How Long Can You Drive With A Bad Torque Converter: Risks And Mechanical Impact

When your vehicle begins to shudder like it’s crossing a rumble strip or hesitates during a simple gear shift, the clock begins ticking on your transmission’s lifespan. Drivers often wonder if they can squeeze a few more weeks of commuting out of a failing torque converter before facing a significant repair bill. This expert guide provides a professional analysis of how long you can safely drive with a bad torque converter, the mechanical risks of delay, and the reliable signs that your car is no longer safe for the road. Understanding these dynamics is the difference between a minor component swap and a complete powertrain failure.

Understanding the Operational Limits of a Failing Torque Converter

📤 Share Image

The torque converter serves as the hydraulic bridge between your engine and transmission. When this component begins to degrade, the distinction between a “worn” unit and a “failed” unit determines whether you are driving a manageable risk or a ticking time bomb. A worn converter often manifests through the Torque Converter Clutch (TCC) shudder—a brief vibration felt during lock-up. In these early stages, a vehicle may physically sustain 500 to 1,000 miles of operation. However, once the failure progresses to hydraulic slippage or internal mechanical breakage, the vehicle’s “safe” driving distance drops to zero.

Driving habits play a decisive role in this timeline. Constant stop-and-go city traffic subjects the converter to repeated heat cycles and fluid shear, rapidly accelerating the wear of the internal needle bearings and the stator’s one-way clutch. Conversely, steady highway cruising at a locked-up RPM may prolong the life of a failing unit by bypassing the fluid-coupling phase. However, if the lock-up clutch mechanism itself is the point of failure, highway speeds will actually exacerbate the issue through excessive heat generation.

From a professional perspective, once the vehicle triggers “limp mode”—a diagnostic state where the Transmission Control Module (TCM) restricts the vehicle to a single gear (usually 2nd or 3rd)—you have reached the absolute end of the operational window. Limp mode is a final protective measure to prevent the engine from over-revving against a slipping converter or to stop the pump from sucking in more debris.

🚗 Short-Term Drivability

- Mild vibration at 45-60 MPH (TCC Shudder)

- Slightly higher-than-normal RPMs during acceleration

- Small delays in gear engagement (1-2 seconds)

⛔ Immediate Stop Required

- Engine stalls at stop signs (Seized stator)

- Metallic grinding or loud “whining” noises

- Total loss of motive power in Drive or Reverse

By The Numbers

Avoidable Catastrophic Failures

The “Safe” Diagnostic Window

The Mechanical Consequences of Driving With a Malfunctioning Torque Converter

Neglecting a torque converter issue is a high-risk gamble that almost always ends in a “Domino Effect” of internal destruction. When a converter fails, it doesn’t just stop working; it begins to disintegrate internally. As the friction material on the lock-up clutch or the metal on the internal bearings wears down, it releases thousands of microscopic particles into the transmission fluid. This fluid is the lifeblood of the entire system, and it carries those contaminants directly into the delicate valve body and clutch packs.

Thermal degradation is the second major threat. A failing converter generates extreme friction, pushing transmission fluid temperatures well beyond the safe operating threshold of 200 degrees Fahrenheit. For every 20-degree increase above the optimal 175°F, the life of your transmission fluid is effectively halved. High heat causes the fluid to oxidize, losing its lubricating properties and turning into a varnish that sticks to internal components, leading to further slippage and eventual seizure.

The transmission oil pump is perhaps the most vulnerable victim. This pump draws fluid directly through the system; if the converter has shed metallic “glitter,” these hard particles will scar the pump’s internal gears. Once the pump is damaged, the transmission loses the hydraulic pressure required to hold the gear sets in place, resulting in a total mechanical meltdown. This is precisely how a $300-$600 torque converter issue transforms into a $4,000 complete transmission rebuild.

In many high-mileage Ford 6R80 transmissions, a neglected TCC failure leads to the disintegration of the friction disc. This debris quickly clogs the internal filter, starving the planetary gear sets of lubrication. Within just 50 miles of the initial “shudder” becoming severe, the gears overheat and weld together, necessitating a total replacement rather than a simple repair.

