Signs Of Bad Master Cylinder: Identifying Hydraulic Failure In Your Braking System

When you depress the brake pedal, you are trusting a complex hydraulic system to convert your foot’s pressure into the mechanical force required to stop a multi-ton vehicle. This transformation relies entirely on the integrity of the hydraulic circuits, where physics and precision engineering meet. The master cylinder is the heart of this system, serving as the primary pump that distributes pressurized fluid to the calipers and wheel cylinders. When it fails, the results can range from a slightly soft pedal to a complete and catastrophic loss of braking ability. In this comprehensive guide, we will analyze the specific signs of a bad master cylinder, from physical symptoms and visual cues to electronic warnings, ensuring you can identify and address failure before it compromises your safety.

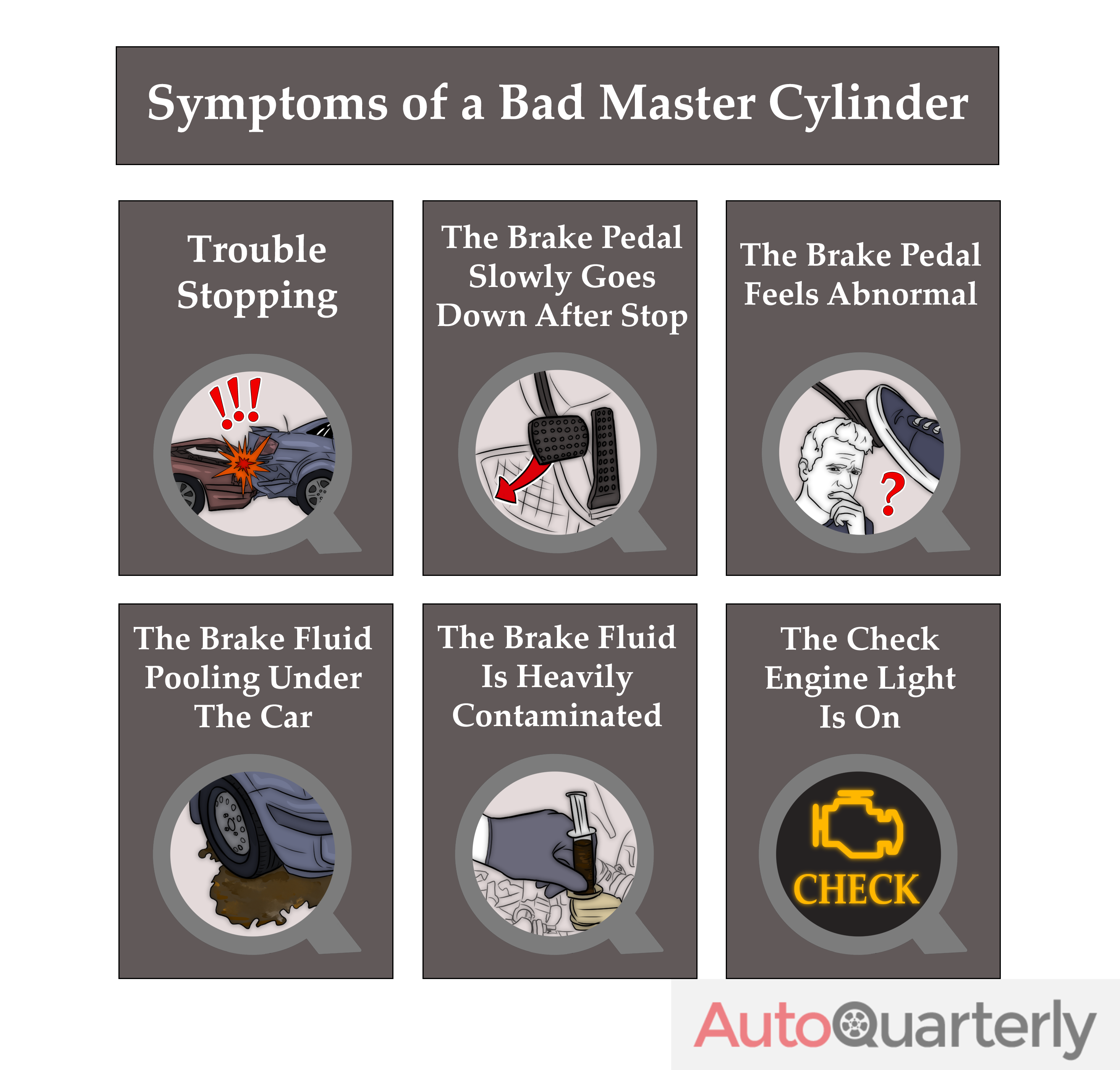

Recognizing Abnormal Brake Pedal Behavior and Sponginess

📤 Share Image

The most immediate feedback a driver receives regarding the health of the professional braking system comes through the pedal. In a healthy hydraulic setup, the master cylinder maintains static pressure for at least 30 seconds without more than 1/4 inch of pedal movement. When internal seals—specifically the primary and secondary cups—begin to fail, the tactile response of the pedal changes dramatically. These seals are responsible for containing hydraulic pressures ranging from 800 to 2,000 PSI depending on the vehicle weight and braking force applied.

