7.3 Powerstroke Crank No Start: Troubleshooting Guide for Quick Fixes

A 7.3 Powerstroke crank no start issue often stems from fuel system problems or sensor malfunctions. Diagnosing the exact cause requires systematic troubleshooting.

The 7. 3 Powerstroke engine is known for its durability and reliability. Yet, issues like crank no start can occur, frustrating many owners. Common culprits include fuel delivery problems, faulty sensors, or electrical issues. For efficient diagnosis, checking fuel pressure, inspecting the injection control pressure sensor, and examining the camshaft position sensor are crucial steps.

These components often fail and lead to starting issues. Identifying the root cause quickly can save time and prevent further engine damage. Regular maintenance and timely repairs ensure the 7. 3 Powerstroke engine runs smoothly, providing dependable performance.

Credit: www.youtube.com

Common Causes

If your 7.3 Powerstroke engine won’t start, several common causes could be at play. Diagnosing the issue quickly can save time and money. Here, we explore some typical reasons behind a crank no start condition.

Battery Issues

A weak or dead battery is a frequent culprit. Battery issues can prevent the engine from starting. Check the battery voltage using a multimeter. A fully charged battery should read around 12.6 volts.

- Inspect battery terminals for corrosion.

- Ensure the battery connections are tight.

- If the battery is old, consider replacing it.

Sometimes, the battery may have enough charge to power accessories but not enough to crank the engine. Always make sure the battery is in good condition.

Fuel System Problems

Problems in the fuel system can also lead to a crank no start situation. Ensure there is enough fuel in the tank. Use the following checklist to diagnose fuel system issues:

- Check the fuel filter for clogs.

- Inspect the fuel lines for leaks.

- Ensure the fuel pump is working correctly.

- Verify the fuel injectors are not clogged.

A clean fuel system is essential for engine performance. Regular maintenance can help prevent these problems.

Addressing these common causes can often resolve crank no start issues in your 7.3 Powerstroke engine. Regular checks and maintenance can keep your engine running smoothly.

