5.4 3V Cam Phaser Torque Specs: Essential Guide for Accurate Installation

The torque specs for the 5.4 3V cam phaser are 30 ft-lbs. Ensure bolts are tightened to this specification.

The cam phaser is a crucial component in the 5. 4 3V engine. Proper torque specifications ensure optimal performance and longevity. Mechanics and DIY enthusiasts must adhere to the 30 ft-lbs torque spec. This prevents potential engine damage and maintains efficiency.

Incorrect torque can lead to engine malfunctions and costly repairs. Always use a calibrated torque wrench for accuracy. Regular maintenance and proper torqueing keep your engine running smoothly. Keeping these specifications in mind helps maintain engine health. Accurate torque application is key to engine reliability. Ensure all bolts are tightened evenly for best results.

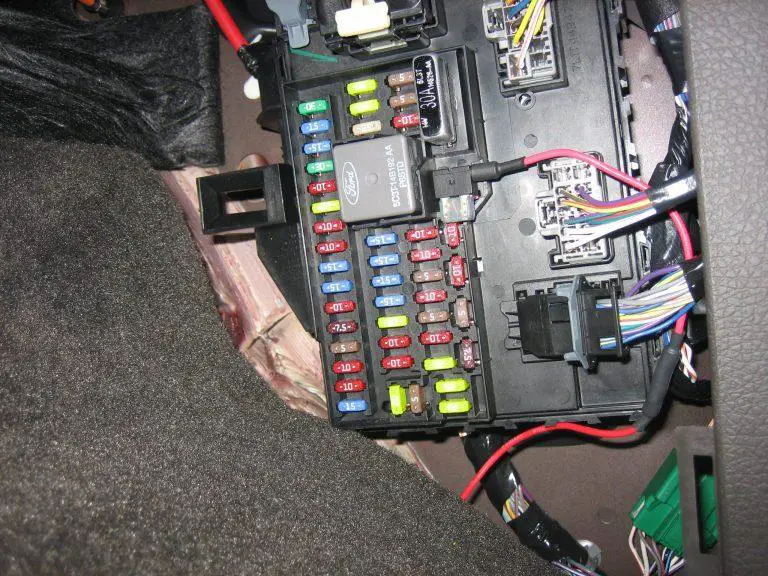

Credit: www.f150forum.com

Introduction To Cam Phasers

The 5.4 3V Cam Phaser Torque Specs are crucial for engine performance. Understanding cam phasers helps you maintain engine efficiency. This section introduces cam phasers and their role.

Purpose Of Cam Phasers

Cam phasers adjust the camshaft position relative to the crankshaft. This adjustment optimizes engine performance. It helps in fuel efficiency and emissions control.

Cam phasers achieve this by controlling valve timing. They use hydraulic pressure to change camshaft angles. This results in smoother engine operation.

Common Applications

Cam phasers are common in modern internal combustion engines. They are especially prevalent in variable valve timing (VVT) systems.

Here are some common applications:

- Passenger cars

- Light trucks

- High-performance vehicles

Ford’s 5.4L 3V engines frequently use cam phasers. These engines are found in many Ford models. Proper torque specs are essential for these engines.

Understanding 5.4 3v Engines

The 5.4 3V engine is a popular choice for many vehicle owners. Known for its power and reliability, it’s used in various Ford models. Let’s dive into the details of this engine.

Engine Overview

The 5.4 3V engine is a V8 engine, part of Ford’s Modular engine family. It features three valves per cylinder, providing better airflow and combustion efficiency. This engine is known for its durability and performance.

It powers many Ford trucks and SUVs. This includes the F-150, Expedition, and Lincoln Navigator. The engine’s design focuses on delivering a balance of power and fuel efficiency.

Key Features

Here are some key features of the 5.4 3V engine:

- Three Valves Per Cylinder: Enhances airflow and combustion.

- Variable Camshaft Timing: Optimizes engine performance and fuel efficiency.

- Cast Iron Block: Provides durability and strength.

- Aluminum Cylinder Heads: Reduces weight and improves cooling.

- Electronic Throttle Control: Ensures smooth and responsive throttle input.

