Ford Truck Restoration Parts Catalog: Sourcing Authentic Components For Vintage F-Series And Bronco Projects

Restoring a classic Ford truck is more than a mechanical endeavor; it is a commitment to preserving an American automotive legacy that spans from the early F-1 models to the iconic Dentside era. Whether you are reviving a family heirloom or building a period-correct showstopper, the integrity of the finished project depends entirely on the components you select. However, the greatest challenge for any restorer is navigating the sea of inferior components to find parts that actually fit, function, and last. This comprehensive guide will provide a professional breakdown of how to utilize a Ford truck restoration parts catalog to source high-quality, reliable components that meet expert standards.

Identifying Authentic Body Panels in a Ford Truck Restoration Parts Catalog

📤 Share Image

Achieving the perfect silhouette on a ‘Bumpside’ (1967-1972) or ‘Dentside’ (1973-1979) Ford F-Series requires more than just a talented body technician; it requires quality sheet metal. When browsing a trusted catalog, the first technical specification to verify is the steel gauge. Many generic imports utilize thin 22-gauge steel, which lacks the structural integrity for a truck’s work-ready frame and is notoriously difficult to weld without warping. Professional restorers demand 18-gauge to 20-gauge steel, matching the original factory thickness.

Die-Stamped Precision and Tooling

The crisp lines of a 1965 F-100 cab corner or a 1978 F-150 bedside cannot be replicated by low-pressure molds. Reliable manufacturers utilize original Ford tooling or modern high-pressure die-stamping to ensure that body lines and curves match the original 1950s and 60s assembly line standards. When evaluating panels, look for a “licensed by Ford” or “OEM-quality” designation, which usually indicates a maximum allowable deviation of no more than 0.05 inches from original dimensions.

Always confirm that your new floor pans, cab corners, and rocker panels come with a professional E-coating (Electro-Deposit Primer). Unlike standard transport primer, E-coating provides superior corrosion resistance and prevents flash rust during the long months of a multi-year restoration.

Sourcing Reliable Drivetrain and Engine Components for Peak Performance

The powertrain of a vintage Ford is its heartbeat. Whether you are maintaining a period-correct FE-Series big block (360 or 390 cubic inch) or a versatile Windsor 351W, the complete restoration of these engines requires modern materials designed for today’s operating environments. Over 60% of restoration mechanical failures are attributed to inferior seals; therefore, a professional catalog should specify Viton or high-temp synthetic rubber compositions for all gaskets and rear main seals to combat modern oil formulations and higher operating temperatures.

Transmission and Axle Integrity

A reliable drivetrain extends beyond the engine block. For those refurbishing a 1970 F-250 Highboy, sourcing high-tensile strength U-joints for the Dana 44 front axle is non-negotiable. Similarly, when rebuilding an NP435 manual or a C6 automatic, selecting transmission rebuild kits with expert-grade synchros and friction discs is essential for handling the torque of a modified 460 V8 swap.

Ethanol Compatibility

Use zinc-plated fuel lines and ethanol-ready pumps to prevent degradation from modern E10 pump gas.

Cooling Upgrades

Evaluate high-efficiency aluminum radiators for high-HP builds or original copper-brass for factory aesthetics.

Selecting Quality Interior Trim and Upholstery Materials

The interior is where the tactile quality of your restoration is most apparent. Ford utilized several distinct textures—Sierra, Corinthian, and Knitted vinyl—across its Custom, Ranger, and Lariat trim levels. An authoritative parts catalog will distinguish between these grains, ensuring your 1972 Ford Ranger XLT features the correct woodgrain door panel inserts and seat patterns.

Durability and Modern Comfort

Original Ford vinyl was typically 30-35 oz weight. When sourcing reproduction upholstery, ensure the material meets or exceeds this weight for long-term durability against UV exposure and wear. Furthermore, the professional choice for dash pads is a urethane-molded pad. Unlike cheap plastic covers that warp and crack, these full-replacement pads provide the soft-touch finish and factory contours required for a high-end build, such as a color-matched dashboard for a 1979 F-150.

By The Numbers: Interior Quality

OEM Vinyl Weight

Urethane Dash Pads

Evaluating Electrical Systems and Chassis Hardware for Longevity

Electrical and chassis failures are common pitfalls for novice restorers. For a safe and functional foundation, modernization is often necessary. This starts with the wiring harness architecture. Modern modular fuse blocks using blade-style fuses are significantly more reliable and safer than the original glass-style fuses, which are prone to corrosion and high-resistance heat.

Safety and Structural Integrity

The chassis requires equal attention to detail. When replacing worn leaf spring shackles on a 1985 Ford Bronco or performing a frame-off restoration, all hardware must meet professional standards. Grade 8 bolts have a proof load of 120,000 psi, making them the industry standard for truck chassis restoration. Using lower-grade hardware in suspension or towing components is a dangerous compromise that should be avoided at all costs.