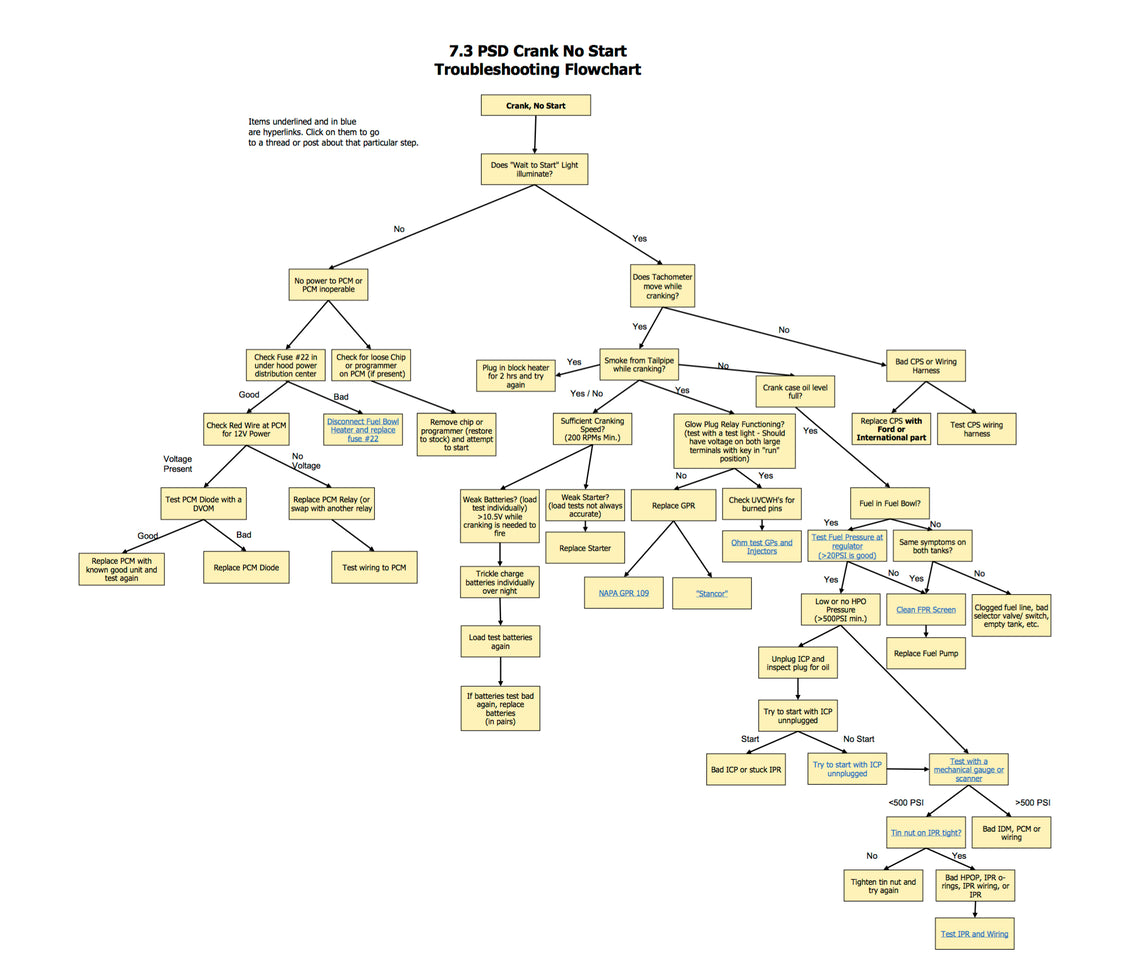

Credit: www.powerstroke.org

Initial Checks

Experiencing a crank no start issue with your 7.3 Powerstroke can be frustrating. Performing initial checks can save you time and money. These checks help identify the root cause quickly. Let’s dive into the first steps.

Inspect Battery

A weak or dead battery is a common cause of crank no start. Ensure the battery terminals are clean and tight. Use a multimeter to check the battery voltage. The voltage should read around 12.6 volts for a fully charged battery. If the voltage is below 12.4 volts, the battery may need charging or replacement.

| Battery Condition | Voltage Reading |

|---|---|

| Fully Charged | 12.6 volts |

| Needs Charging | 12.4 volts |

| Weak/Dead | Below 12.4 volts |

Check Fuel Level

Low fuel can cause a crank no start issue. Always ensure the fuel tank is above the quarter mark. The 7.3 Powerstroke engine needs enough fuel to create the required pressure. Low fuel levels can cause air pockets in the fuel system. These air pockets prevent the engine from starting.

- Keep the tank above the quarter mark

- Check for fuel leaks

- Ensure the fuel filter is clean

These initial checks can often resolve crank no start issues. Addressing these basic elements can save you from unnecessary repairs.

Diagnosing Fuel System

The 7.3 Powerstroke engine sometimes has crank no start issues. Diagnosing the fuel system can help. Let’s break it down. We’ll look at the fuel filter and fuel pump.

Fuel Filter

The fuel filter catches dirt and debris. If it gets clogged, fuel can’t flow. This could cause a crank no start issue.

Steps to check the fuel filter:

- Locate the fuel filter housing.

- Remove the filter cap.

- Inspect the filter for dirt.

- Replace the filter if it’s dirty.

Fuel Pump

The fuel pump sends fuel to the engine. If it fails, the engine won’t start.

Steps to check the fuel pump:

- Turn the ignition key to the “On” position.

- Listen for a humming sound from the fuel tank.

- If you don’t hear it, the pump might be faulty.

Check the fuel pressure with a gauge. Attach the gauge to the fuel rail. The pressure should be within the specified range.

| Component | Action | Result |

|---|---|---|

| Fuel Filter | Inspect and Replace | Improved Fuel Flow |

| Fuel Pump | Check Sound and Pressure | Ensure Proper Function |

Electrical System

The electrical system is crucial for your 7.3 Powerstroke. It ensures the engine starts and runs smoothly. If your truck has a crank no start issue, the electrical system might be the culprit. Here, we’ll focus on two key components: the ignition switch and the wiring harness.

Ignition Switch

The ignition switch is essential for starting your engine. It sends power to the starter motor. If it fails, your engine won’t start. Check the ignition switch for wear and tear.

A faulty ignition switch may cause intermittent starting problems. Inspect it closely. If needed, replace it to avoid crank no start issues.

Wiring Harness

The wiring harness connects various electrical components. It ensures they communicate effectively. Any damage to the wiring harness can cause starting problems.

Inspect the harness for signs of wear or damage. Look for frayed wires or loose connections. Repairing these issues can solve many crank no start problems.

Use a multimeter to check for continuity in the wiring. This helps identify broken wires. Fixing these can restore your engine’s starting ability.

Sensor Issues

The 7.3 Powerstroke is a durable engine, but sensor issues can cause crank no start problems. Two main sensors are crucial: the Crankshaft Position Sensor and the Camshaft Position Sensor. Both sensors play a vital role in engine performance.

Crankshaft Position Sensor

The Crankshaft Position Sensor helps monitor the position and speed of the crankshaft. If this sensor fails, the engine may not start. The sensor sends signals to the engine control unit (ECU). The ECU uses this information to adjust fuel injection and timing.

A faulty Crankshaft Position Sensor can lead to several issues:

- Engine cranks but does not start

- Erratic engine behavior

- Check engine light turns on

To diagnose a bad Crankshaft Position Sensor, use an OBD-II scanner. This tool will read error codes from the ECU. If the sensor is faulty, replace it immediately.

Camshaft Position Sensor

The Camshaft Position Sensor tracks the camshaft’s position. It ensures the engine’s valves open and close at the right times. A bad Camshaft Position Sensor can disrupt this timing.