Below is a table summarizing some of the technical specifications:

| Feature | Description |

|---|---|

| Displacement | 5.4 liters |

| Horsepower | 300-320 HP |

| Torque | 365-390 lb-ft |

| Compression Ratio | 9.8:1 |

Understanding these features can help in maintaining and optimizing the engine’s performance. Proper knowledge ensures the engine runs smoothly and efficiently.

Importance Of Correct Torque Specs

The 5.4 3V Cam Phaser Torque Specs are crucial for engine health. Correct torque specs ensure parts are secure and function properly. Incorrect torque can lead to engine damage and costly repairs.

Impact On Engine Performance

Proper torque specs directly affect engine performance. When torque specs are correct, the cam phaser works efficiently.

- Ensures smooth timing adjustments

- Reduces engine noise

- Improves fuel efficiency

- Prevents wear and tear

Correct torque specs also maintain the balance of the engine. This balance is essential for optimal performance.

Consequences Of Incorrect Torque

Incorrect torque specs can cause serious problems. Under-torquing may lead to loose parts. Over-torquing can damage threads and parts.

- Engine Noise: Loose parts cause knocking sounds.

- Poor Performance: Timing issues affect engine efficiency.

- Wear and Tear: Over-torquing damages internal parts.

- Expensive Repairs: Incorrect torque leads to costly fixes.

Always use a torque wrench to ensure correct specs. Refer to the manufacturer’s manual for precise numbers. This helps maintain engine health and performance.

Required Tools And Equipment

Working on the 5.4 3V Cam Phaser Torque Specs requires precision and the right tools. Having the correct equipment ensures the job is done properly. Below is a detailed list of the required tools and safety gear.

Essential Tools

- Torque Wrench: You need this to tighten bolts accurately.

- Socket Set: A complete set including both metric and standard sizes.

- Cam Phaser Locking Tool: Keeps the camshaft in place.

- Breakover Bar: Provides extra leverage for tough bolts.

- Engine Timing Tool Kit: Ensures precise timing during the installation.

- Ratchet and Extensions: Access hard-to-reach bolts easily.

Safety Gear

- Safety Glasses: Protect your eyes from debris.

- Mechanic Gloves: Protect your hands and improve grip.

- Ear Protection: Safeguard your ears from loud noises.

- Work Boots: Ensure your feet are protected.

- Face Mask: Prevent inhaling harmful particles.

Step-by-step Installation Guide

Installing the 5.4 3V cam phaser requires precision. This guide helps you through each step. Follow along to ensure a smooth installation process.

Preparation Steps

Before starting, gather all necessary tools and parts. Proper preparation ensures a seamless process.

- Safety Gear: Wear gloves and safety glasses.

- Tools Required: Torque wrench, socket set, and camshaft alignment tool.

- Parts Needed: New cam phaser, gaskets, and bolts.

Ensure the engine is cool. Disconnect the battery to prevent any electrical issues. Lay out all tools and parts within reach.

Installation Process

Follow these steps to install the cam phaser:

- Remove Engine Cover: Unscrew bolts and lift the cover off.

- Access Timing Chain: Remove the valve cover to expose the timing chain.

- Align Camshaft: Use the camshaft alignment tool to keep it in place.

- Remove Old Cam Phaser: Use a socket set to loosen and remove bolts.

- Install New Cam Phaser: Place the new cam phaser and secure it with bolts.

- Torque Specs: Tighten bolts to the specified torque of 30 ft-lbs.

- Reassemble Components: Put the valve cover and engine cover back.

- Reconnect Battery: Ensure all connections are secure and reconnect the battery.

Double-check all connections and bolts. Start the engine and listen for any unusual noises.

Credit: www.f150online.com

Torque Specifications For 5.4 3v Cam Phasers

Understanding the correct torque specifications for the 5.4 3V Cam Phasers is crucial. Proper torque ensures engine performance and longevity. This guide provides essential details on torque values and the recommended sequence.