The ‘Sinking’ Pedal and Internal Bypass Leaks

A classic symptom of master cylinder failure is the “sinking” pedal. Imagine sitting at a red light with your foot steadily on the brake. Without any change in leg pressure, you notice the pedal slowly drifting toward the floorboard. This occurs because of an internal bypass leak. Fluid is not leaking out of the vehicle; instead, it is leaking past the internal rubber seals within the cylinder bore. As the seals lose their ability to maintain a tight interface with the cylinder walls, pressurized fluid “bypasses” the piston and returns to the low-pressure side of the reservoir, causing the pedal to drop.

Spongy Feel and Inconsistent Travel

A “mushy” or spongy pedal often indicates that air has entered the hydraulic lines or that the internal seals are no longer providing a crisp cut-off of fluid. Unlike hydraulic fluid, air is compressible. When you apply the brakes, the force is wasted on compressing the air pockets rather than moving the brake pads. Furthermore, you may notice inconsistent pedal travel. In some instances, the vehicle may require two “pumps” of the pedal to build sufficient stopping pressure—a clear sign that the first stroke failed to displace enough fluid to overcome the internal mechanical gaps or seal failures.

Mechanical Resistance and Kickback

Damaged primary or secondary pistons can also cause irregular mechanical resistance during the stroke. If the internal return spring is broken or the piston is scored, you might feel a “pedal kickback” or a grinding sensation as the piston moves through its bore. This mechanical interference prevents the smooth modulation of braking force, making it difficult to achieve a reliable and predictable stop.

If your pedal feels firm while the engine is off but sinks when the engine is running, the issue is likely the master cylinder being unable to hold pressure under the added force of the power brake booster.

External Brake Fluid Leaks and Visible Contamination

While internal leaks are common, visual inspections of the master cylinder body and fluid reservoir often provide the “smoking gun” needed for a complete diagnosis. As an expert technician will tell you, the exterior of the master cylinder should remain dry and free of oily residue. Any evidence of moisture suggests a breach in the primary containment system.

Leaks at the Mounting Flange

One of the most frequent points of failure is the rear cup seal. When this seal fails, fluid escapes from the back of the cylinder and leaks between the master cylinder and the brake booster. Because brake fluid acts as a potent solvent, a key visual indicator is peeling or bubbling paint on the brake booster directly below the mounting flange. If left unchecked, this fluid can enter the brake booster housing, destroying the internal rubber diaphragm and leading to a loss of power assist.

Assessing Brake Fluid Quality

Brake fluid is hygroscopic, meaning it actively absorbs moisture from the atmosphere. It can absorb up to 3% of its weight in water within just 12 months in humid climates. This moisture lowers the boiling point of the fluid and accelerates internal corrosion of the metal cylinder bore. During inspection, look for a shift from clear or golden fluid to a dark brown or black “sludge.” This dark sediment is often composed of microscopic particles of the internal rubber seals that have disintegrated over time, signifying that the master cylinder is nearing the end of its functional life.

Brake Fluid Health Indicators

Max Annual Water Absorption

Interval for Fluid Degradation

Dashboard Warning Lights and Electronic Diagnostic Indicators

Modern vehicles are equipped with sophisticated sensors designed to monitor the health of the trusted hydraulic system. When the master cylinder begins to fail, the vehicle’s onboard computer (ECM/BCM) will often detect the anomaly before the driver notices a change in performance.

The Brake Warning Light and Fluid Level Sensors

The most common indicator is the red “Brake” warning light. This is typically triggered by a float switch in the reservoir. If the master cylinder is leaking externally, the fluid level will drop, triggering the light. In some vehicles, a differential pressure switch is used. This switch monitors the pressure between the two hydraulic circuits (front and rear). If one circuit loses pressure due to a failed internal seal, the switch moves to one side, completing an electrical circuit and illuminating the dashboard light.

ABS and Electronic Stability Control (ESC) Malfunctions

Approximately 70% of modern vehicles utilize a combined ABS/ESC module that requires a minimum threshold of hydraulic pressure to remain active. If the master cylinder cannot provide consistent pressure, the ABS module may detect a “low pressure” fault. This often results in the illumination of the ABS or Traction Control lights. Using a professional diagnostic scanner may reveal a P0557 (Brake Pressure Sensor Circuit Low) or similar fault code, indicating that the system can no longer modulate pressure accurately for safety interventions.

Never ignore a red brake warning light. While a yellow ABS light means you’ve lost anti-lock capabilities, a red light often indicates a catastrophic loss of hydraulic pressure that could result in total brake failure.