Common symptoms of a failing Camshaft Position Sensor include:

- Engine stalls while driving

- Poor fuel economy

- Engine misfires

Like the Crankshaft Position Sensor, an OBD-II scanner can help diagnose issues with the Camshaft Position Sensor. Once identified, replace the faulty sensor to restore engine performance.

Glow Plugs

The 7.3 Powerstroke engine relies on glow plugs to start in cold weather. These small heaters warm the air in the cylinders, making it easier for the engine to start. Properly functioning glow plugs are essential for a smooth start, especially in winter.

Testing Glow Plugs

To ensure your glow plugs are working, you need to test them. Follow these steps:

- Turn off the engine and remove the key.

- Locate the glow plugs on the engine.

- Disconnect the electrical connector from each glow plug.

- Use a multimeter to check resistance. Set it to the Ohms setting.

Good glow plugs should show a resistance between 0.5 and 2 Ohms. If the resistance is higher or lower, the glow plug is faulty.

Replacing Glow Plugs

Faulty glow plugs need replacement to ensure reliable engine starts. Follow these steps for replacing glow plugs:

- Turn off the engine and remove the key.

- Remove the valve cover to access the glow plugs.

- Disconnect the electrical connector from the glow plug.

- Use a deep socket wrench to unscrew the glow plug.

- Install the new glow plug by screwing it in place.

- Reconnect the electrical connector.

- Replace the valve cover.

It is recommended to replace all glow plugs at once. This ensures even performance across all cylinders. A properly functioning set of glow plugs guarantees a smooth start, even in the coldest weather.

Air Intake

The air intake system is vital for your 7.3 Powerstroke engine. It ensures the engine gets clean air. Dirty air can cause a crank no start issue. Let’s explore the key components of the air intake system.

Air Filter

The air filter blocks dirt and debris from entering the engine. A clogged air filter restricts airflow. This can lead to poor engine performance. Regularly check and replace the air filter. This keeps the engine running smoothly.

| Air Filter Condition | Action Required |

|---|---|

| Clean | No action needed |

| Dirty | Replace the filter |

Turbocharger

The turbocharger boosts engine power by forcing more air into the engine. A faulty turbocharger reduces air intake. This can cause a crank no start problem. Inspect the turbocharger regularly.

- Check for oil leaks around the turbo.

- Listen for unusual noises while the engine runs.

- Ensure the turbo spins freely.

Maintaining a healthy turbocharger is crucial. It ensures your engine performs optimally.

Credit: m.youtube.com

Professional Help

The 7.3 Powerstroke engine is a reliable workhorse. But, it can have issues like a crank no start. When the problem persists, seeking professional help is crucial. This section will guide you on when to call a mechanic and how to choose the right service for your 7.3 Powerstroke crank no start issue.

When To Call A Mechanic

Identifying the exact problem can be challenging. Here are signs that indicate it’s time to call a mechanic:

- Repeated Cranking: The engine cranks but won’t start after multiple attempts.

- Strange Noises: Unusual sounds during the cranking process.

- Fuel Issues: Strong fuel smell or visible leaks.

- Warning Lights: Check engine light remains on.

- Battery Problems: New battery but still facing starting issues.

Choosing The Right Service

Not all mechanics are familiar with the 7.3 Powerstroke engine. Here’s how to choose the right service:

| Criteria | Details |

|---|---|

| Specialization | Look for mechanics who specialize in diesel engines. |

| Experience | Check their experience with 7.3 Powerstroke engines. |

| Reviews | Read customer reviews and ratings online. |

| Certifications | Ensure they have relevant certifications and training. |

| Warranty | Check if they offer a warranty on repairs. |

Make sure to ask questions and get a clear estimate. This will help you make an informed decision.

Frequently Asked Questions

What Causes A 7.3 Crank But Not Start?

A 7. 3 crank but no start can be caused by fuel delivery issues, faulty sensors, or a weak battery. Check the fuel pump, injectors, and glow plugs.

Why Does My Ford Super Duty Crank But Won’t Start?

Your Ford Super Duty may crank but not start due to a faulty fuel pump, dead battery, or clogged fuel filter. Check for spark and fuel pressure. Inspect the ignition switch and fuses. Consult a mechanic for a thorough diagnosis if the issue persists.

What Are The Symptoms Of A Bad Ipr On A 7.3 Powerstroke?

A bad IPR on a 7. 3 Powerstroke can cause hard starts, rough idling, stalling, poor acceleration, and reduced fuel economy.

What Are The Symptoms Of Idm Failure 7.3 Powerstroke?

IDM failure in a 7. 3 Powerstroke shows symptoms like rough idle, no start, stalling, and loss of power. Check engine light often appears.

Conclusion

Resolving a 7. 3 Powerstroke crank no start issue can be challenging. Follow these steps and tips to troubleshoot effectively. Regular maintenance and timely repairs ensure your engine runs smoothly. Keep this guide handy for quick reference. With patience and the right approach, you’ll get your engine roaring again.