Torque Values

The torque values for the 5.4 3V Cam Phasers are specific. Using the correct torque prevents engine damage.

| Component | Torque Specification |

|---|---|

| Cam Phaser Bolts | 30 lb-ft (40 Nm) |

| Timing Chain Tensioner | 89 lb-in (10 Nm) |

| Timing Cover Bolts | 18 lb-ft (25 Nm) |

Recommended Sequence

Follow the recommended sequence for tightening the cam phaser bolts. This ensures even pressure distribution.

- Start with the inner bolts.

- Move outward in a criss-cross pattern.

- Double-check each bolt to ensure proper torque.

Use a reliable torque wrench for accuracy. Proper sequence and torque values maintain engine health.

Common Mistakes To Avoid

Proper torque specs are crucial for the 5.4 3V cam phaser. Incorrect torque can lead to engine issues. Two main mistakes are over-tightening and under-tightening. Let’s explore these mistakes.

Over-tightening

Over-tightening the cam phaser can cause damage. Excessive force may strip threads. This leads to costly repairs. Use a torque wrench for accuracy.

- Stripped threads reduce cam phaser effectiveness.

- Over-tightened bolts may break under stress.

- Torque wrench ensures correct force application.

Under-tightening

Under-tightening poses its own risks. Loose cam phasers can cause engine timing issues. This can affect engine performance.

- Loose bolts can lead to vibrations.

- Incorrect timing affects engine efficiency.

- Proper torque maintains engine stability.

| Mistake | Effect |

|---|---|

| Over-Tightening | Stripped threads, broken bolts |

| Under-Tightening | Engine timing issues, vibrations |

Maintenance Tips

Maintaining your 5.4 3V cam phaser torque specs can extend your engine’s life. Regular maintenance ensures optimal performance and prevents costly repairs.

Regular Inspections

Conducting regular inspections is crucial for your cam phaser. Check for any signs of damage or wear. Use a torque wrench to ensure the cam phaser bolts are tight.

Follow these steps for inspection:

- Turn off the engine and let it cool.

- Remove the engine cover to access the cam phaser.

- Visually inspect the cam phaser for any visible damage.

- Use a torque wrench to check the bolt tightness.

Regular inspections help detect issues early. This prevents major damage later.

Signs Of Wear

Watch for signs of wear on your cam phaser. Early detection can save you from expensive repairs.

Here are common signs of wear:

- Loud ticking noise from the engine.

- Poor engine performance.

- Check engine light is on.

- Oil leaks around the cam phaser area.

If you notice any of these signs, inspect the cam phaser immediately. Addressing wear early can save your engine.

| Inspection Step | Reason |

|---|---|

| Visual check | Identify obvious damage. |

| Tightness check | Ensure bolts are secure. |

| Listen for noise | Detect ticking sounds. |

| Check for leaks | Identify oil leaks early. |

These maintenance tips help keep your 5.4 3V cam phaser in top shape. Regular checks and knowing signs of wear can prevent bigger issues. Stay proactive and extend your engine’s life.

Credit: www.expeditionforum.com

Frequently Asked Questions

What Are The Torque Specs For A Cam Phaser?

The torque specs for a cam phaser typically range from 85 to 95 ft-lbs. Always check your vehicle’s manual for exact specifications.

What Is The Torque On The 2005 Ford F150 5.4 Cam Cap?

The torque specification for the cam cap on a 2005 Ford F150 5. 4 is 89 inch-pounds. Ensure proper tightening.

What Are The Symptoms Of A Cam Phaser On A Ford F150?

Symptoms of a faulty cam phaser on a Ford F150 include rough idling, engine knocking, poor fuel efficiency, and decreased performance. You might also hear a rattling noise from the engine, especially during startup. Prompt attention can prevent further damage.

Why Do Ford Cam Phasers Go Bad?

Ford cam phasers often fail due to oil sludge buildup, poor lubrication, or worn internal components. Regular maintenance can prevent issues.

Conclusion

Understanding the 5. 4 3V cam phaser torque specs is essential for engine performance. Proper torque ensures longevity and reliability. Always refer to the manufacturer’s manual for precise guidelines. Following the correct specifications can prevent costly repairs and enhance engine efficiency.

Keep your vehicle running smoothly by adhering to these torque specs.