Uneven Braking Performance and Mechanical Binding

A malfunctioning master cylinder doesn’t always result in a lack of pressure; sometimes, it results in imbalanced pressure or pressure that fails to release. Modern master cylinders utilize a tandem design, where the system is split into two independent hydraulic circuits. A failure in just one of these circuits can cause the vehicle to behave erratically during deceleration.

Vehicle Pulling and Reduced Power

If one of the internal circuits fails (either a front/rear split or a diagonal split), the braking force will be unevenly distributed. For example, if the circuit powering the front right and rear left wheels fails, the vehicle will pull sharply to one side during hard braking. This imbalance can increase stopping distance by 50% or more, as only two wheels are effectively doing the work of four.

The “Locked” Brake Scenario and Compensating Ports

A less common but equally dangerous sign of failure is “brake drag.” Inside the master cylinder is a small opening called the compensating port (or bypass port). Its job is to allow fluid to return to the reservoir when you release the brake pedal. If this port becomes blocked by debris or a swollen internal seal, the pressure remains trapped in the lines. As you drive, the friction causes the fluid to heat up and expand, which further applies the brakes. You may notice your wheels feeling excessively hot or smelling a “burning” scent even after a short, gentle drive.

Tandem Circuit Safety

Modern master cylinders are designed so that if one half fails, the other half still provides enough pressure to stop the vehicle, albeit with significantly reduced efficiency.

Professional Diagnostic Methods for Master Cylinder Verification

Before replacing a master cylinder, it is vital to perform a comprehensive diagnostic to rule out other components like air in the lines, failing calipers, or a bad ABS modulator. Trusted automotive professionals recommend replacing the master cylinder every 100,000 to 150,000 miles as preventative maintenance, but physical testing is the only way to be certain of failure.

📋

Diagnostic Step-by-Step

Using professional line clamps (hose pinch pliers), isolate the master cylinder from the rest of the system. If the pedal still sinks with the lines clamped, the internal seals are objectively failed.

Remove the master cylinder mounting nuts and pull the unit away from the booster slightly. If fluid is present in the booster cavity, a catastrophic rear seal failure is confirmed.

Quality of Replacement Components

When choosing a replacement, always opt for a reliable, professional-grade new unit. While “rebuilt” units are cheaper, they often reuse the original metal casting which may have microscopic pitting. Under the high-pressure environment of a braking system, a brand-new casting ensures the longevity of the internal seals and the quality of the hydraulic seal. A professional repair also involves “bench bleeding” the new master cylinder before installation to ensure all air is removed from the internal chambers, preventing immediate “sponginess” upon first use.

Identifying a failing master cylinder requires a keen awareness of your vehicle’s hydraulic feedback and a commitment to regular visual inspections. A soft, spongy, or sinking pedal is the most frequent indicator of internal seal failure, while visual checks for dark, contaminated fluid or leaks at the booster mounting flange are essential for early detection. Furthermore, dashboard lights and uneven braking performance signify that the hydraulic circuits are no longer balanced. If you experience any of these symptoms, seek a professional inspection immediately. Do not drive a vehicle with a suspected hydraulic failure; instead, have it towed to a trusted repair facility to ensure a high-quality, reliable repair that restores your vehicle’s safety to factory standards.

Frequently Asked Questions

Can I drive with a bad master cylinder?

Driving with a failing master cylinder is extremely dangerous and is not recommended. Because the master cylinder is the primary source of hydraulic pressure for your brakes, a failure can lead to significantly increased stopping distances or a total loss of braking power. For your safety and the safety of others, have the vehicle towed to a professional technician immediately upon noticing symptoms.

How much does it cost to replace a master cylinder?

The cost of a professional master cylinder replacement typically ranges from $300 to $600, depending on the vehicle make and model. This includes the cost of a high-quality new part, fresh brake fluid, and the labor required to bleed the entire hydraulic system. Some luxury or performance vehicles with integrated electronic brake boosters may incur higher costs for parts and specialized calibration.

Will a bad master cylinder cause my brakes to squeal?

Generally, no. Brakes squealing is usually caused by worn brake pads, glazed rotors, or vibrating hardware at the wheel assembly. A master cylinder failure is related to hydraulic pressure, which affects pedal feel and stopping force rather than the high-pitched acoustic feedback associated with friction material wear. However, if a failing master cylinder causes brake drag, it could lead to overheating and subsequent noise.

How long does a master cylinder typically last?

A high-quality, original equipment master cylinder typically lasts between 100,000 and 200,000 miles. Its lifespan depends heavily on regular maintenance, specifically brake fluid flushes every two to three years. Neglecting fluid changes allows moisture and contaminants to accumulate, which causes the internal rubber seals to degrade prematurely and the metal bore to corrode, leading to failure.

Can I just replace the seals in my master cylinder?

While rebuild kits exist, most expert mechanics recommend replacing the entire unit with a new, professional-grade master cylinder. Rebuilding a cylinder requires honing the internal bore to a perfect finish; if the bore is pitted or scarred, new seals will fail quickly. Installing a complete, bench-bled unit is the most reliable way to ensure long-term safety and performance.