✅ Chassis Pros

- Polyurethane bushings for improved handling

- Dual-master cylinder disc conversions

- 12-volt electrical upgrades

- Powder-coated frame components

❌ Chassis Cons

- Grade 5 or ungraded hardware

- Corroded original glass fuses

- Single-circuit brake reservoirs

- Worn rubber spring bushings

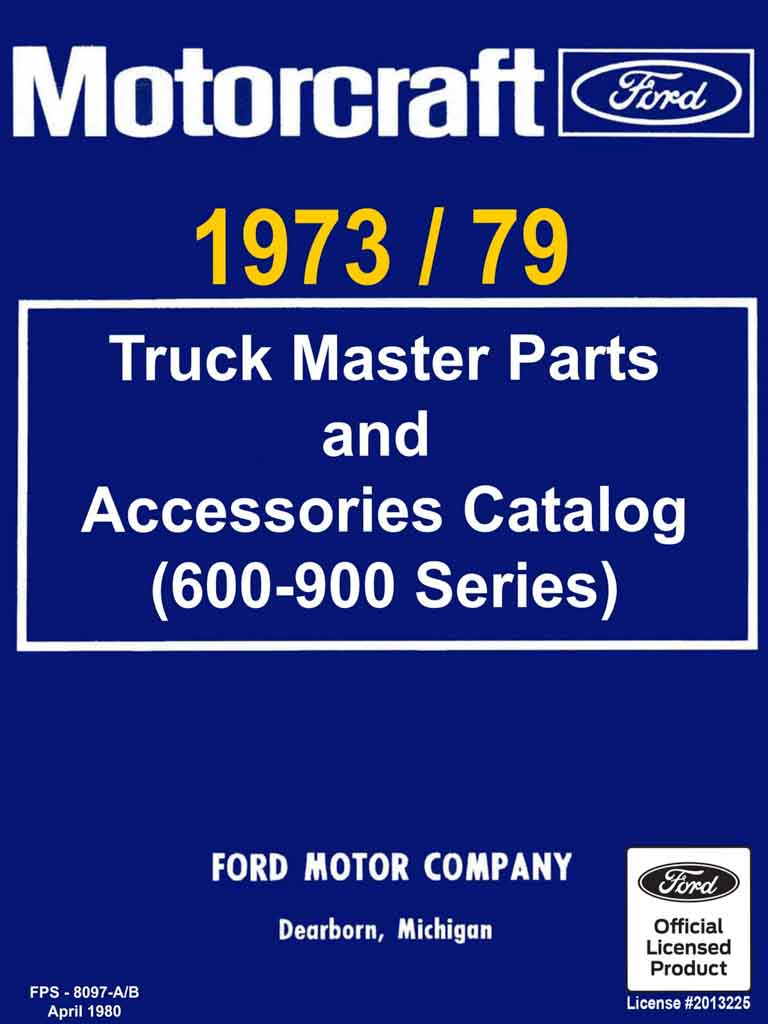

Navigating the Catalog for Expert-Level Project Planning

A comprehensive restoration catalog is more than just a price list; it is a technical guide. Expert restorers use these catalogs to cross-reference Ford’s ‘Basic Part Number’ system. For example, knowing that “2001” always refers to brake shoes/pads across different model years helps verify fitment for complex builds where axles or components may have been swapped by previous owners.

📋

Strategic Restoration Workflow

Use the catalog diagrams to inventory your disassembled 1969 F-100 project. Identify missing trim or fasteners early.

Purchase “Master Kits” for weatherstripping and body bolts. This ensures no component is overlooked and reduces shipping costs on oversized items.

Restoration projects that use a structured inventory system from a catalog are 40% more likely to be completed within their initial two-year timeline. Timing is everything: coordinate the delivery of heavy items like hoods or bed floors to coincide with your metalwork phase. Furthermore, understand when to prioritize “New Old Stock” (NOS) parts. For high-point concours restorations, original Ford surplus is king, but for a daily driver, modern quality reproductions often offer better longevity and ease of replacement.

Oversized body panels and crates can have lead times of 4-8 weeks. Never wait until the metal is cut to order your replacement panels; always have the new part on the floor to verify dimensions before removing original steel.

In summary, prioritize heavy-gauge steel and E-coated panels for body longevity to ensure your truck remains rust-free for decades. Always source drivetrain components that meet or exceed original Ford SAE specifications, and use a systematic catalog approach to ensure every bolt, seal, and trim piece is accounted for before assembly. Following these professional standards will result in a restoration that not only looks factory-new but performs with reliable, modern-day efficiency.

Download our technical parts checklist and begin inventorying your Ford F-Series or Bronco project today to ensure a professional-grade finish.

Frequently Asked Questions

How do I know if the parts in the catalog will fit my specific year?

A reliable Ford truck restoration parts catalog uses Ford’s original engineering part numbers and VIN decoding guides. Always verify your truck’s production date and series (e.g., F-100 vs. F-150), as mid-year changes in the 1970s often affected steering column and brake configurations. Expert catalogs will explicitly list these ‘split-year’ fitments.

What is the difference between OEM, NOS, and reproduction parts?

OEM (Original Equipment Manufacturer) parts are made by the original supplier. NOS (New Old Stock) refers to vintage parts made decades ago but never used. Reproduction parts are newly manufactured. For a professional restoration, NOS is prized for trim, while high-quality reproductions are often preferred for mechanical systems where rubber or seals might have aged on the shelf.

Is it better to buy individual bolts or a complete hardware kit?

For a professional result, complete hardware kits are highly recommended. These kits are curated to include Grade 5 or Grade 8 fasteners with the correct finishes (zinc, chrome, or black oxide). Buying individually often leads to mismatched heads and incorrect thread pitches, which can compromise the structural integrity of your truck’s chassis and body mounts.

Why is the gauge of the sheet metal important for body parts?

Sheet metal gauge determines the strength and weldability of the panel. Original Ford trucks utilized 18 to 20-gauge steel. Many low-quality catalog options use 22-gauge steel, which is thinner, prone to warping during welding, and lacks the dent resistance required for a durable, professional truck restoration. Always verify the gauge before purchasing floors or bedsides.

Can I find parts for 4WD Ford trucks in a standard restoration catalog?

Yes, but you must look for expert catalogs that distinguish between 2WD and 4WD components. Classic Ford 4x4s, such as the ‘Highboy’ F-250, have unique suspension heights, transfer case linkages, and front-axle assemblies (like the Dana 44 or 60). A trusted catalog will provide specific sections for these heavy-duty components to ensure mechanical compatibility.