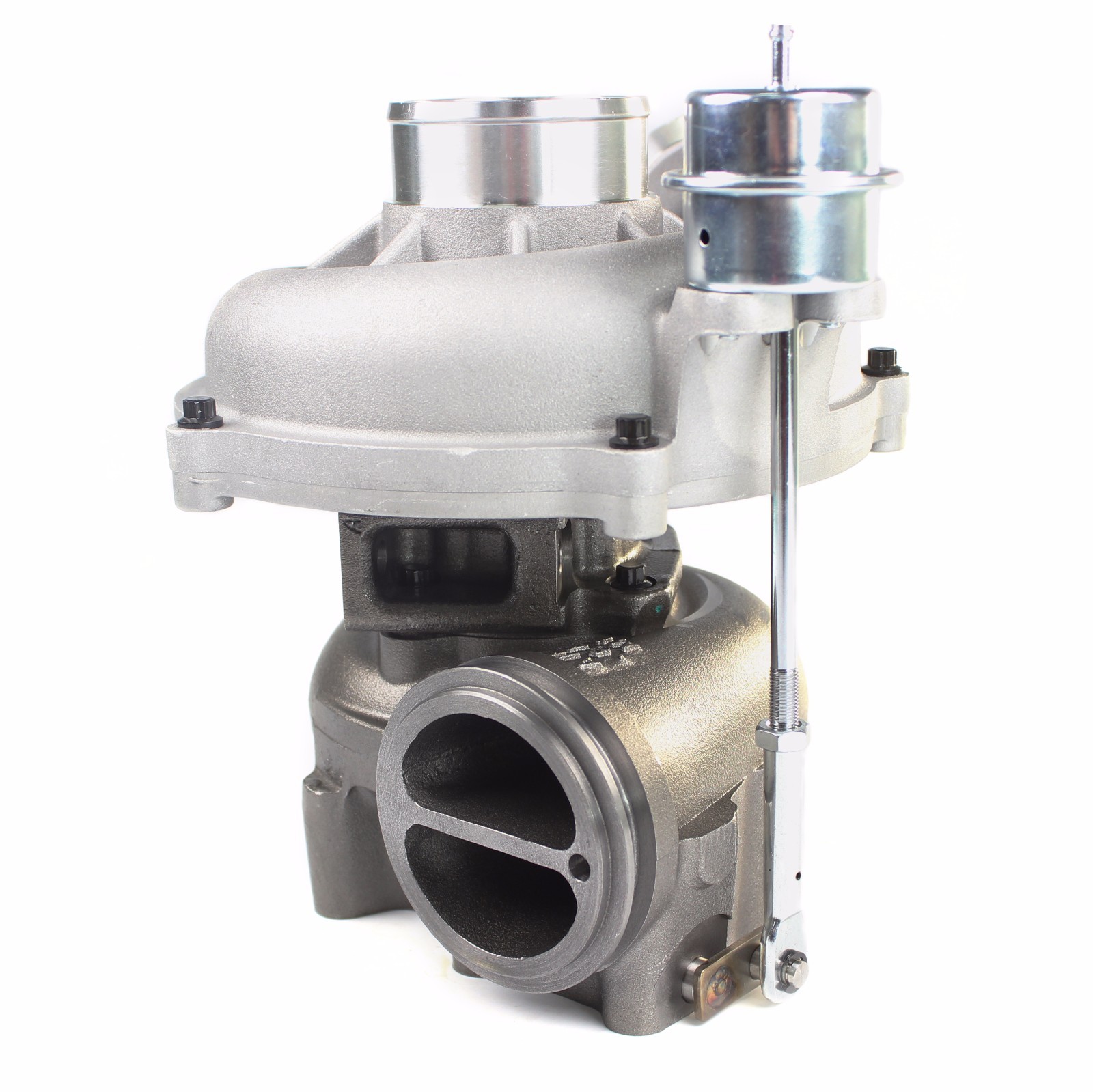

The Ford 7.3L Powerstroke diesel remains a titan of the industry, revered for its million-mile durability and bulletproof iron block. However, even the most reliable engines from the late 90s suffer from dated turbocharger technology, characterized by sluggish low-end response, excessive exhaust gas temperatures (EGTs), and the notorious “turbo surge” that plagues heavy towing. If you are looking to modernize your rig without the $2,500 price tag of a full T4 conversion, the 9-blade compressor wheel is the industry-standard solution. In this complete guide, we will explore the engineering behind the 9-blade design, why it outperforms stock components, and how you can implement this professional-grade upgrade to unlock your engine’s true potential.

Overview: The Evolution of 7.3 Powerstroke Induction

📤 Share Image

The Garrett GTP38 turbocharger, found on 1999.5–2003 Powerstroke engines, was designed for a different era of diesel performance. The factory compressor wheels typically featured a “staggered” or high blade count (often 5×5 or 7×7 configurations) made of cast aluminum. While reliable for stock boost levels, these wheels are heavy and aerodynamically inefficient by modern standards. As owners began adding performance tuners, larger injectors, and high-flow intake systems, the limitations of the stock wheel became glaringly apparent.

Enter the 9-blade billet wheel. By utilizing aerospace-grade quality aluminum and reducing the blade count, engineers created a wheel that moves more air (CFM) with less physical effort. This isn’t just about making more boost; it is about comprehensive efficiency. A 9-blade wheel is lighter, meaning it has less rotational inertia and can “spool” or spin up to speed significantly faster than the heavy cast factory wheel. For the 7.3 enthusiast, this translates to immediate power off the line and a broader powerband during highway passing maneuvers.

By The Numbers

Average EGT Reduction

Faster Spool Time

Surge Incidents Reported

Key Benefits of the 9-Blade Turbo Configuration