Identifying Critical Warning Signs and Professional Diagnostic Indicators

To accurately assess the health of your drivetrain, you must look beyond general symptoms and utilize expert diagnostic techniques. The most common indicator is the “Rumble Strip” phenomenon. This is a very specific vibration that occurs when the torque converter clutch is struggling to engage or disengage. It feels as if you are driving over the safety grooves on the side of a highway, typically occurring between 30 and 50 MPH under light acceleration.

Professional Diagnostic Methods

- The Stall Speed Test: A trusted method used by specialists. With the vehicle in gear and your foot firmly on the brake, the accelerator is pressed. If the engine RPM rises significantly above the manufacturer’s specified stall speed without the vehicle attempting to move, the converter’s internal turbine or stator is failing to transfer torque.

- Transmission Fluid Analysis: Perform a “white cloth test.” Wipe the transmission dipstick on a clean white cloth. If you see a “glittery” sheen (metal flakes) or if the fluid smells distinctly like burnt toast, the converter has already begun to disintegrate.

- OBD-II Code Scanning: Modern vehicles monitor the RPM discrepancy between the engine and the transmission input shaft. A difference of more than 15% often triggers codes like P0741 (TCC Performance) or P0700 (Transmission Control System Malfunction).

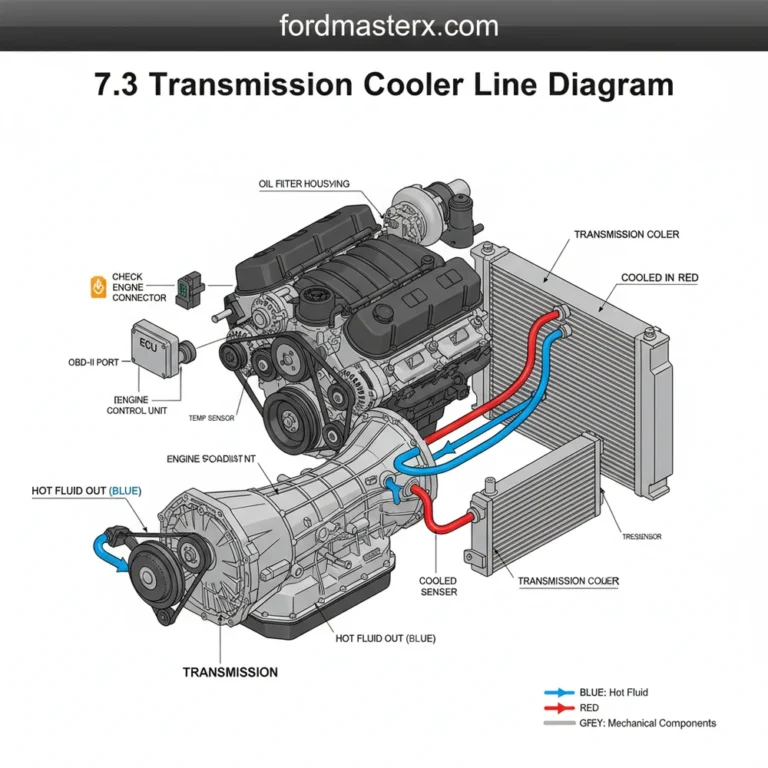

- Infrared Thermal Check: Use an infrared thermometer to measure the temperature of the transmission cooler lines. If the “out” line from the converter is significantly hotter (over 220°F) than the “in” line, the converter is generating excessive internal friction.

Safety Implications and Roadside Risks of Torque Converter Failure

Beyond the financial burden of repairs, a failing torque converter poses significant safety risks to the driver and other motorists. The most hazardous scenario is unexpected engine stalling. If the one-way stator clutch within the converter seizes, it creates a direct mechanical link that prevents the engine from idling while the wheels are stationary. This causes the engine to die every time you slow down for a red light or a stop sign, potentially leaving you stranded in the middle of a busy intersection.

Loss of acceleration is another critical danger. When internal hydraulic pressure drops due to a failing converter turbine, the vehicle may fail to respond when you press the gas pedal. Imagine attempting to merge onto a highway or clear a four-lane intersection only to have your vehicle lose motive power. Statistics indicate that over 15% of highway breakdowns related to powertrain failure are attributed to neglected hydraulic components like the torque converter, often resulting in high-speed rear-end collisions.

