6.0 Powerstroke Fuel Pump Diagram: Easy Setup Guide

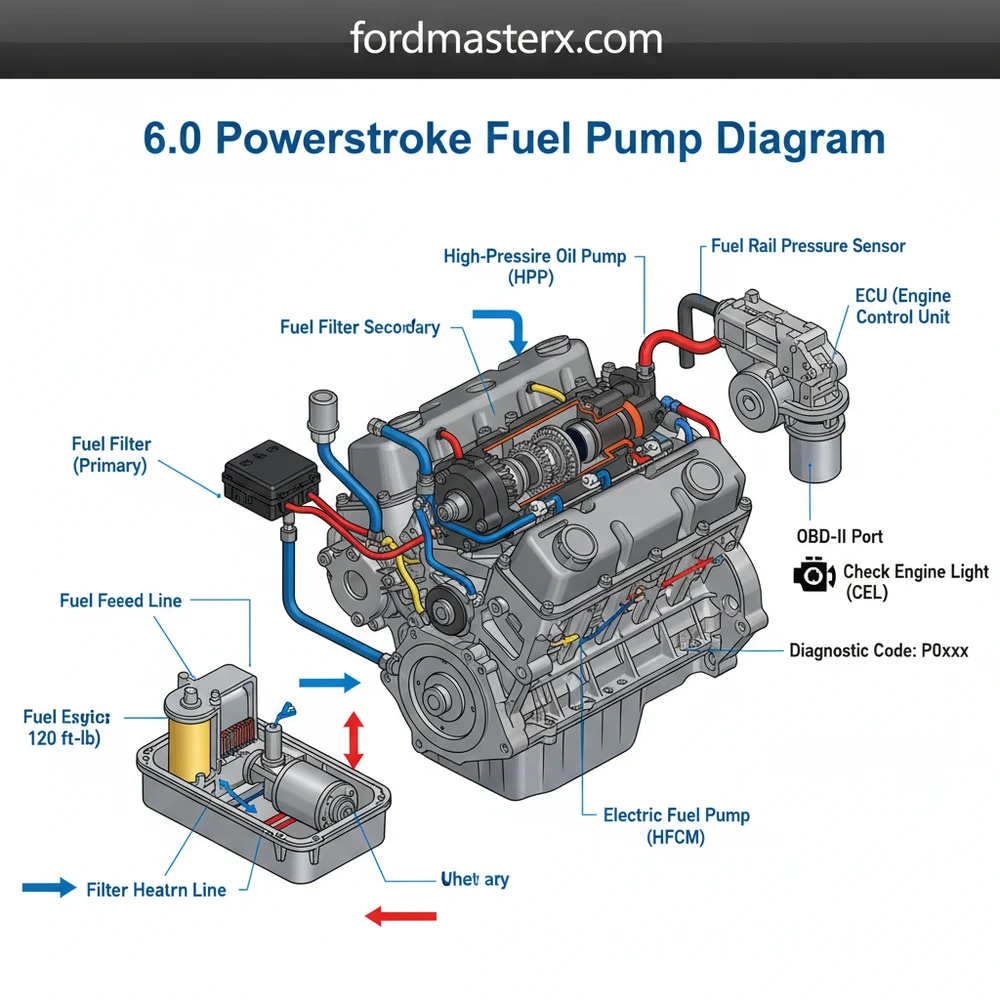

The 6.0 Powerstroke fuel pump diagram illustrates the Horizontal Fuel Conditioning Module (HFCM) located on the driver-side frame rail. It details the primary pump, fuel heater, water separator, and electrical connections to the ECU. This schematic helps identify fuel flow paths and wiring pinouts essential for diagnosing low-pressure fuel system failures.

📌 Key Takeaways

- Visualize fuel flow from the tank to the secondary filter

- The Horizontal Fuel Conditioning Module (HFCM) is the primary unit

- Relieve fuel pressure before opening lines to prevent injury

- Use an OBD-II scanner to monitor real-time fuel pressure PIDs

- Use this diagram during pump replacement or when chasing electrical faults

The 6.0L Powerstroke engine, found in Ford Super Duty trucks from 2003 to 2007, is an engineering marvel that demands precise fuel delivery to maintain its performance. Unlike many other diesel engines of its era, the 6.0L relies on a complex fuel system where the fuel pump serves not just to move liquid, but to condition it. For the DIY enthusiast, understanding the 6.0 Powerstroke fuel pump diagram is the first step in diagnosing “crank, no-start” conditions or poor engine performance. The heart of this system is the Horizontal Fuel Conditioning Module (HFCM), located on the driver’s side frame rail. This module combines the electric fuel pump, the primary fuel filter, and the water-in-fuel sensor into one unit. Because the fuel also acts as a coolant and lubricant for the HEUI (Hydraulic Electronic Unit Injector) system, any failure in the pump or a drop in pressure can lead to catastrophic injector failure. This guide provides a deep dive into the layout, wiring, and mechanics of the 6.0 fuel delivery system.