When you consult a professional diesel technician about 7.3 performance, they will likely point to three main pain points: heat, lag, and surge. The 9-blade compressor wheel addresses all three through superior geometry. Because the blades are thinner and more aggressively pitched, they can grab larger “gulps” of air at lower RPMs.

Elimination of Turbo Surge

The 9-blade design changes the map of the compressor, moving the surge line further to the left. This stops the “chuffing” sound heard when towing heavy loads up grades.

Lower Exhaust Gas Temps

Higher air volume leads to a better air-fuel ratio. This cooler, denser air charge directly results in lower EGTs, protecting your valves and pistons.

Increased Horsepower

While gain varies by tune, most users see a 15–25 HP increase on the top end as the 9-blade wheel continues to flow air where the stock wheel would choke.

Understanding the “Wicked Whistle”

Beyond performance, there is the subjective benefit of sound. The 9-blade wheel is famous for producing a distinct, high-pitched whistle reminiscent of a jet engine. This occurs because the blade frequency matches the resonant characteristics of the GTP38 housing. For many, this expert-level acoustic signature is reason enough to make the switch, providing that signature “Powerstroke Whistle” that enthusiasts crave.

How It Works: Aerodynamics and Material Science

To understand why the 9-blade turbo 7.3 Powerstroke setup is so effective, we must look at the physics of airflow. A turbocharger’s job is to compress intake air, but doing so generates heat. The stock 7.3 wheel uses a thick blade profile that creates significant turbulence at the “leading edge” of the blade. This turbulence acts as a barrier, preventing air from entering the compressor housing efficiently.

Billet Construction vs. Cast Aluminum: The 9-blade wheels are CNC-machined from a solid block of forged aluminum. This professional manufacturing process allows for much thinner blades and a smaller center hub. A smaller hub means more surface area is dedicated to the blades themselves, increasing the total volume of air moved per revolution. Because the wheel is lighter, the “moment of inertia” is reduced, allowing the turbine side of the turbo to spin the compressor side up to speed with less exhaust backpressure.