Finally, the extreme heat generated by a malfunctioning converter can create a fire hazard. When transmission fluid reaches its flashpoint due to overheating, it can vent through the dipstick tube or overflow vent. If this aerosolized oil hits the hot exhaust manifold, an under-hood fire can ignite instantly. If you smell something burning or see smoke emanating from the front of the vehicle, you must pull over immediately and call for a tow to a reliable repair facility.

A shattered internal turbine can cause the internal splines of the converter to strip entirely. This results in a complete power disconnection where the engine will rev freely but the vehicle will not move an inch. If this happens while driving, you will lose power steering and brake boost efficiency as the engine stalls, making the vehicle extremely difficult to control.

Strategic Maintenance and Quality Repair Options

When it comes to torque converter failure, the “wait and see” approach is a fallacy. Because these are sealed units, they cannot be repaired individually; the entire component must be replaced. For high-mileage vehicles, proactive replacement is the only expert-recommended path. If you catch the failure early, you can save the rest of the transmission. If you wait, you will be paying for a full overhaul.

📋

Step-by-Step Recovery Plan

Replacing the converter alone is insufficient. You must perform a comprehensive flush of the transmission lines and the external cooler to ensure no residual metallic debris remains to destroy the new unit.

Avoid budget-tier remanufactured converters. For heavy-duty or towing applications, invest in a professional-grade billet converter with reinforced internal welds for superior longevity.

Industry standards suggest that a professional torque converter replacement typically takes between 5 to 10 labor hours. This variation depends largely on the vehicle’s drivetrain; Rear-Wheel Drive (RWD) vehicles are generally simpler, whereas Front-Wheel Drive (FWD) or All-Wheel Drive (AWD) setups require dropping the entire subframe and transaxle. When selecting a transmission specialist, ensure they offer a complete warranty on both labor and parts, usually 12 months or 12,000 miles at minimum.

Proactive Replacement

Costs $800 – $1,500 total. Preserves the transmission’s internal hard parts and ensures safety.

Reactive Rebuild

Costs $3,000 – $5,000 total. Result of continued driving after symptom onset.

In summary, while a vehicle may physically move for a short period with minor converter shudder, doing so risks a total transmission rebuild. The primary threats of continued driving are catastrophic heat buildup and metallic debris contamination of the entire hydraulic system. Safety should always take precedence, as a failing converter can cause unpredictable engine stalling in dangerous traffic conditions. Do not risk a full transmission failure; consult a trusted automotive professional today for a diagnostic fluid analysis and pressure test.

Frequently Asked Questions

Can a bad torque converter damage the rest of my transmission?

Yes, absolutely. As the internal components of the torque converter degrade, they release metallic particulates and friction material into the transmission fluid. This debris circulates through the valve body, clogs the internal filter, and scores the clutch plates, often turning a simple converter replacement into a multi-thousand dollar total transmission overhaul.

Will a bad torque converter throw a check engine light?

In most modern vehicles manufactured after 1996, a failing torque converter will trigger a Diagnostic Trouble Code (DTC). The most common codes are P0740 or P0741, which indicate issues with the Torque Converter Clutch (TCC) circuit or performance. Professional diagnostic tools can also monitor ‘slip’ in real-time to confirm a failure.

Is it safe to drive 100 miles with a shuddering torque converter?

Driving 100 miles is generally possible if the symptoms are limited to a light vibration or shudder. However, this is not recommended. Each mile driven increases the internal fluid temperature and the likelihood of debris entering the transmission pump. It is best to drive only to a reliable repair facility.

Can I just change the transmission fluid to fix a torque converter issue?

A fluid change is rarely a permanent fix for mechanical failure. While fresh fluid may temporarily reduce ‘shudder’ due to improved friction modifiers, it cannot repair a broken stator, worn bearings, or a damaged lock-up clutch. In fact, on high-mileage failing units, new detergent-rich fluid can sometimes worsen slipping issues.

How do I know if the noise I hear is the torque converter or the transmission?

Expert technicians use a process of elimination: if a whining noise occurs only when the vehicle is in gear and under load, but disappears in Neutral or Park, the torque converter is the likely culprit. Conversely, if the noise persists in all gears including Neutral, the issue is more likely the transmission’s internal oil pump.