Main Components and Features of the HFCM

The fuel delivery system on a 6.0 Powerstroke is divided into two main stages: the low-pressure suction/conditioning stage at the frame rail and the high-pressure distribution stage at the engine. Understanding the components within the 6.0 Powerstroke fuel pump diagram requires identifying these key parts:

- The HFCM (Horizontal Fuel Conditioning Module): Located on the driver-side frame rail, roughly under the driver’s seat. It houses the electric fuel pump, the 10-micron primary fuel filter, and a water separator.

- Primary Fuel Filter: This is a large, pleated element inside the HFCM. It is designed to catch large debris and separate water from the diesel before it reaches the pump motor.

- The Electric Pump Motor: A DC motor integrated into the HFCM that pushes fuel toward the engine at a specific pressure (ideally 45-55 PSI).

- Water-in-Fuel (WIF) Sensor: A probe located at the bottom of the HFCM that triggers a dashboard light when water reaches a certain level in the reservoir.

- Secondary Fuel Filter Housing: Located on top of the engine, next to the oil filter housing. This contains a 4-micron filter that provides the final cleaning before fuel enters the cylinder heads.

- Fuel Pressure Regulator (The “Blue Spring” Location): Attached to the side of the secondary filter housing. This regulates the return of fuel to the tank and maintains the system’s “head pressure.”

How to Read and Use the Fuel Pump Diagram

To effectively use a 6.0 Powerstroke fuel pump diagram for DIY repairs, you must understand the flow path and the electrical pinouts. The diagram isn’t just a map of pipes; it’s a logic gate for troubleshooting.

The Mechanical Flow Path

The flow starts at the fuel tank. Fuel is sucked through the suction line into the HFCM. Inside the HFCM, it passes through the primary filter first. This is crucial: the filter protects the pump motor. After the pump, the pressurized fuel travels up the frame rail via a 3/8-inch steel line to the secondary filter housing on the engine. From there, it splits into two lines that feed the front of the left and right cylinder heads. Finally, excess fuel exits the rear of the heads (or the regulator housing, depending on the model year) and returns to the tank via a return line.

Electrical Wiring and Pinouts

The HFCM has a multi-pin electrical connector. If your pump isn’t turning on, you need to check these specific wires using the diagram as a guide:

- Red with Yellow Stripe (Pin 1): This is the main 12V power feed coming from the fuel pump relay (via the inertia switch).

- Black (Pin 4): This is the ground wire. It must have a clean connection to the frame or battery negative to ensure the pump runs at full speed.

- Pink with Black Stripe: Typically associated with the Water-in-Fuel sensor signal to the PCM/Instrument cluster.

When reading the diagram, ensure you are looking at the “harness side” or the “component side” of the plug. Testing for 12V at the Red/Yellow wire during the first 20 seconds of “Key On, Engine Off” (KOEO) is the standard method for verifying the electrical integrity of the pump circuit.

Tips for Maintaining and Upgrading the System

The 6.0 Powerstroke fuel system is sensitive to maintenance intervals. Following a few expert tips can prevent the need for an expensive tow and pump replacement.

The original fuel regulator spring in the 6.0L often weakens over time, leading to fuel pressures dropping below 40 PSI. This causes “starvation” at the injectors, which results in internal damage. Installing the “Blue Spring Kit” (Ford Part #3C3Z-9T517-AG) increases pressure to a healthy 55-65 PSI and is considered a mandatory DIY upgrade for engine longevity.

Use OEM Filters Only: One of the most common mistakes DIYers make is using aftermarket “will-fit” fuel filters. The 6.0L fuel system requires a patented “Aqua-Bloc” media found in Motorcraft or Racor filters. Aftermarket filters often lack the water-separating membrane, allowing moisture to reach the injectors and cause rust and stiction. Furthermore, some aftermarket filters are slightly shorter or taller, which can cause fuel to bypass the filter entirely or prevent the cap from sealing correctly.