The Role of the 360-Degree Thrust Bearing

When installing a high-performance 9-blade wheel, expert builders always recommend a comprehensive rebuild of the turbo’s internal bearings. The stock GTP38 uses a 270-degree thrust bearing, which has a gap in its lubrication circle. As you increase boost with a 9-blade wheel, the axial load (the force trying to push the shaft out of the turbo) increases. A 360-degree thrust bearing provides a full circle of lubrication and support, ensuring your upgraded turbo remains reliable for another 200,000 miles.

Getting Started: Installation and Best Practices

Ready to transform your truck? Upgrading to a 9-blade wheel is a task that an experienced DIYer can handle in a weekend. However, precision is key. This is a trusted procedure, but it requires attention to detail—specifically regarding torque specs and cleanliness. Before starting, ensure you have a clean workspace; even a tiny piece of grit can destroy a turbo spinning at 100,000 RPM.

The compressor wheel nut on the Garrett GTP38 is REVERSE THREADED (Left-Hand Thread). Attempting to loosen it in the standard direction will snap the turbine shaft, requiring a total turbo replacement. Always turn clockwise to loosen!

📋

Step-by-Step Guide to Installation

Disconnect the batteries, remove the intake piping, and unbolt the turbo from the pedestal. Disconnect the EBPV actuator and oil feed/drain lines. Careful with the “collector” bolts; they are prone to snapping.

Place the turbo in a soft-jaw vice. Using a 12-point socket on the turbine side and a wrench on the compressor nut, spin the old wheel off (remember: clockwise to loosen). Clean the shaft threads thoroughly before installing the new 9-blade wheel.

Torque the new wheel to manufacturer specs. Reinstall the turbo with new O-rings. Crucial: Before starting the engine, pull the IDM fuse and crank the engine for 15 seconds to prime the turbo with oil. Failure to prime can lead to immediate bearing failure.

Choosing the Right Housing (0.84 vs 1.0 A/R)

To maximize the efficiency of your 9-blade wheel, you should consider your exhaust housing. The stock 0.84 A/R housing provides quick spooling but can be restrictive at high RPMs. If you frequently tow over 10,000 lbs, many experts recommend pairing the 9-blade wheel with a 1.0 A/R non-wastegated exhaust housing. This combination provides the best balance of low-end response and top-end EGT control, creating a truly comprehensive performance package.

✅ Pros

- Virtually eliminates turbo surge

- Drop-in fitment for GTP38 housings

- Noticeable reduction in EGTs

- More aggressive, professional sound

- Increased compressor efficiency

❌ Cons

- Requires removal of the turbocharger

- Whistle may be too loud for some

- Still limited by the stock center section

- Requires precise torque to avoid imbalance

Professional Recommendations for Maintenance

Once your 9-blade turbo is installed, maintaining it is straightforward but essential. High-performance wheels allow the turbo to reach higher shaft speeds, which places a premium on oil quality. Always use a high-zinc, heavy-duty diesel engine oil and stick to a strict 5,000-mile change interval. Additionally, ensure your air filtration is top-tier; even a small amount of “dusting” will erode the sharp leading edges of your new billet wheel, negating the performance gains.

After installing a high-flow 9-blade wheel, your system will be under higher pressure. This often reveals “hidden” boost leaks in the plenum RTV or the intercooler boots. Build a simple pressure tester to ensure you aren’t losing that newfound reliable boost to the atmosphere.

Summary and Final Thoughts

The 9-blade turbo upgrade for the 7.3 Powerstroke is a comprehensive solution for owners who want modern performance from their trusted old-school workhorse. By improving aerodynamics and reducing rotational mass, this upgrade effectively cures the engine’s most common induction complaints. In summary, remember:

- The 9-blade billet wheel provides superior airflow and surge protection compared to stock cast wheels.

- Combining the wheel with a 360-degree thrust bearing ensures long-term quality and durability.

- Correct installation, including attention to reverse threads and oil priming, is vital for success.

If you are tired of high EGTs and sluggish towing, don’t wait. Source a professional 9-blade wheel kit today and experience the difference that modern engineering can make in your 7.3 Powerstroke.