Drain the Water Separator Monthly: On the side of the HFCM, there is a 6mm Allen plug (or a yellow lever on later models). You should drain this monthly to remove accumulated water. If the plug is stuck, many enthusiasts replace it with a “knurled” brass plug that can be turned by hand.

Troubleshooting Common Fuel Pump Issues

If your 6.0 Powerstroke is stumbling, losing power under load, or failing to start, use the following troubleshooting steps based on the fuel pump layout.

Testing for Pressure

The first step in any fuel-related diagnosis is checking the pressure. There is a test port (Schrader valve) on the secondary fuel filter housing on the engine. Using a mechanical fuel pressure gauge, check the pressure at idle and under WOT (Wide Open Throttle).

- Healthy: 50–60 PSI.

- Marginal: 40–45 PSI (Change filters immediately and check the regulator).

- Critical: Below 40 PSI (Do not drive; injector damage is imminent).

No-Start Scenarios

If the pump isn’t humming when you turn the key to the “On” position, check the Inertia Switch. This is a safety device located behind the passenger-side kick panel that cuts power to the fuel pump in the event of an impact. Sometimes a hard jar or a heavy kick to the trim panel can trip it. Press the red button on top to reset it. If that isn’t the issue, check Fuse 40 (20A) in the under-dash panel and the fuel pump relay.

Air in the System

If you have recently changed your filters and the truck won’t start, you likely have air in the lines. The 6.0L is somewhat self-priming, but it requires a specific procedure. Turn the key to “On” for 30 seconds (you will hear the pump buzz), then turn it off. Repeat this 3 to 5 times before attempting to crank the engine. This cycles fuel through the HFCM and pushes air back to the tank through the return line.

In conclusion, the 6.0 Powerstroke fuel pump and its surrounding module are vital to the engine’s health. By understanding the HFCM’s location, the flow path to the secondary filter, and the critical importance of maintaining at least 45 PSI of pressure, DIY owners can keep their trucks running reliably for hundreds of thousands of miles. Always prioritize OEM parts and keep a close eye on your fuel pressure to avoid the high cost of injector replacement.

Step-by-Step Guide to Understanding the 6.0 Powerstroke Fuel Pump Diagram: Easy Setup Guide

Identify the HFCM on the driver-side frame rail using the diagram layout to locate the primary pump housing.

Locate the electrical connectors and fuel line quick-connect fittings to ensure clear access for testing or removal.

Understand how the ECU sends power through the fuel pump relay by tracing the wiring path on the schematic.

Apply the correct torque spec when reinstalling the HFCM mounting bolts to prevent vibration-induced leaks or hardware failure.

Verify that the check engine light is off after cycling the ignition and checking for any active diagnostic code.

Complete the process by checking for leaks while the engine is idling and confirming steady fuel pressure via OBD-II.

Frequently Asked Questions

Where is the 6.0 Powerstroke fuel pump located?

The primary fuel pump is located on the driver-side frame rail, roughly beneath the driver’s seat area. It is housed within the Horizontal Fuel Conditioning Module (HFCM), which also contains the primary fuel filter and the water separator drain valve for the diesel system.

What does the 6.0 Powerstroke fuel pump diagram show?

The diagram maps the electrical harness, fuel inlet and outlet lines, and the water-in-fuel sensor. It clarifies how the pump receives power from the relay and how the ECU monitors the system’s electrical integrity to prevent engine starvation and injector damage.

How many electrical connections does the fuel pump have?

The HFCM assembly typically features two main electrical connectors. One connector provides power and ground to the fuel pump motor, while the other connects to the water-in-fuel (WIF) sensor and the fuel heater element, which are critical for cold weather operation.

What are the symptoms of a bad 6.0 fuel pump?

Common symptoms include hard starting, engine stalling under load, and a check engine light. You may also pull a specific diagnostic code related to low fuel pressure using an OBD-II tool, or notice an audible change in the pump’s humming sound during the pre-glow cycle.

Can I replace the 6.0 Powerstroke fuel pump myself?

Yes, replacing the HFCM or the internal pump is a common DIY task. It requires basic hand tools and a way to catch draining fuel. Always ensure the system is depressurized and follow the manufacturer’s torque spec for the mounting bolts to ensure a leak-free seal.

What tools do I need for fuel pump diagnostics?

You will need a 36mm socket for the fuel filter cap, an OBD-II scanner to check for codes, and a fuel pressure gauge kit. A torque wrench is also recommended for reinstallation to ensure all fasteners meet the required specifications for frame-mounted components.